Patents

Literature

33results about How to "Reduce mechanical deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

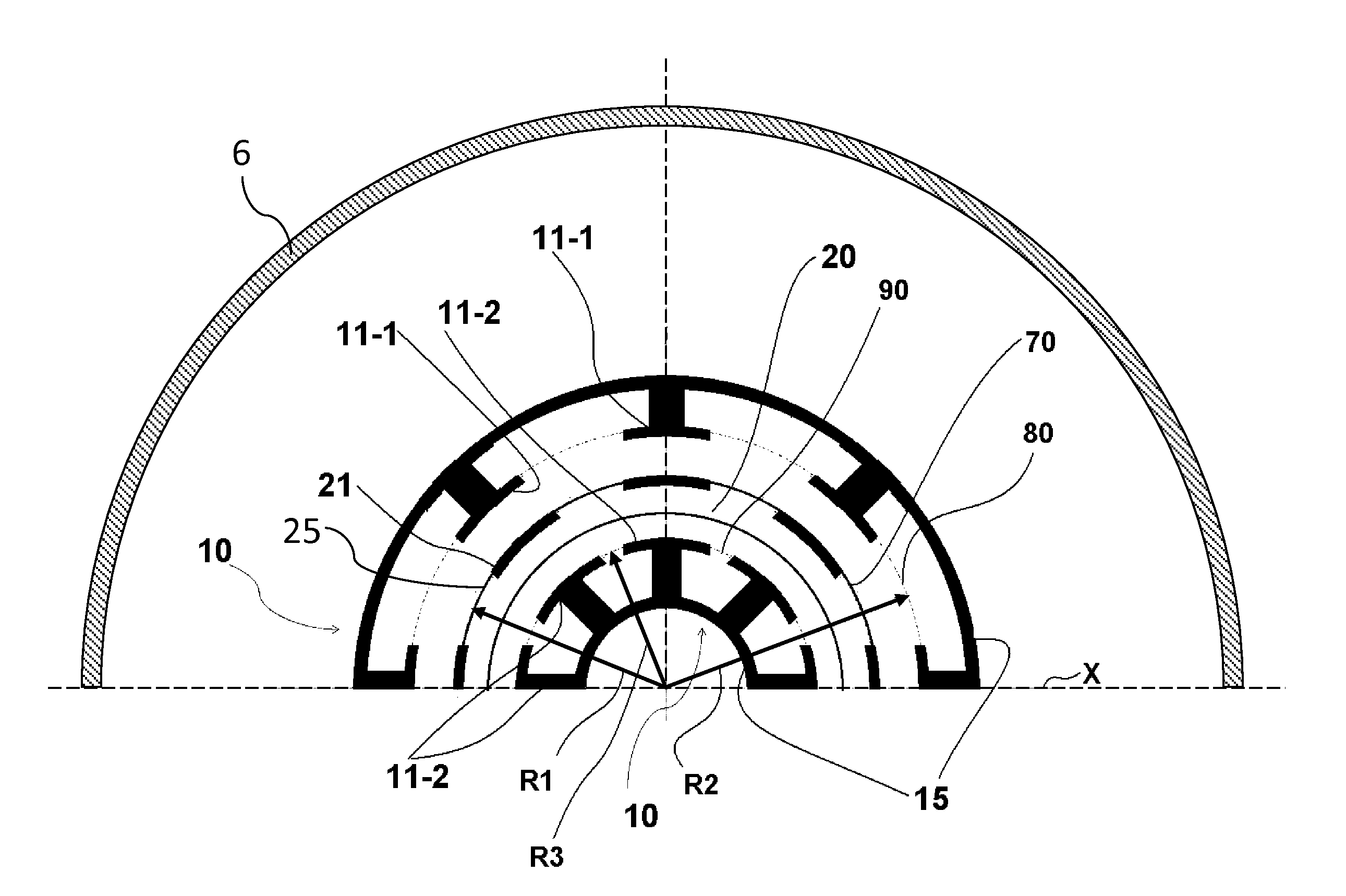

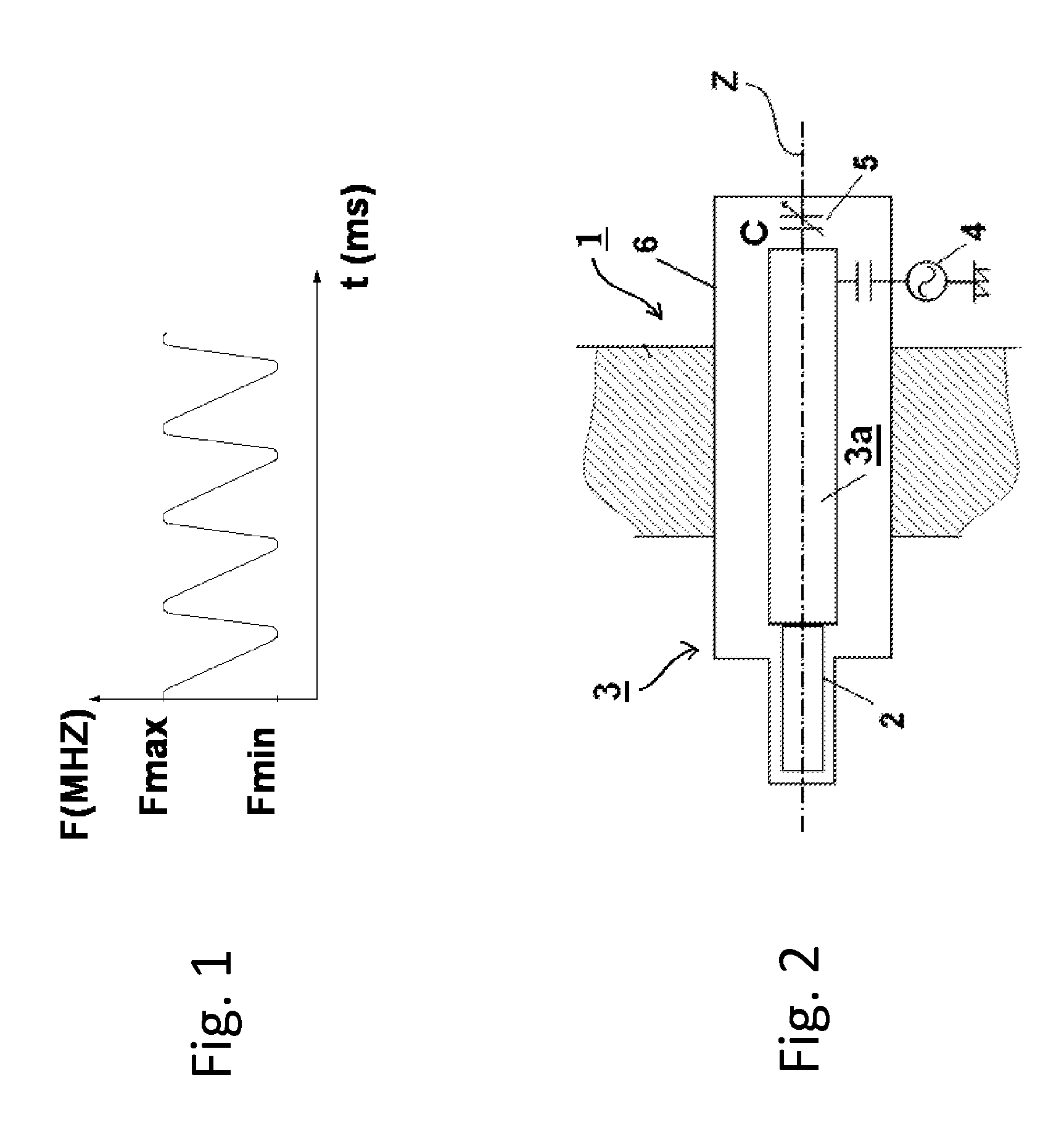

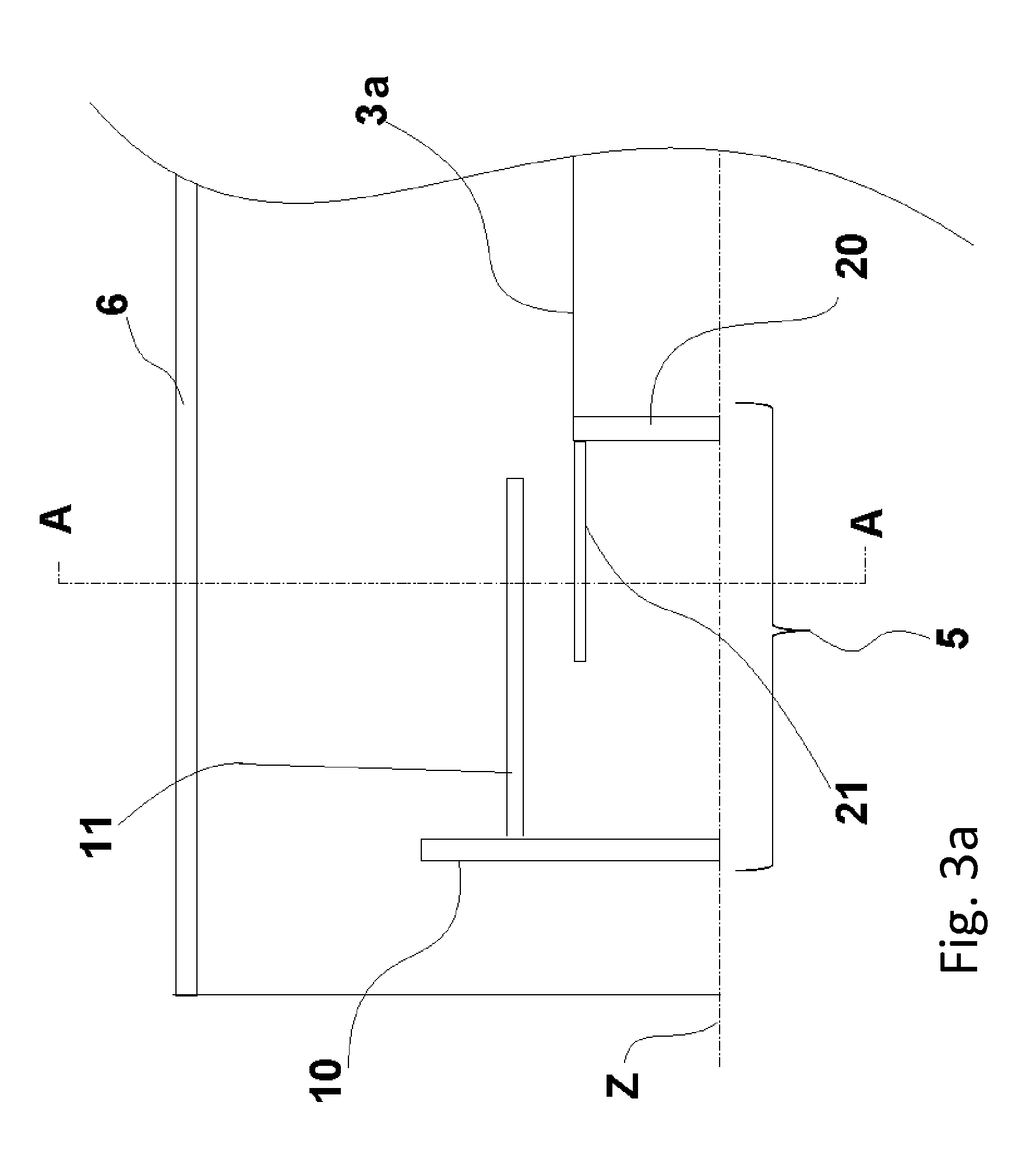

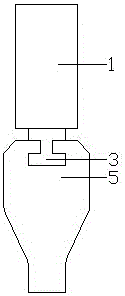

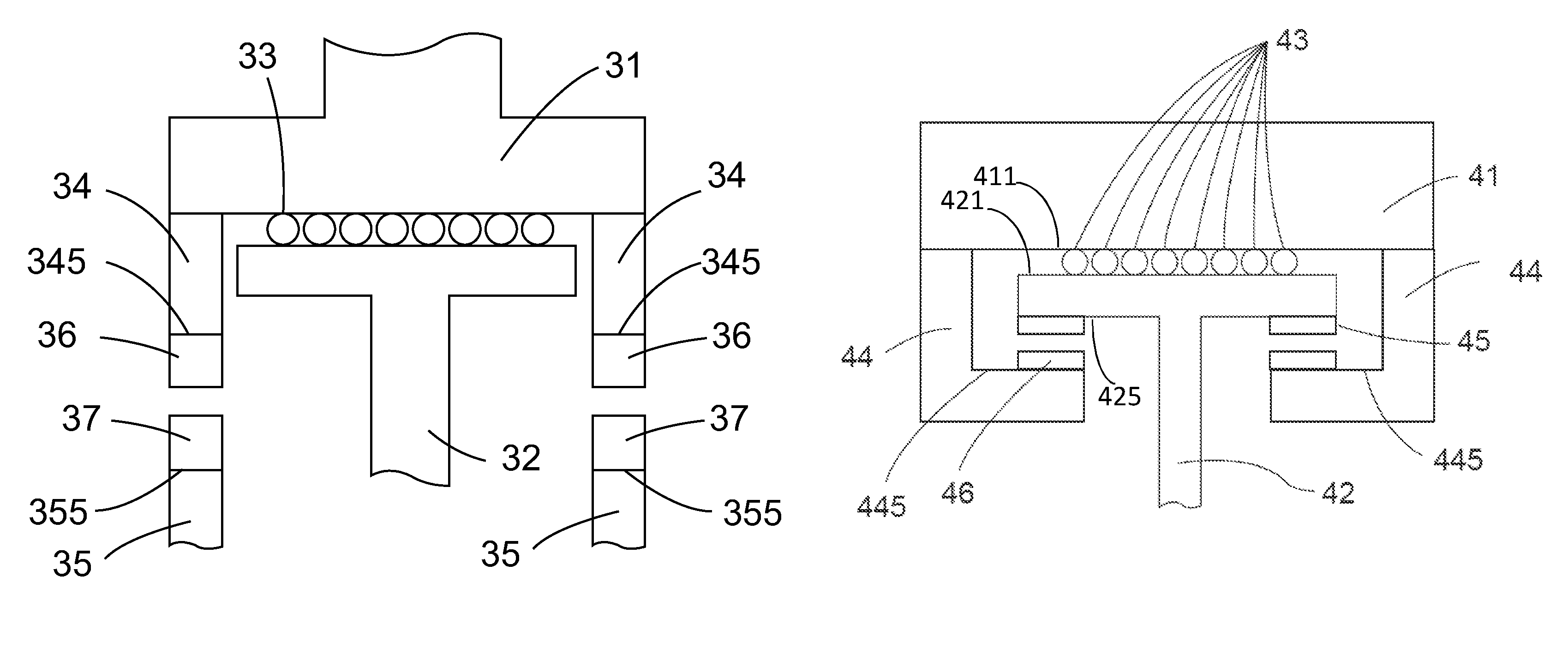

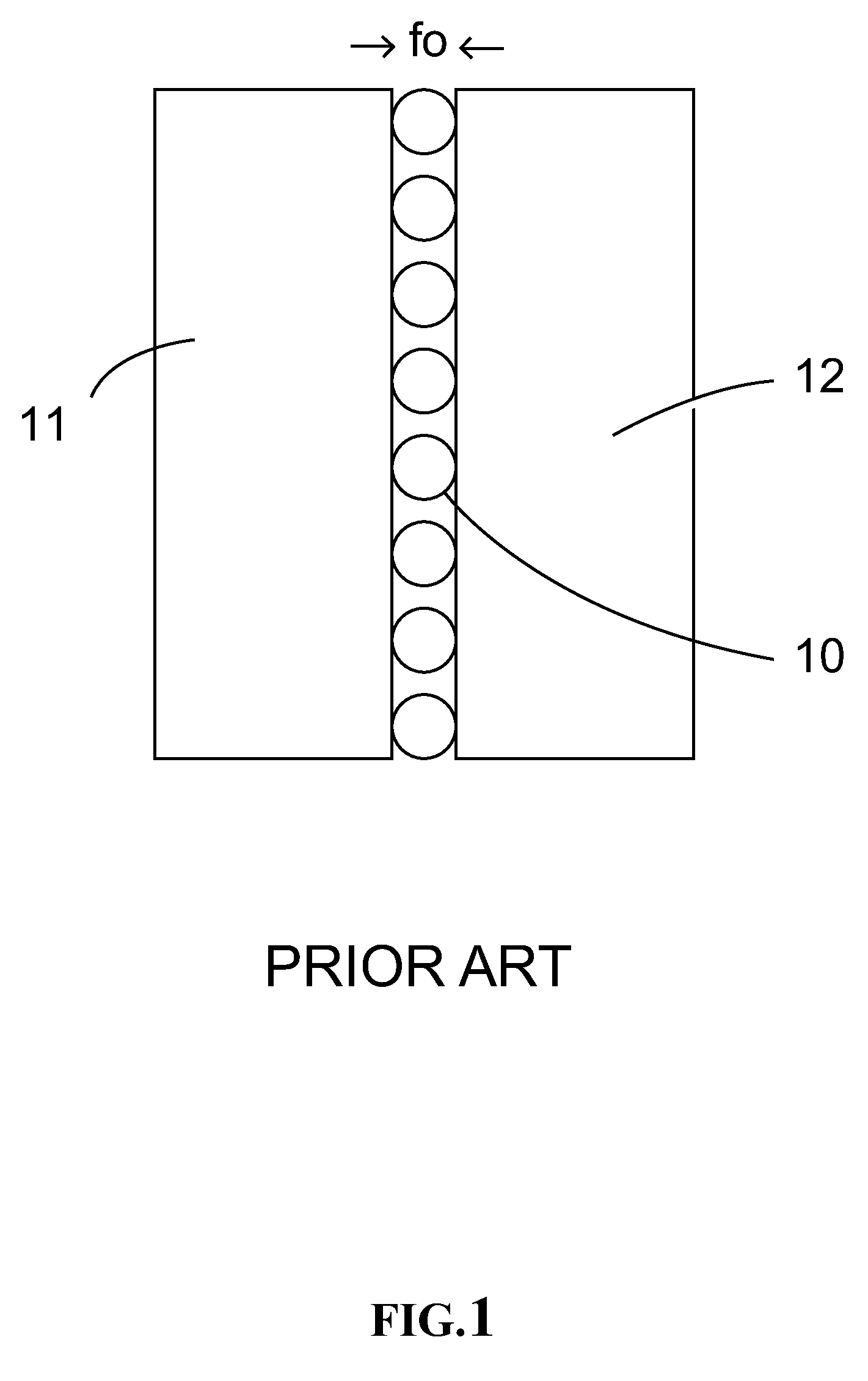

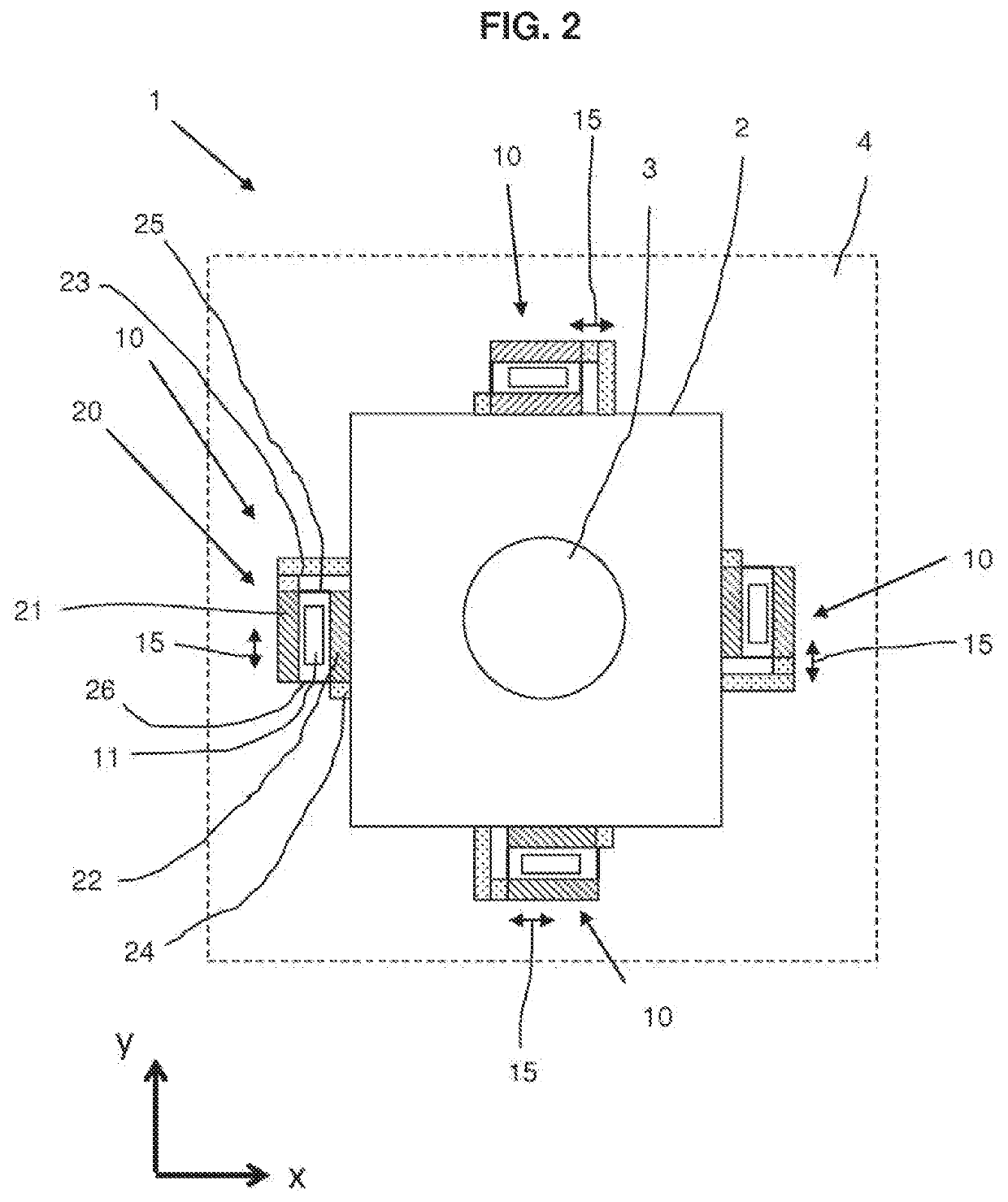

Variable rotating capacitor for synchrocyclotron

ActiveUS9355784B2Speed up the flowReducing local overheatingCapacitor with electrode area variationMagnetic resonance acceleratorsEngineeringCapacitor

