A downhole blowout preventer for workover operations

A technology of operating wells and blowout preventers, which is applied in the direction of wellbore/well components, wellbore/well valve devices, buildings, etc., to achieve the effect of throttling in the pipe string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

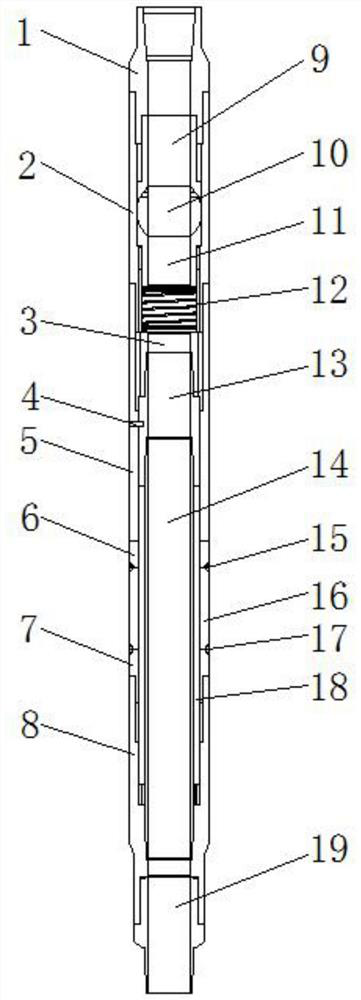

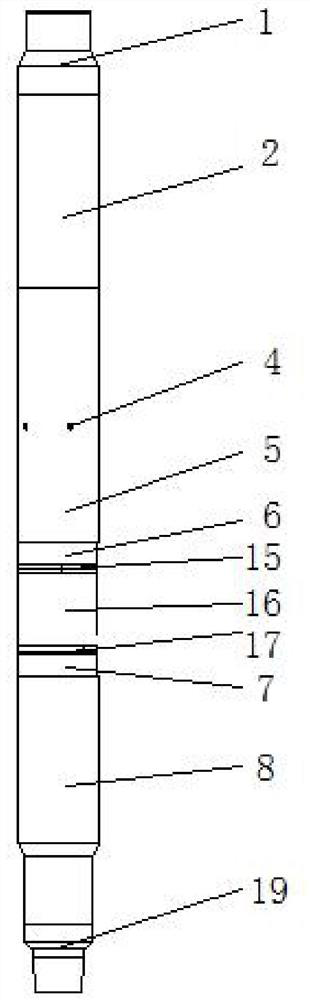

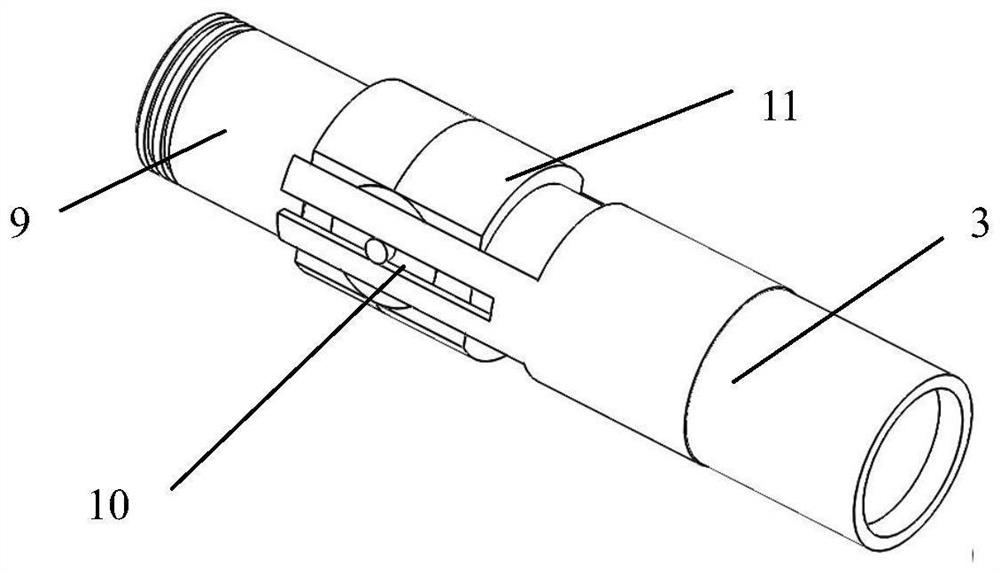

[0014] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0015] like Figure 1-Figure 5 As shown, a downhole blowout preventer for well workover operation includes: upper joint 1, upper short joint 2, thrust joint 3, pressure bearing shear nail 4, sliding sleeve 5, upper push ring 6, lower push ring 7, lower short Section 8, upper valve seat 9, valve ball 10, lower valve seat 11, preload spring 12, central pipe joint 13, central pipe 14, back ring group I15, rubber cylinder 16, back ring group II17, torque cylinder 18, lower Connector 19. The whole tool is installed on the workover string through the upper joint 1 located at the upper part of the tool and the lower joint 19 located at the lower part of the tool. Both the upper joint 1 and the lower joint 19 are connected with the workover string through API pipe threads, and there is no abnormality in the oil and gas well When the pressure fluctuates, the tool acts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com