Magnetic gage stand arrangement used for precision measurement

A magnetic base and precision measurement technology, applied in the direction of measuring devices, measuring gauges, measuring instrument components, etc., can solve problems affecting measurement, affecting measurement accuracy, unstable support rods, etc., and achieve strong resistance to external vibrations and other interference , reduce mechanical deformation, convenient and quick measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

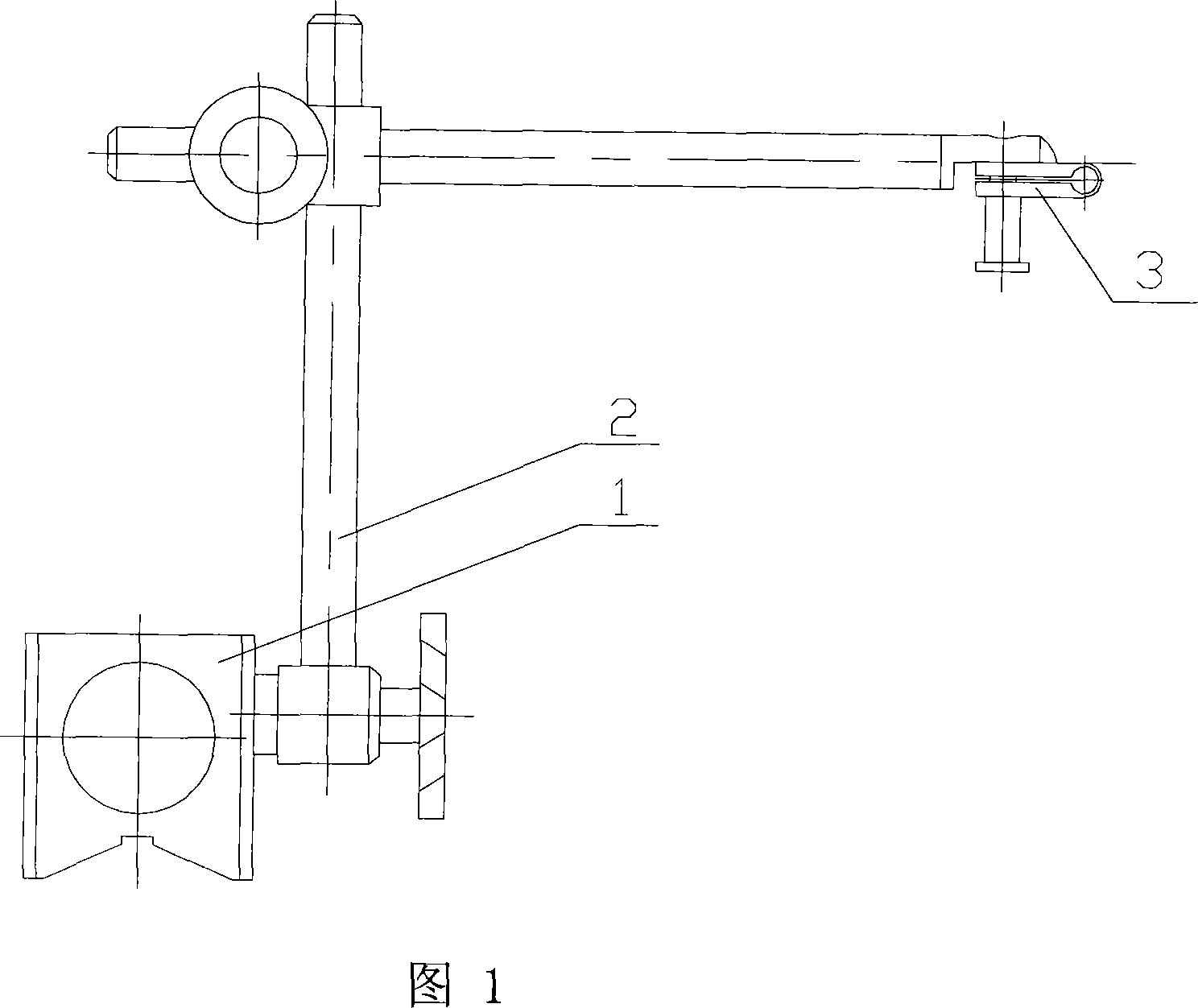

[0022] As shown in Figure 4 and Figure 5, a magnetic table base device for precision measurement, it includes a base 1, a support rod 2, a fine-tuning head 3, and a beam 11, the fine-tuning head 3 is set on the fine-tuning screw, and the fine-tuning screw passes through The elongated fine-tuning screw sliding hole on the crossbeam 11, the fine-tuning screw below the crossbeam 11 is screwed with nut 12, and the fine-tuning screw above the crossbeam 11 is screwed with nuts (tighten 2 nuts on the fine-tuning screw, the fine-tuning screw and the crossbeam 11 fixed connections). The two ends of the beam 11 are respectively fixedly connected with a sliding sleeve 10, and the two sliding sleeves 10 are respectively set on the upper end of a support rod 2, and the sliding sleeve 10 is provided with a fastening screw 9 (the two ends of the sliding sleeve 10 can be opened, Screw holes are respectively arranged at both ends, and the fastening screw 9 is screwed into two screw holes; or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com