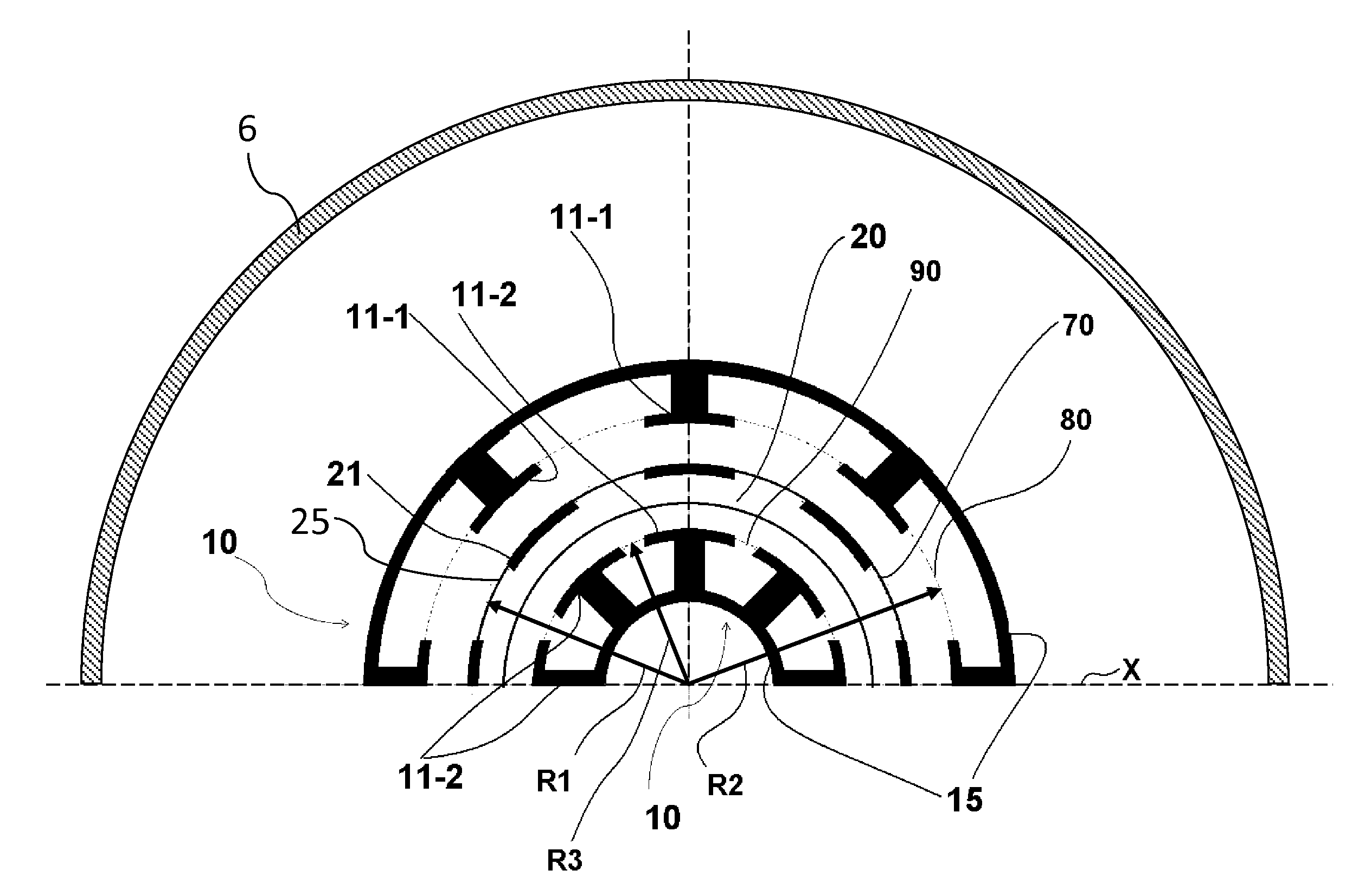

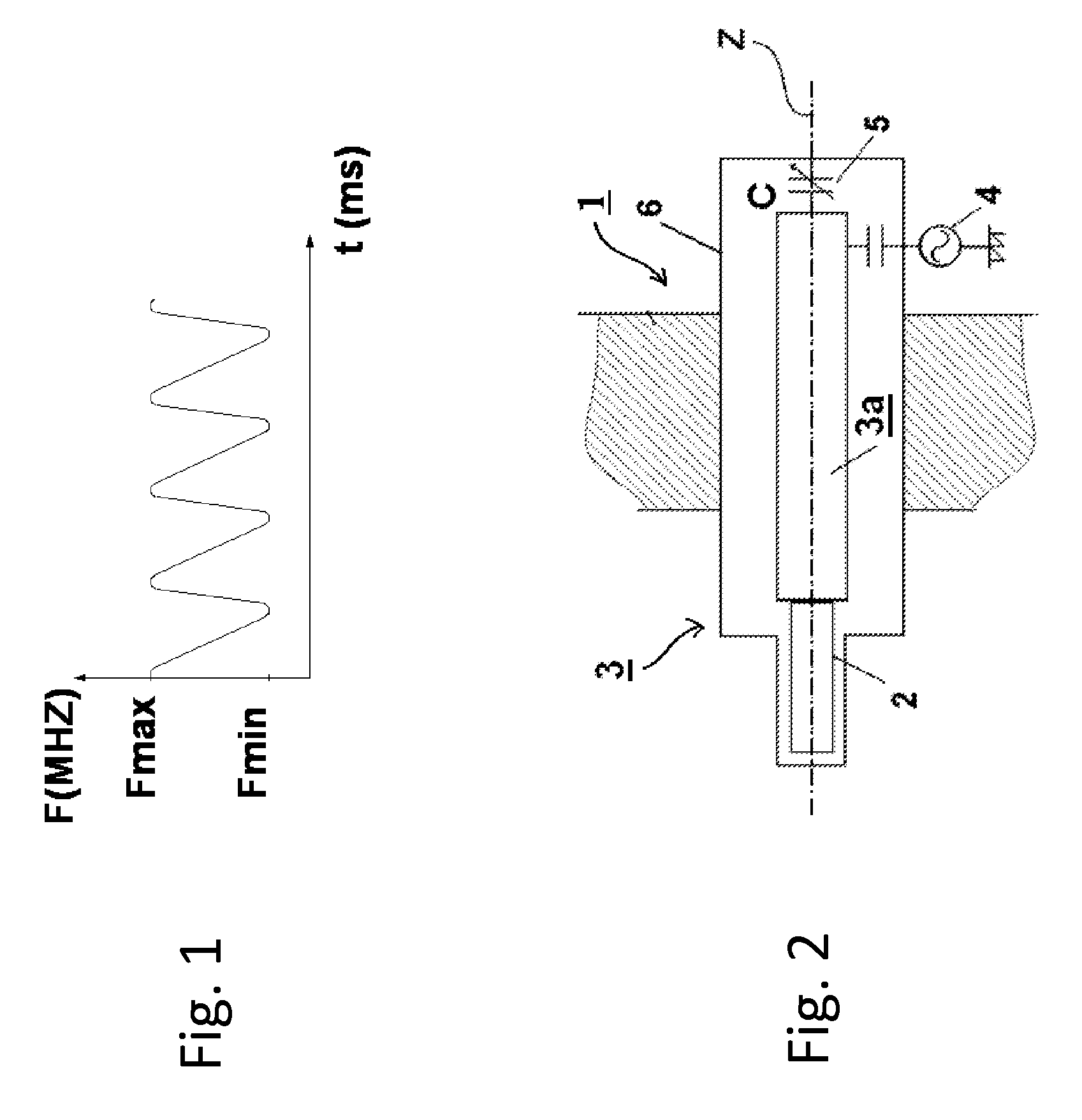

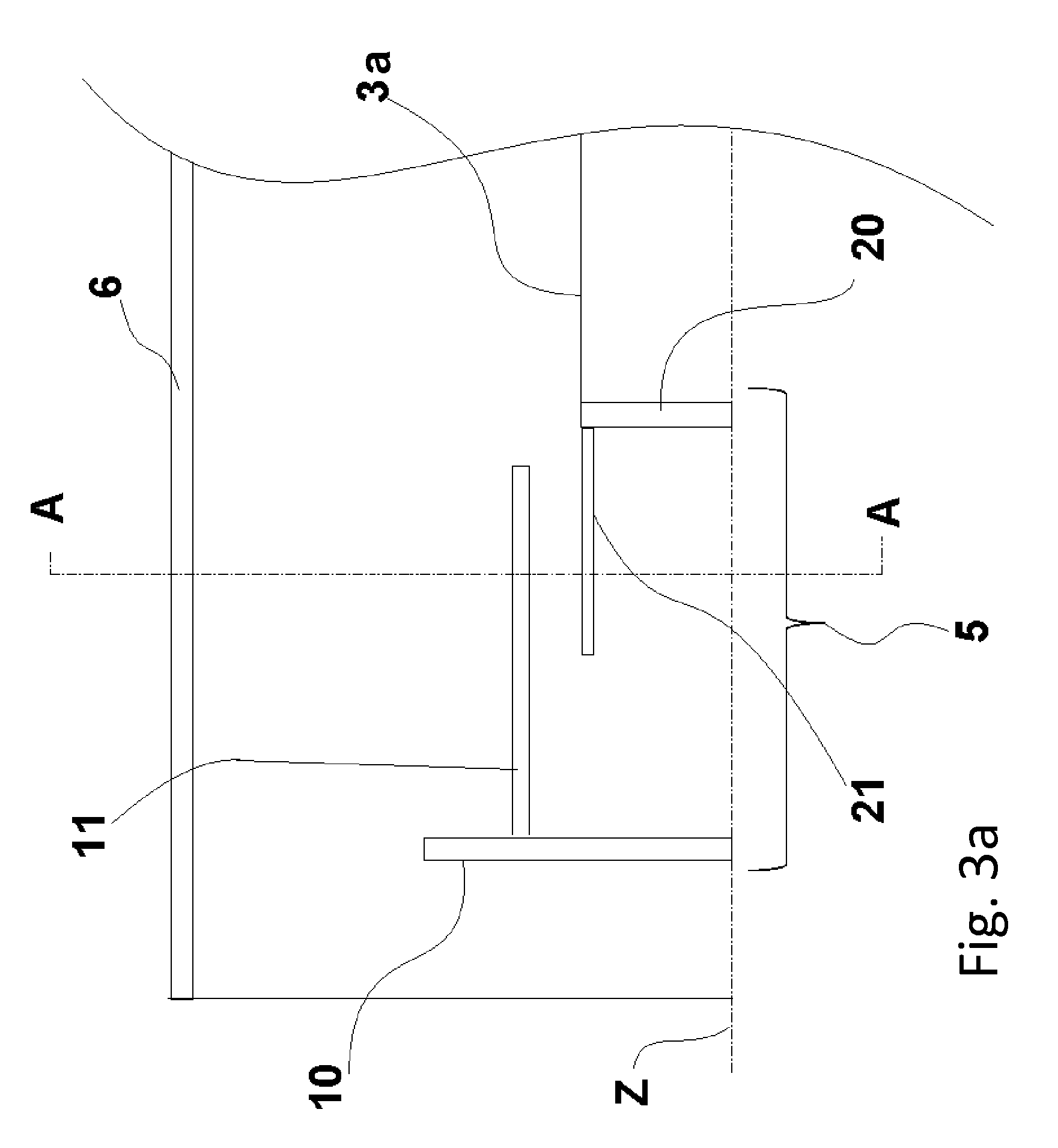

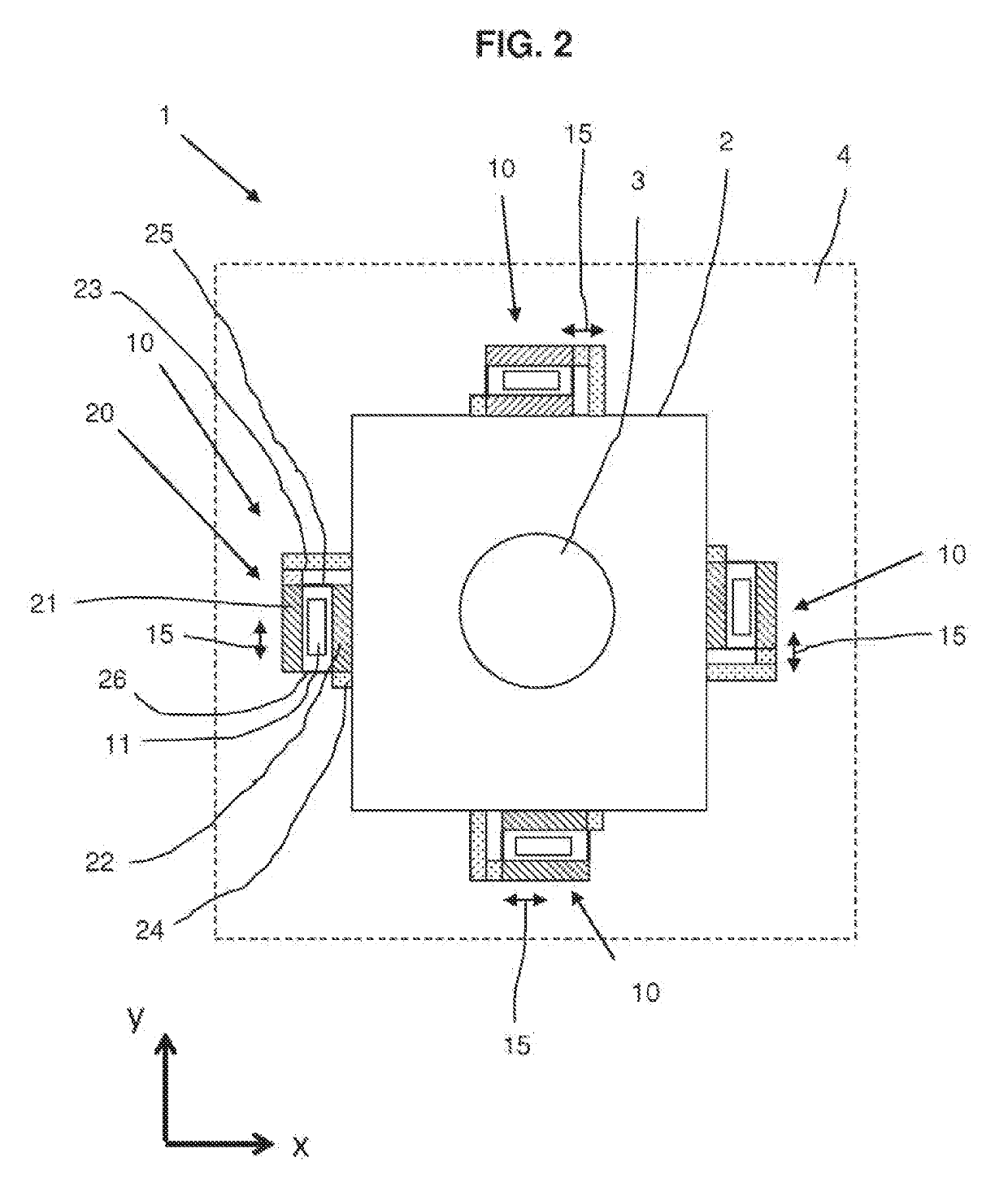

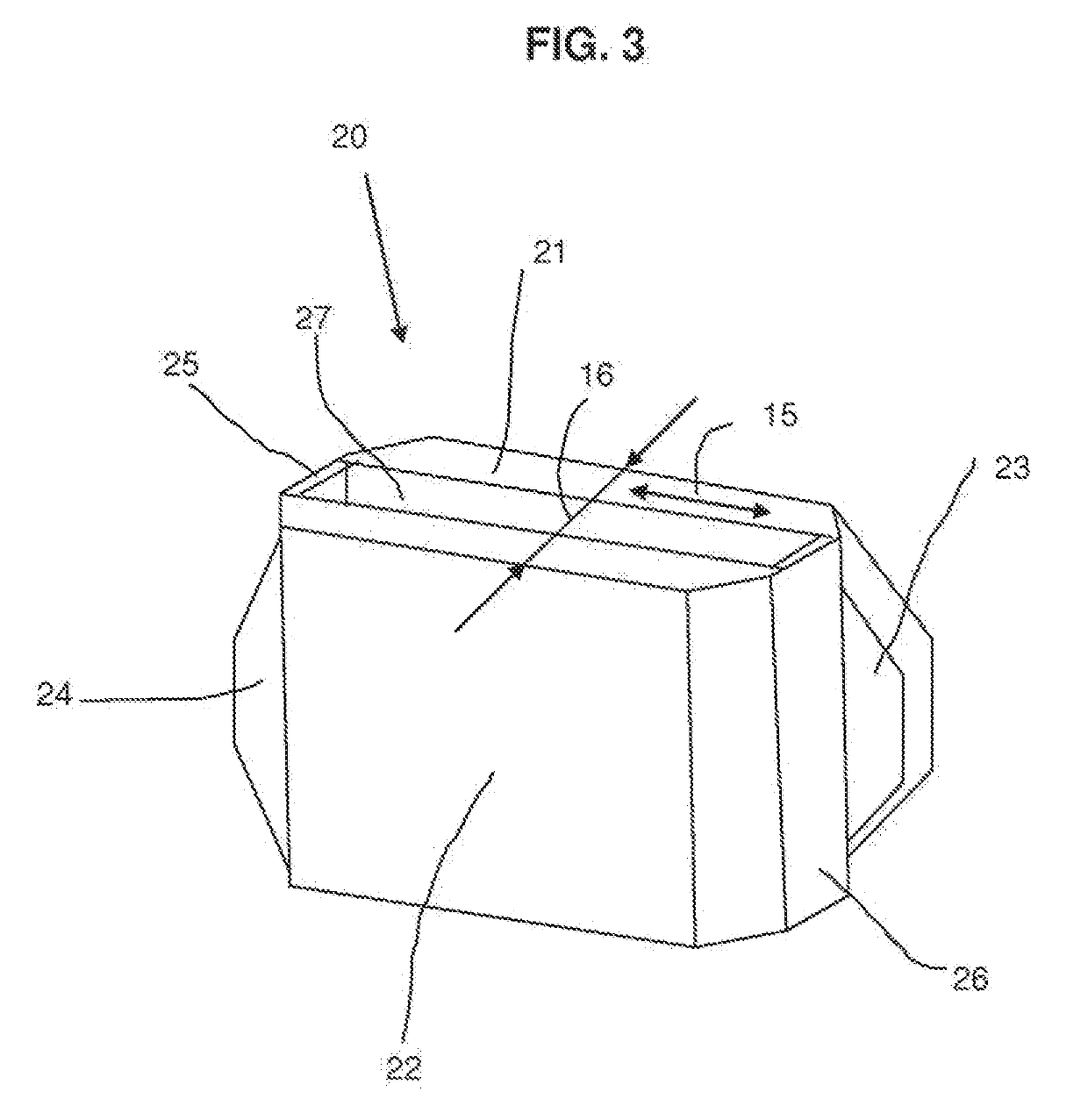

A variable rotating capacitor or RotCo 5 that can be connected via a transmission line 3 to the dee 2 of a synchrocyclotron 1 so as to adjust a resonant frequency of the synchrocyclotron as a function of time and which comprises a cylindrical rotor 10 and a cylindrical stator 20 that are coaxial with the Z axis. The rotor comprises a plurality of circumferentially-distributed rotor electrodes 11 extending parallel to its rotation axis Z. The stator comprises a plurality of circumferentially-distributed stator electrodes 21 extending parallel to the rotation axis Z. Each stator electrode 21 consists of a single metal plate and all said plates are distributed over one and the same stator circumference 25. This makes it possible for the RF currents in the electrodes to be better distributed and thus reduces the local overheating.The present invention also relates to a synchrocyclotron comprising such a RotCo.

Owner:ION BEAM APPL

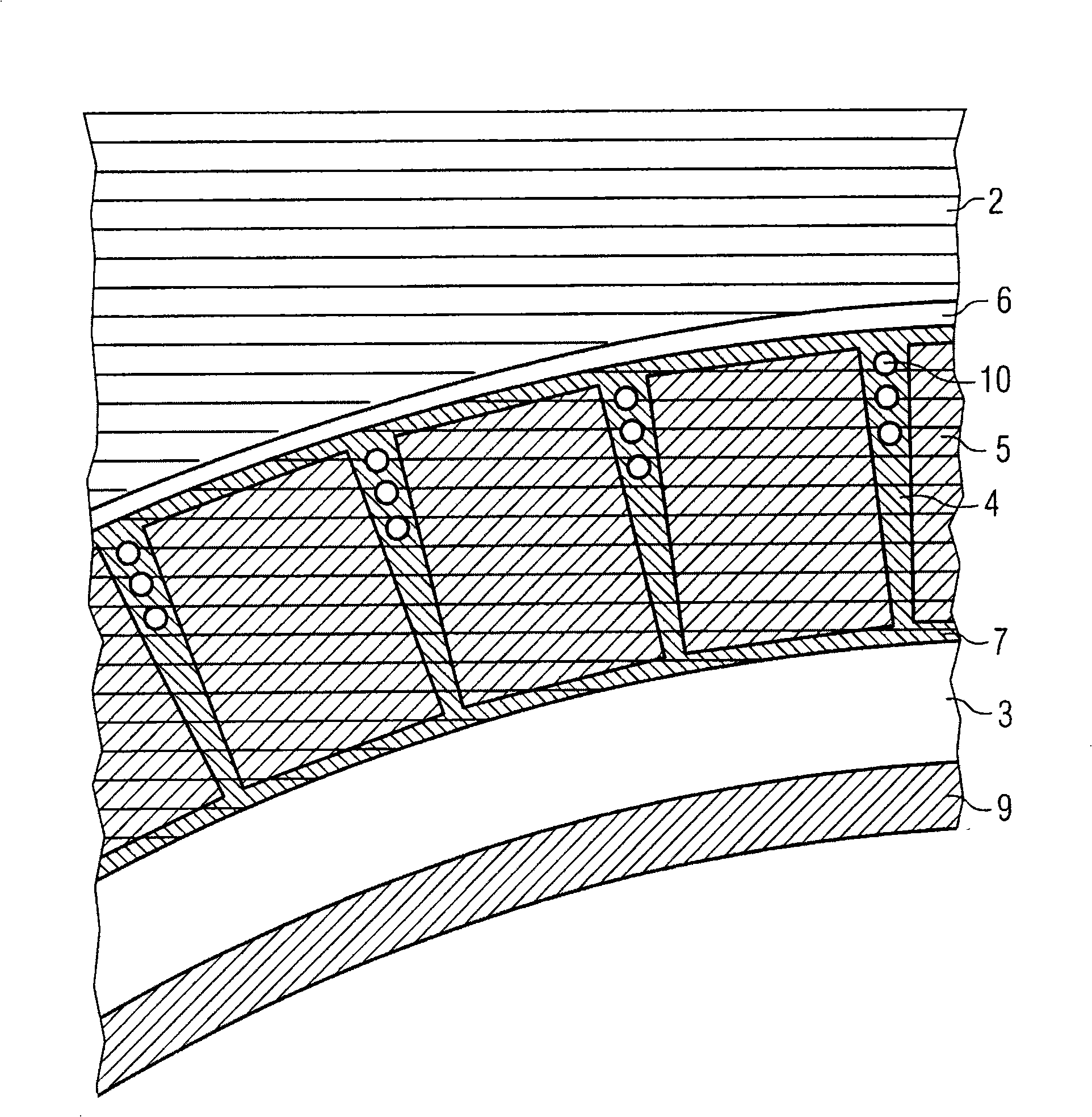

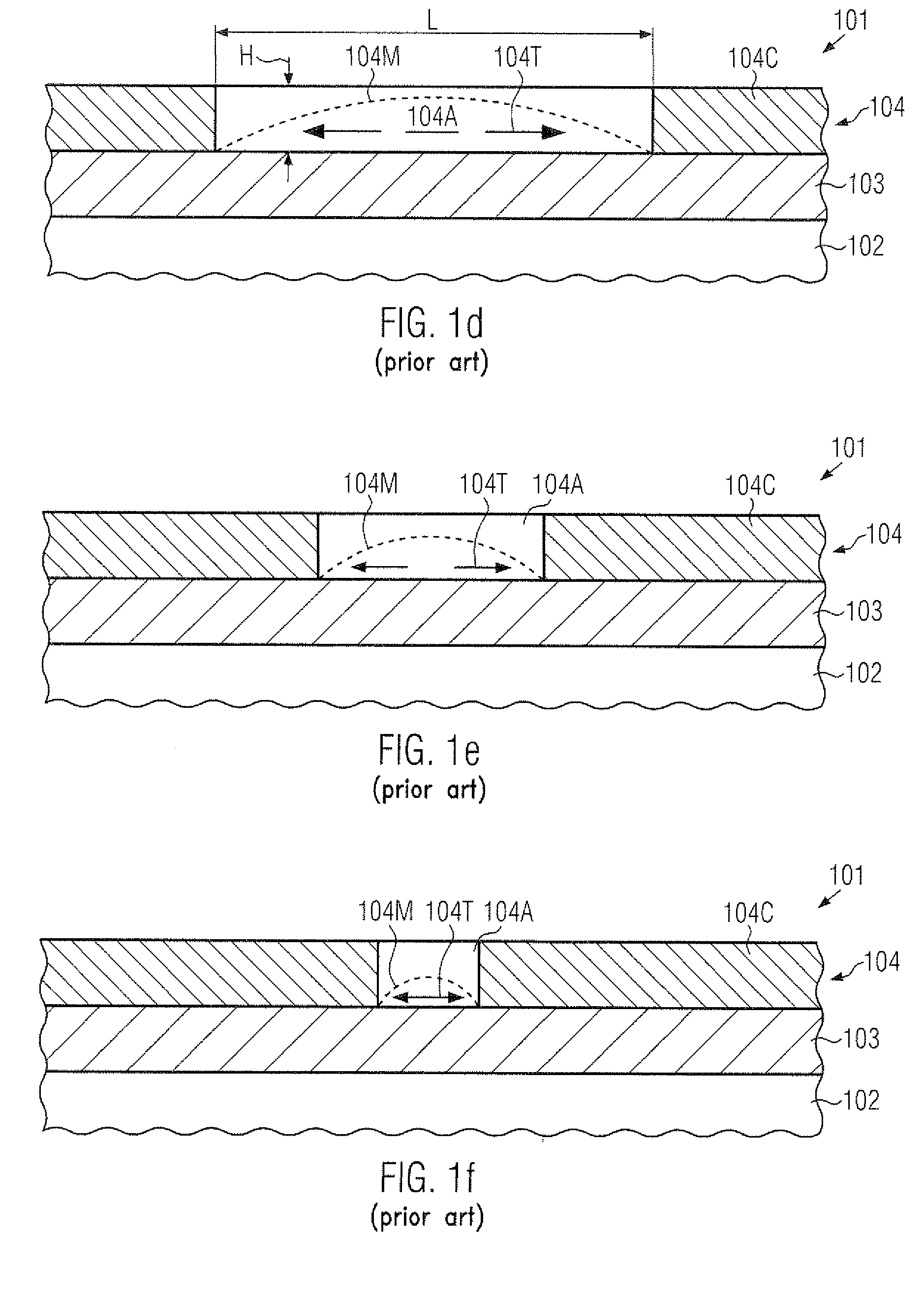

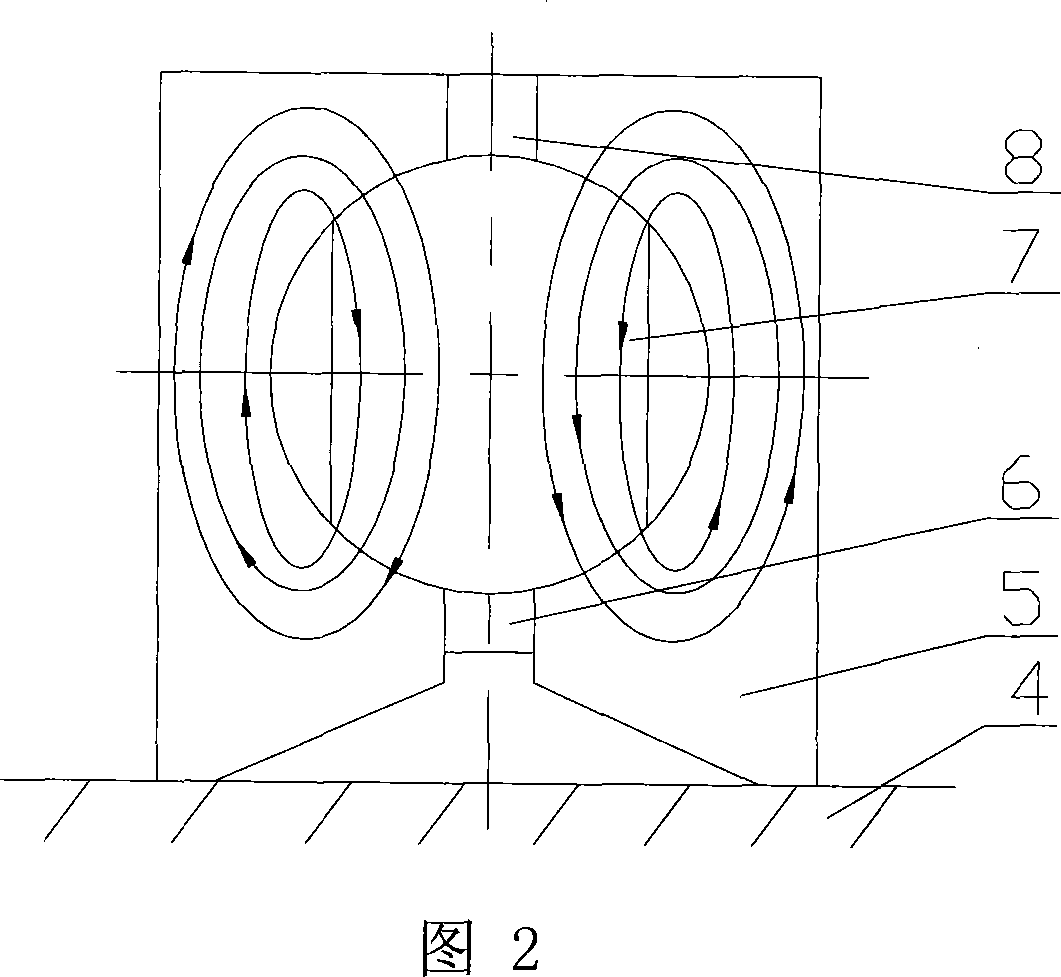

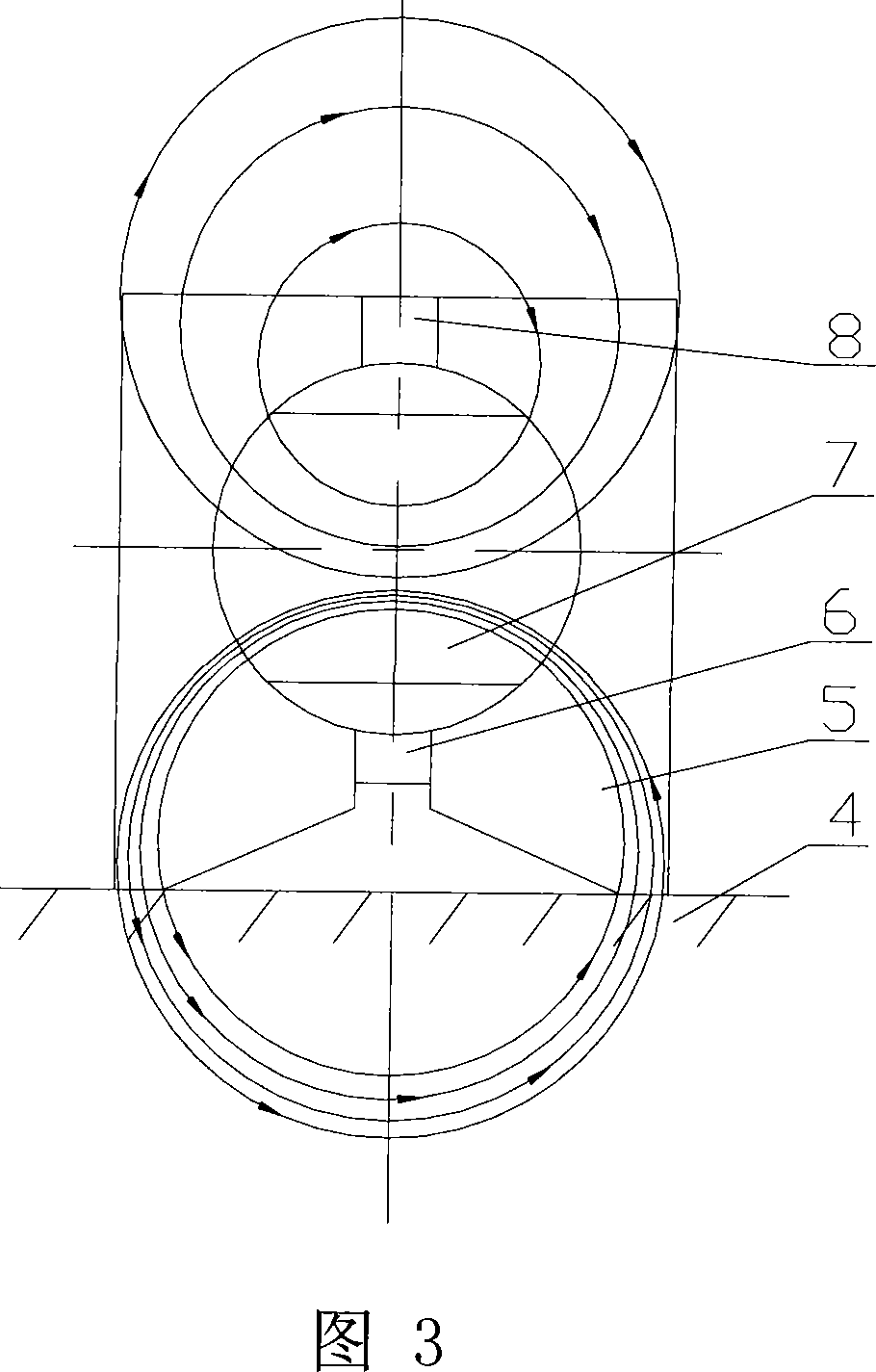

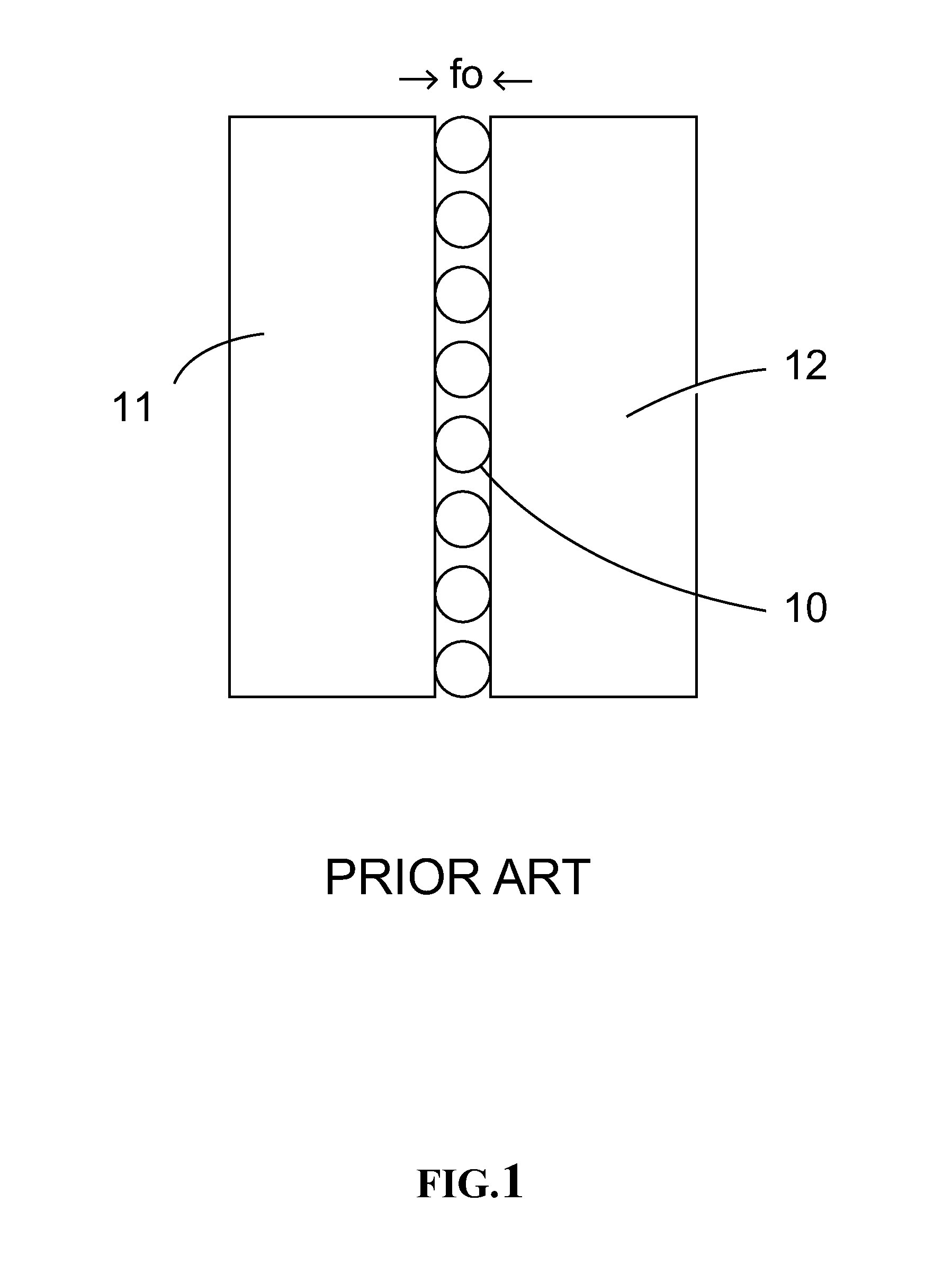

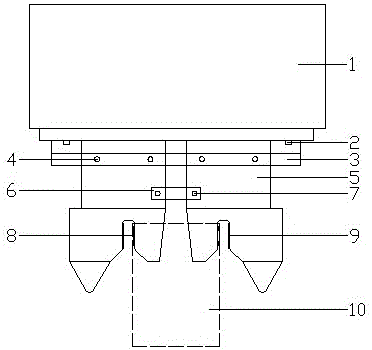

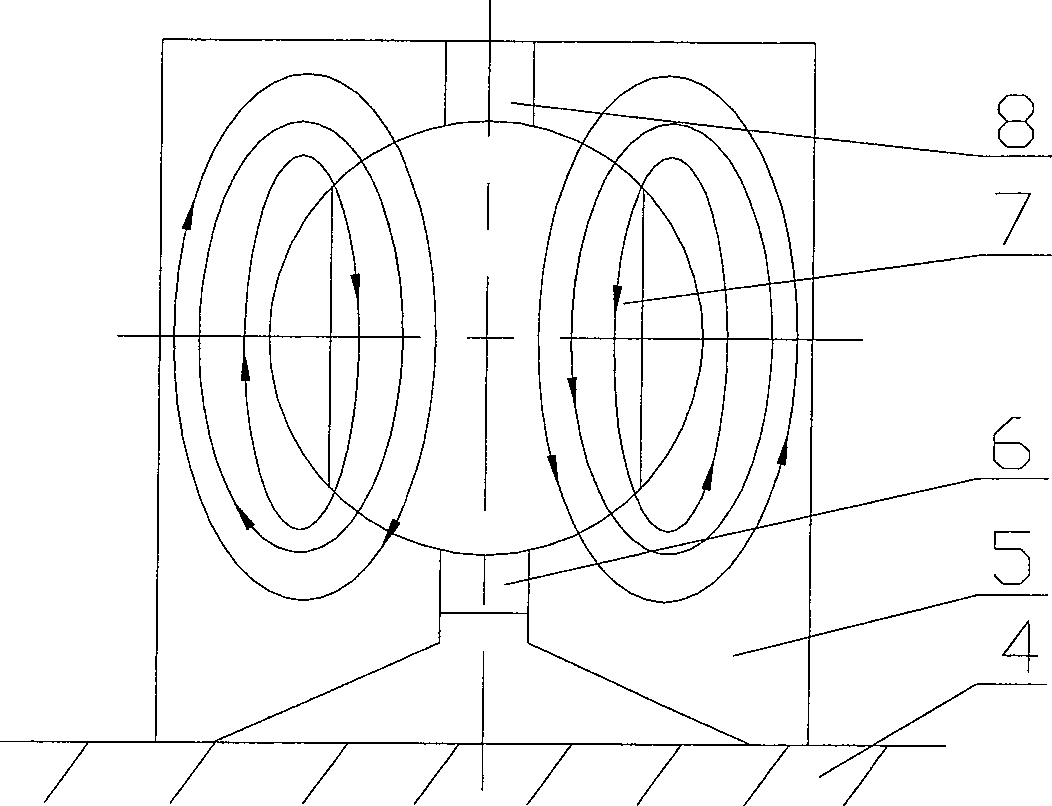

Device for superposed mri and pet imaging

ActiveCN101254100AImprove cooling effectAvoid wrinkling artifactsComputerised tomographsDiagnostic recording/measuringPet imagingPet mr imaging

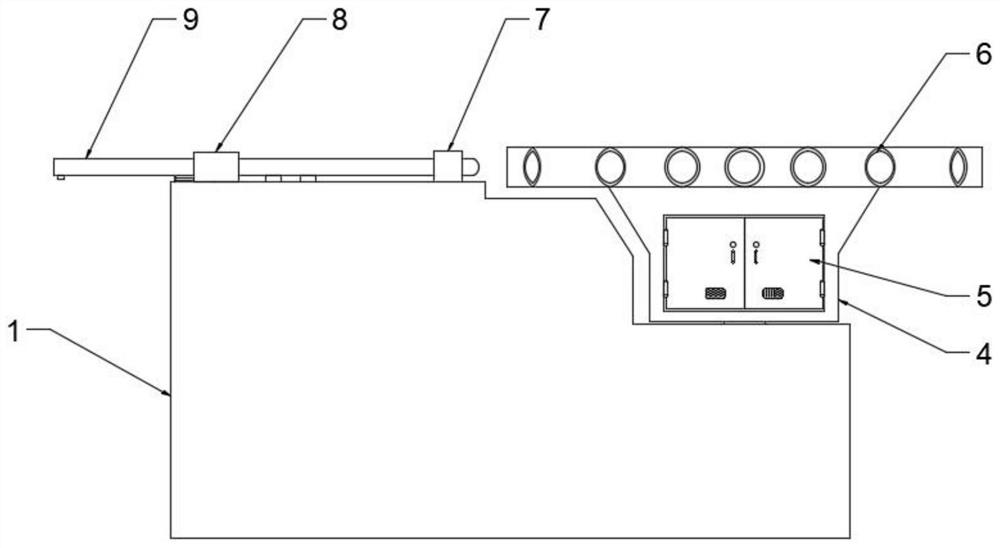

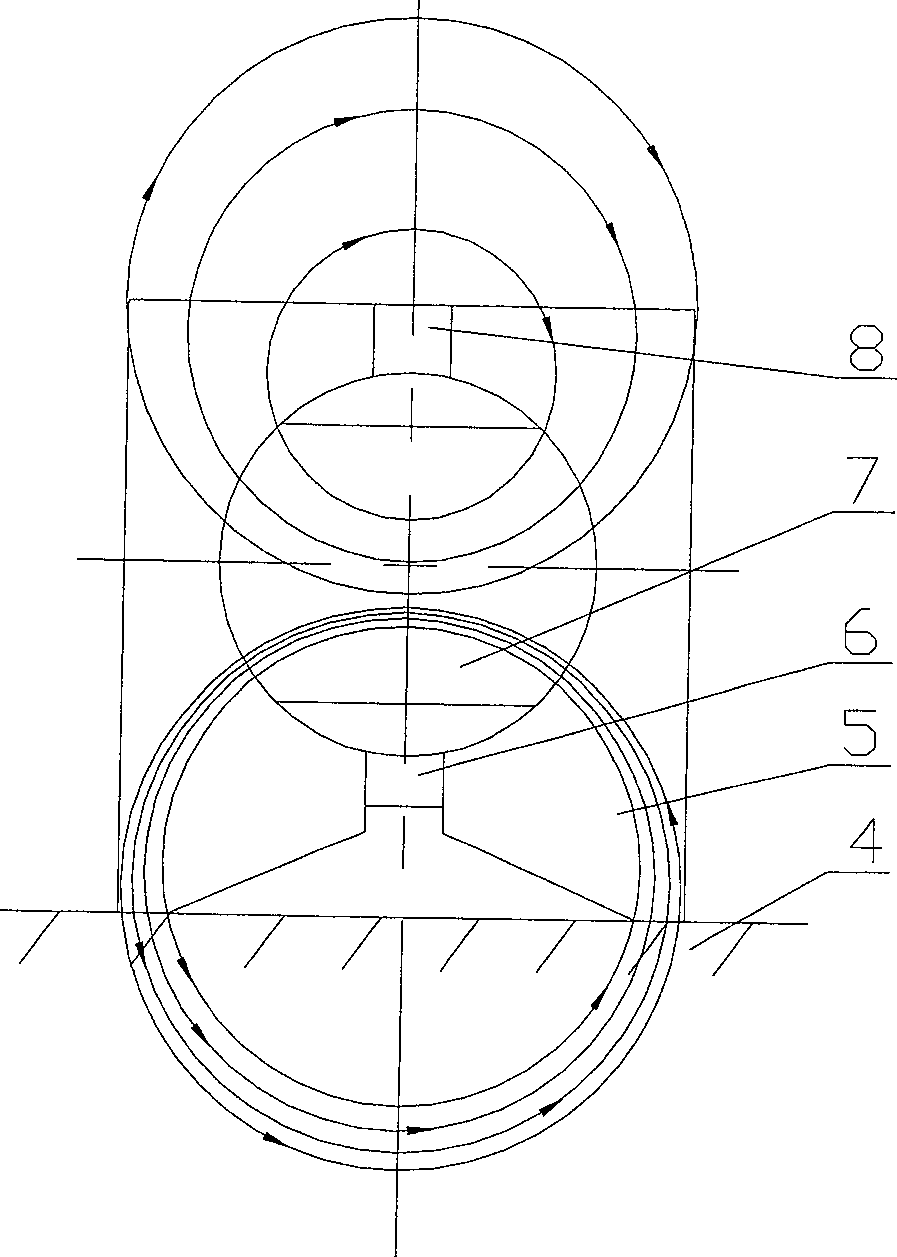

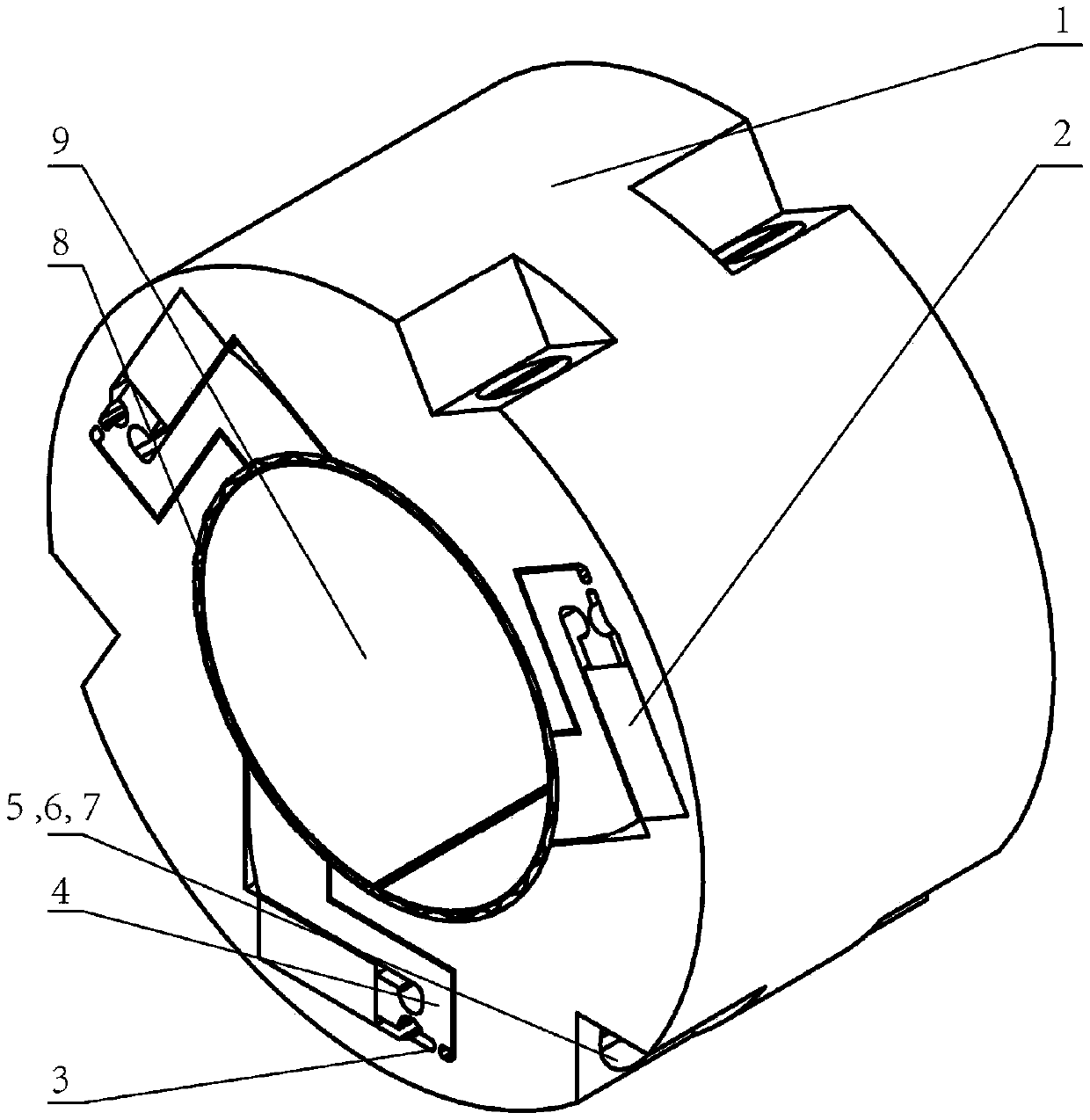

A device is disclosed for superposed magnetic resonance imaging and positron emission tomography imaging. The device includes a magnetic resonance imaging magnet which defines a longitudinal axis (z); a magnetic resonance imaging gradient coil (2) arranged radially within the magnetic resonance imaging magnet; a magnetic resonance imaging HF coil (3) arranged radially within the magnetic resonance imaging gradient coil (2); and a multiplicity of positron emission tomography detection units arranged in pairs opposite one another about the longitudinal axis (z). The many positron emission tomography detection units (5) are arranged radially within the magnetic resonance imaging gradient coil (2) and can be inserted into the device and can be removed from the device along the longitudinal axis (z). A carrier tube (7) is preferably provided having a multiplicity of pockets (4), which in each case extend along the longitudinal axis, for accommodating at least one positron emission tomography detection unit (5).

