Denitration catalyst module box with ammonia adsorption function and preparation method thereof

A denitration catalyst, ammonia adsorption technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

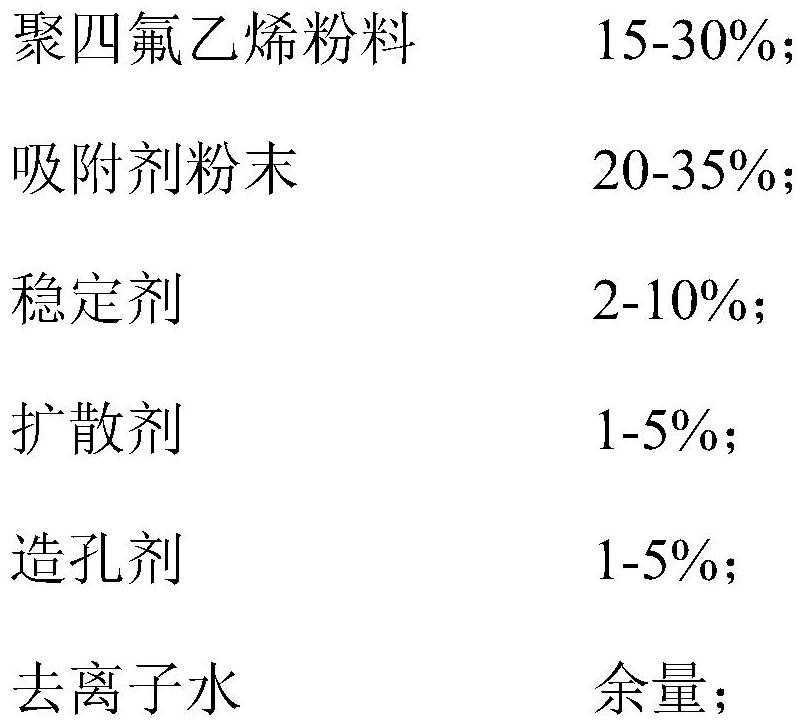

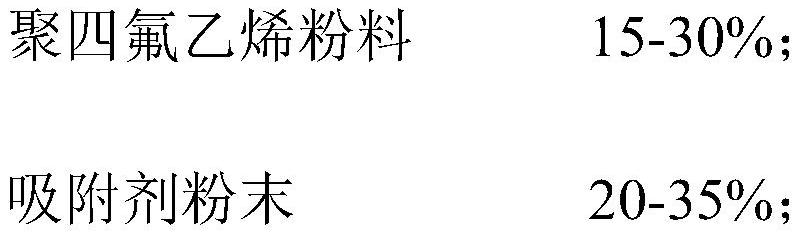

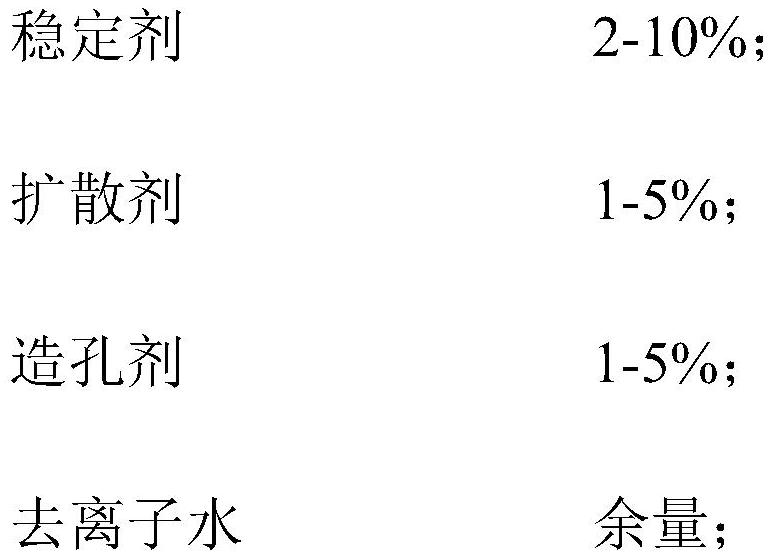

[0030] This embodiment provides a denitration catalyst module box with ammonia adsorption function and a preparation method thereof.

[0031] The denitrification catalyst module box is composed of a module box substrate and a selective adsorption function coating. The base of the module box is a hollow box with hollow upper and lower bottom surfaces, which can be loaded with denitrification catalysts. The selective adsorption functional coating is a coating formed on the surface of the module box base by heat treatment after the base of the module box is coated with a functional coating slurry.

[0032] The preparation method of the denitration catalyst module box comprises the following steps:

[0033] Step 1, preparation of adsorbent powder:

[0034] According to the active component of the adsorbent Ce-Nb-Al-O x Composite Oxide and Adsorption Auxiliary Si-Fe-Ni-W-Mn-O x The mass ratio of composite oxide is 1:0.05, the molar ratio of Ce / Nb / Al element is 1:0.1:0.1, and the ...

Embodiment 2

[0050] This embodiment provides a denitration catalyst module box with ammonia adsorption function and a preparation method thereof.

[0051] The denitrification catalyst module box is composed of a module box substrate and a selective adsorption function coating. The base of the module box is a hollow box with hollow upper and lower bottom surfaces, which can be loaded with denitrification catalysts. The selective adsorption functional coating is a coating formed on the surface of the module box base by heat treatment after the base of the module box is coated with a functional coating slurry.

[0052] The preparation method of the denitration catalyst module box comprises the following steps:

[0053] Step 1, preparation of adsorbent powder:

[0054] According to the active component of the adsorbent Ce-Nb-Al-O x Composite Oxide and Adsorption Auxiliary Si-Fe-Ni-W-Mn-O x The mass ratio of composite oxide is 1:0.25, the molar ratio of Ce / Nb / Al element is 1:0.25:0.5; the m...

Embodiment 3

[0067] This embodiment provides a denitration catalyst module box with ammonia adsorption function and a preparation method thereof.

[0068] The denitrification catalyst module box is composed of a module box substrate and a selective adsorption function coating. The base of the module box is a hollow box with hollow upper and lower bottom surfaces, which can be loaded with denitrification catalysts. The selective adsorption functional coating is a coating formed on the surface of the module box base by heat treatment after the base of the module box is coated with a functional coating slurry.

[0069] The preparation method of the denitration catalyst module box comprises the following steps:

[0070] Step 1, preparation of adsorbent powder:

[0071] According to the active component of the adsorbent Ce-Nb-Al-O x Composite Oxide and Adsorption Auxiliary Si-Fe-Ni-W-Mn-O x The mass ratio of composite oxide is 1:0.5, the molar ratio of Ce / Nb / Al element is 1:1:1; the molar r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com