Turbine guide vane cooling air flow adjustment device

A technology for turbine guide vanes and cooling airflow, which is applied in the field of aero-engines, can solve the problems of unadjustable cooling air and does not have a large cooling air adjustment capability, and achieves simple structure, convenient assembly and disassembly, and good interchangeability and economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

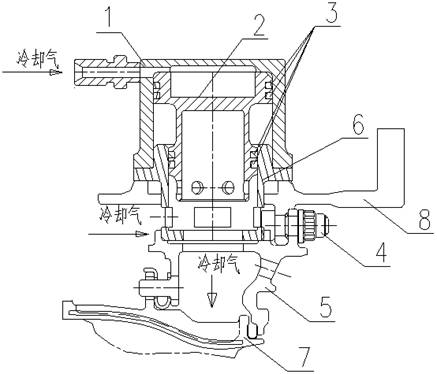

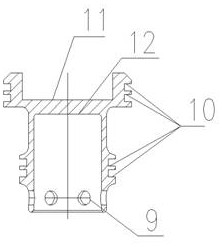

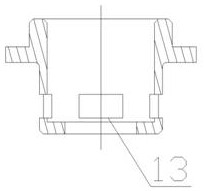

[0021] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a turbine guide vane cooling air flow adjustment device, which includes a body, an intake casing 5 , a high-pressure turbine guide vane 7 and a piston 2 . The body has a cylindrical structure with an open lower end and a closed upper end. The upper end of the cylinder wall of the body is provided with a first air inlet hole, and the lower end of the cylinder wall of the body is provided with a second air inlet hole 13, and the first air inlet hole and the second air inlet hole 13 are all communicated with the inner cavity of the body; the intake casing 5 is open at both ends, and the upper opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com