Owner:SIEMENS HEATHCARE GMBH

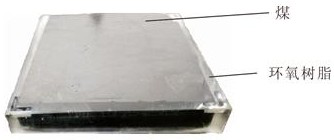

Variable Rotating Capacitor for Synchrocyclotron

ActiveUS20140103839A1Reduce mechanical deformationLess sensitiveCapacitor with electrode area variationMagnetic resonance acceleratorsPower flowCapacitor

A variable rotating capacitor or RotCo 5 that can be connected via a transmission line 3 to the dee 2 of a synchrocyclotron 1 so as to adjust a resonant frequency of the synchrocyclotron as a function of time and which comprises a cylindrical rotor 10 and a cylindrical stator 20 that are coaxial with the Z axis. The rotor comprises a plurality of circumferentially-distributed rotor electrodes 11 extending parallel to its rotation axis Z. The stator comprises a plurality of circumferentially-distributed stator electrodes 21 extending parallel to the rotation axis Z. Each stator electrode 21 consists of a single metal plate and all said plates are distributed over one and the same stator circumference 25. This makes it possible for the RF currents in the electrodes to be better distributed and thus reduces the local overheating.The present invention also relates to a synchrocyclotron comprising such a RotCo.

Owner:ION BEAM APPL

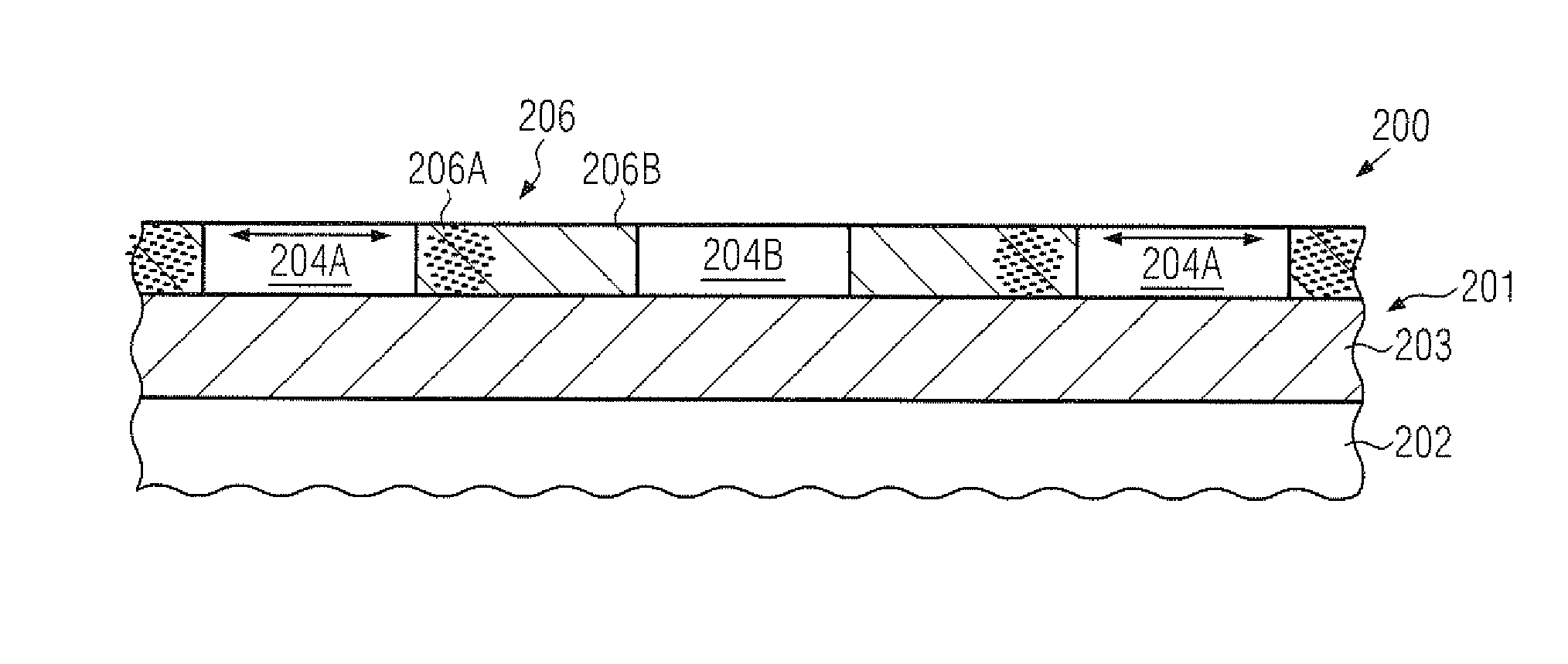

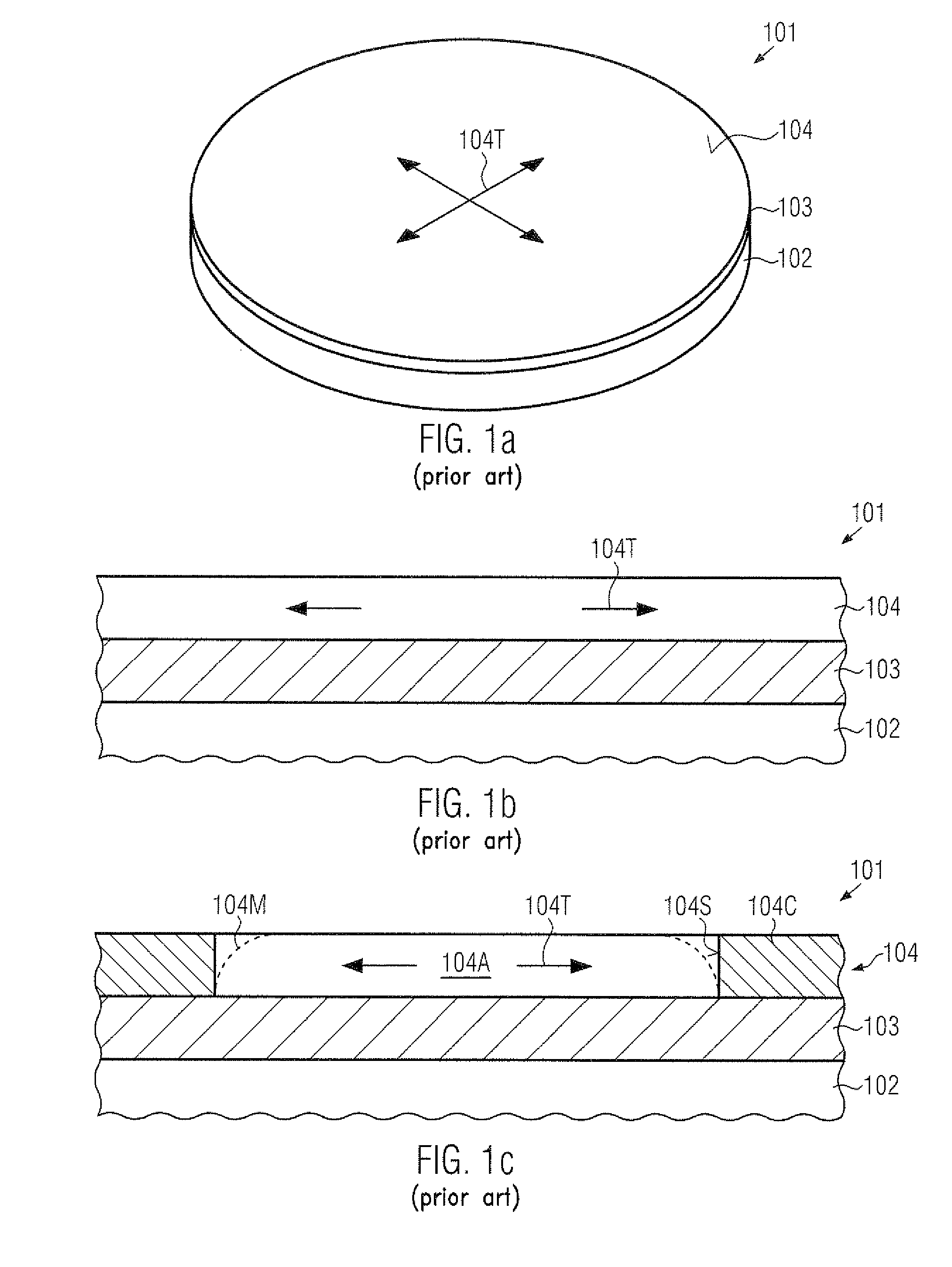

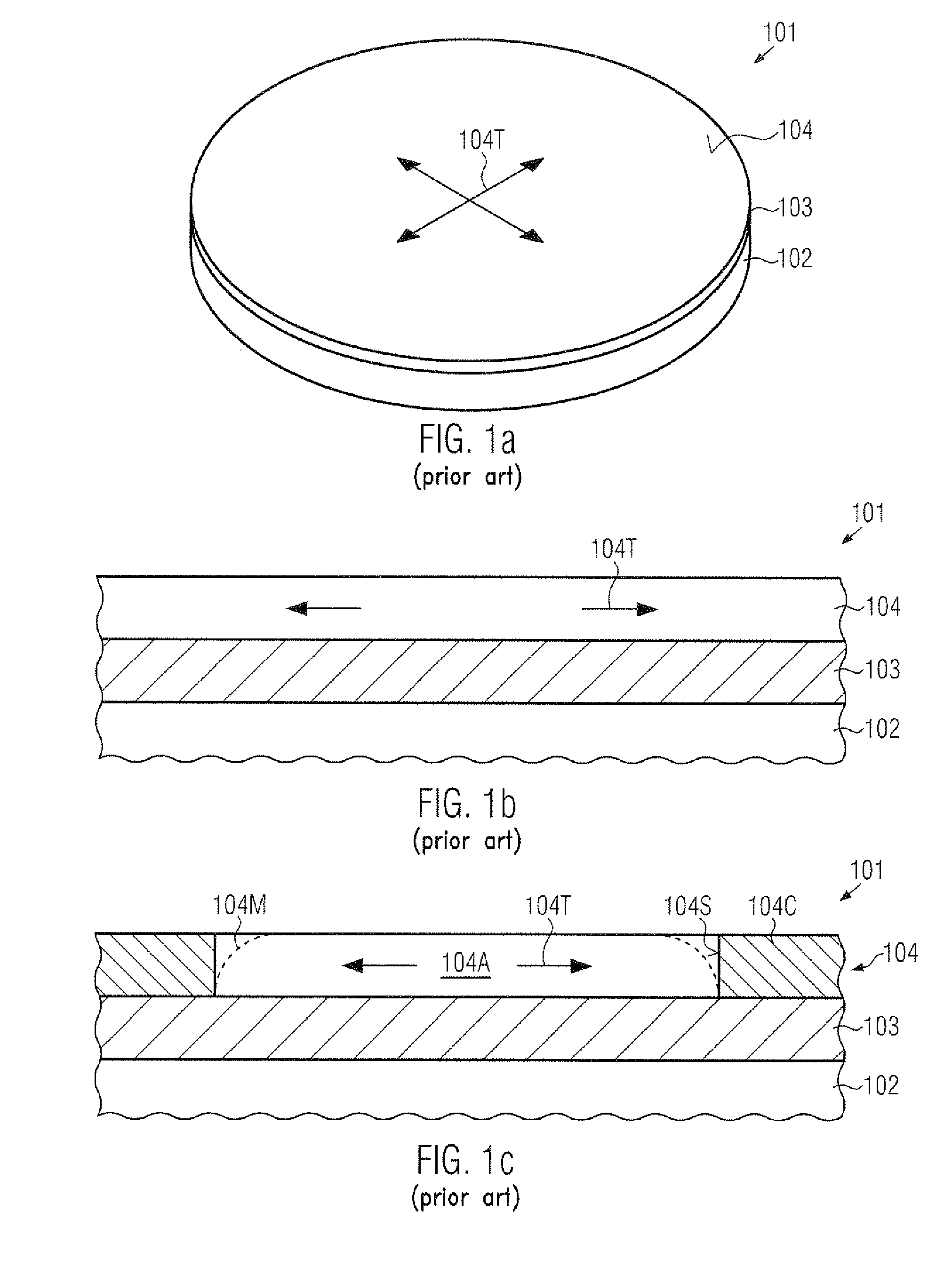

Strain memorization in strained SOI substrates of semiconductor devices

InactiveUS8329531B2Improve mechanical stabilityInhibition is effectiveSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateEngineering

In sophisticated semiconductor devices, the initial strain component of a globally strained semiconductor layer may be substantially preserved during the formation of shallow trench isolations by using a rigid mask material, which may efficiently avoid or reduce a deformation of the semiconductor islands upon patterning the isolation trenches. Consequently, selected regions with high internal stress levels may be provided, irrespective of the height-to-length aspect ratio, which may limit the application of globally strained semiconductor layers in conventional approaches. Furthermore, in some illustrative embodiments, active regions of substantially relaxed strain state or of inverse strain type may be provided in addition to the highly strained active regions, thereby enabling an efficient process strategy for forming complementary transistors.

Owner:GLOBALFOUNDRIES INC

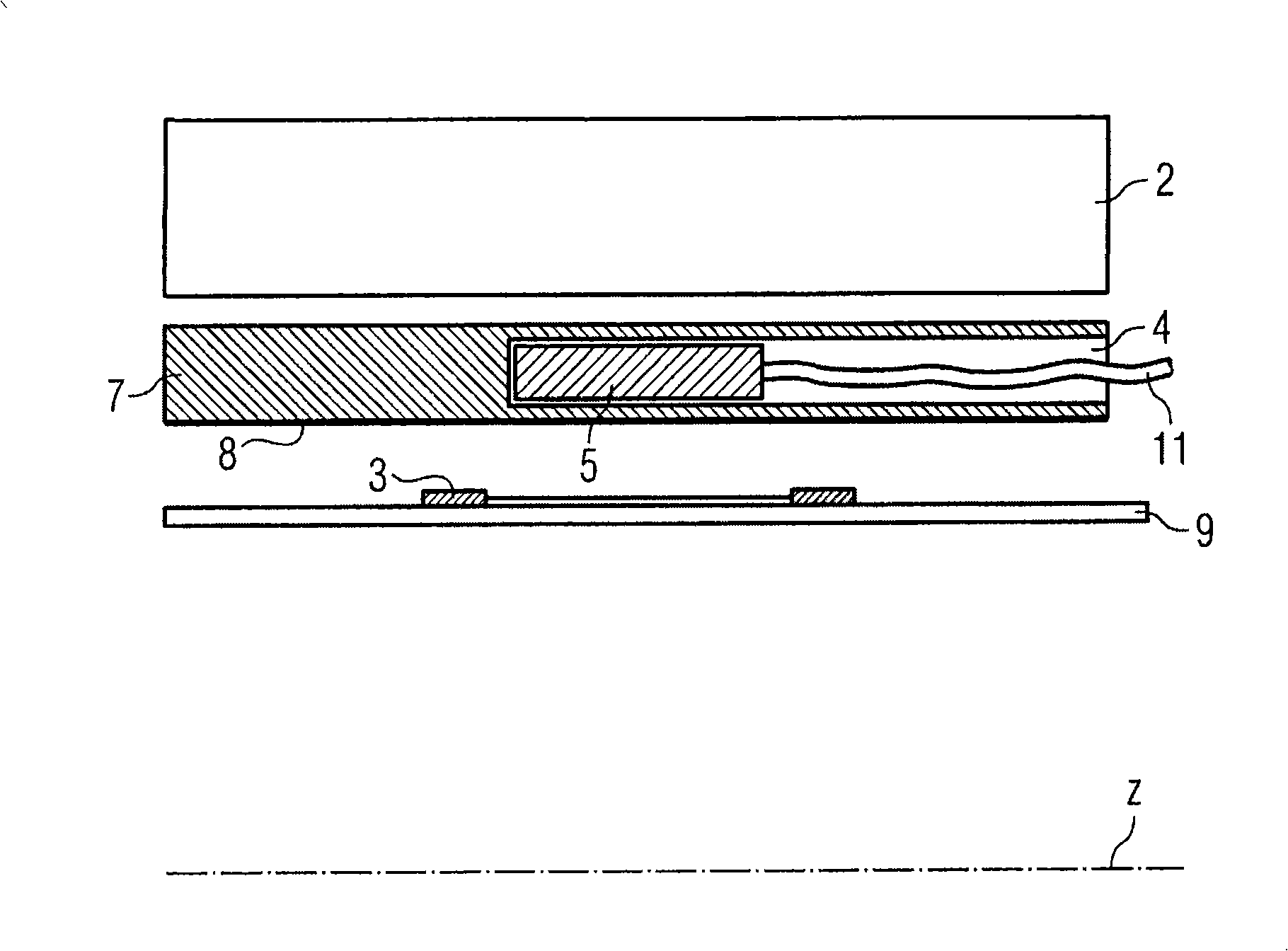

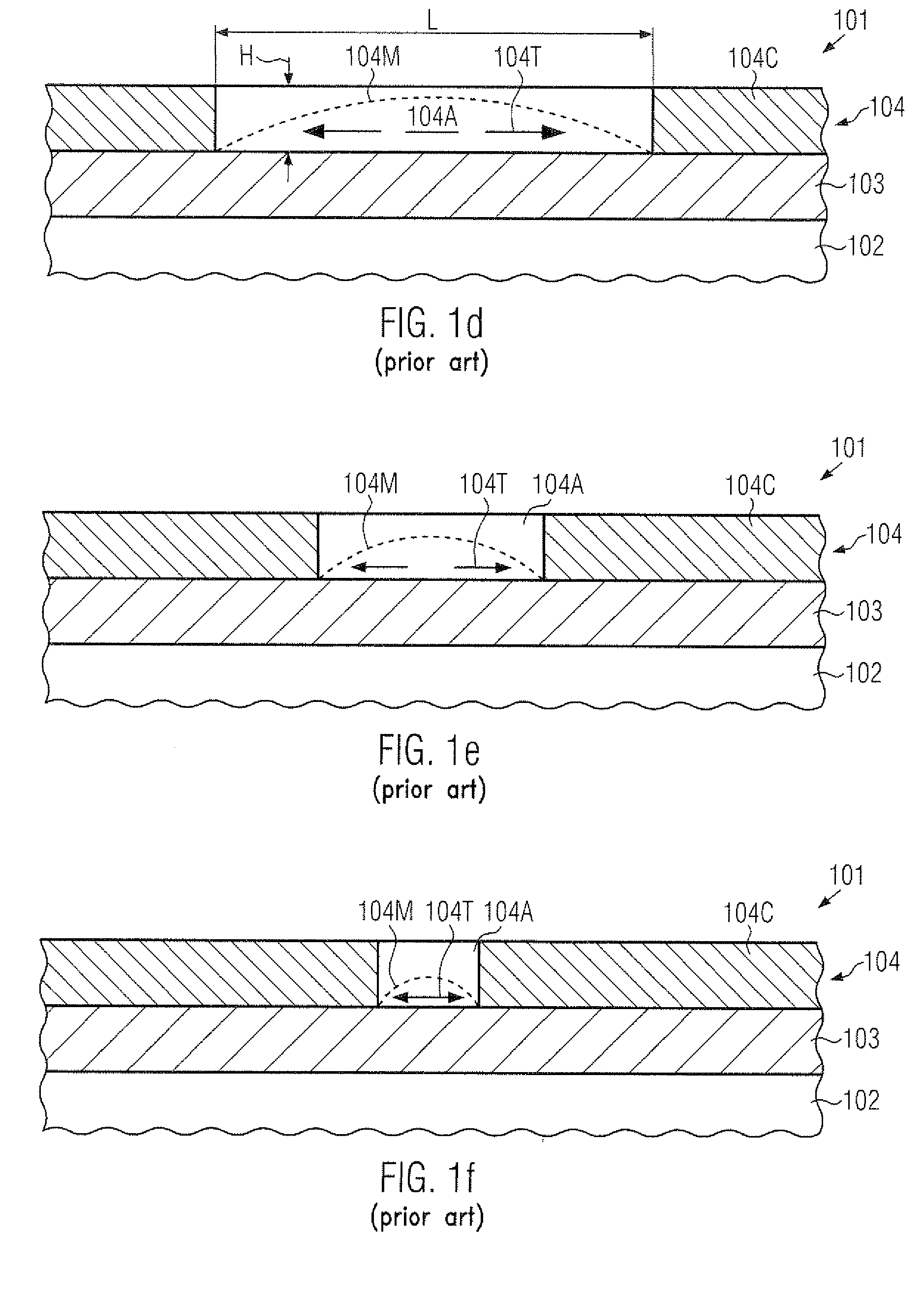

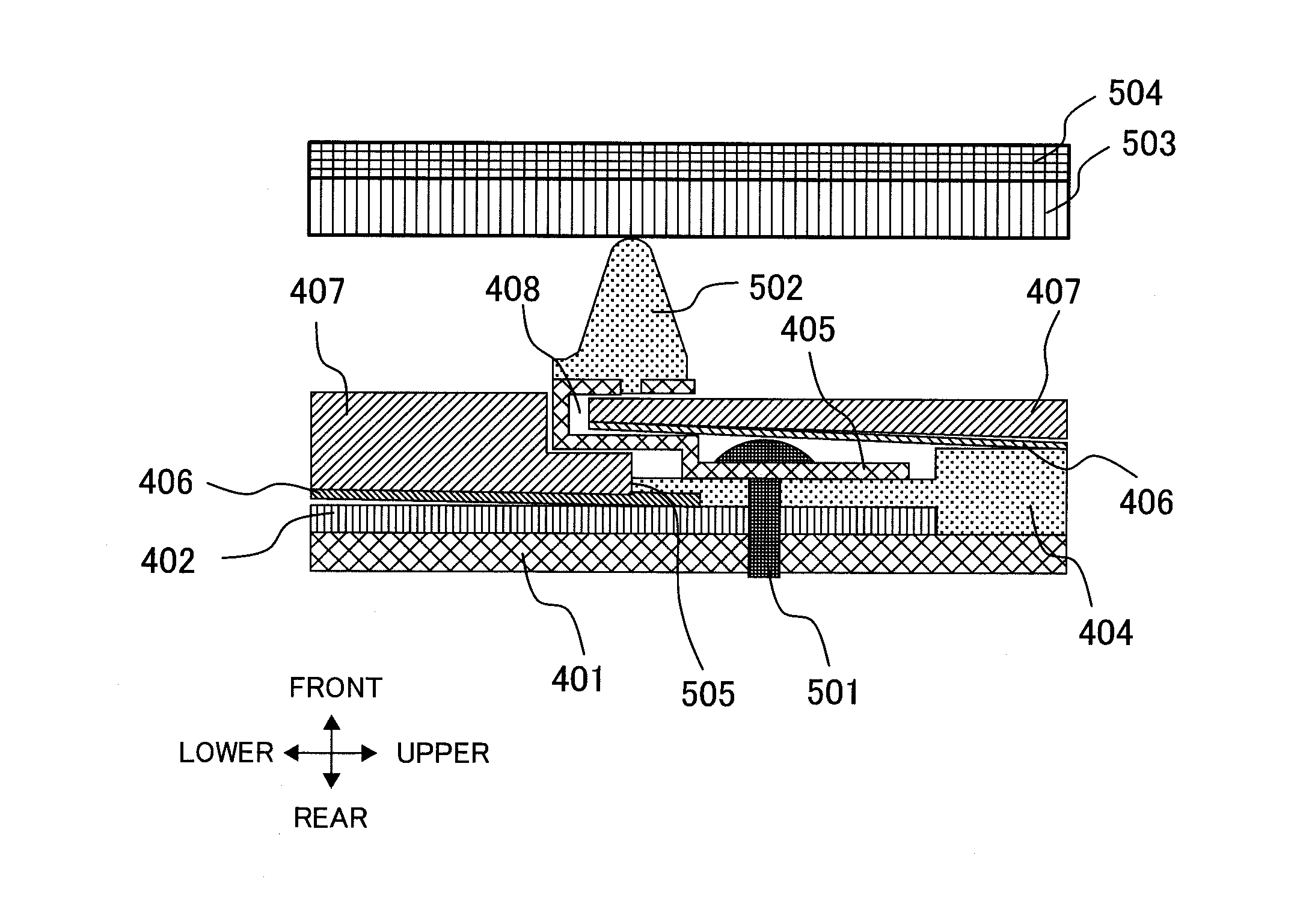

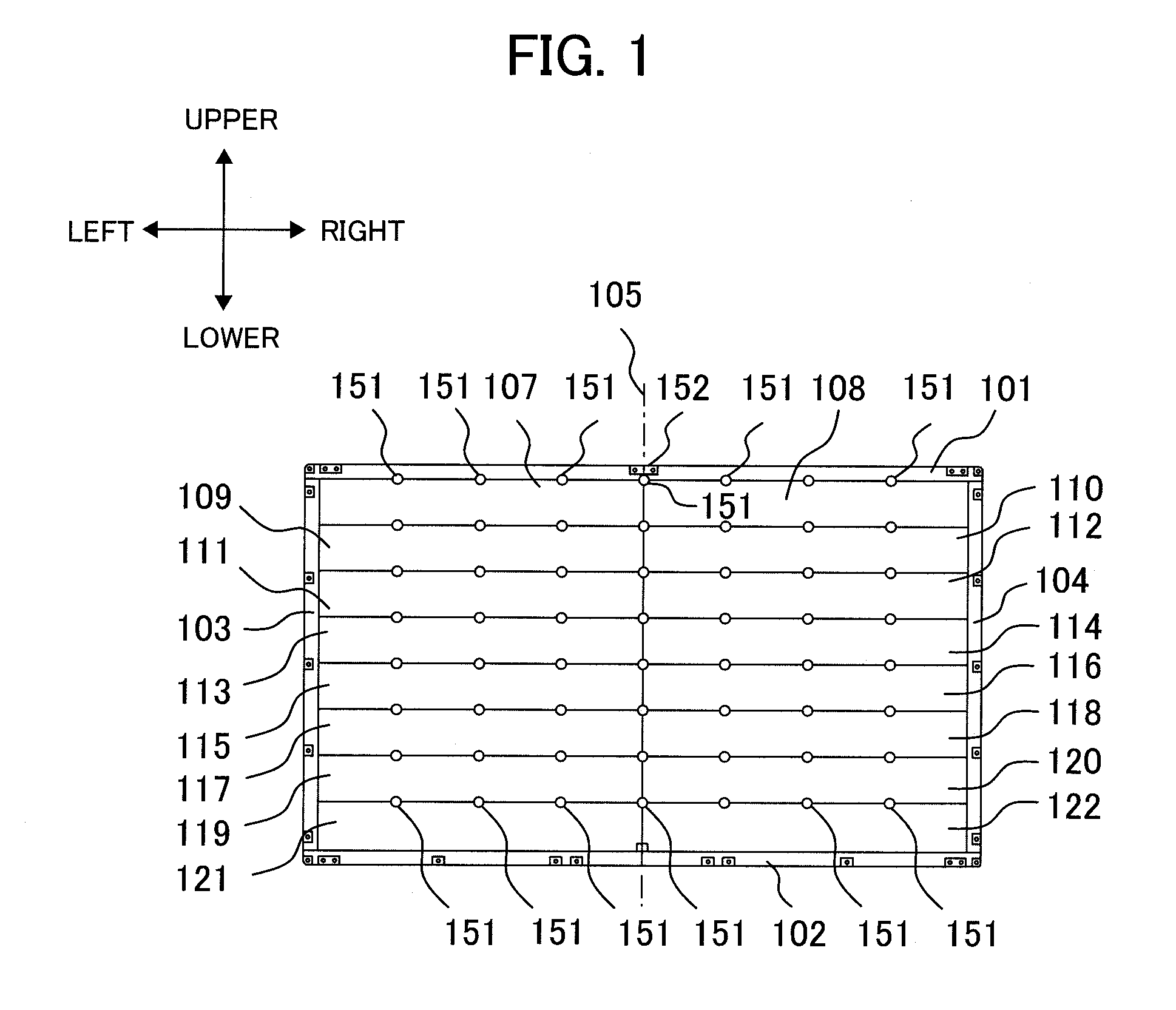

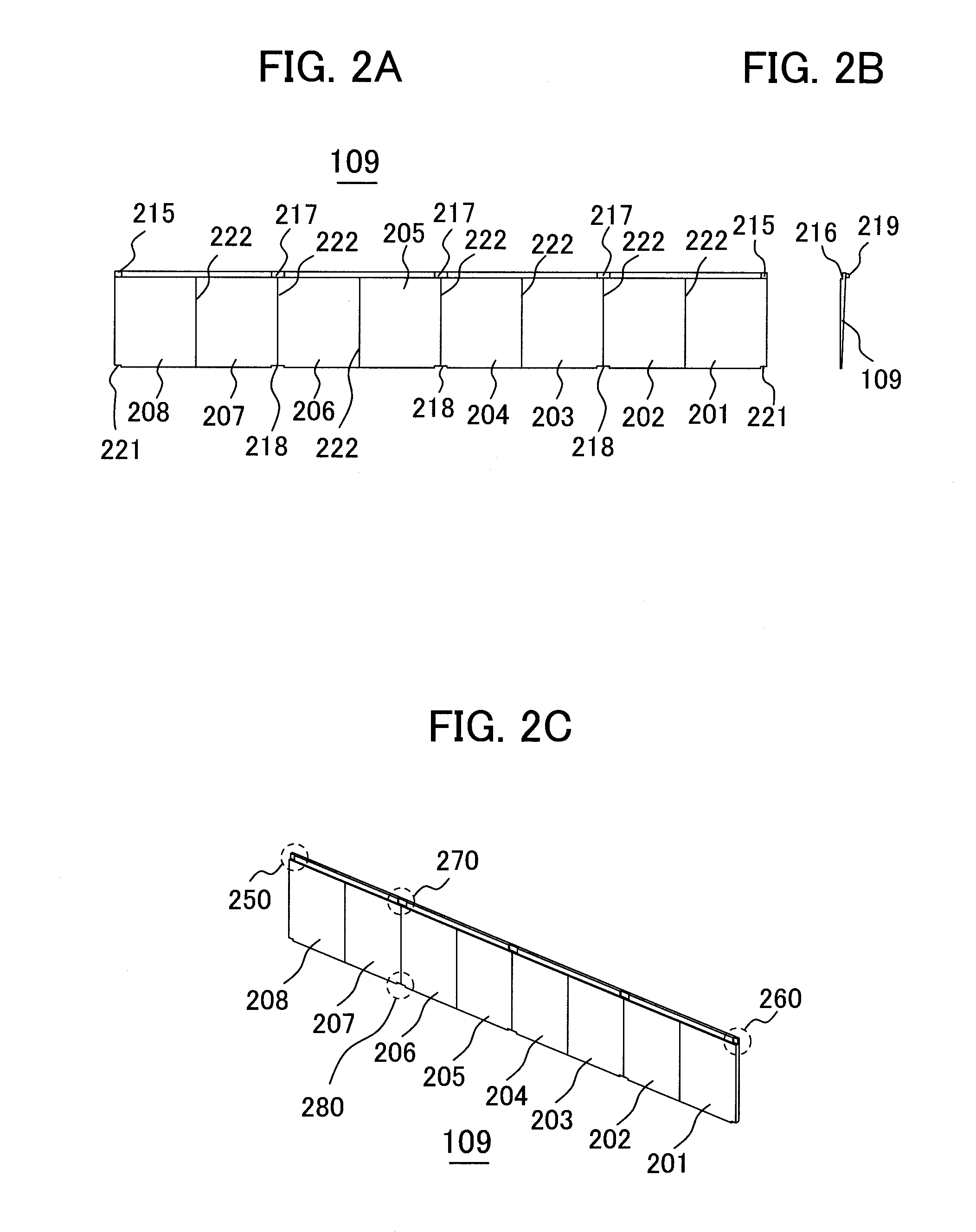

Liquid crystal display device

InactiveUS20110051042A1Reduce brightness unevennessUnevenness of light outputPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device is provided in which, even when divided light guide plate blocks are thermally expanded or contracted as a result of a temperature change, the generation of clearances and mechanical deformations between such divided light guide plate blocks is prevented, making it possible to reduce the brightness unevenness of the liquid crystal display device. To realize the above feature, light guide plate blocks are arranged such that one or two of them are arranged in each horizontal row with only an upper side of each light guide plate block fixed to a chassis and, furthermore, such that the upper side fixed to the chassis of each light guide plate block is based on a center in the horizontal direction of the liquid crystal display panel so as to reduce the effects of thermal expansion and contraction of each light guide plate block.

