Low-temperature flue gas section free radical enhanced selective catalytic reduction denitration method and device

A low-temperature flue gas and free radical technology, applied in the field of flue gas denitrification, can solve problems such as increased production costs, difficult application of denitrification technology in power plants, and difficulty in obtaining temperature windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

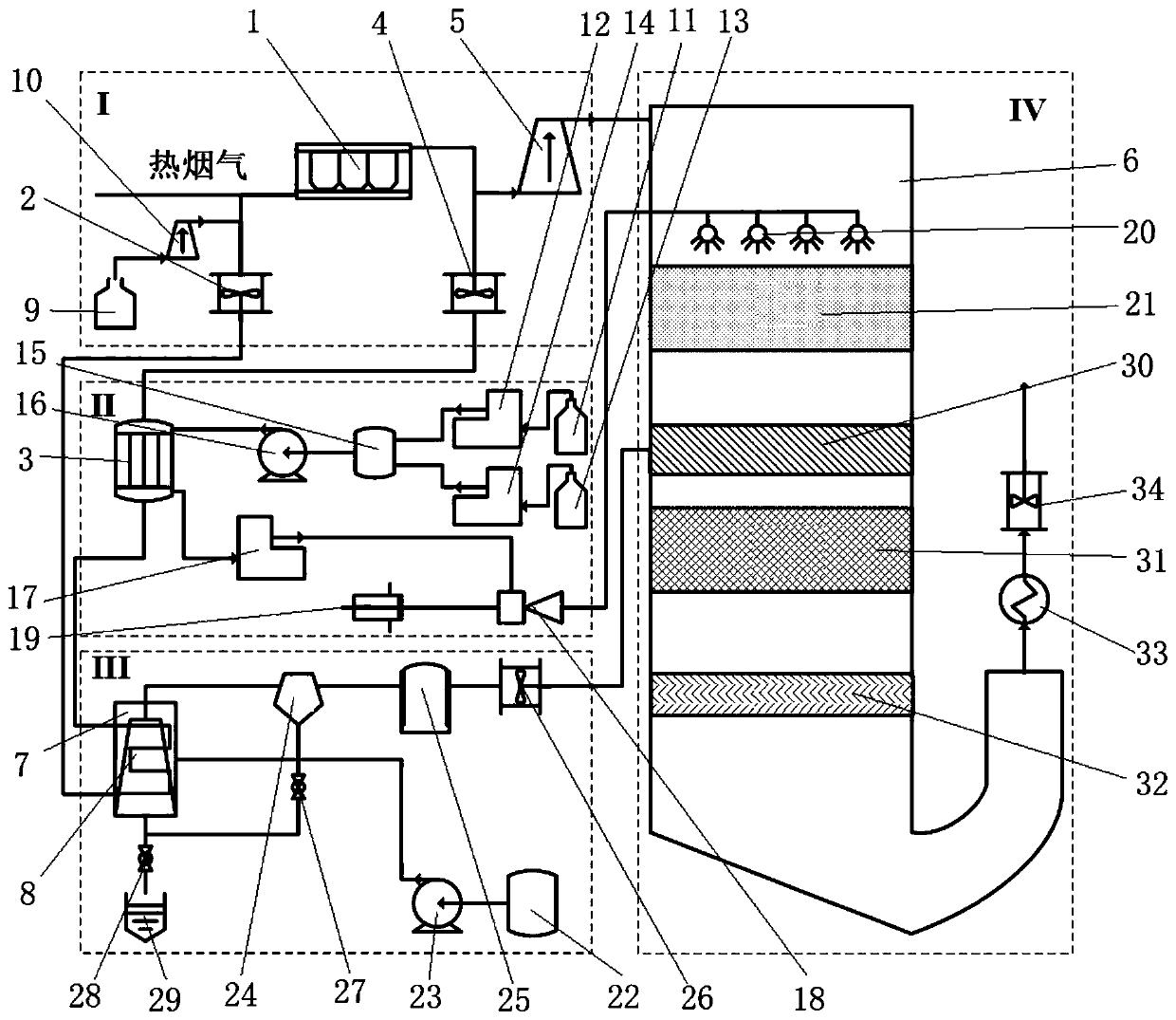

[0023] An embodiment of the free radical-enhanced selective catalytic reduction method in the low-temperature flue gas section of the present invention comprises the following steps:

[0024] 1) Extract part of the flue gas before the dust removal device into the preheating system, and the flue gas discharged from the preheating system and the flue gas after passing through the dust removal device enter the denitrification reactor together;

[0025] 2) Use the heat of the preheating system to preheat the hydrogen peroxide solution. The preheated hydrogen peroxide solution enters the denitration reactor and evaporates into hydrogen peroxide vapor at the temperature of the flue gas. Under the action of the first catalyst, the flue gas Oxidation treatment of NO in

[0026] 3) Using the heat of the preheating system to preheat the aqueous ammonia solution, so that the ammonia water turns into ammonia gas and enters the denitration reactor to mix with the oxidized flue gas in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com