Efficient multifunctional sock turning machine

A multi-functional, sock-turning machine technology, applied in mechanical cleaning, high-pressure cleaning, textiles and papermaking, etc., can solve the problems affecting the personal safety of the operator, finger impact, danger, etc., to reduce danger, prolong service life, reduce The effect of the possibility of mechanical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

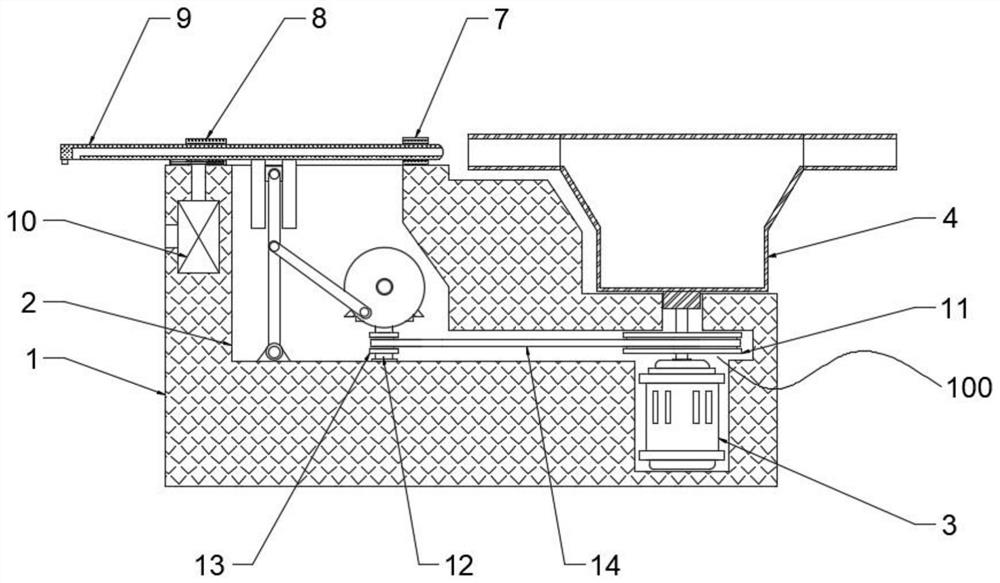

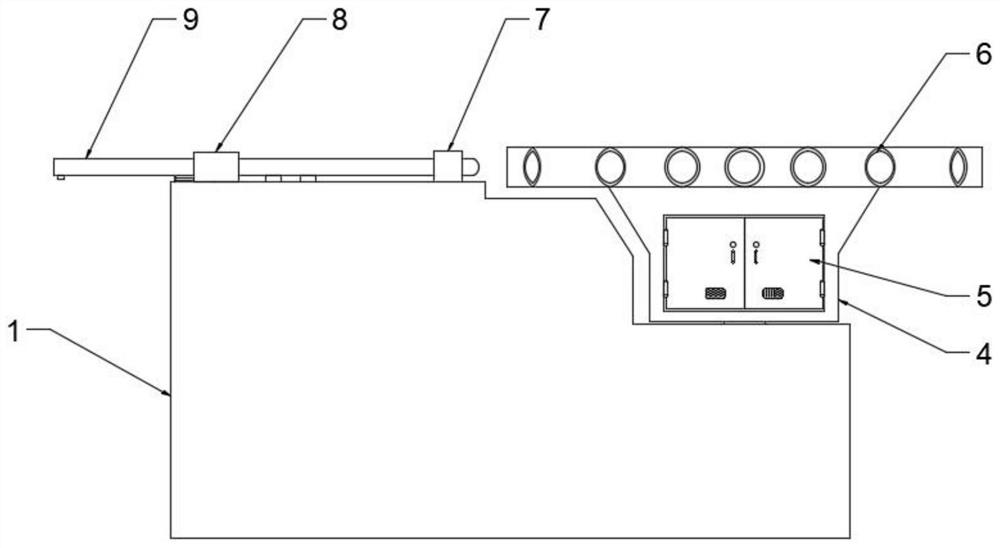

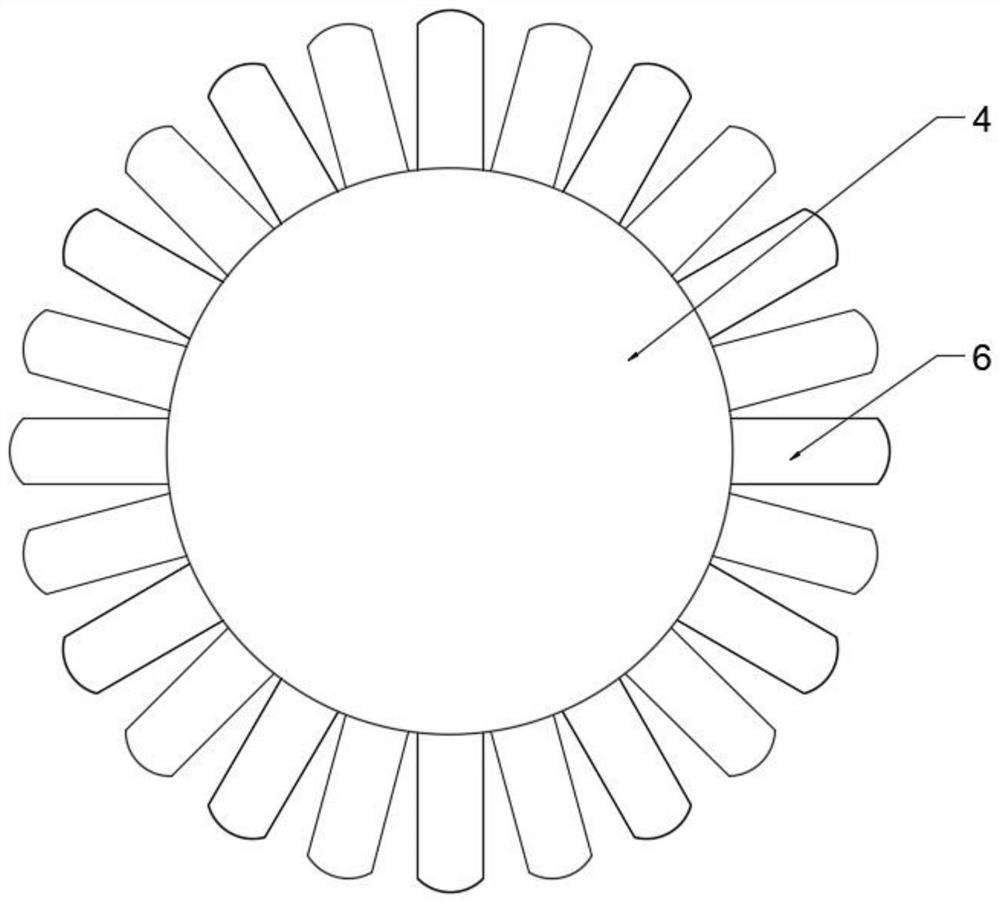

[0028] see Figure 1-9 , including a main body 1, an inner cavity 2 is opened inside the main body 1, a slow motor 3 is installed inside the inner cavity 2, a collection box 4 is fixedly connected to the driving end of the slow motor 3, and the collection box 4 is located outside the main body 1 , the top side of the collection box 4 is equidistantly fixed with a socks sleeve 6, the side surface of the collection box 4 is equipped with a box door 5, and the upper surface of the main body 1 is fixed with a first stop ring 7 and a second stop ring 8. The inside of the first limiting ring 7 and the second limiting ring 8 are jointly slidably connected with a sock-turning rod 9, the diameter of the sock-turning rod 9 is smaller than the inner diameter of the sock-putting sleeve 6, and the center point of the sock-turning rod 9 and the sock-putting sleeve The center point of the pipe 6 is located on the same horizontal plane, and the shortest distance between the inner diameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com