Owner:HITACHI CONSUMER ELECTRONICS CORP

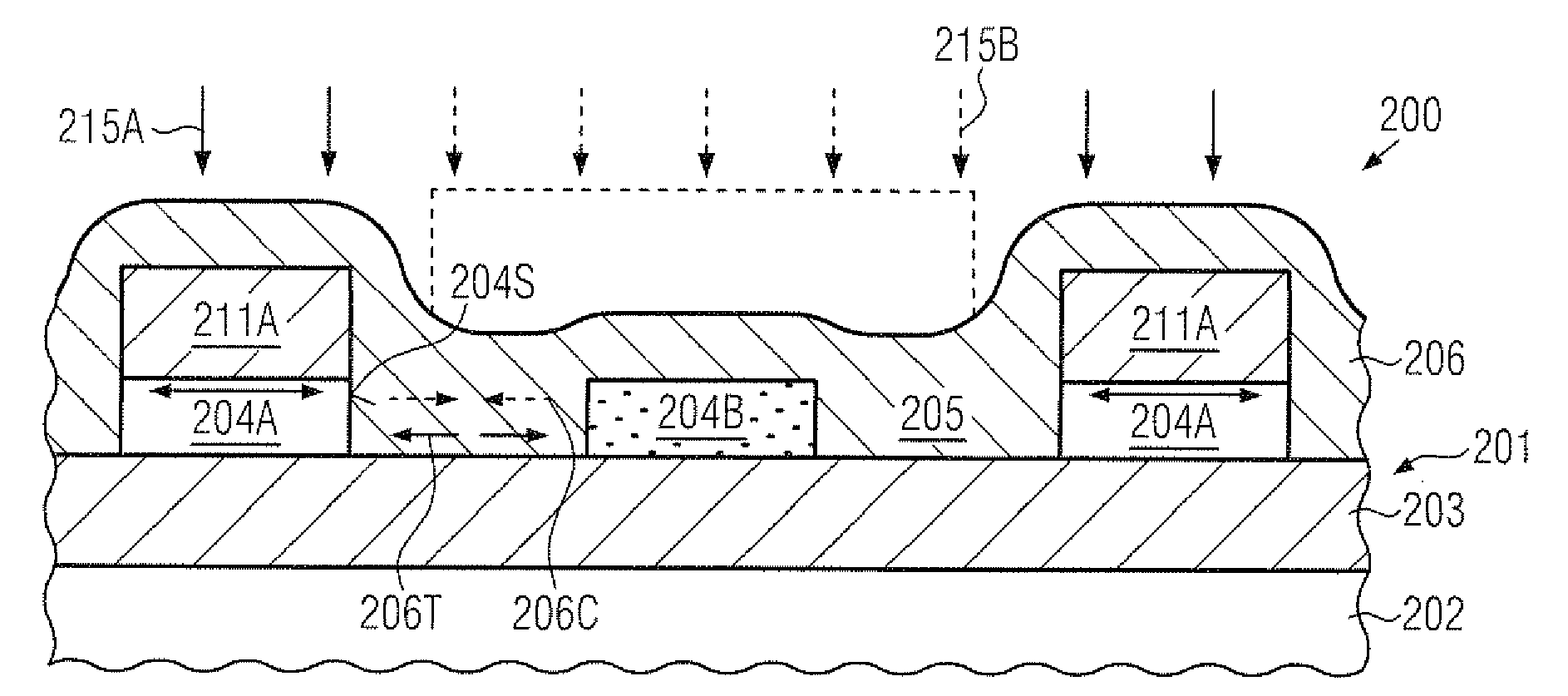

Strain memorization in strained soi substrates of semiconductor devices

InactiveUS20110210427A1Improve mechanical stabilityReducing strain relaxationSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateEngineering

In sophisticated semiconductor devices, the initial strain component of a globally strained semiconductor layer may be substantially preserved during the formation of shallow trench isolations by using a rigid mask material, which may efficiently avoid or reduce a deformation of the semiconductor islands upon patterning the isolation trenches. Consequently, selected regions with high internal stress levels may be provided, irrespective of the height-to-length aspect ratio, which may limit the application of globally strained semiconductor layers in conventional approaches. Furthermore, in some illustrative embodiments, active regions of substantially relaxed strain state or of inverse strain type may be provided in addition to the highly strained active regions, thereby enabling an efficient process strategy for forming complementary transistors.

Owner:GLOBALFOUNDRIES INC

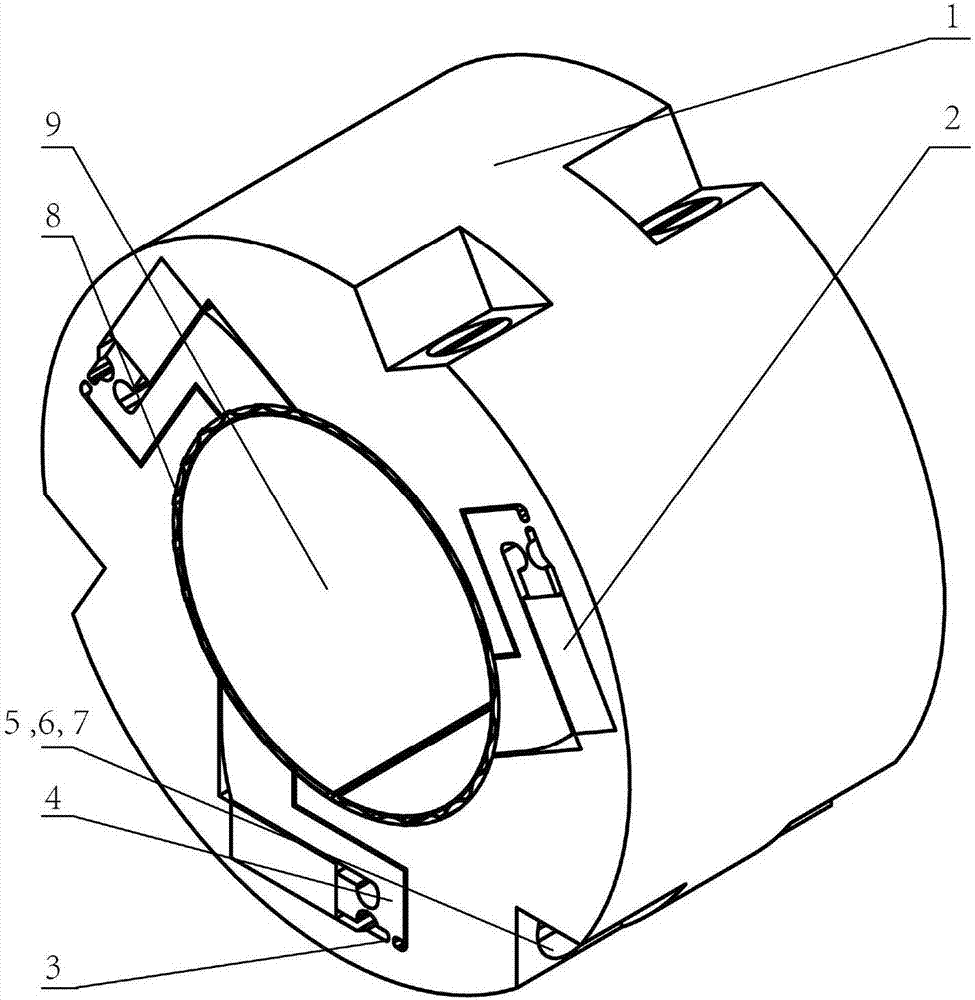

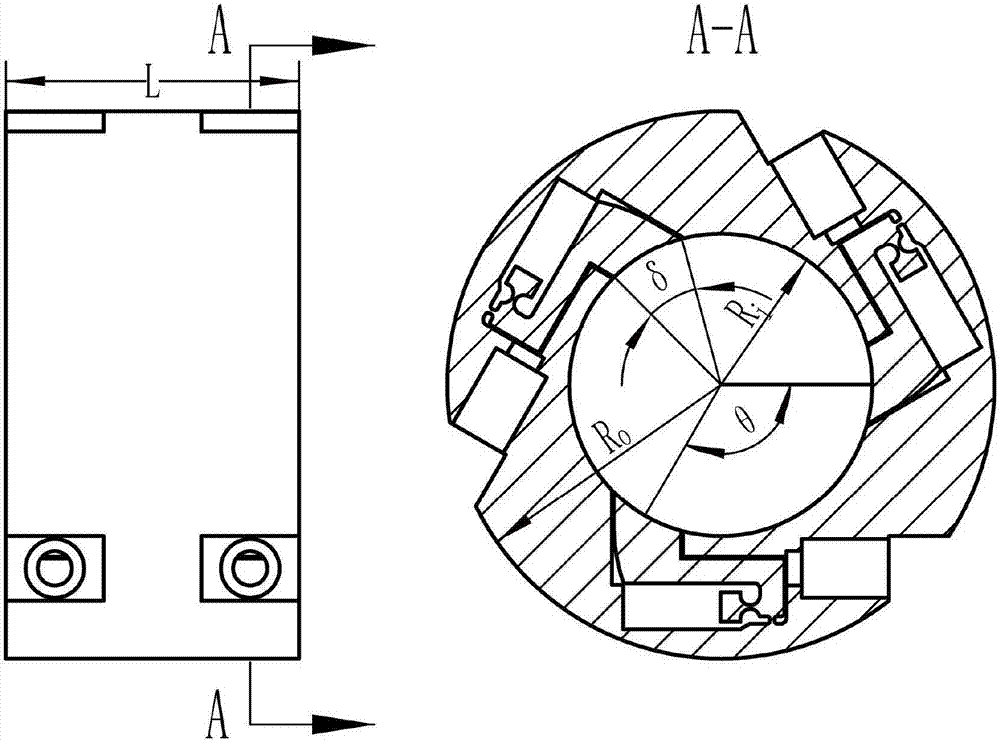

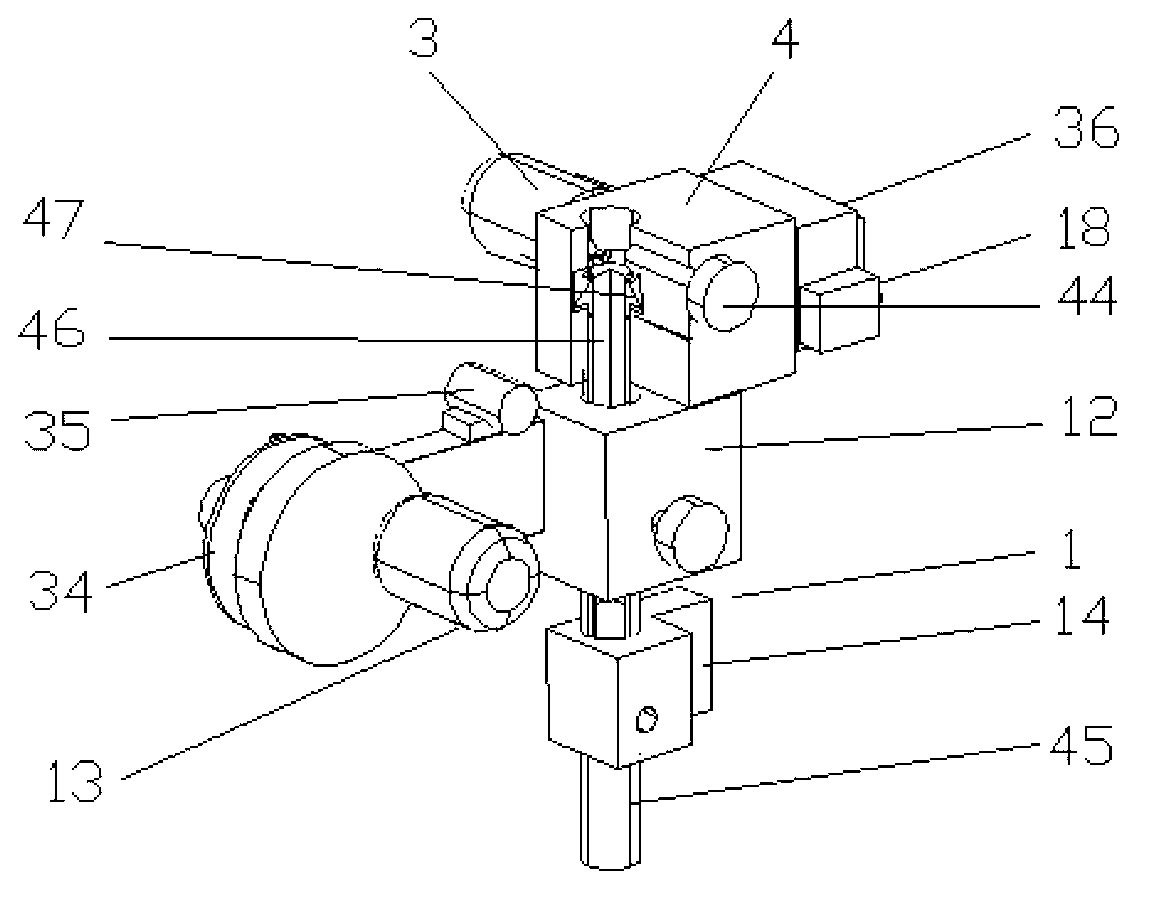

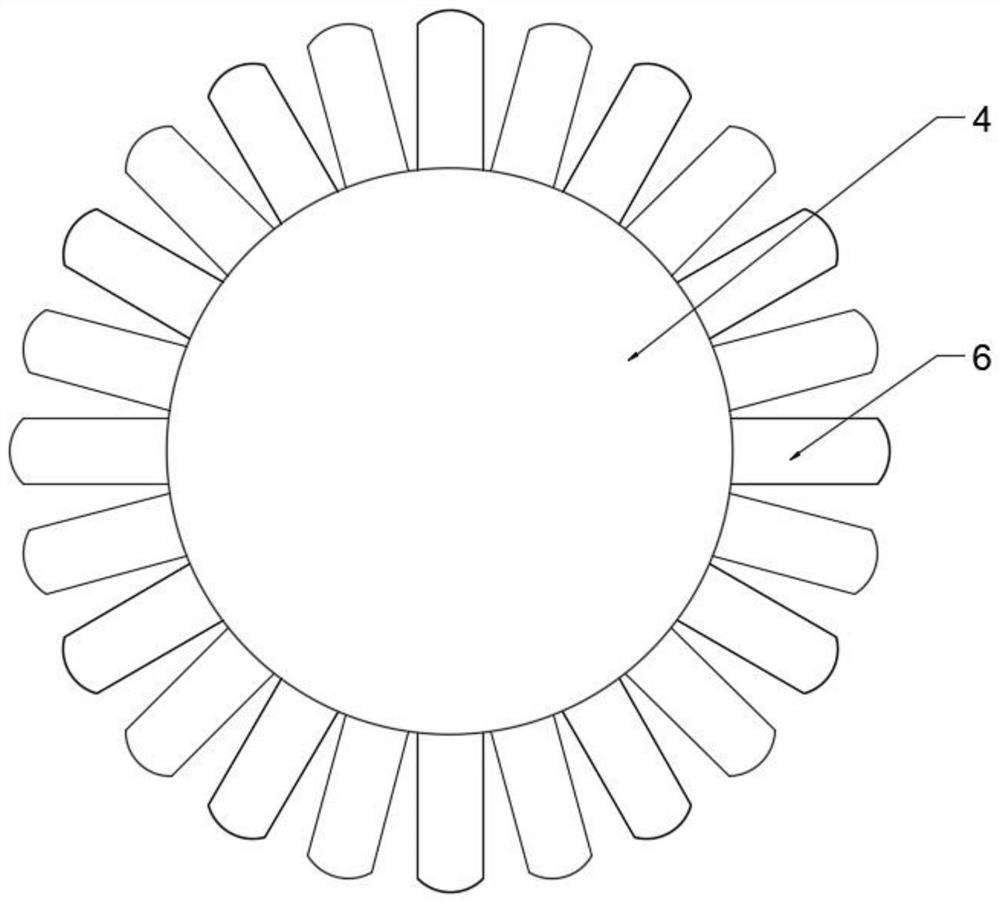

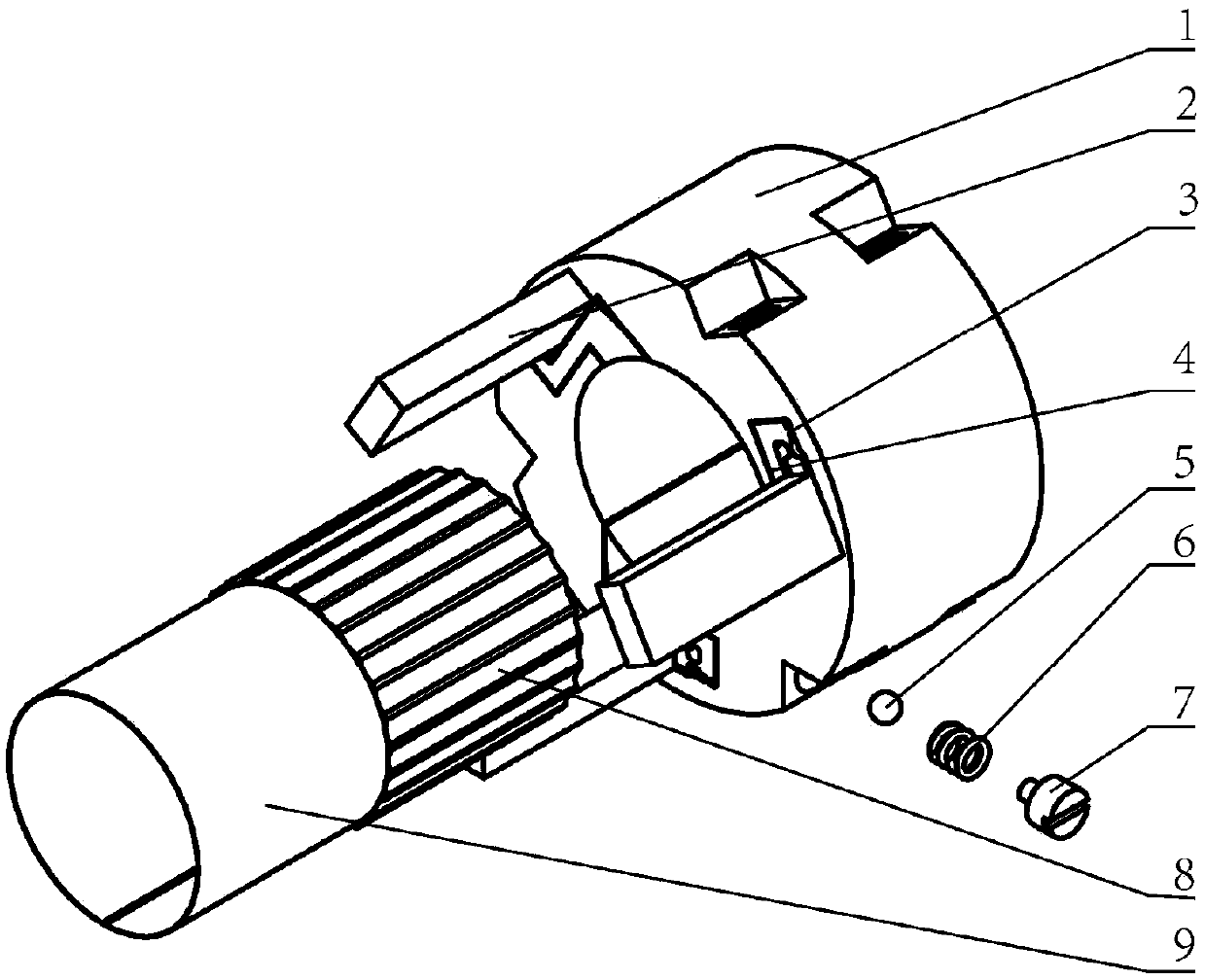

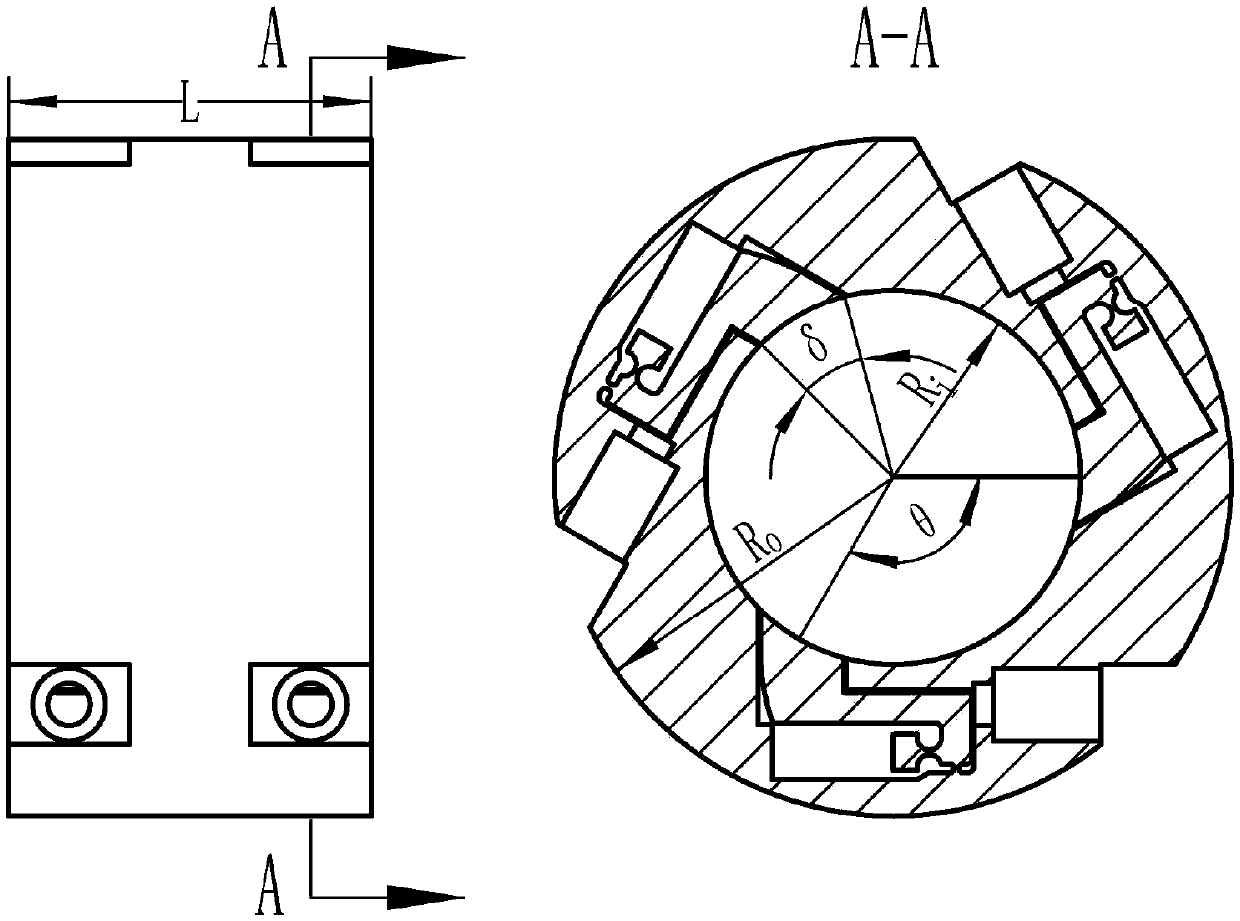

Novel active air foil bearing based on PZTs and flexible hinges

ActiveCN106884870AStable jobImproved stiffness propertiesSliding contact bearingsWire cuttingRound face

The invention discloses a novel active air foil bearing. The bearing comprises a shaft sleeve, the PZTs, the flexible hinges, rigid push rods, precompression exertion devices, wave foil and top foil; the shaft sleeve is machined through wire cutting, three PZT mounting through grooves circumferentially and evenly distributed, the corresponding flexible hinges and the corresponding rigid push rods are obtained, the top ends of the rigid push rods are flush with the inner cylindrical face of the shaft sleeve, the PZTs are mounted in the through grooves, the corresponding precompression exertion devices are designed for the PZTs, the wave foil is formed by pressing of elastic materials, and is arranged on the shaft sleeve and the inner cylindrical faces of the rigid push rods, one end of the wave foil is welded to the inner round face of the shaft sleeve, and the other end of the wave foil is free. The top foil is arranged on the wave foil in a covering manner. Through control over power supply signals of the PZTs, the PZTs mechanically deform, the flexible hinges are enlarged to deform, and are supported through the rigid push rods to be attached to the wave foil on the push rods and the inner wall of the shaft sleeve, a gap between a bearing and a supporting rotor is changed, the wedge space is increased, the crossed coupling effect is weakened, the bearing dynamic pressure effect is enhanced, the rigid characteristic of the bearing is improved, and finally the aims of actively controlling the rigidity characteristics of the bearing and improving the stability of the bearing are achieved.

Owner:HUNAN UNIV

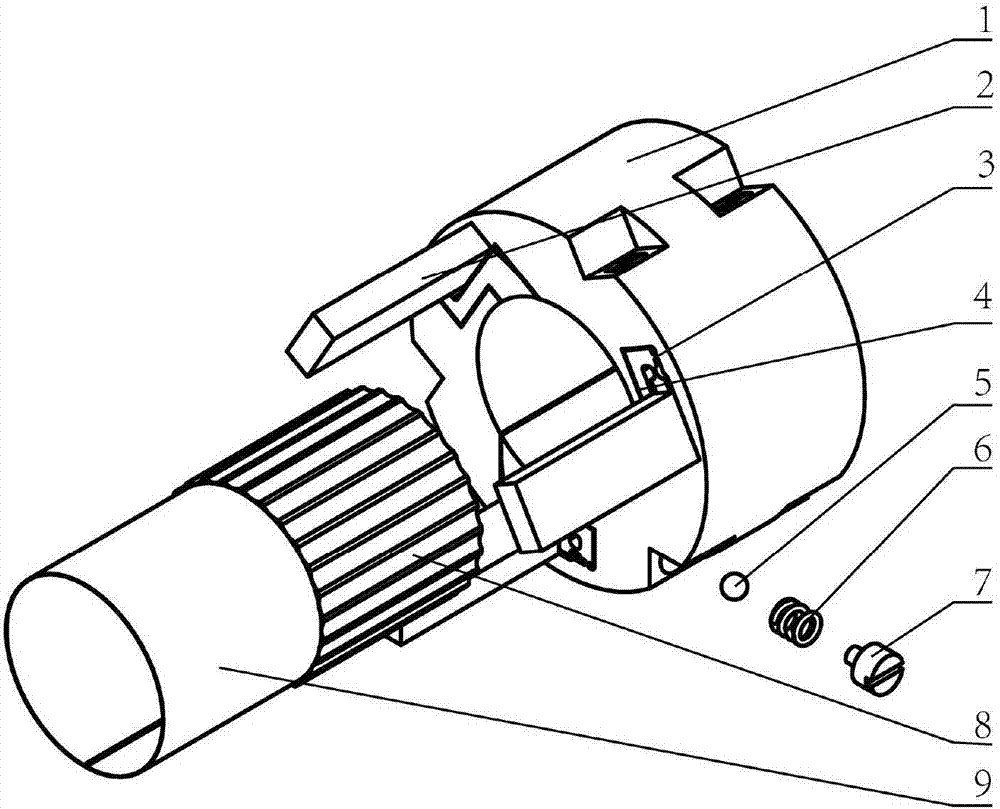

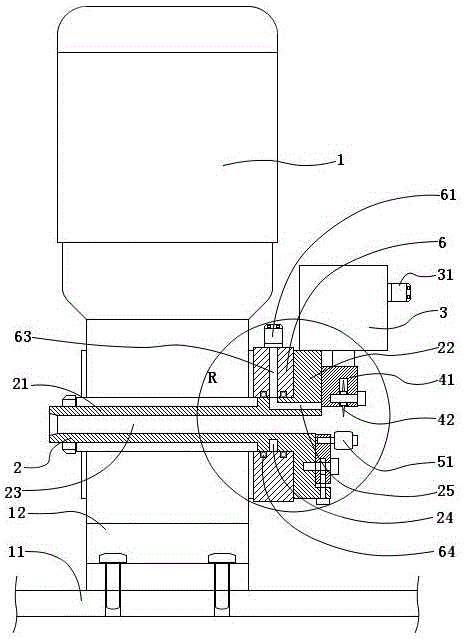

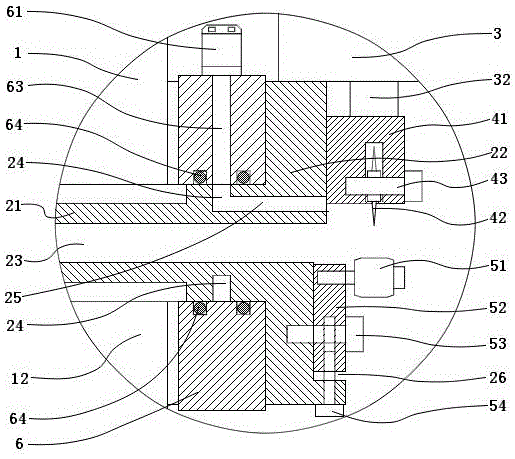

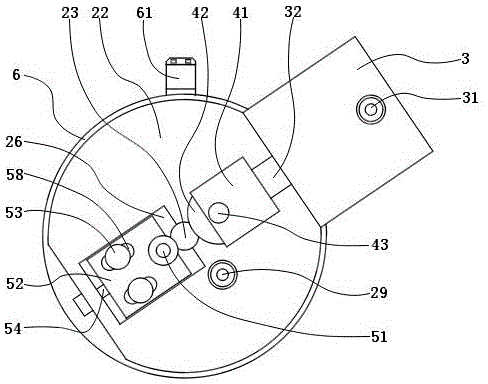

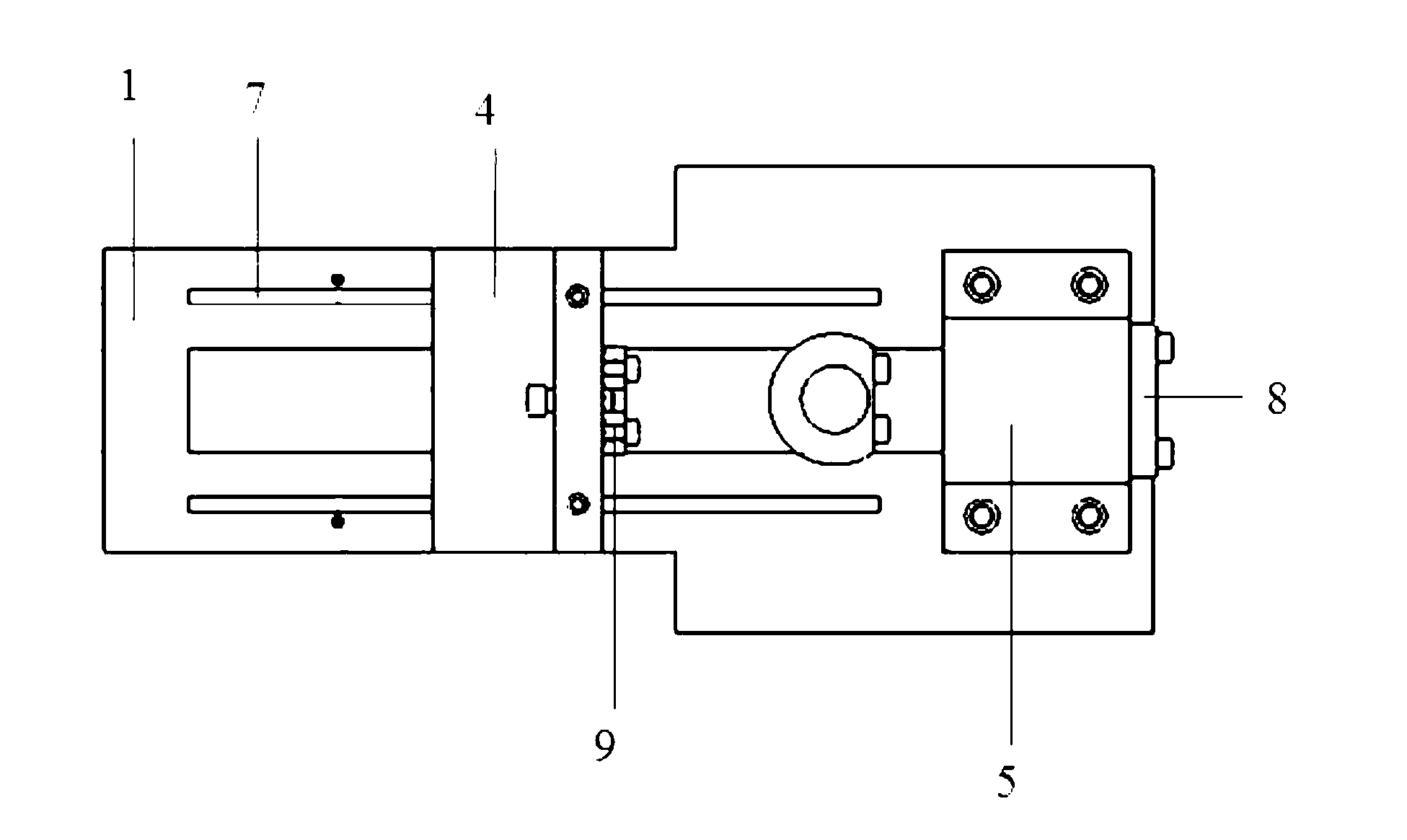

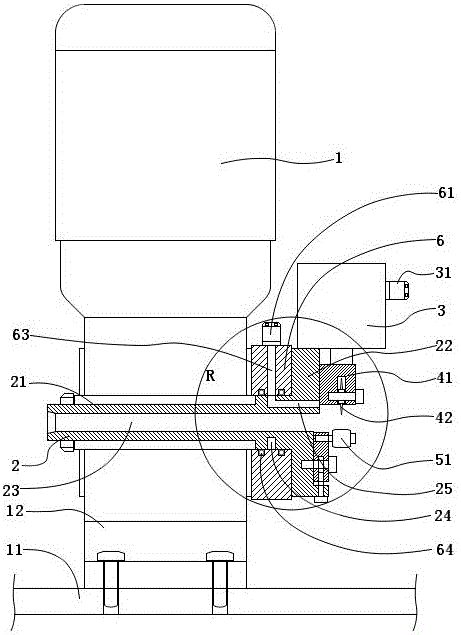

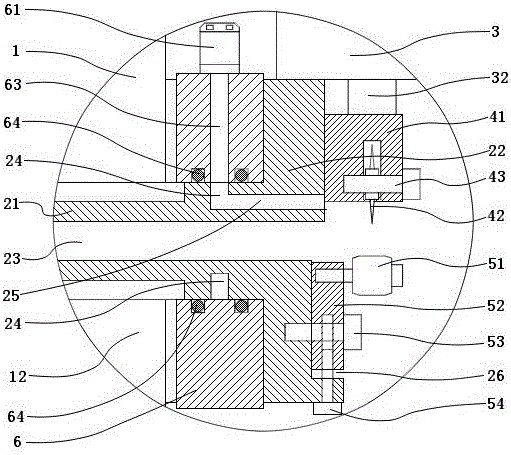

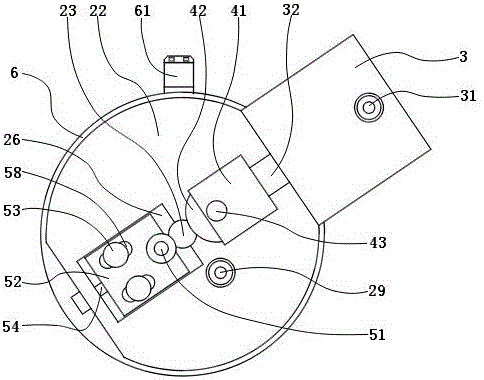

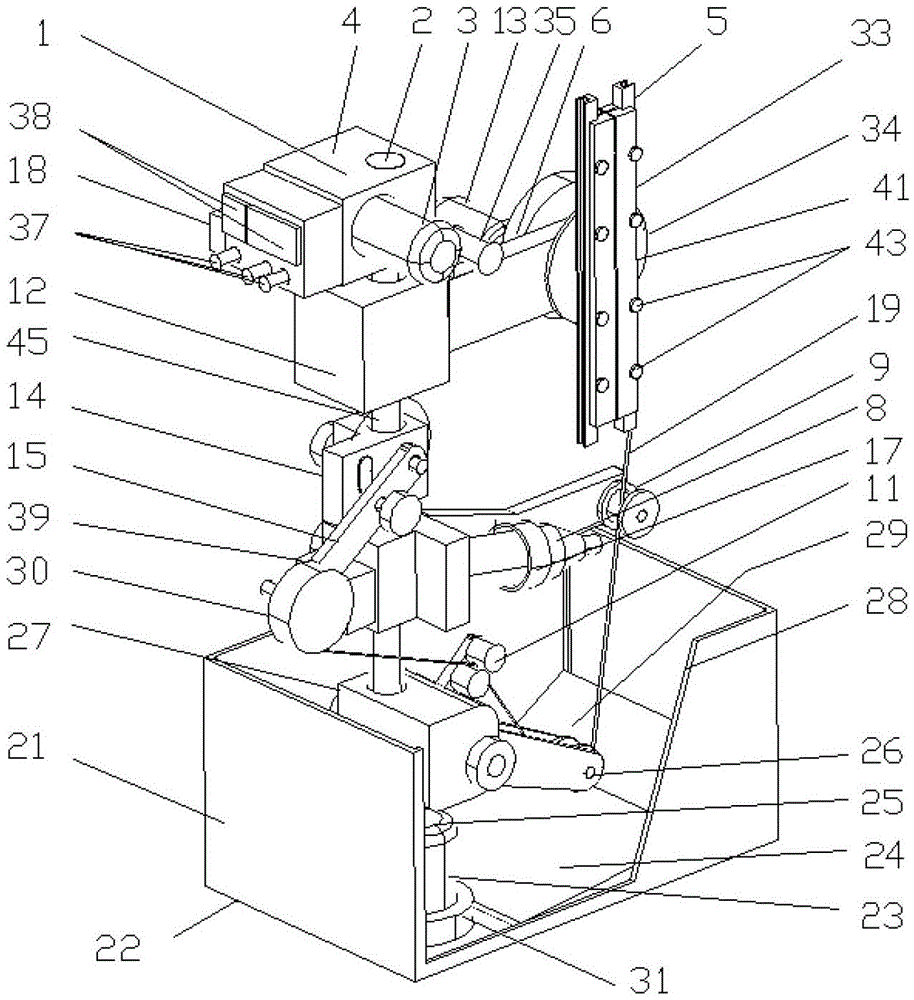

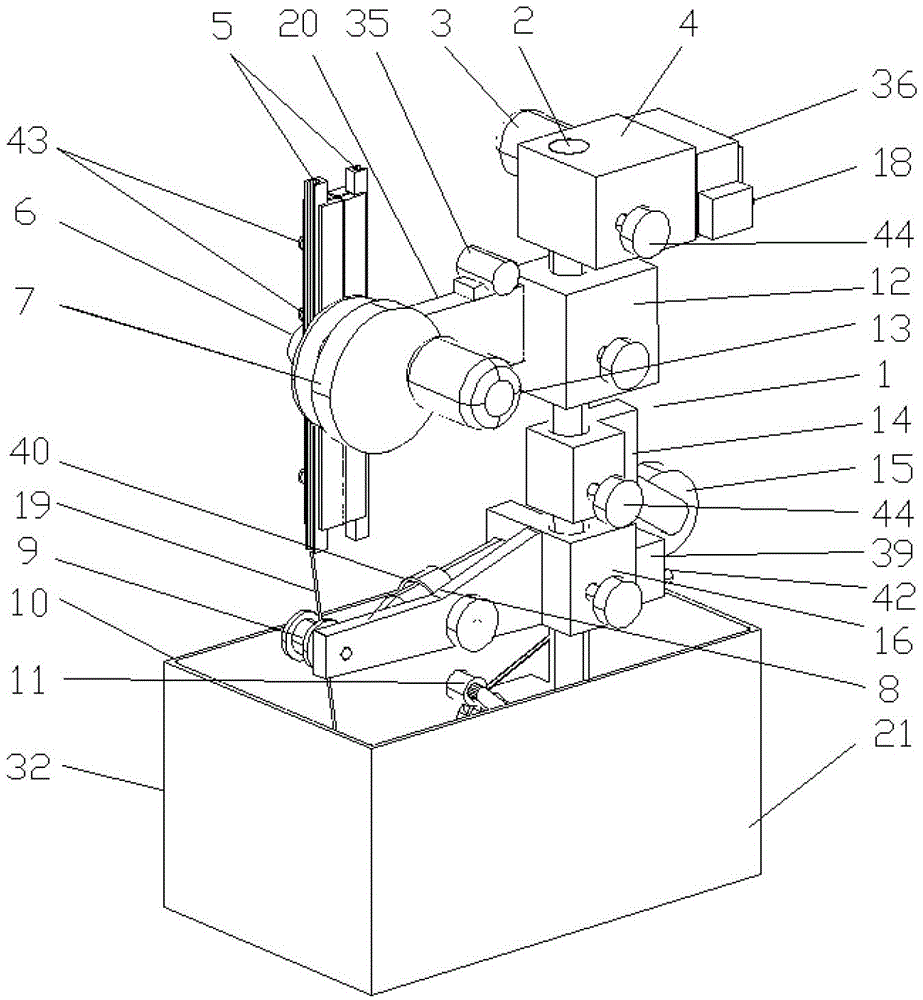

Rotary cutoff device for evaporating pipe

The invention discloses a rotary cutoff device for an evaporating pipe. The rotary cutoff device comprises a motor, a rotary guide body, a blade, a pneumatic radial pushing mechanism, a cutting supporting mechanism and a rotary air supply mechanism. The rotary guide body is of an integral structure composed of a pipe body and an annular disc, and a pipe hole is formed in the axial direction of the center. The rotary guide body can be driven by the motor to rotate. The pneumatic radial pushing mechanism, the cutting supporting mechanism and the blade are arranged on the rotary guide body and can rotate along with the rotary guide body. The pneumatic radial pushing mechanism is used for driving the blade to move on the annular disc in the radial direction. The rotary air supply mechanism is used for providing compressed air for work of an air cylinder when the air cylinder rotates along with the rotary guide body. When the rotary cutoff device works, the blade rotates around the axis of the evaporating pipe, the evaporating pipe is cut off, and therefore when the evaporating pipe is cut off, a cutting opening is flat. The blade is pushed to the center of the evaporating pipe and faces the inner side of the evaporating pipe even though burrs are generated, and connecting and mounting cannot be influenced after and before evaporation.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

