Method for manufacturing real coal two-dimensional microfluid model

A manufacturing method and microfluidic technology, applied in teaching models, instruments, graphics and image conversion, etc., can solve problems such as failure to observe channel fluid flow, adsorption, diffusion, failure to achieve nanoscale microscopic models, and poor observation effects. , to achieve the effect of reducing human influence, ensuring consistency and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

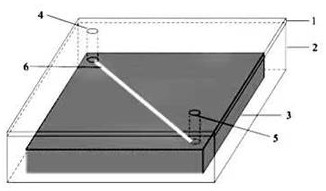

[0026] The technical solutions in the examples of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0027] Extract the fracture network:

[0028] Step 1, drill a columnar coal sample with a diameter of 2.5 cm in the block sample, and then use sandpaper to grind the columnar sample into a cylindrical sample of 2.5*5 cm;

[0029] Step 2: Use alcohol to clean the cylindrical coal sample, and then place it in the CT scanning room for scanning to obtain a picture of the fracture network developed inside the sample, and then perform sharpening and noise reduction on the picture to obtain a higher quality fracture network picture.

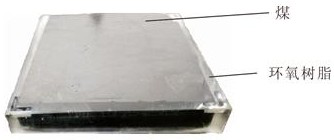

[0030] Cut real coal samples:

[0031] Step 1: Select a coal block of about 20*20*20 cm, and use a wire cutting machine to cut out a coal block with a size of 7.2*7.2*1.5 cm. It is required that the natural cracks on the surface of the coal block are not de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com