Flue gas denitration system and method for boiler under full-load working condition

A full-load, flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as leakage, high safety risks, and poor variability in ammonia production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific examples, which are explanations of the present invention rather than limitations.

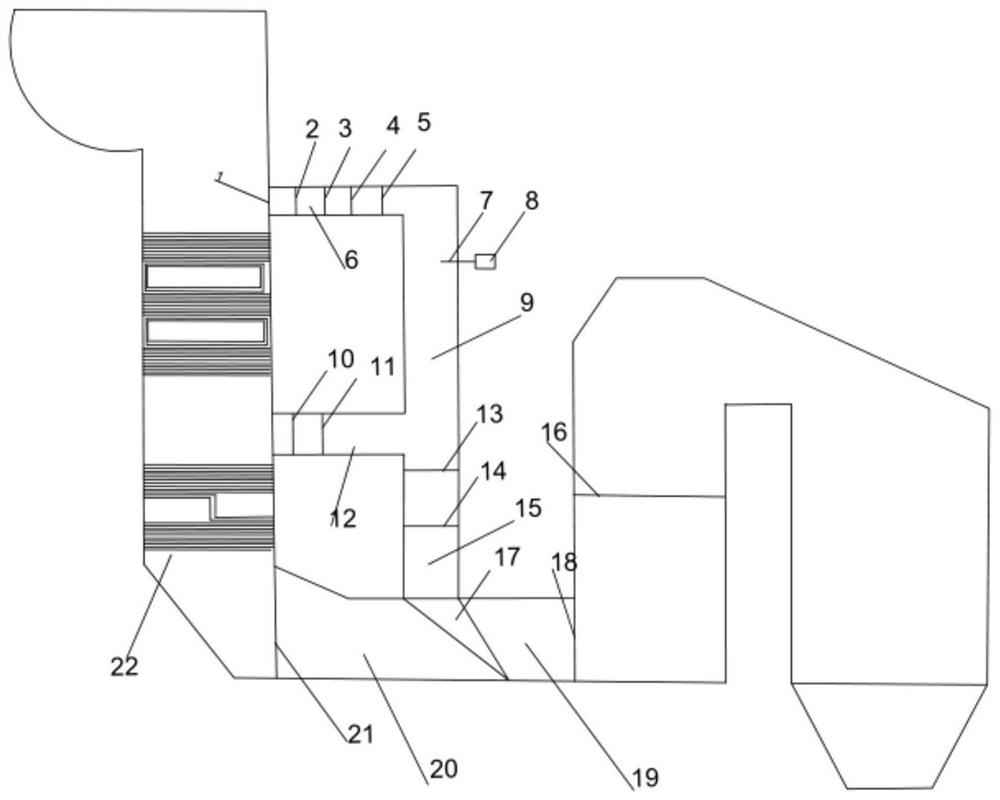

[0029] The present invention provides a flue gas denitrification system under the full load condition of the boiler, such as figure 1 As shown, it includes high-temperature flue gas leading flue 6, high-temperature flue gas introducing flue 12, low-load bypass introducing flue 15, low-temperature flue gas main flue 20, mixing flue 19, fly ash separator 1 on the boiler side , the first expansion joint 2, the first closing baffle door 3, the first adjusting baffle door 4, the second expansion joint 10, the second closing baffle door 11, the third expansion joint 13, the third closing baffle Panel door 14, urea direct injection pyrolysis flue 9, urea spray gun 7, urea solution metering module 8, high temperature fan 5, second adjustment baffle door 21, diversion groove 17, deflector 18, static mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com