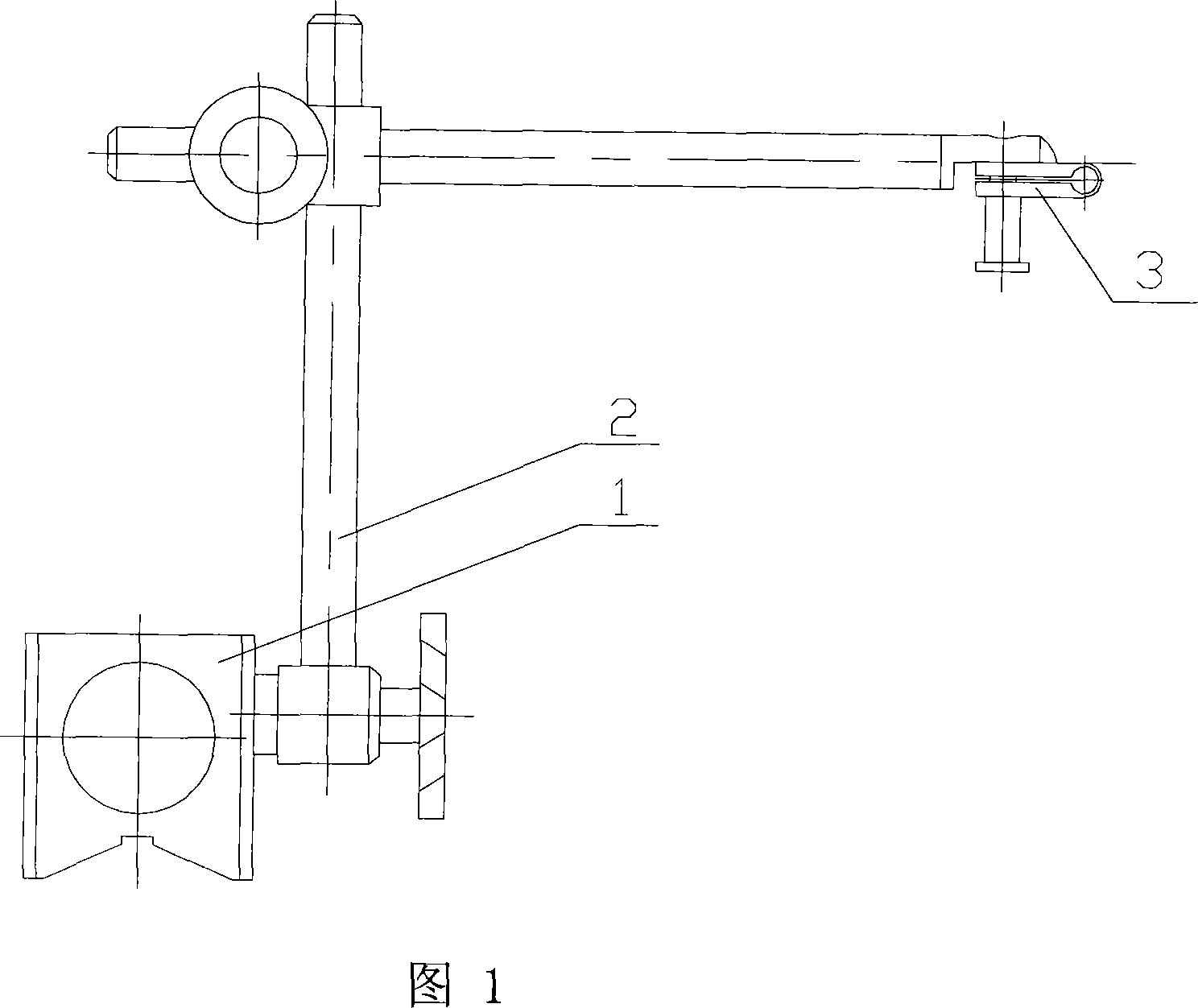

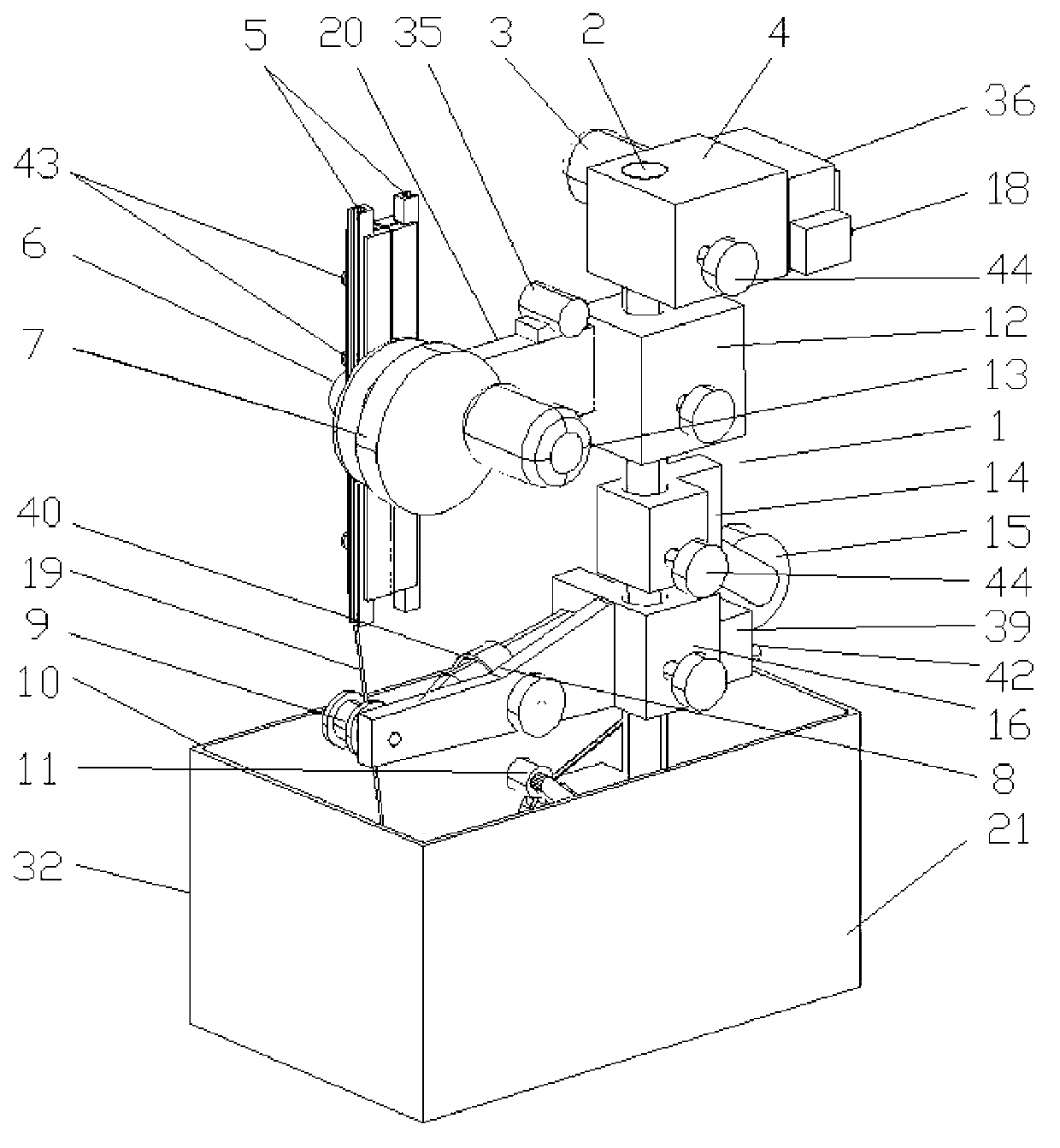

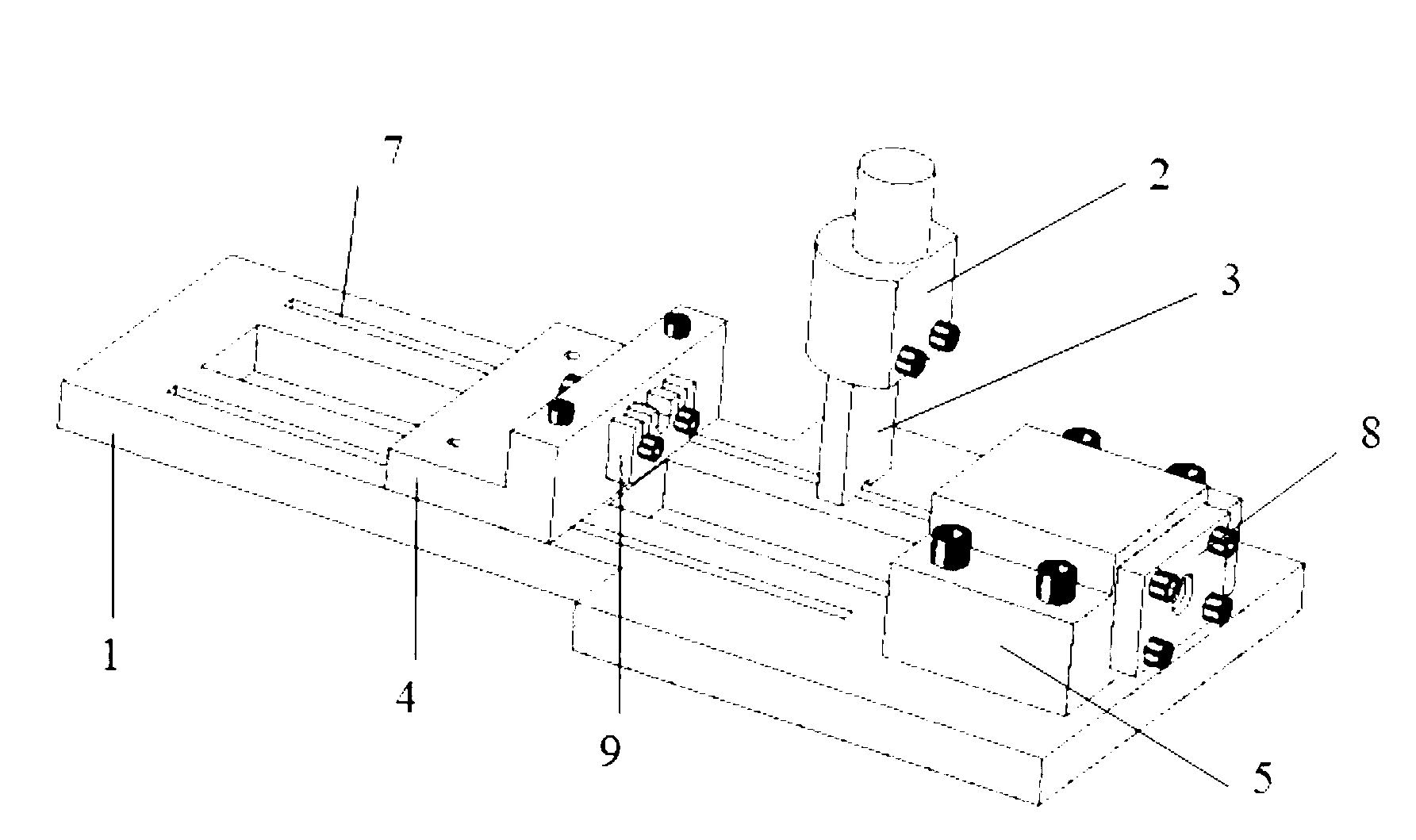

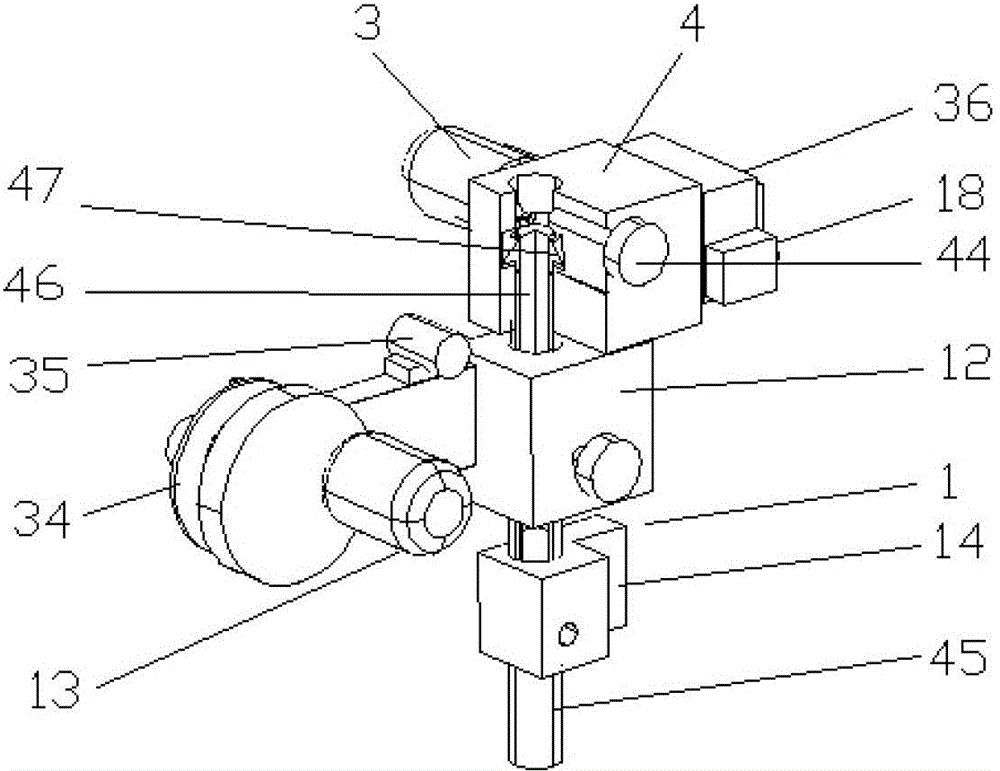

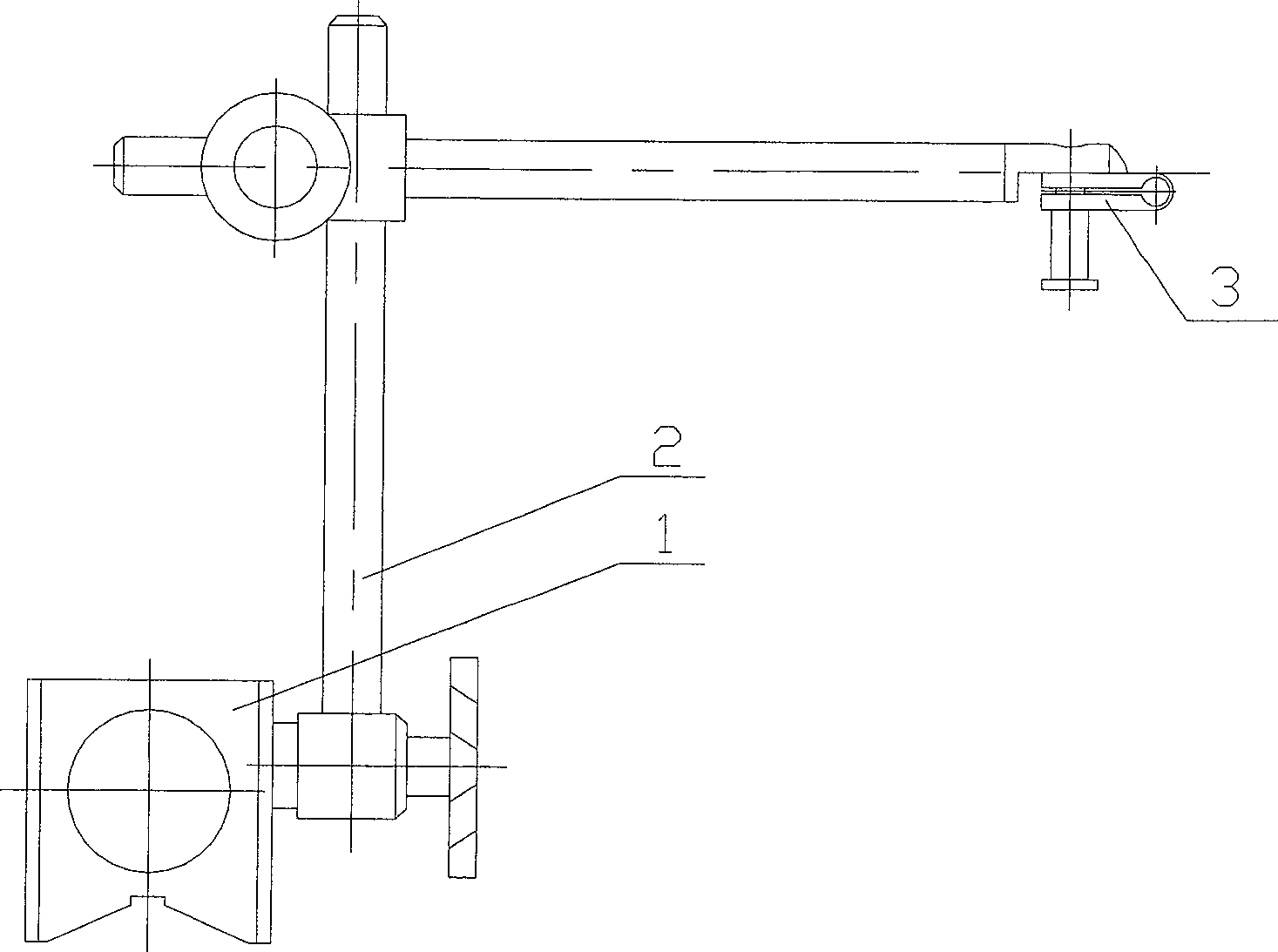

Magnetic gage stand arrangement used for precision measurement

InactiveCN101063601AEasy to placeReduce articulationMeasurement apparatus componentsFeeler-pin gaugesEngineeringSpiral coil

This invention relates to one magnetic socket device, which comprises socket, supportive bar and micro adjuster and is characterized by the following: the micro adjust probe is set on beam with two parts fixed on one slide cover with each one covered on supportive bar top end and two down end fixed on one socket; the base socket is composed of seat, spiral coil, aluminum coils skeleton and connection screw nail; the spiral coil is around aluminum skeleton on the skeleton chamber fixed by connection nail with two ends connected to wire through wire hole and power.

Owner:WUHAN UNIV OF TECH

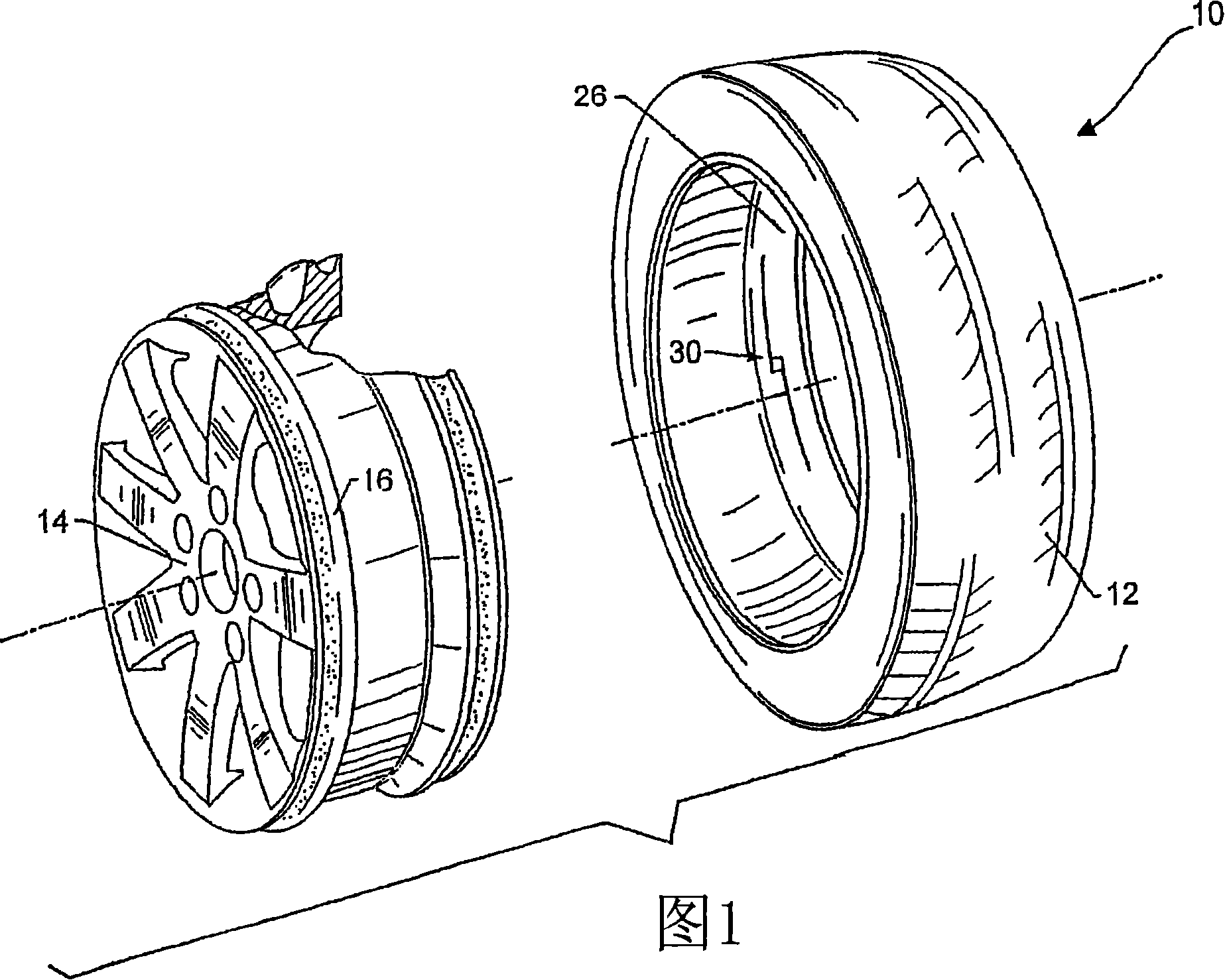

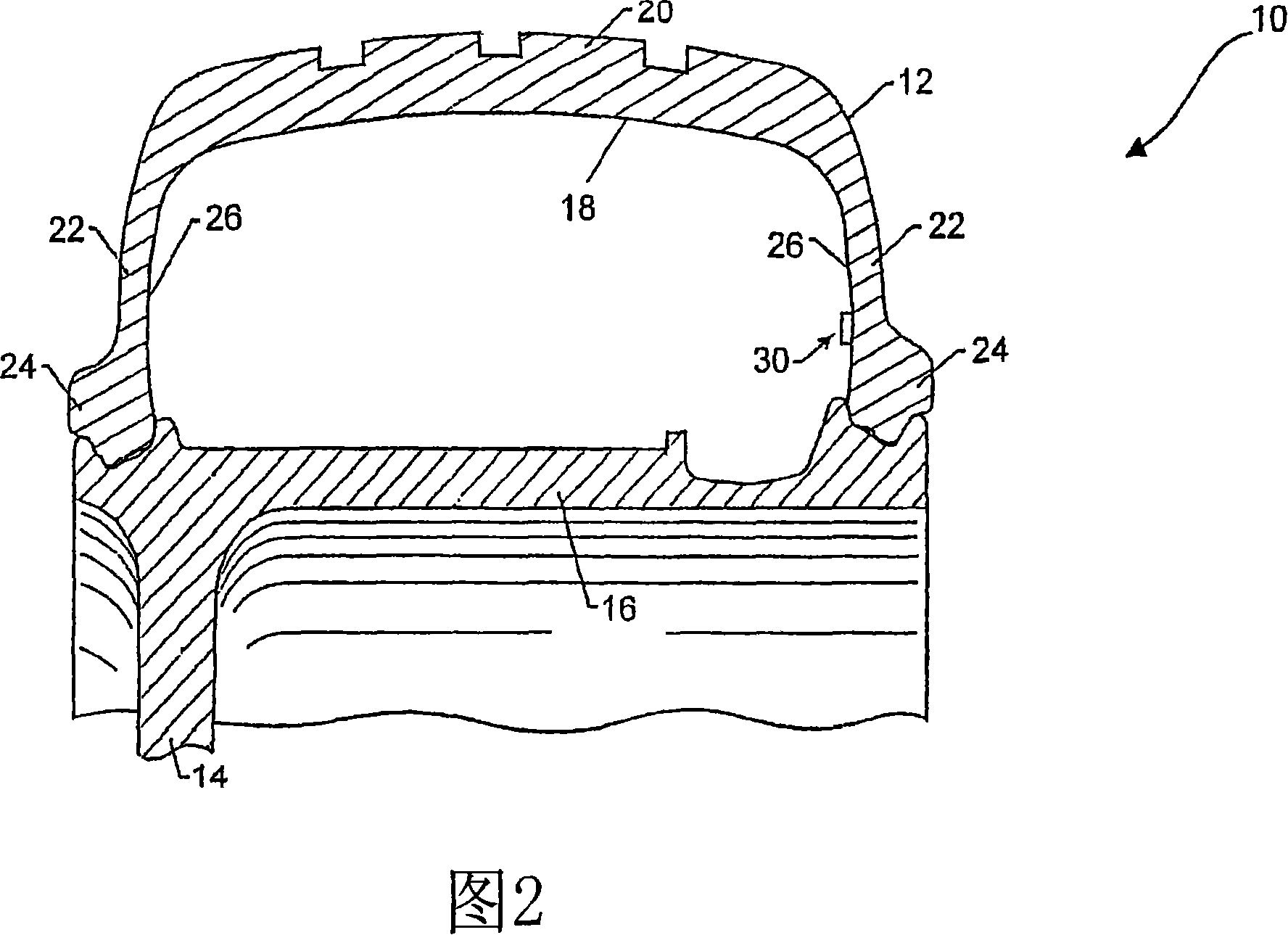

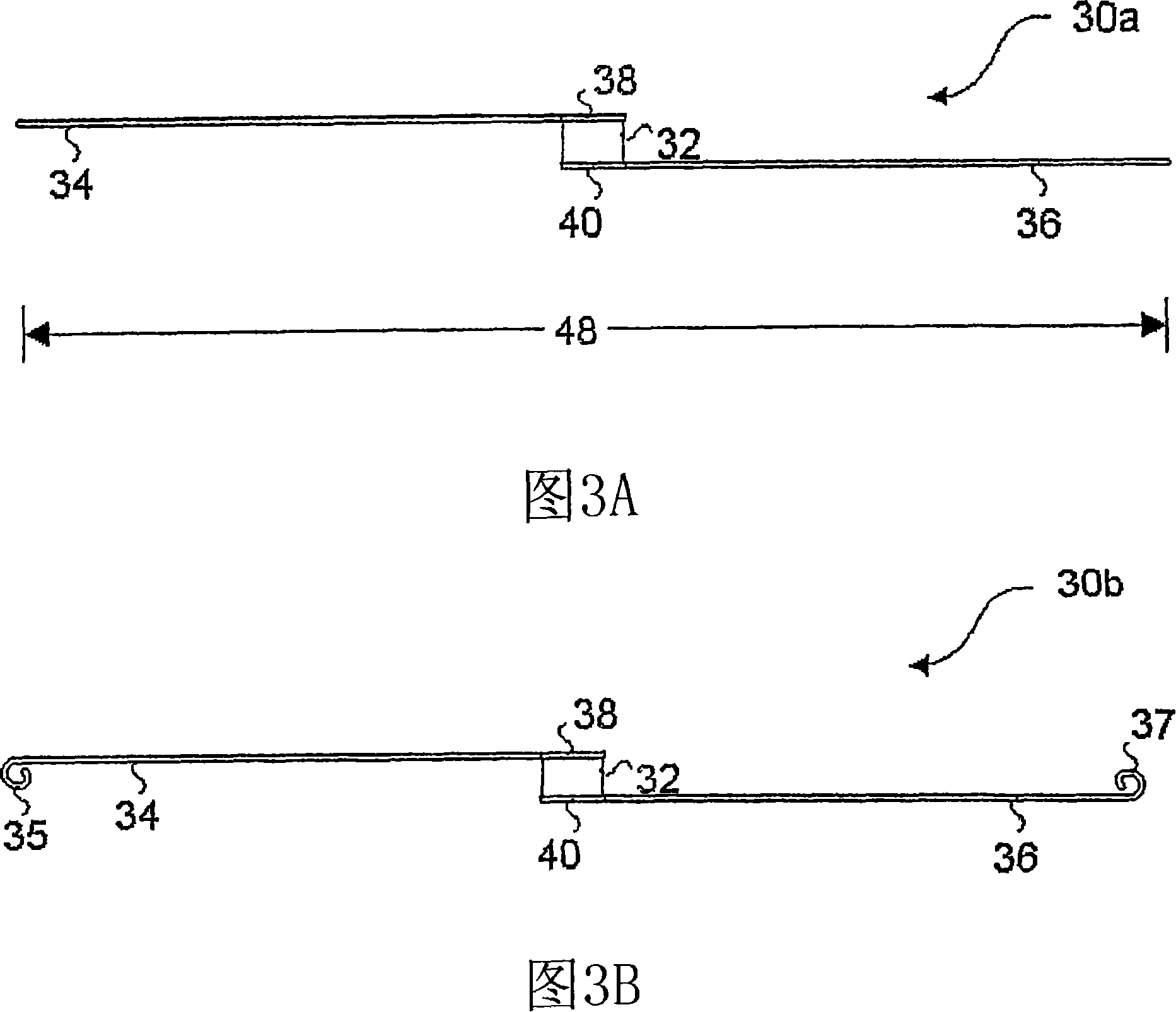

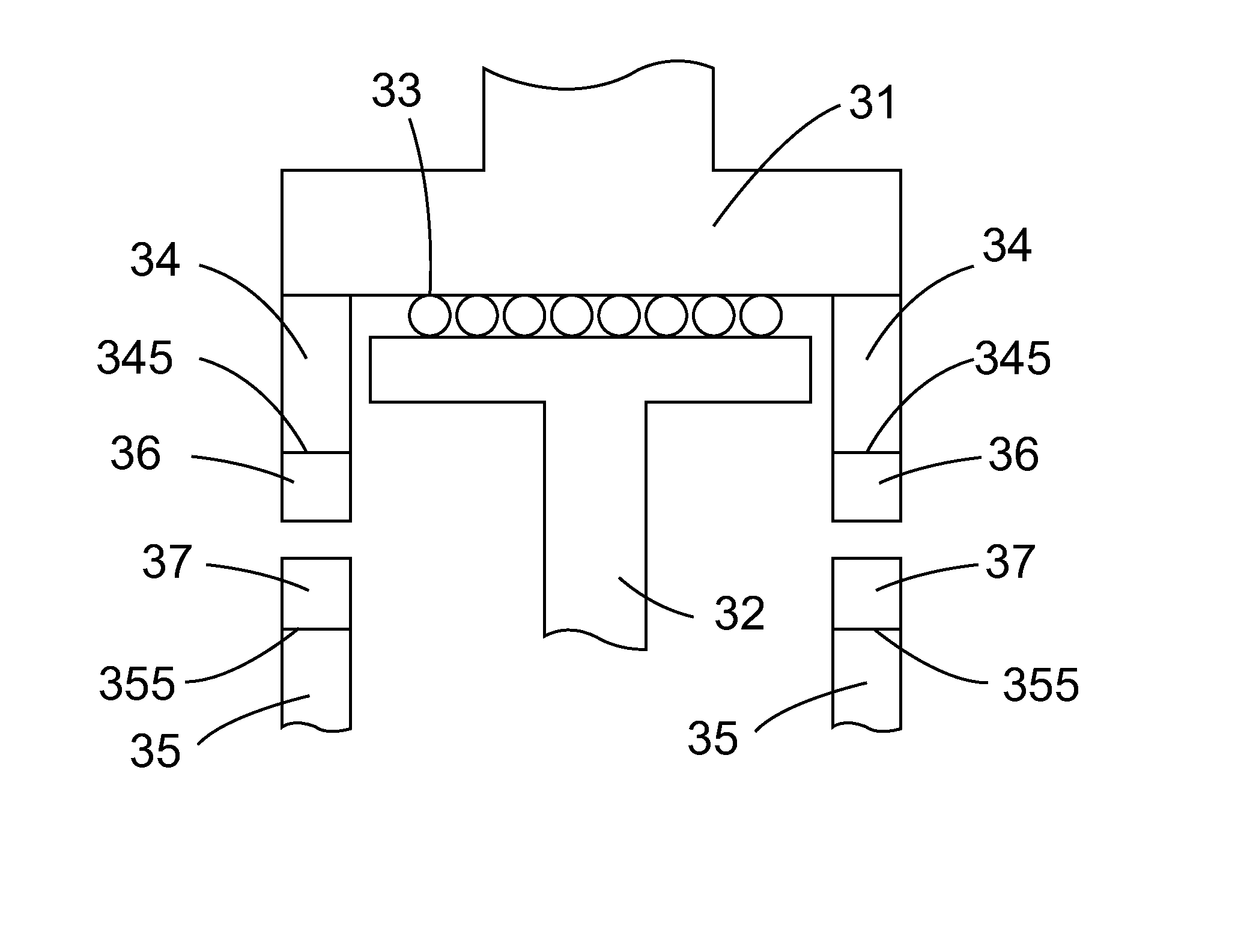

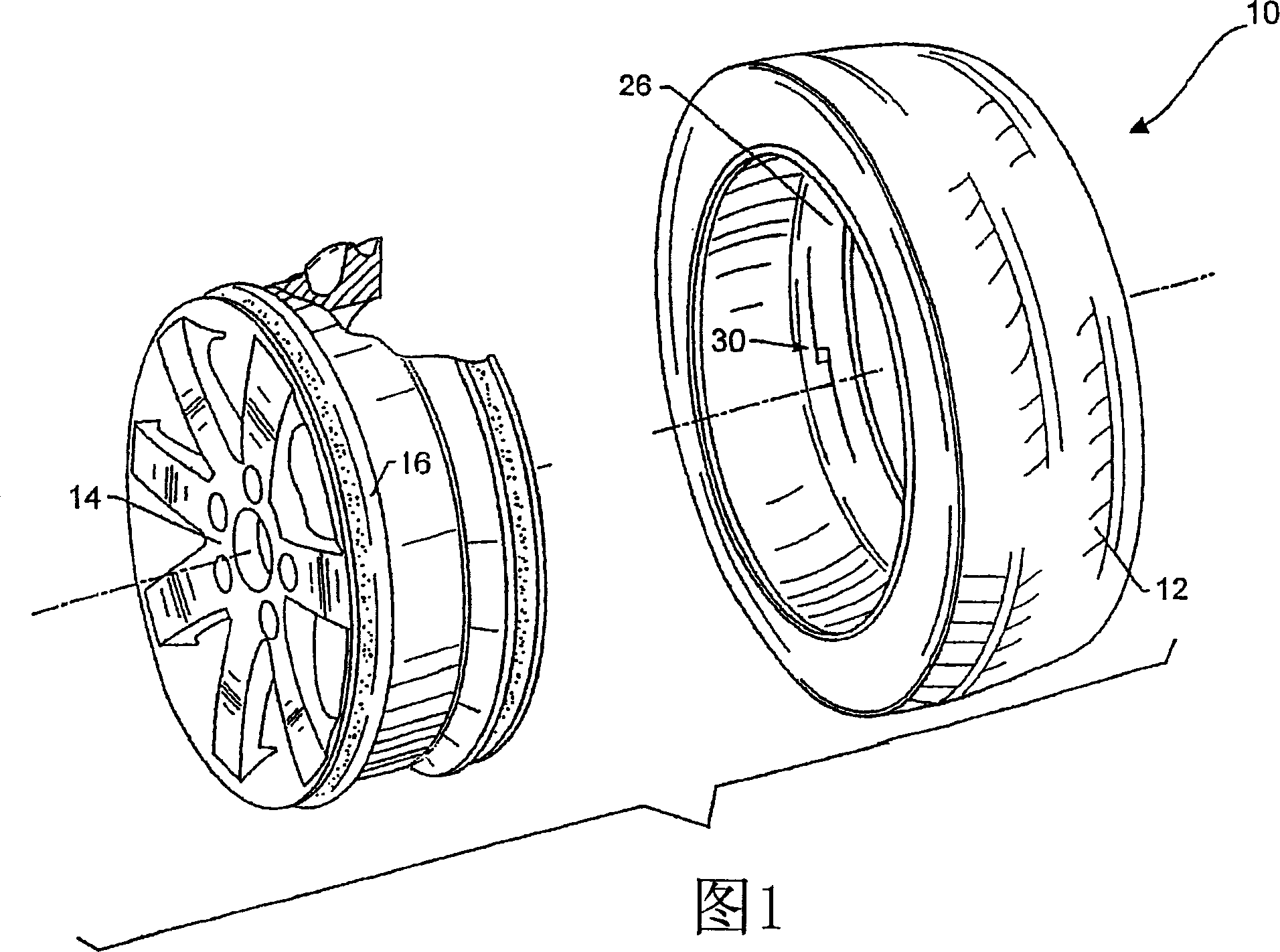

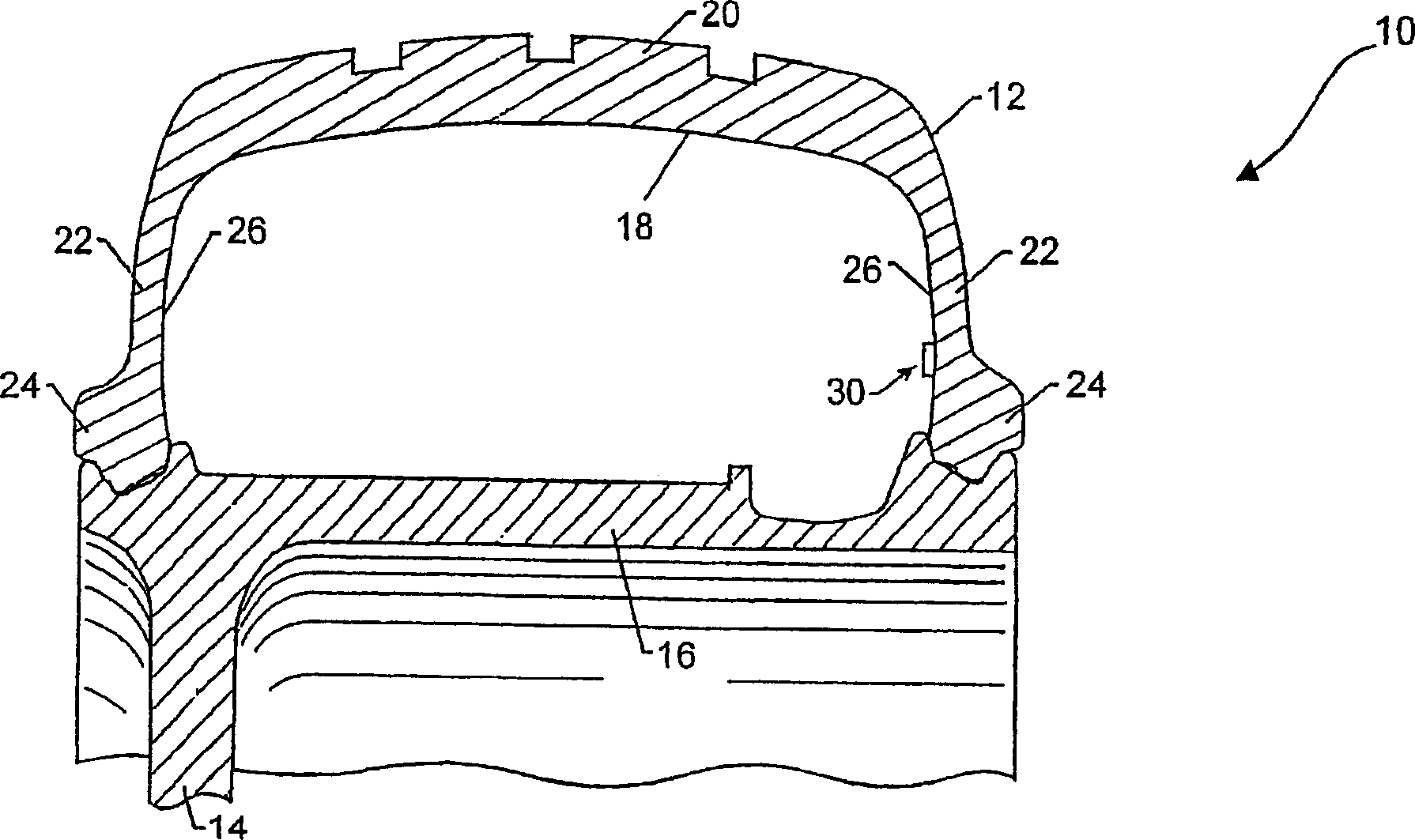

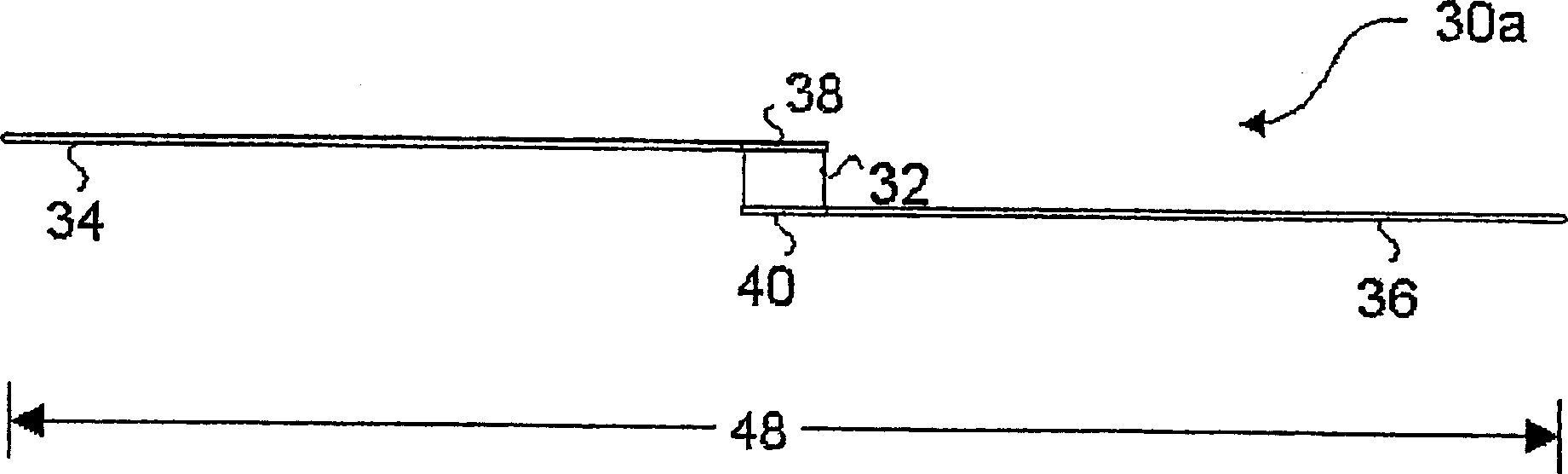

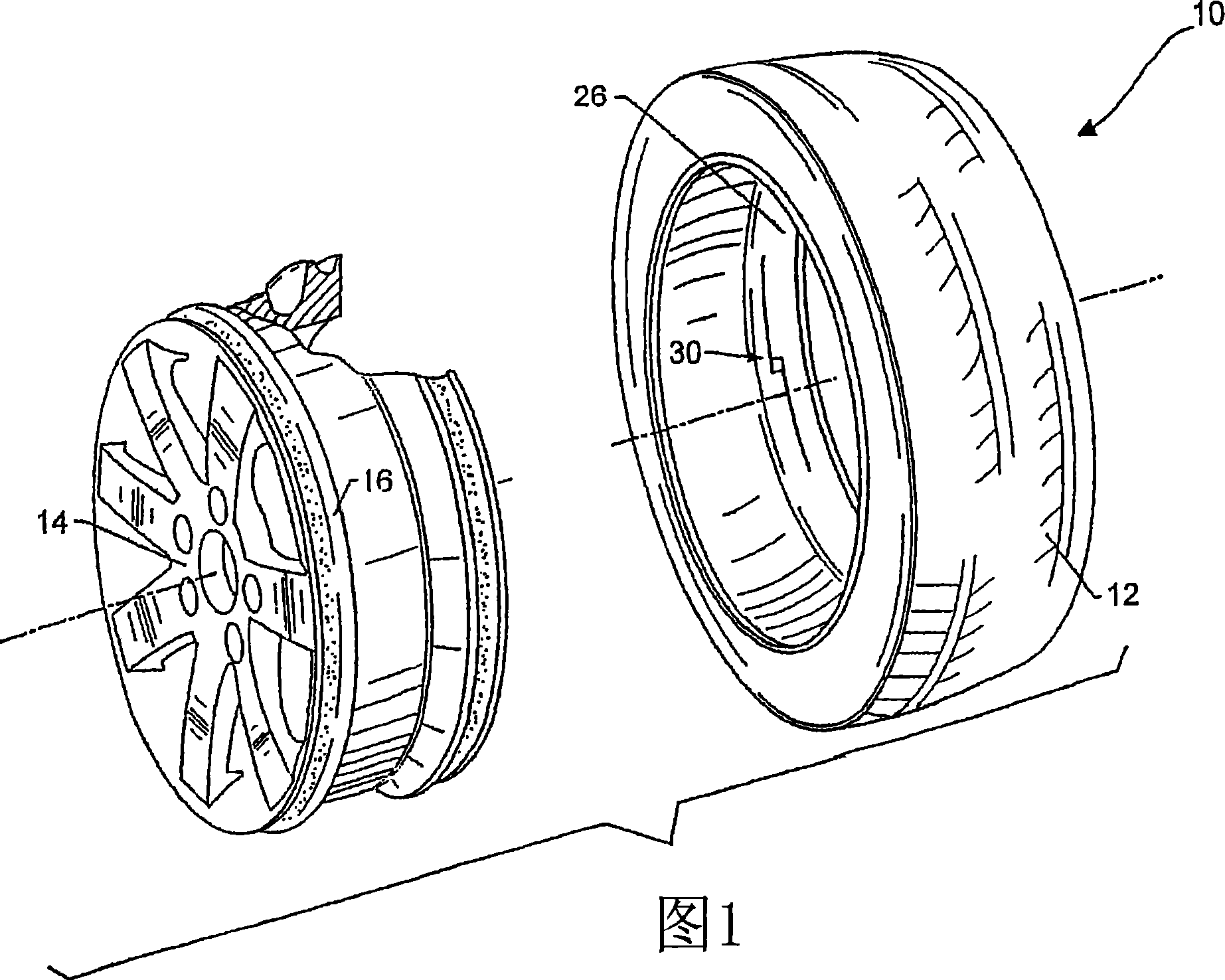

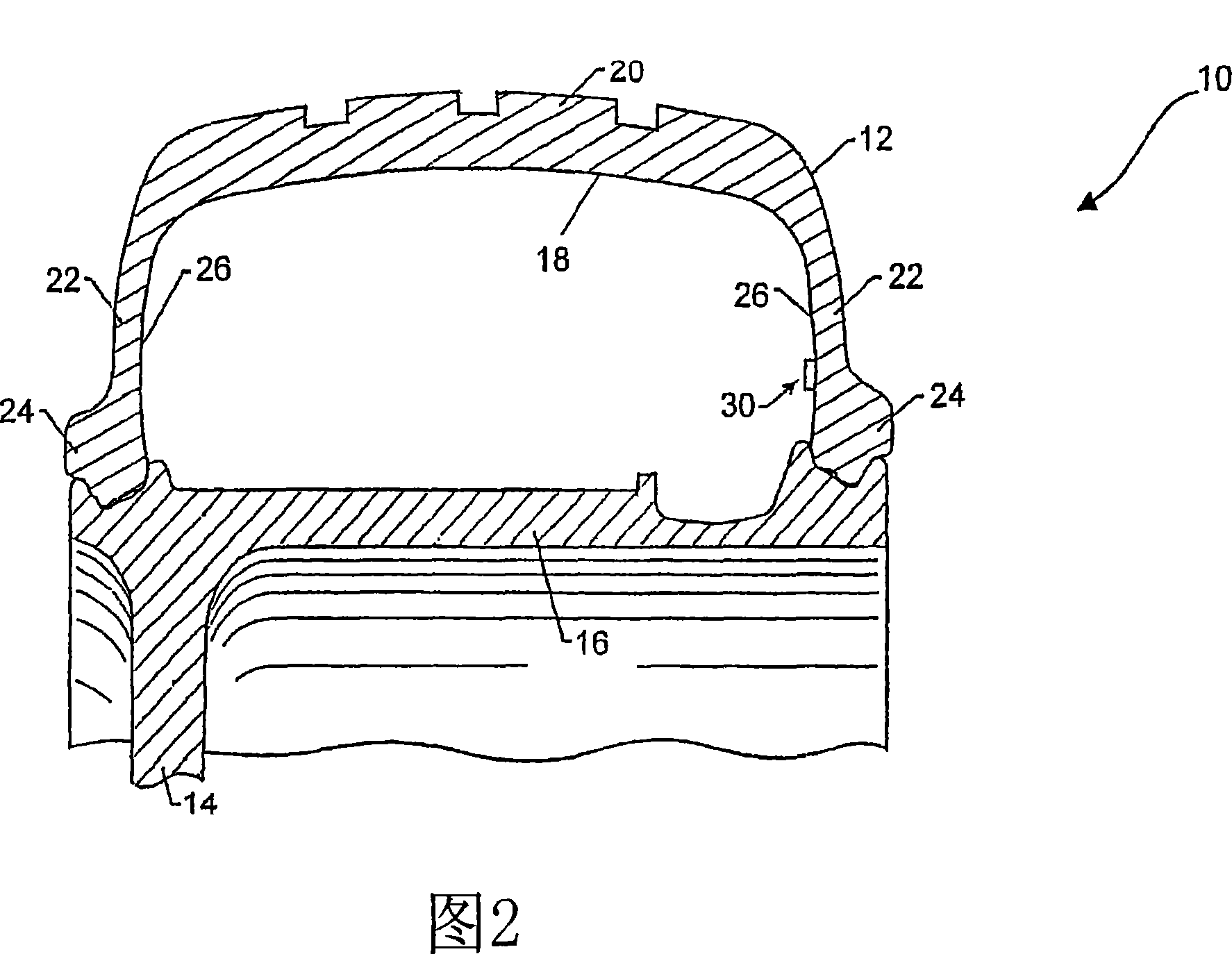

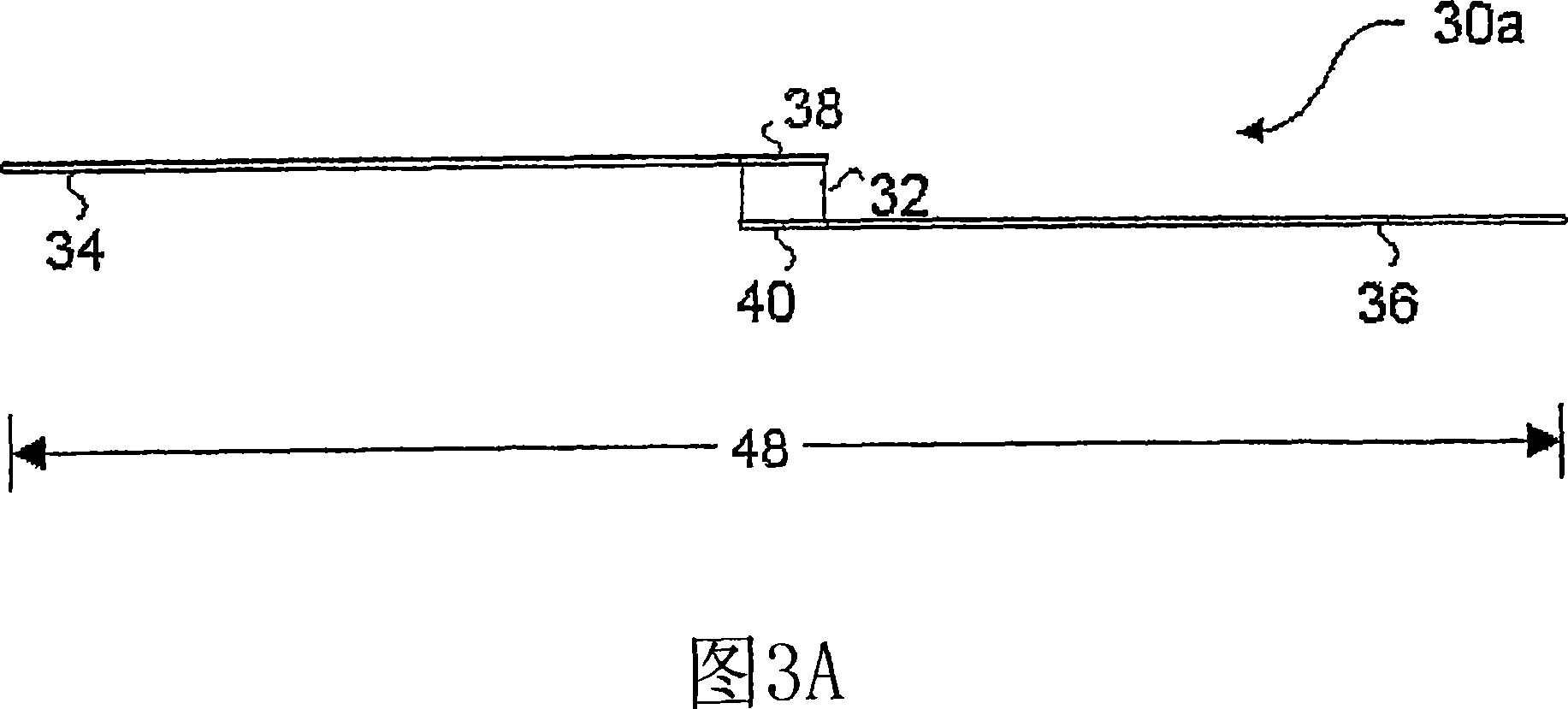

Tyre electronic component with multi-frequency antenna

InactiveCN101114730AReduce mechanical deformationEasy to manufactureAntenna adaptation in movable bodiesMulti bandResonance

A tire component (10) with an electronic component (30) integrated on the tire component (10) comprises a tire structure (12) and the integrated electronic component (30). The electronic component optimization comprises at least one RF device (32) and one multi-band antenna which can wirelessly communicate at least between a first resonance band and a second resonance band. The multi-band antenna comprises at least a first antenna conductor and a second antenna conductor which are connected with the RF device so as to facilitate the transmission of RF signals. The signals can comprise the tire identification information or the measured status information, such as the tire temperature, the pressure and other characteristics. The first antenna conductor and the second antenna conductor optimizations are used together as at least two dipole antennas, such as two half-wavelength dipole antennas, or as one half-wavelength dipole antenna and one two third wavelength dipole antenna.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

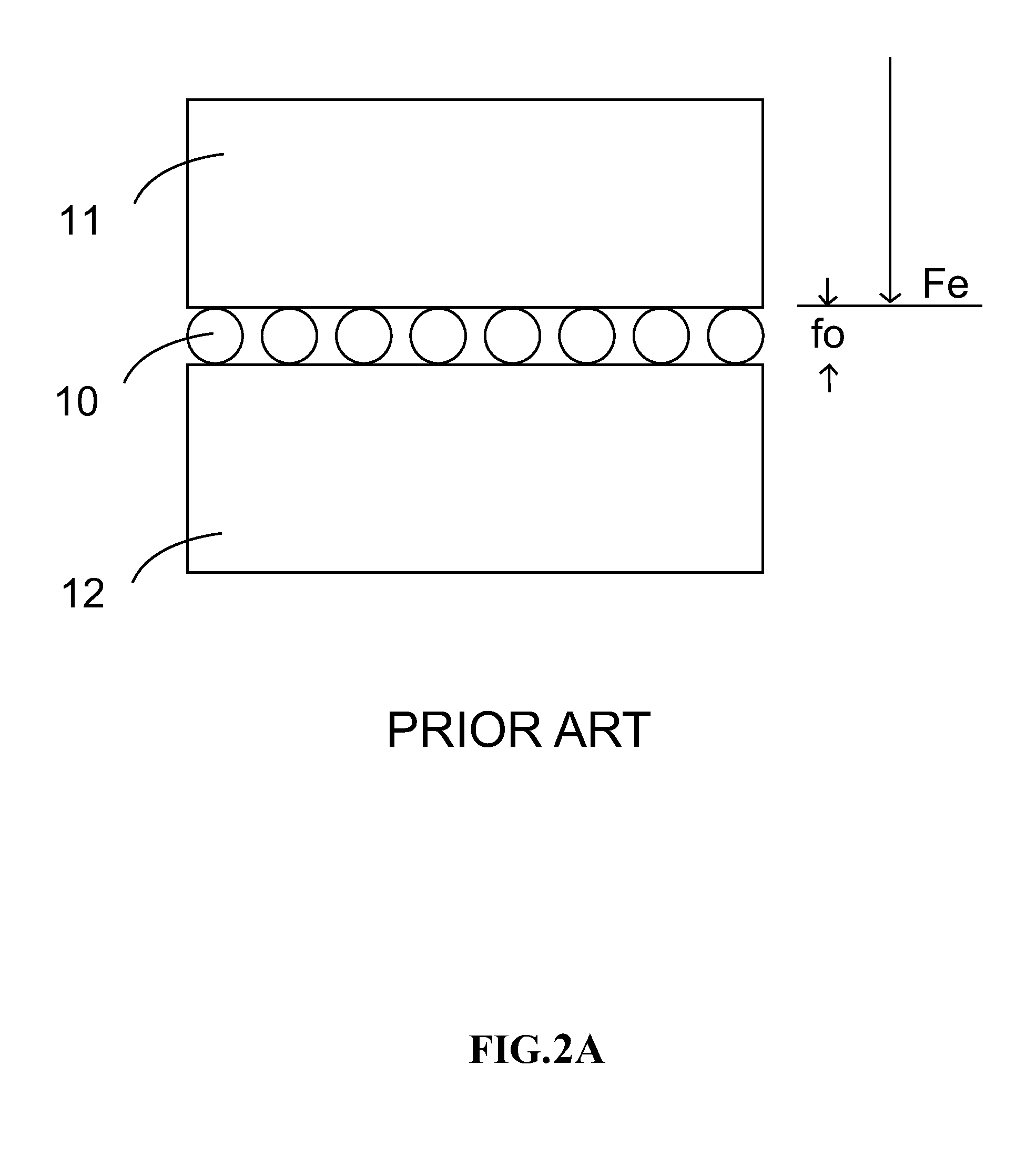

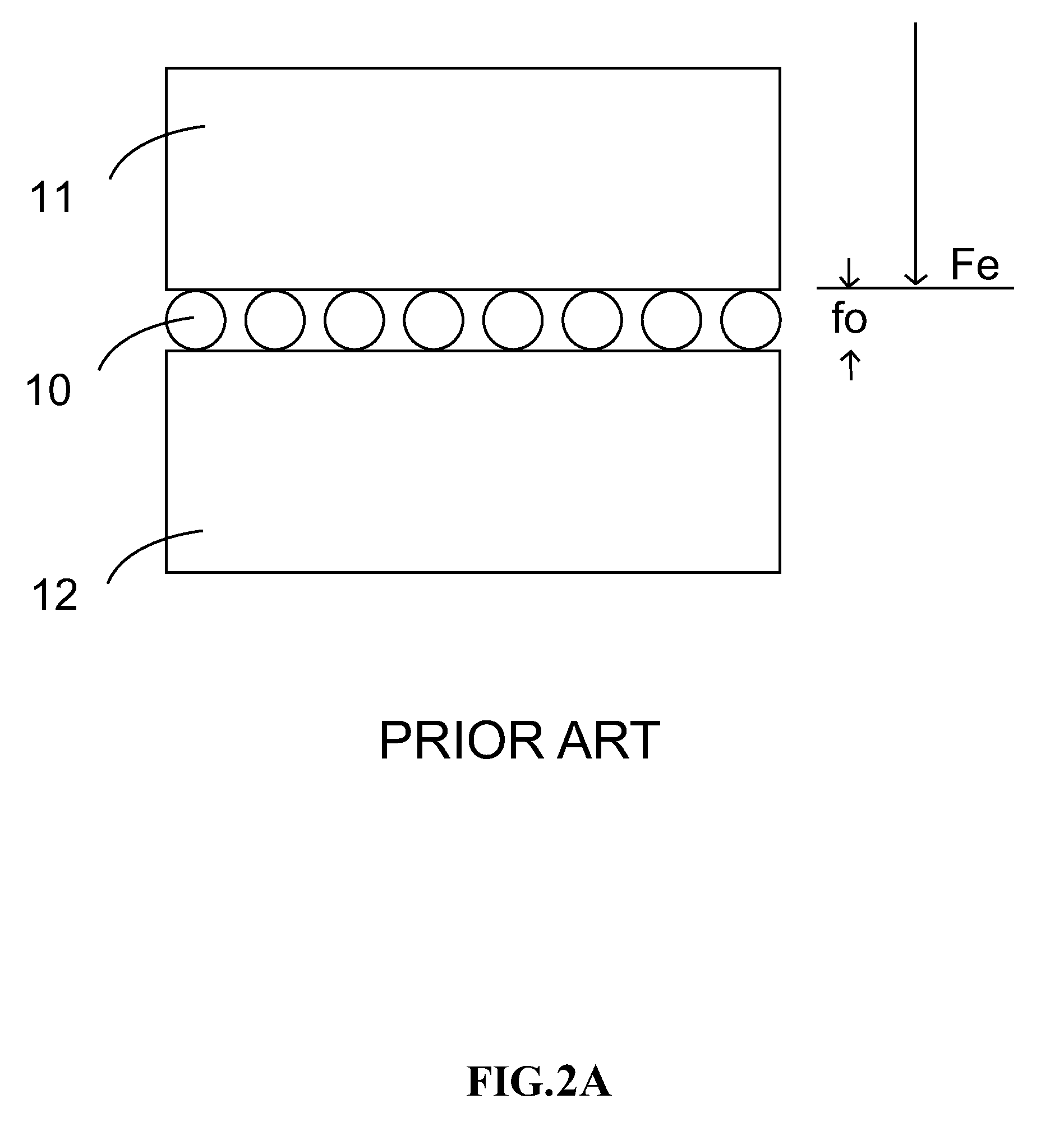

Axial passive magnet bearing system

ActiveUS20130293049A1Reduce frictionReduce lossWind energy generationMechanical energy handlingMagnetic tension forceContact type

An axial passive magnet bearing system utilizes the friction-less characteristic of non-contact type permanent magnet bearing to minimize the disadvantages induced by frictions. For example, both the energy and material loses of the mechanical bearing. Two permanents magnet are made of permanent magnet materials and positioned over two opposite surfaces of two mechanical structures, where mechanical bearing(s) is located therebetween. Hence, the magnetic force between the two magnets can improve some disadvantages among the two mechanical structures and the mechanical bearings, such as friction and energy loss.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Tire electronics assembly having a multi-frequency antenna

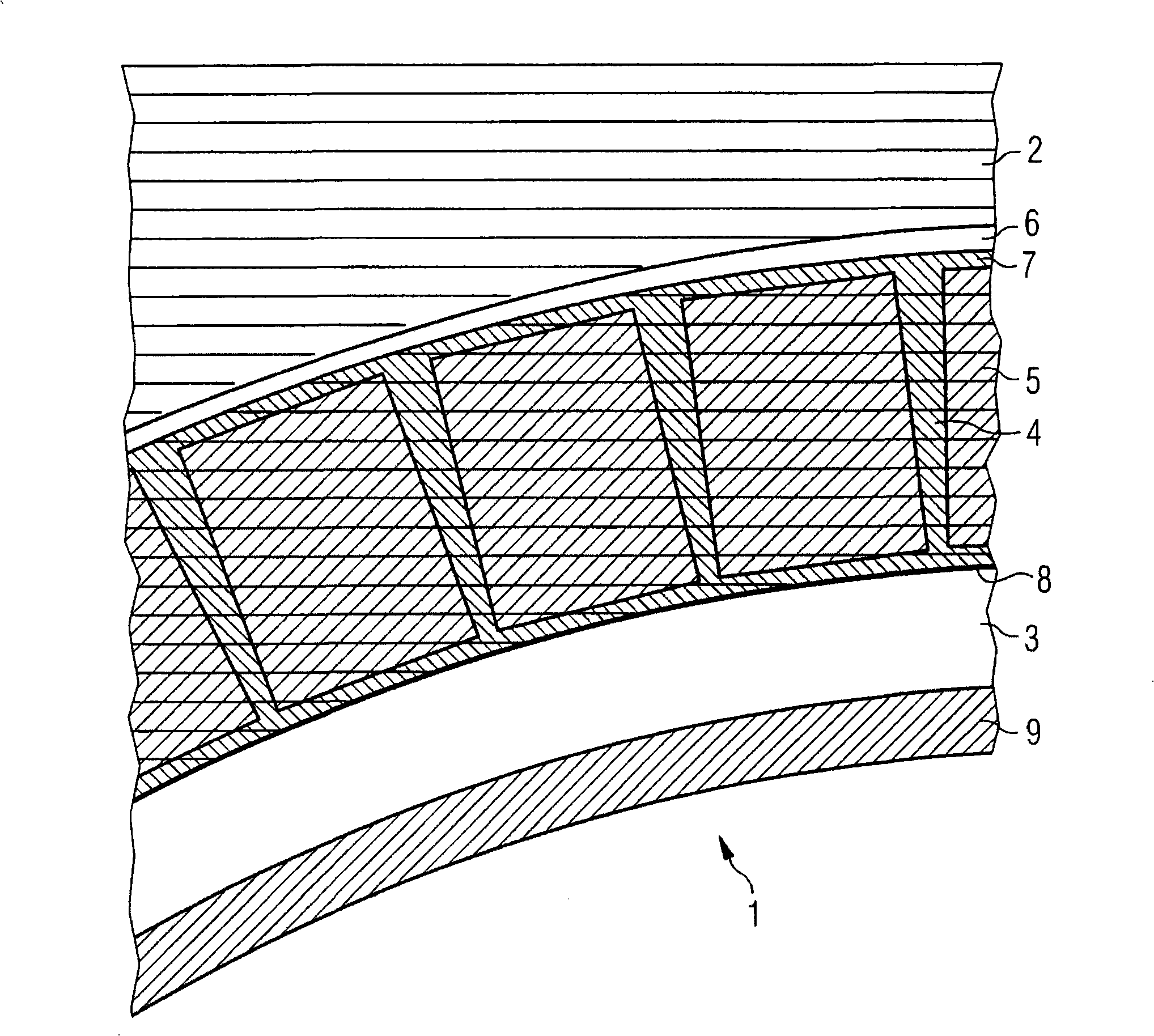

InactiveCN1741914AReduce mechanical deformationEasy to manufactureMeasurement devicesSimultaneous aerial operationsIntegrated electronicsWavelength

A tire assembly with integrated electronic components includes a tire structure and an integrated electronics assembly, which preferably includes at least a radio frequency (RF) device and a multi-frequency antenna that enables wireless communication in at least first and second resonant frequency bands. Such multi-frequency antenna further comprises at least first and second antenna wires connected to the RF device, thus facilitating the transmission of RF signals which may include information such as tire identification information or measured condition information such as tire temperature, pressure, and other characteristics. The first and second antenna wires preferably function together as at least two dipole antennas, for example, two half-wave dipole antennas or one half-wave dipole antenna and one three-half-wave dipole antenna.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

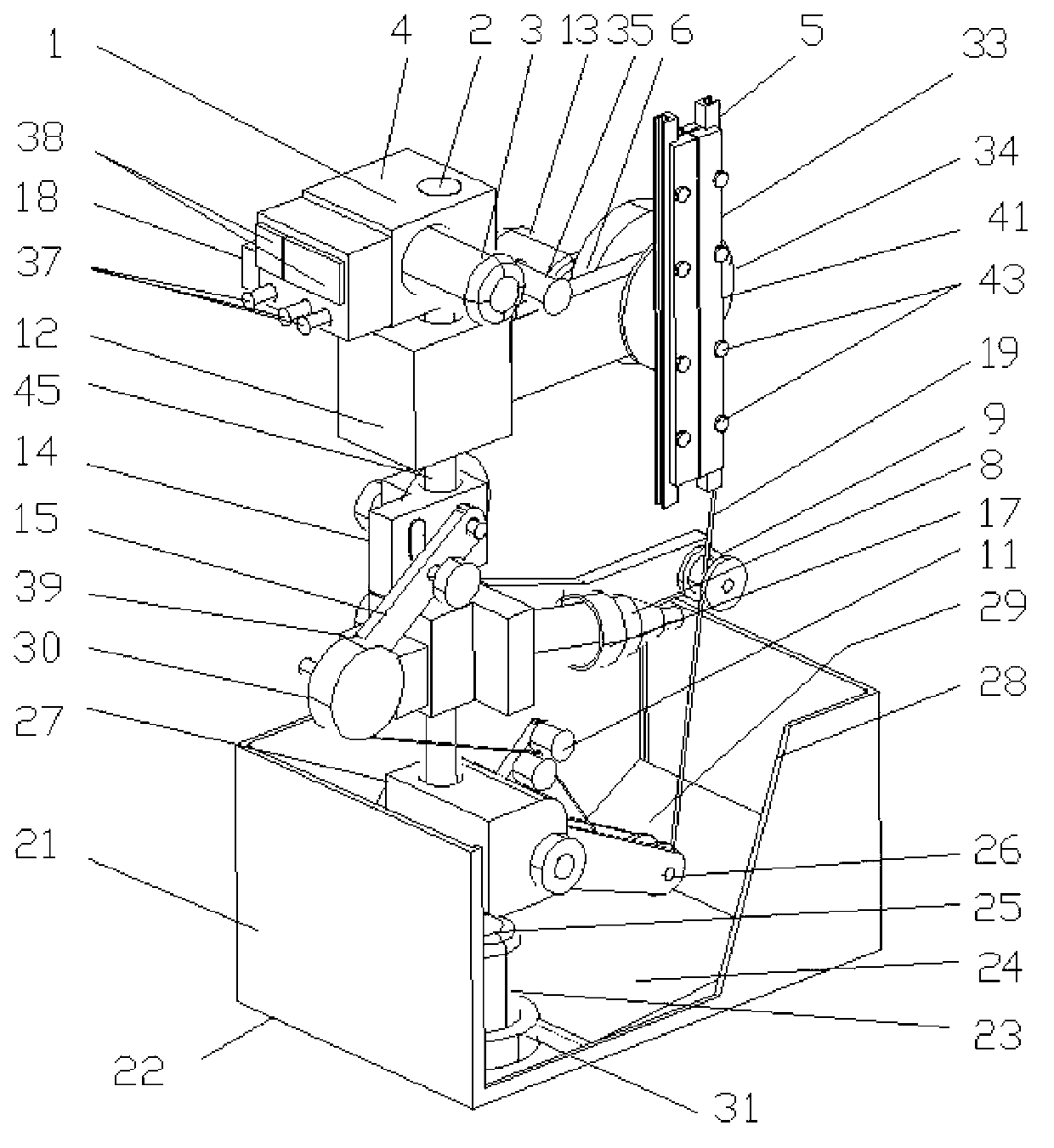

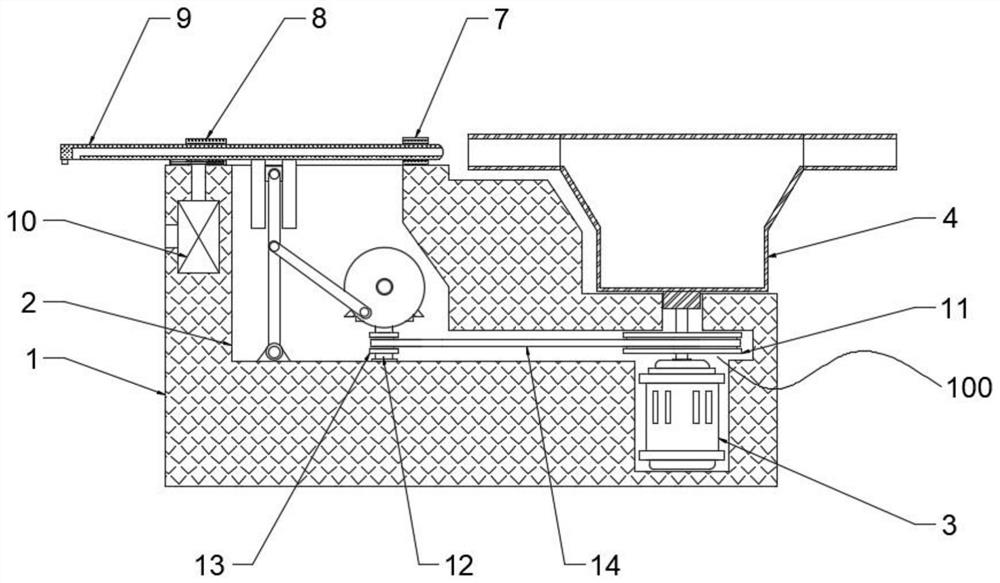

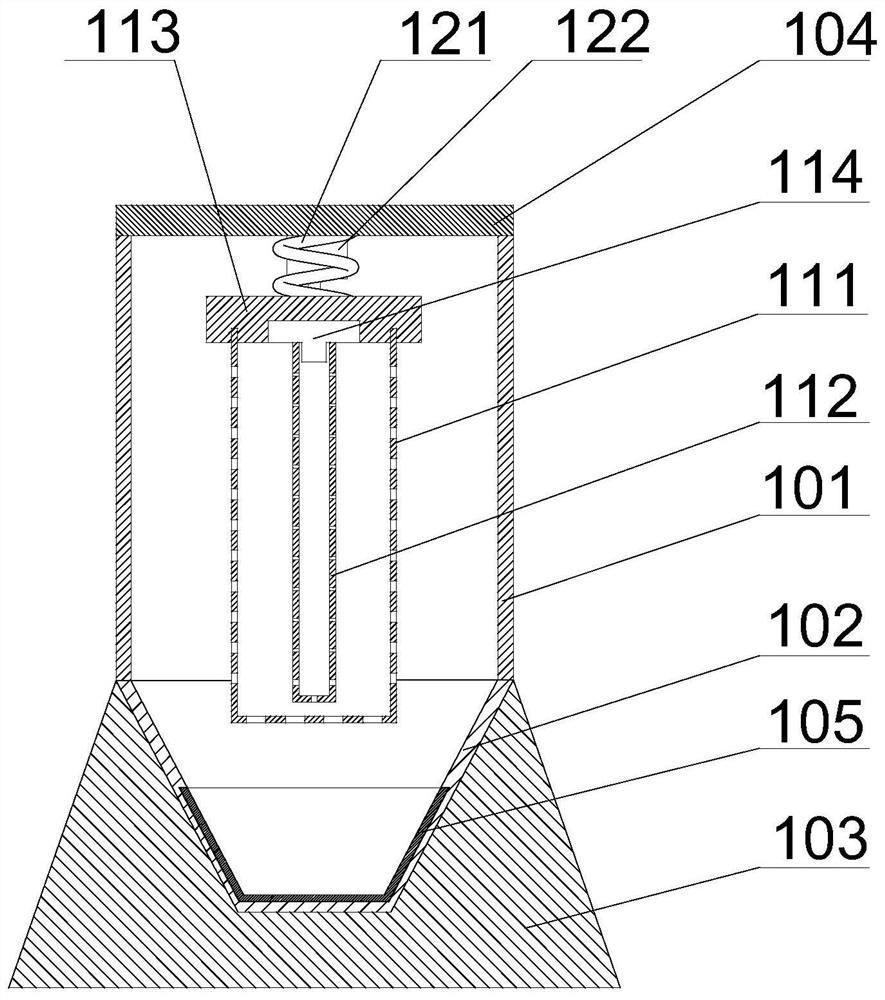

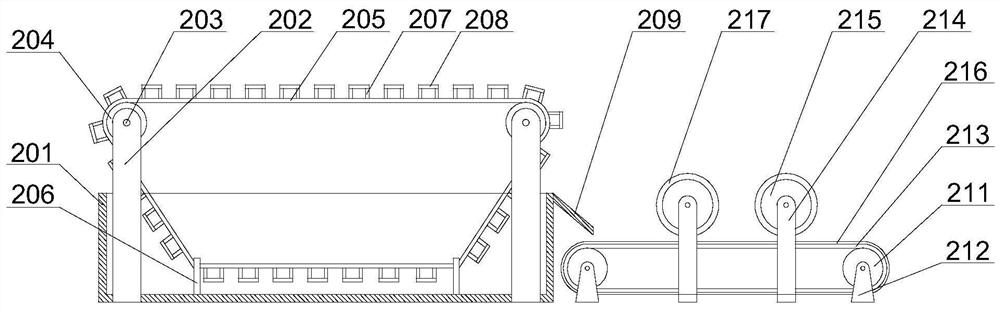

Magnetic wave instrument magnetic core forming machine

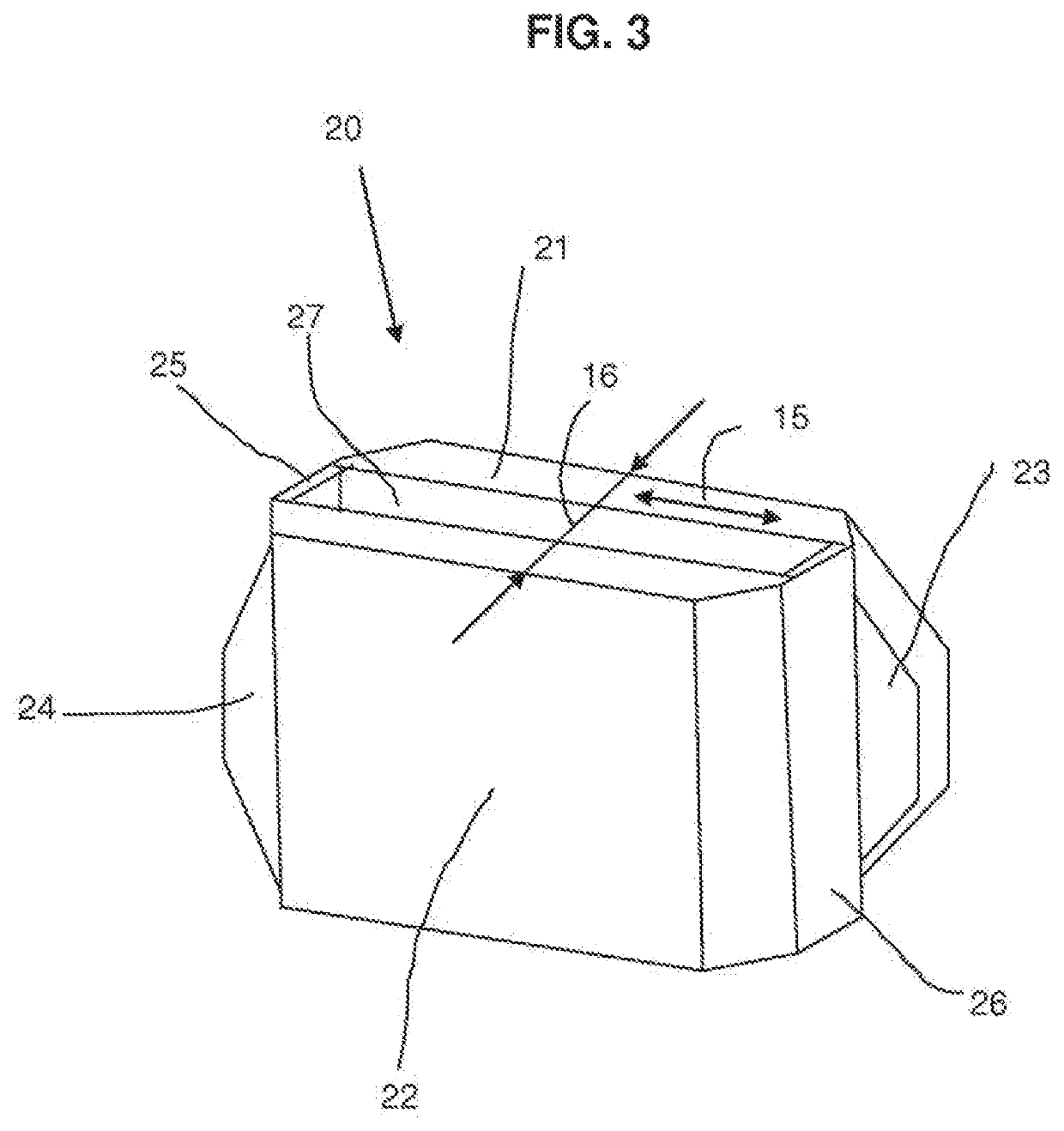

InactiveCN103280307AReduce mechanical deformationReasonable design structureInductances/transformers/magnets manufactureWinding machineSolution agitator

The invention discloses a magnetic wave instrument magnetic core forming machine which comprises a heat treating forming groove frame combination device for a rod-shaped magnetic core, a lifting column device, a magnetic core tape winding machine magnetic core tape coating fluid container groove, a hot-air drying device and the like. The heat treating forming groove frame combination device for the road-shaped magnetic core is composed of a straight-groove-shaped magnetic core forming groove frame, a pressing plate and a forming groove combination device. The rod-shaped magnetic core is located in a straight groove and pressed tightly by the pressing plate and the combination device, wherein the width of the pressing plate is same as that of the straight groove. Moreover, the magnetic wave instrument magnetic core forming machine comprises a rotating device, an alignment clamping device, a submerged rolling shaft and a raw material rolling shaft support. The magnetic core tape winding machine magnetic core tape coating fluid container groove is composed of a rectangular hexahedron type plastic container groove, wherein the lifting column device and a liquor stirrer are installed at the bottom of the plastic container groove. The hot-air drying device is a magnetic core tape coating quick-drying device which is located above the liquor level of the magnetic core tape coating fluid container groove and fixed in the middle of a lifting column with a hot-air blower as a body.

Owner:NAT SPACE SCI CENT CAS

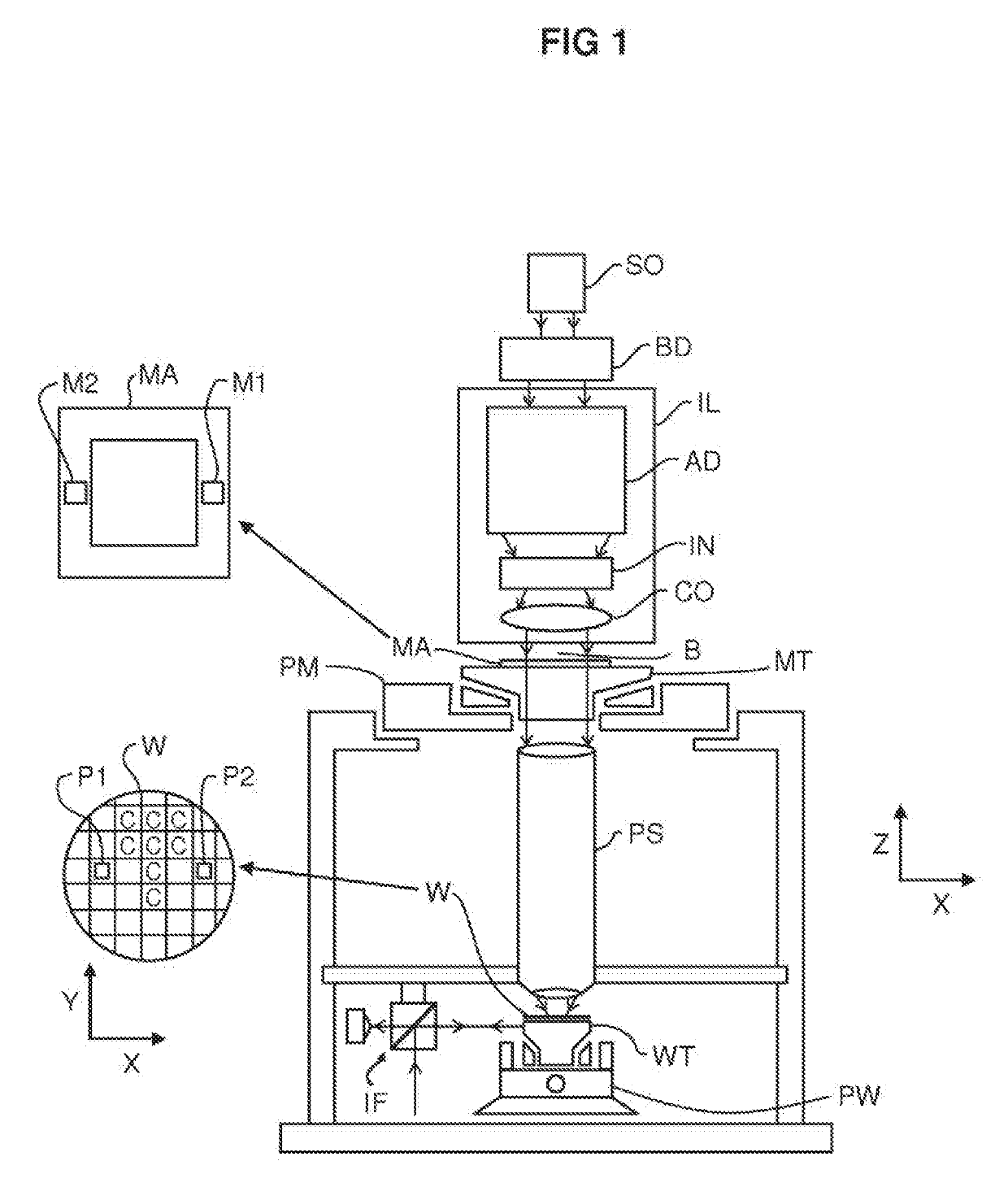

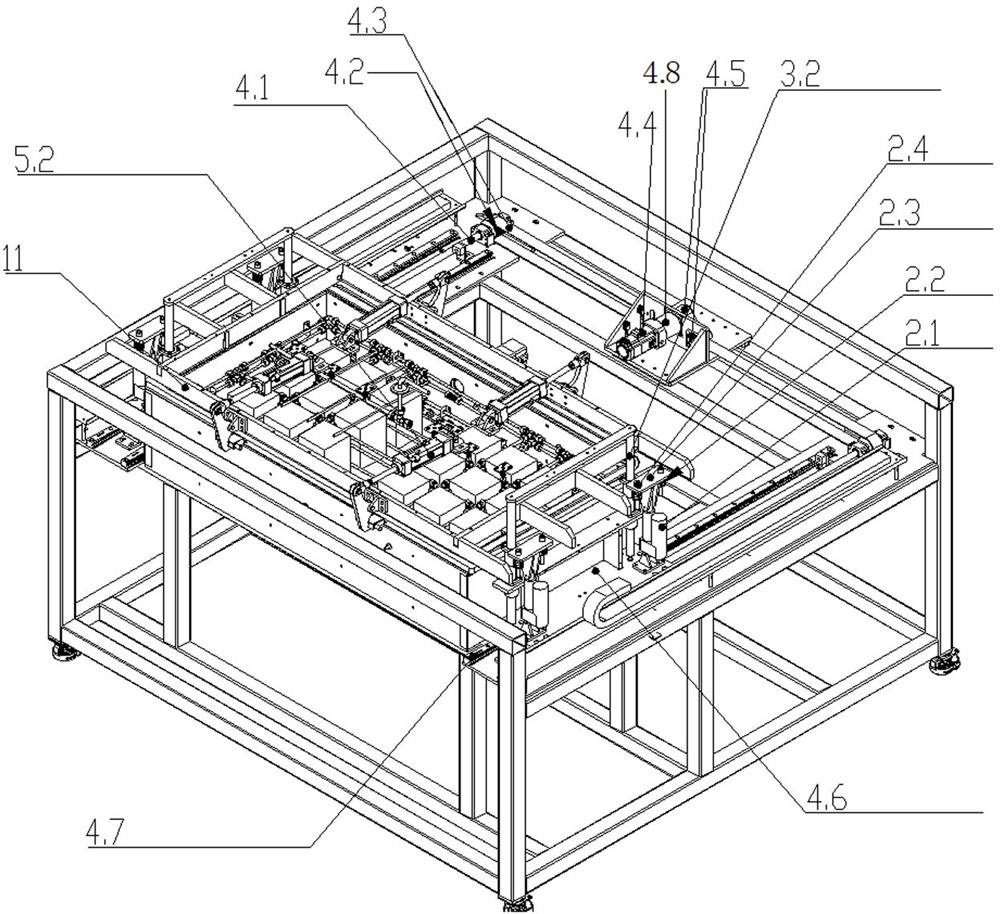

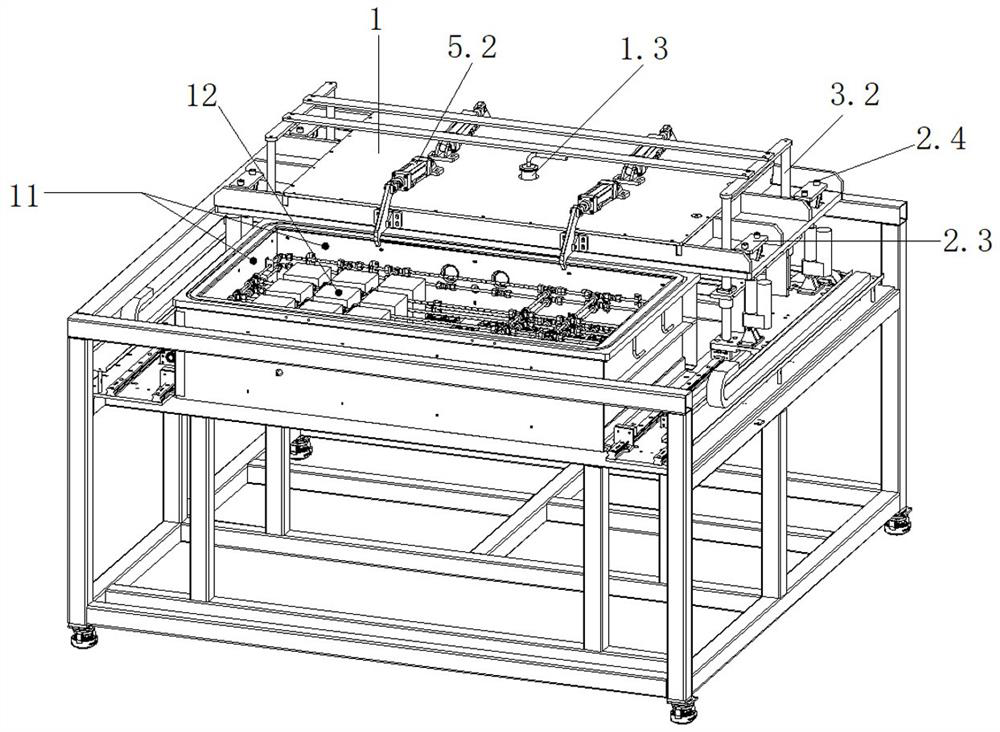

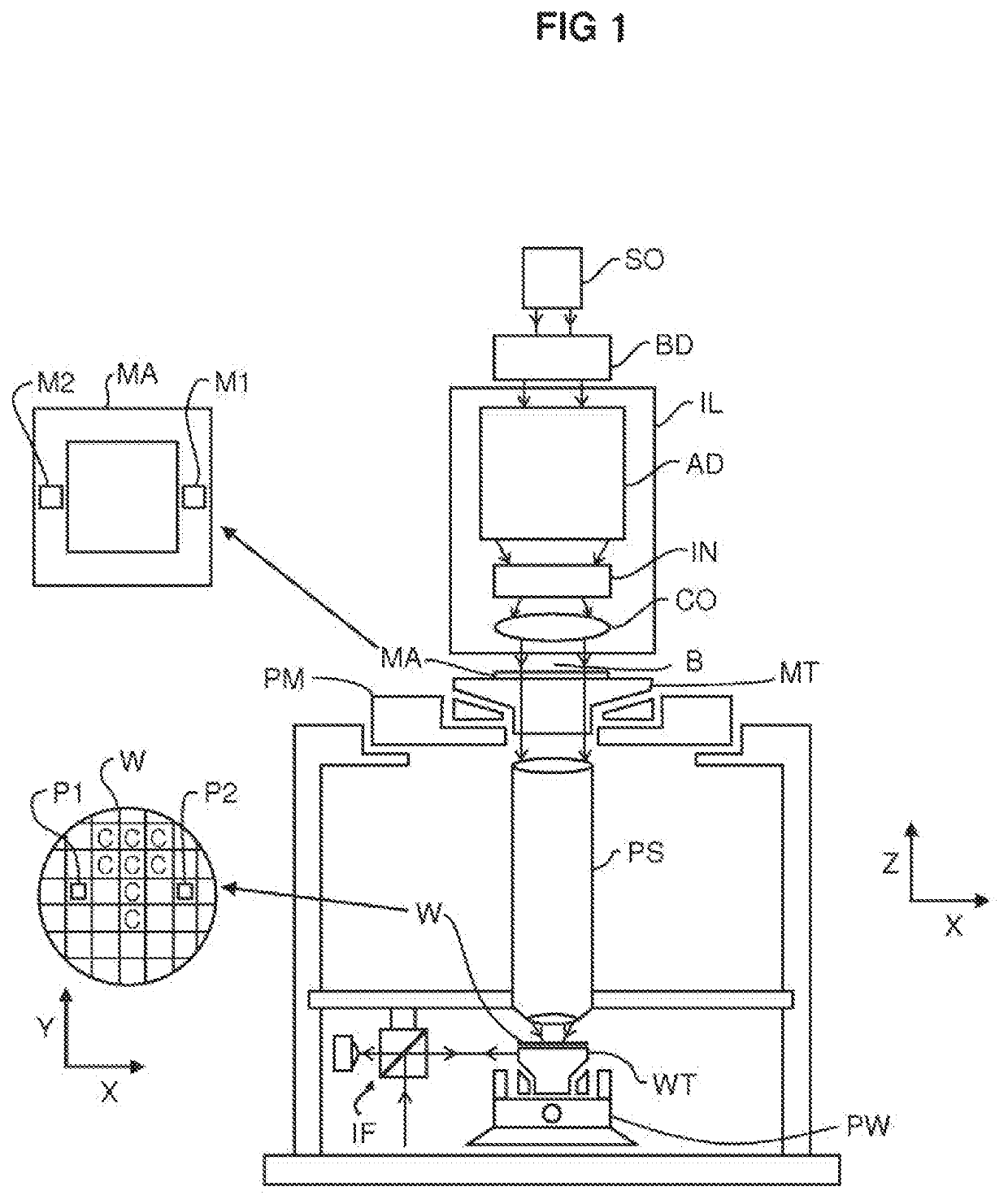

Stage system, lithographic apparatus and device manufacturing method

ActiveUS20190294057A1Reduce mechanical deformationMagnetic circuitNon-rotating vibration suppressionActuatorSpacer device

The invention pertains to a stage system, and to a lithographic apparatus and a method for manufacturing a device in which a stage system is used.In the stage system a positioning system is provided comprising an actuator adapted to position an object table. The actuator comprises a magnet assembly and a coil assembly.The magnet assembly comprises a first magnetic body and a second magnetic body, which are in use subjected to a internal magnetic force.The magnet assembly has a separate interface for connecting each magnetic body to the object table separately. The magnet assembly further comprises a spacer device, which holds the first and second magnetic body at a relative distance to each other in at least the direction of the internal magnetic force.

Owner:ASML NETHERLANDS BV

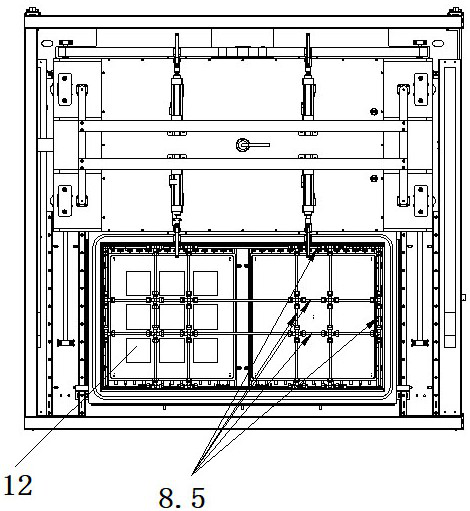

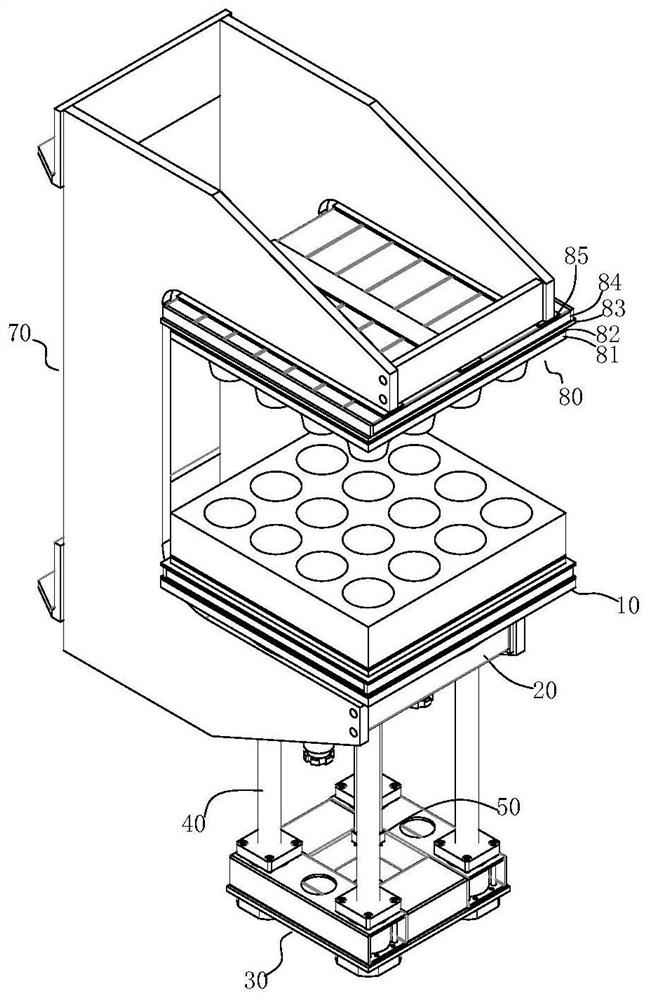

Vacuum equipment for vacuum welding or annealing of semiconductor chip

ActiveCN112103225AEasy for automatic loadingConvenient for automatic loading and unloadingSemiconductor/solid-state device manufacturingRobot handSemiconductor chip

The invention relates to vacuum equipment for vacuum welding or annealing of a semiconductor chip, and the equipment comprises a vacuum cabin and a vacuum cabin upper cover, and further comprises a translation mechanism, wherein the translation mechanism is connected with the vacuum cabin upper cover and can drive the vacuum cabin upper cover to horizontally move relative to the vacuum cabin; Theequipment also comprises a lifting mechanism which is connected with the vacuum cabin upper cover and can drive the vacuum cabin upper cover to move up and down relative to the vacuum cabin. The vacuum chamber upper cover can move up and down and horizontally relative to the vacuum chamber, the opening and closing door does not occupy the position of an input port, robot automatic feeding is moreconvenient, products can be vertically and automatically input, the top space of a welding area in the vacuum chamber can be increased, robot or mechanical arm automatic feeding and discharging are convenient, and the problem that horizontal input of heavy-load products easily causes scratching of the jig carrying table is effectively solved.

Owner:北京仝志伟业科技有限公司

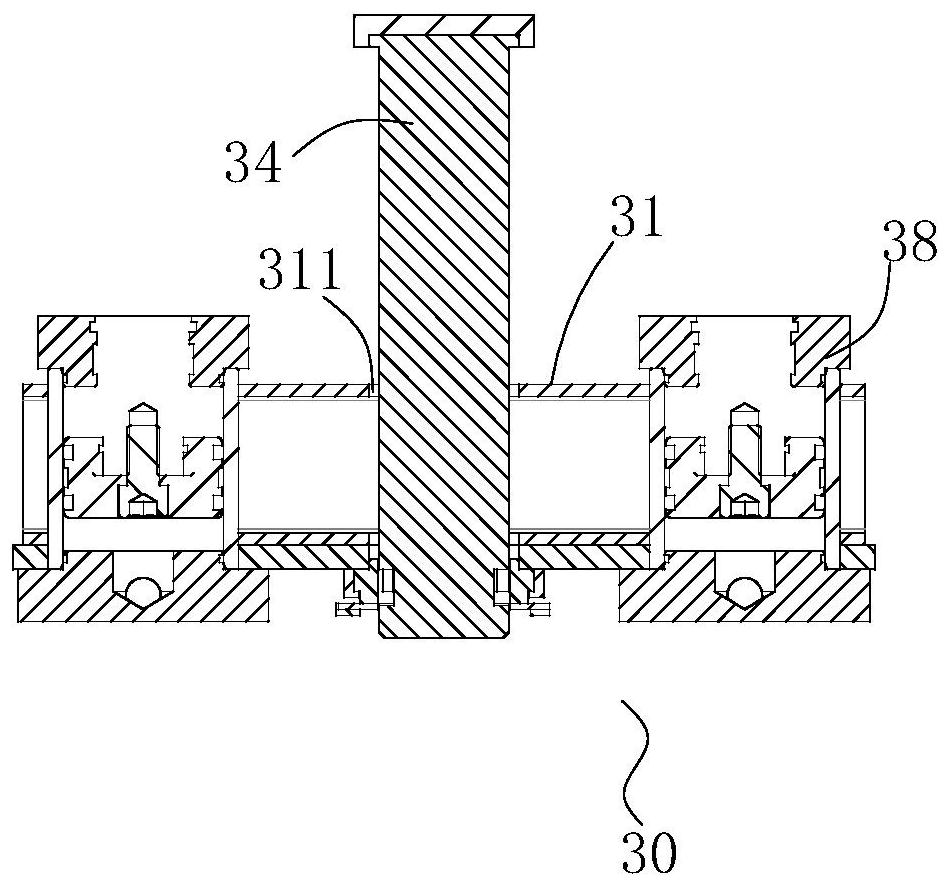

Arc-shaped double-clamp system required by high-frequency vibration of steel pipe pile

The invention relates to an arc-shaped double-clamp system required by high-frequency vibration of a steel pipe pile. A cross beam is fixedly connected to a vibrating hammer through a bolt, two arc-shaped clamps are embedded into a cross beam slot and can move bidirectionally in the cross beam slot to adjust the separation distance for meeting the clamping demands of steel pipe piles with different diameters, the two arc-shaped clamps with the adjusted separation distance are fixedly connected to the cross beam through bolts, and the two arc-shaped clamps are in reinforced connection to through a steel connecting plate and a bolt, so that the adjusted arc-shaped double clamps do not generate displacement when the vibrating hammer vibrates at a high frequency. The system provided by the invention is simple to operate. As an arc-shaped fixed clamp piece and the steel pipe pile are tightly laminated, a hydraulic retractable clamp piece can move freely to clamp and loosen the steel pipe pile, and the double clamps are locked in relative positions through a limiting steel plate and the bolt, so that the mechanical deformation at the end port of the steel pipe pile during high-frequency pile sinking is greatly reduced, and therefore, the steel pipe pile butt joint quality is effectively ensured, and meanwhile, the field construction steps and labor force investment are reduced, and the construction cost is lowered.

Owner:SHANGHAI FOUND ENG GRP

Efficient multifunctional sock turning machine

InactiveCN113737501AReduce riskAvoid homeworkMechanical cleaningPressure cleaningElectric machineryAir pump

The invention relates to the technical field of sock production, and discloses an efficient multifunctional sock turning machine. The machine comprises a main body; an inner cavity is formed in the main body; a low-speed motor is installed in the inner cavity; a collecting box is fixedly connected to the driving end of the low-speed motor; sock placing sleeve pipes are fixedly connected to the side edge of the top of the collecting box at equal intervals; a box door is installed on the side surface of the collecting box; a first limiting ring and a second limiting ring are fixedly connected to the upper surface of the main body; the interiors of the first limiting ring and the second limiting ring are jointly connected with a sock turning rod in a sliding mode; an air blowing pump is installed in the main body; a transmission mechanism is arranged above the low-speed motor; a sock turning mechanism is installed in inner cavity; and a sock taking-off mechanism is arranged above the air blowing pump. According to the invention, the effect of rapidly turning socks is achieved; an operator is far away from a pipeline opening of the air blowing pump when placing the socks, so that the dangerousness to the operator is reduced; and during rotation, the relatively thin sock turning rod does not make contact with a sock placing sleeve, so that the mechanical friction of equipment is reduced.

Owner:徐浩楠

Material breaking device of punching machine

The invention relates to the technical field of machining, in particular to a material breaking device of a punching machine for round steel workpieces. The material breaking device of the punching machine comprises a base and an upper die cavity arranged above the base, an adjusting seat and a lower die cavity with an inner circular tool are arranged on the base, and the lower die cavity is fixed on the base through locking bolts. A tool is arranged in the upper die cavity. The material breaking device of the punching machine is simple in structure, convenient to operate, high in machining precision, and not prone to causing deformation of workpieces, and when mass processing is carried out, work efficiency can be effectively improved, and labor intensity of workers can be reduced.

Owner:HUBEI JIANFENG TECH INC

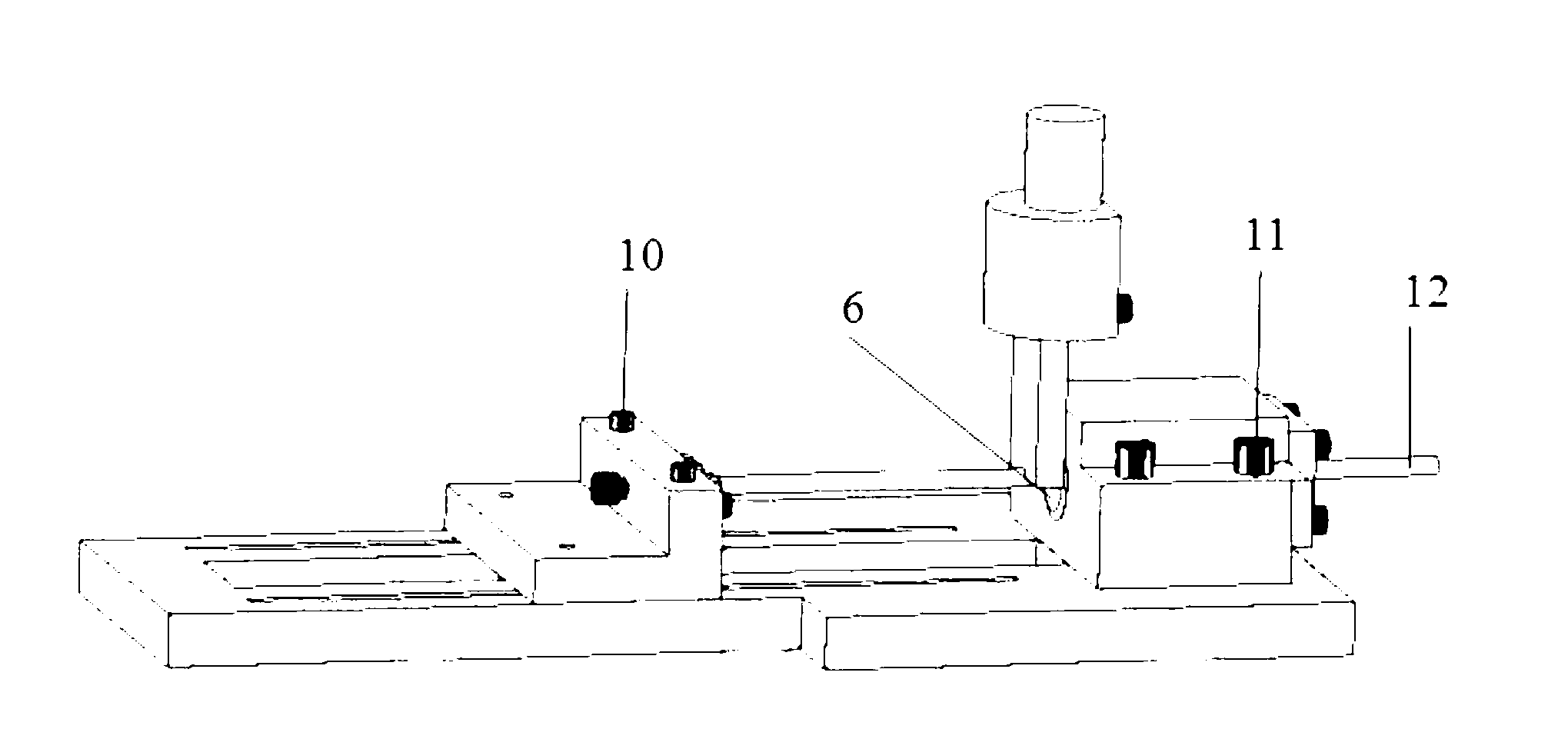

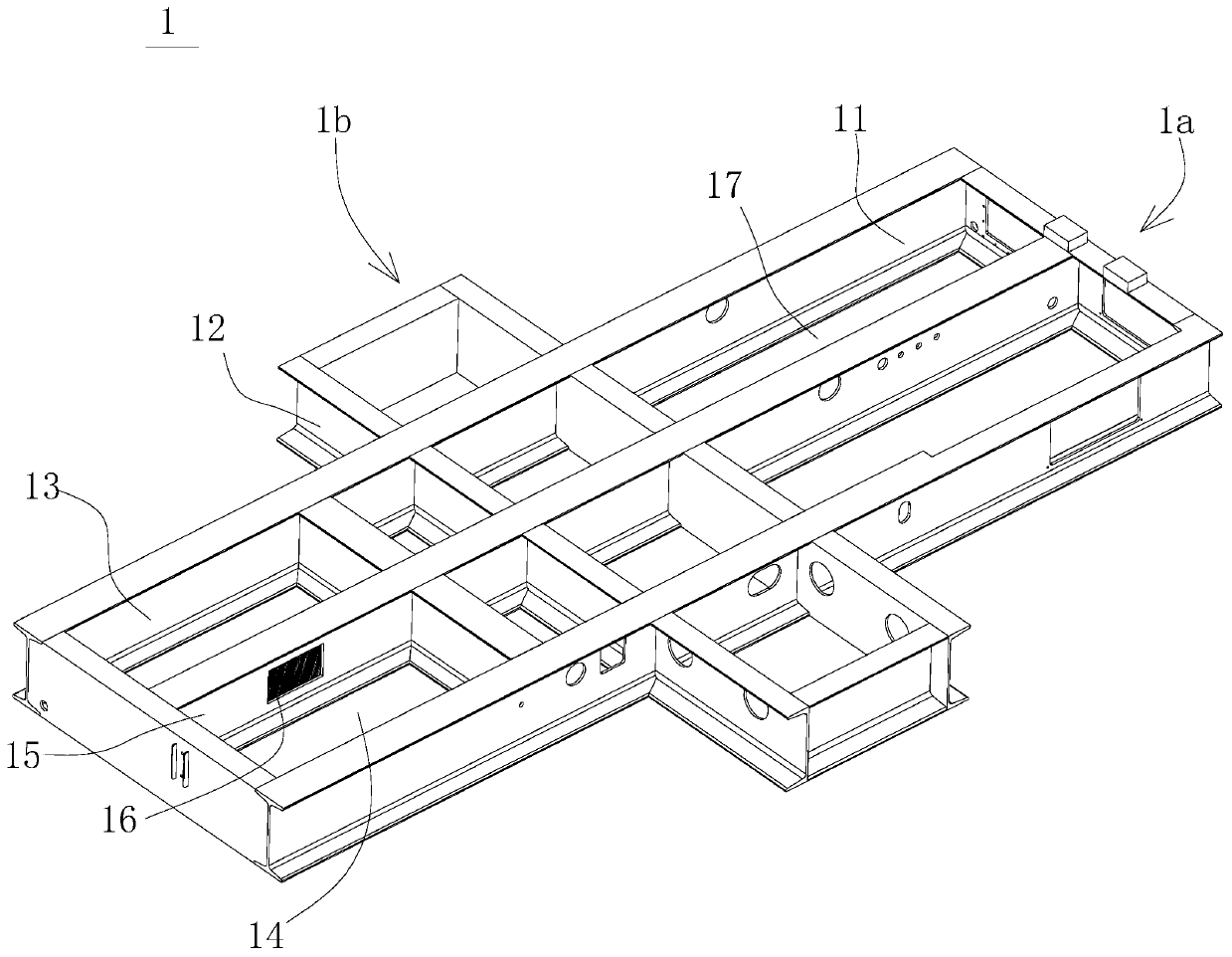

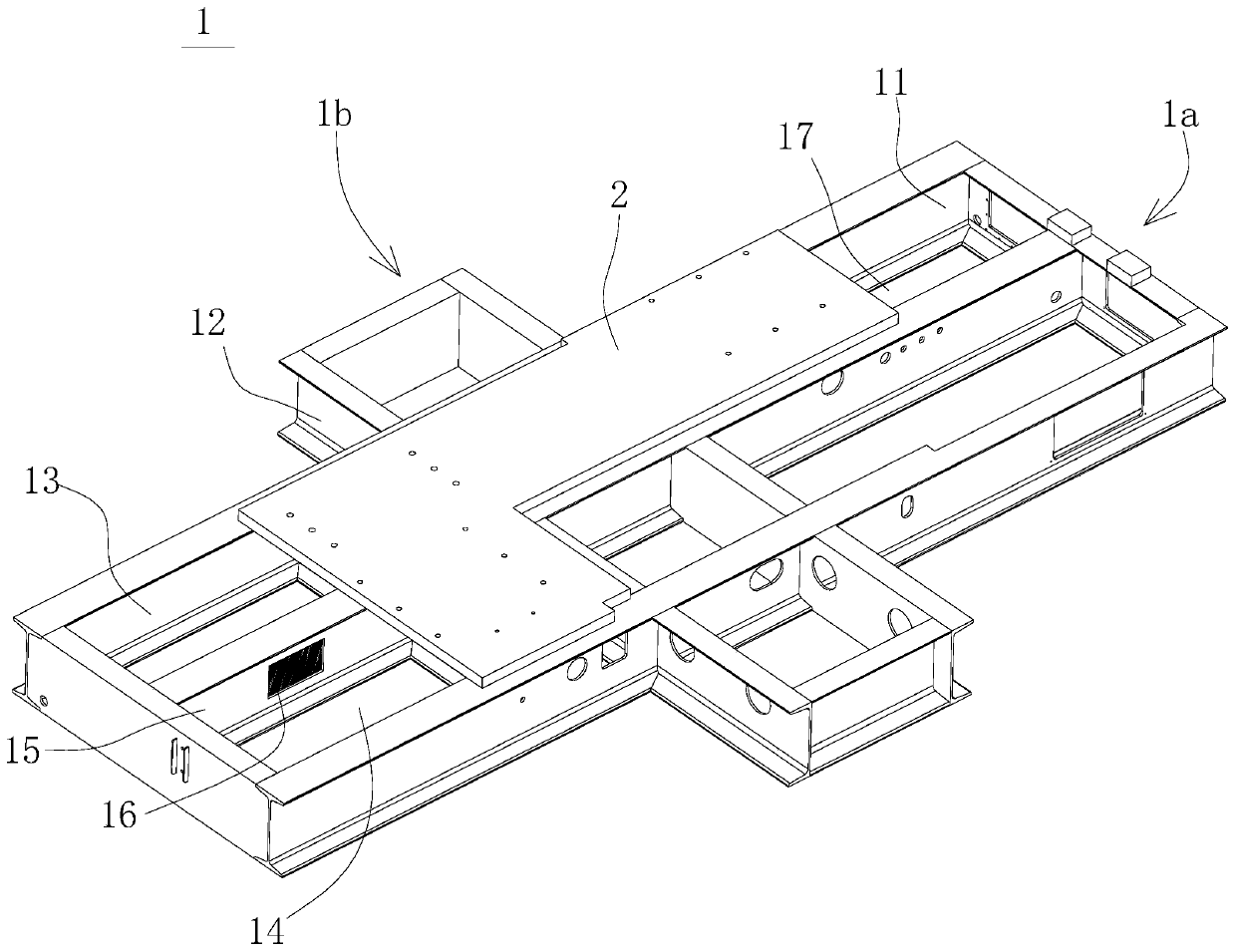

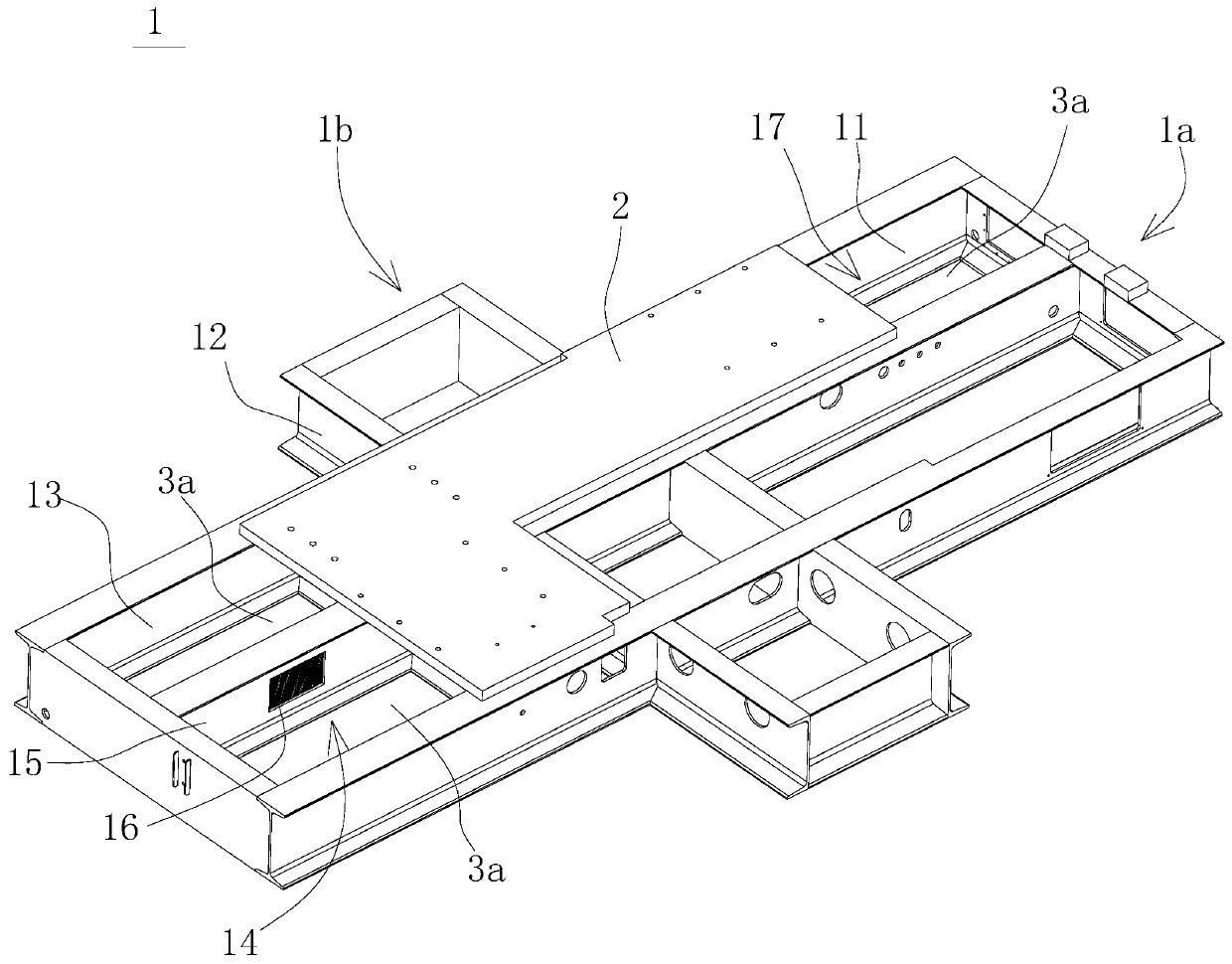

Processing Technology of Band Saw Base

InactiveCN106964916BImprove sealingAdd detection stepsMetal sawing devicesWorkpiece edge portionsFuel tankEngineering

The invention discloses a machining technology for a base of a band sawing machine. The machining technology overcomes the defects of poor firmness and poor welding sealing performance which generally exist during machining for the base of the band sawing machine at present. According to the technical scheme, the machining technology is characterized by comprising the steps that b, a placement plate is arranged at the position, corresponding to a movable clamp and a fixed clamp, of the upper surface of a bottom frame in a full welding manner; c, bottom plates are welded at the positions, at water tanks and an oil tank, on the lower surface of the bottom frame in a full welding manner; d, diesel oil is evenly smeared to the inner side walls of the water tanks and the oil tank and the interiors of the bottom plates, and the oil leakage phenomenon of weld cracks of the water tanks and the oil tank is checked after 50 min to 70 min; e, top plates are arranged at the positions, at the water tanks and the oil tank, on the upper surface of the bottom frame in a full welding manner; f, cover plates are arranged at the portion, besides the placement plate, on the longitudinal part of the bottom frame in a full welding manner; and g, adjusting plates which are horizontally arranged are evenly arranged at the positions, close to the side edge, of the bottom of the bottom frame, and reinforcing ribs are arranged at the positions of the side edge of the bottom frame. The beneficial effects that the band sawing machine is firm in structure, and gaps do not exist at welded positions are achieved.

Owner:宁波市甬塑机械制造有限公司

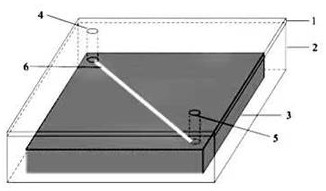

Method for manufacturing real coal two-dimensional microfluid model

ActiveCN114495679AReduce mechanical deformationEnsure consistencyGeometric image transformationEducational modelsEpoxyNano silicon

The invention provides a method for manufacturing a real coal two-dimensional microfluid model. The method comprises the following steps of: 1, scanning a columnar coal sample by using a CT (Computed Tomography) instrument to obtain a real fracture network; 2, a wire cutting machine is adopted, and blocky coal rock of 7.2 * 7.2 * 1.5 cm is cut on the large coal sample; 3, placing the real coal rock block on a silica gel grinding tool with the inner wall size of 8 cm * 8 cm * 2 cm, and pouring the epoxy resin glue until the epoxy resin glue is solidified; step 4, inputting the real fracture network or the simplified fracture into a laser marking machine, and etching the fracture on the surface of the blocky coal sample; and step 5, manufacturing a PET film of 7.2 * 7.2 cm, adding a silica gel coating with a nanometer thickness on one surface of the PET film through a coating process, and then bonding the PET film with the coal rock through the silica gel coating, so that the accuracy and controllability of the experiment are ensured, and the PET film and the nanometer silica gel coating have excellent light transmittance, so that the research on the basic theory of coal bed gas migration is facilitated. The method has important significance in improving the coal bed gas recovery ratio.

Owner:CHINA UNIV OF MINING & TECH

Axial passive magnet bearing system

ActiveUS9163666B2Reduce the applied forceReduce mechanical deformationWind energy generationMechanical energy handlingMagnetic tension forceContact type

An axial passive magnet bearing system utilizes the friction-less characteristic of non-contact type permanent magnet bearing to minimize the disadvantages induced by frictions. For example, both the energy and material loses of the mechanical bearing. Two permanents magnet are made of permanent magnet materials and positioned over two opposite surfaces of two mechanical structures, where mechanical bearing(s) is located therebetween. Hence, the magnetic force between the two magnets can improve some disadvantages among the two mechanical structures and the mechanical bearings, such as friction and energy loss.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

An evaporating tube rotary cutting device

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

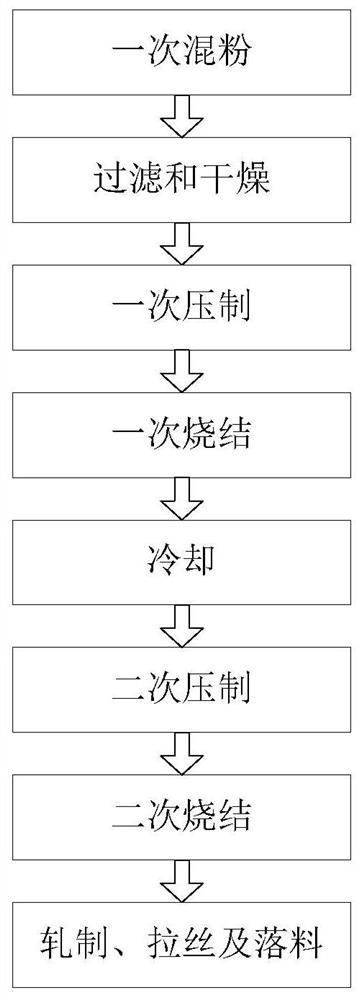

Preparation process of copper-based powder contact and relay formed by prepared contact

ActiveCN112820569AAvoid crackingCause damageContact materialsTransportation and packagingPowder metallurgyCopper

The invention discloses a preparation process of a copper-based powder contact. The preparation process comprises the following steps: S1, performing primary powder mixing; S2, performing filtering and drying; S3, performing primary pressing; S4, performing primary sintering; S5, performing cooling: after the primary sintering is finished, introducing room-temperature rare gas into a furnace for 30-40 minutes, then changing the temperature of the rare gas filled into the furnace, gradually reducing the temperature of the rare gas to 20 DEG C from 100 DEG C in an equal difference manner at a difference value of 10 DEG C, maintaining the filling time of the rare gas at each temperature gradient for 5 minutes, then taking out a blank ingot after the primary sintering, and cooling the blank ingot through a cooling device; S6, performing secondary pressing; S7, carrying out secondary sintering; and S8, performing rolling, wiredrawing and blanking. The invention also discloses a relay formed by the contact prepared by the preparation process. According to the method, the professional cooling step is added in the traditional metal powder metallurgy process, so that the blank ingot subjected to primary sintering can be completely cooled after the cooling step, and the blank ingot is prevented from generating cracks during secondary pressing to influence the property of the contact.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

Magnetic wave instrument magnetic core forming machine

InactiveCN103280307BReduce mechanical deformationReasonable design structureInductances/transformers/magnets manufactureWinding machineSolution agitator

The invention discloses a magnetic wave instrument magnetic core forming machine which comprises a heat treating forming groove frame combination device for a rod-shaped magnetic core, a lifting column device, a magnetic core tape winding machine magnetic core tape coating fluid container groove, a hot-air drying device and the like. The heat treating forming groove frame combination device for the road-shaped magnetic core is composed of a straight-groove-shaped magnetic core forming groove frame, a pressing plate and a forming groove combination device. The rod-shaped magnetic core is located in a straight groove and pressed tightly by the pressing plate and the combination device, wherein the width of the pressing plate is same as that of the straight groove. Moreover, the magnetic wave instrument magnetic core forming machine comprises a rotating device, an alignment clamping device, a submerged rolling shaft and a raw material rolling shaft support. The magnetic core tape winding machine magnetic core tape coating fluid container groove is composed of a rectangular hexahedron type plastic container groove, wherein the lifting column device and a liquor stirrer are installed at the bottom of the plastic container groove. The hot-air drying device is a magnetic core tape coating quick-drying device which is located above the liquor level of the magnetic core tape coating fluid container groove and fixed in the middle of a lifting column with a hot-air blower as a body.

Owner:NAT SPACE SCI CENT CAS

Stage system, lithographic apparatus and device manufacturing method

ActiveUS10620552B2Reduce mechanical deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusMagnetic tension forceActuator

The invention pertains to a stage system, and to a lithographic apparatus and a method for manufacturing a device in which a stage system is used.In the stage system a positioning system is provided comprising an actuator adapted to position an object table. The actuator comprises a magnet assembly and a coil assembly.The magnet assembly comprises a first magnetic body and a second magnetic body, which are in use subjected to a internal magnetic force.The magnet assembly has a separate interface for connecting each magnetic body to the object table separately. The magnet assembly further comprises a spacer device, which holds the first and second magnetic body at a relative distance to each other in at least the direction of the internal magnetic force.

Owner:ASML NETHERLANDS BV

Tyre electronic component with multi-frequency antenna

InactiveCN101114730BReduce mechanical deformationEasy to manufactureAntenna adaptation in movable bodiesMulti bandResonance

A tire component (10) with an electronic component (30) integrated on the tire component (10) comprises a tire structure (12) and the integrated electronic component (30). The electronic component optimization comprises at least one RF device (32) and one multi-band antenna which can wirelessly communicate at least between a first resonance band and a second resonance band. The multi-band antennacomprises at least a first antenna conductor and a second antenna conductor which are connected with the RF device so as to facilitate the transmission of RF signals. The signals can comprise the tire identification information or the measured status information, such as the tire temperature, the pressure and other characteristics. The first antenna conductor and the second antenna conductor optimizations are used together as at least two dipole antennas, such as two half-wavelength dipole antennas, or as one half-wavelength dipole antenna and one two third wavelength dipole antenna.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

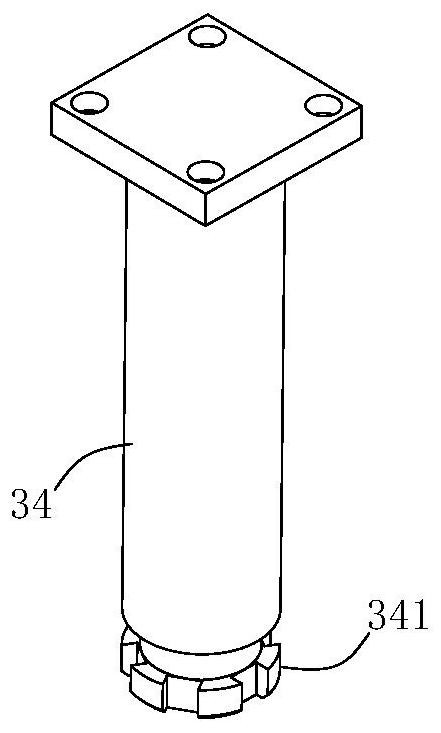

Lower die underframe assembly and hot-pressing lower die structure

PendingCN111648168AWith lock functionAvoid pollutionTextiles and paperRotational axisIndustrial engineering

The invention discloses a lower die underframe assembly and a hot-pressing lower die structure. The lower die underframe assembly comprises an underframe main body and a lock catch mechanism, and an insertion hole is formed in the underframe main body; the lock catch mechanism comprises a shaft sleeve mounting plate, a rotating shaft sleeve and a connecting shaft; a plurality of first splines arearranged at intervals in the circumferential direction of the central through hole of the rotating shaft sleeve; a plurality of second splines are arranged at intervals in the circumferential direction of the outer wall of the lower end part of the connecting shaft; a first driving mechanism is mounted on the bottom surface of the underframe main body; the first driving mechanism is used for driving the rotating shaft sleeve to be switched between an unlocking state and a locking state. The lower die underframe assembly has a locking function, can ensure that the underframe main body is lockedand restrained by the lock catch mechanism to keep still when the die is closed, and also has a pressurization function. The hot-pressing lower die structure has the locking and pressurizing functions, the operation stability is good, the hot-pressing pressure is adjustable, possible leakage points are located below a die and a product, and the die and the product are prevented from being polluted.

Owner:徐允聪

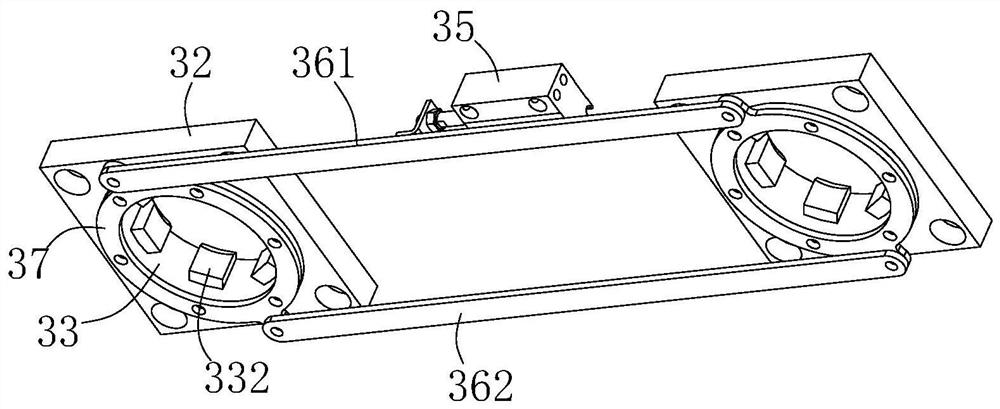

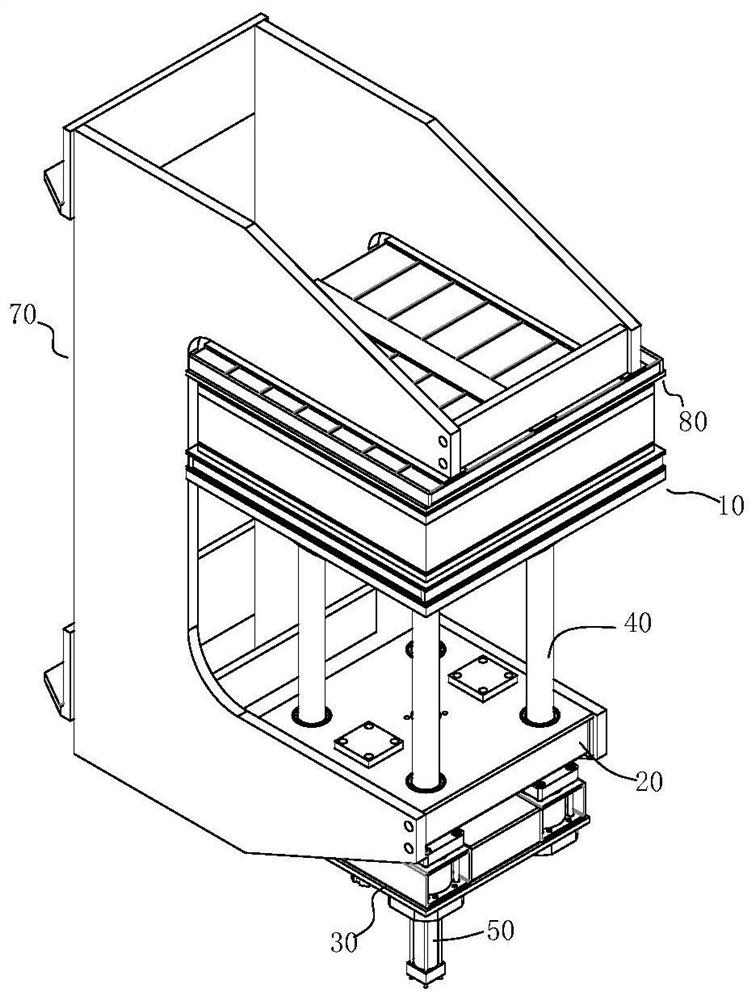

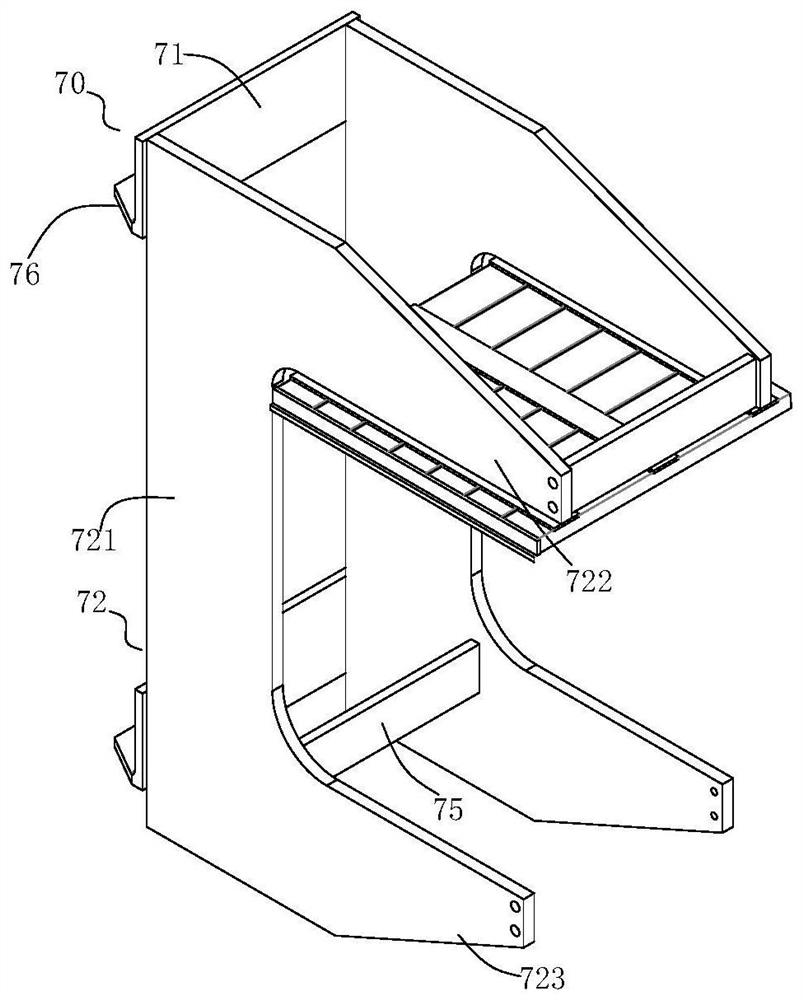

Modular hot-pressing shaping mechanism

PendingCN111648164ALow comprehensive costAvoid pollutionTextiles and paperManufacturing engineeringHot pressing

The invention discloses a modular hot-pressing shaping mechanism, which comprises a fixed frame, wherein a lifting channel is formed in the vertical direction of the fixed frame; a hot-pressing upperdie structure is located above the lifting channel; a hot-pressing lower die structure comprises a hot-pressing lower die assembly, a lower die mounting base plate and a lifting oil cylinder; the hot-pressing lower die assembly is located on the lower portion of the lifting channel; and the lifting oil cylinder drives the hot-pressing lower die assembly to ascend or descend in the vertical direction, so that die assembly or die opening is achieved between the lower die core and the upper die core. Modular manufacturing and mounting can be achieved, the difficulty of machining, manufacturing, mounting, debugging and maintaining can be effectively lowered, and the comprehensive cost of manufacturing and using can be effectively lowered. As a complete and independent hot-pressing shaping working module with excellent performance, the hot-pressing shaping working module not only can automatically, integrally and independently complete the hot-pressing shaping process of pulp molding, but also can be flexibly integrated into various sets of large multi-station pulp molding production equipment according to actual requirements by serially and parallelly combining a plurality of modular units.

Owner:徐允聪

Magnetic gage stand arrangement used for precision measurement

InactiveCN100494872CEasy to placeReduce articulationMeasurement apparatus componentsFeeler-pin gaugesEngineeringSpiral coil

This invention relates to one magnetic socket device, which comprises socket, supportive bar and micro adjuster and is characterized by the following: the micro adjust probe is set on beam with two parts fixed on one slide cover with each one covered on supportive bar top end and two down end fixed on one socket; the base socket is composed of seat, spiral coil, aluminum coils skeleton and connection screw nail; the spiral coil is around aluminum skeleton on the skeleton chamber fixed by connection nail with two ends connected to wire through wire hole and power.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com