Energy-saving production equipment for intelligent manufacturing of printed density electronic circuit board

An electronic circuit board and intelligent manufacturing technology, which is applied in the fields of printed circuit manufacturing, printed circuit, lighting and heating equipment, etc., can solve the problems of power consumption and heat leakage of equipment, and achieve the effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

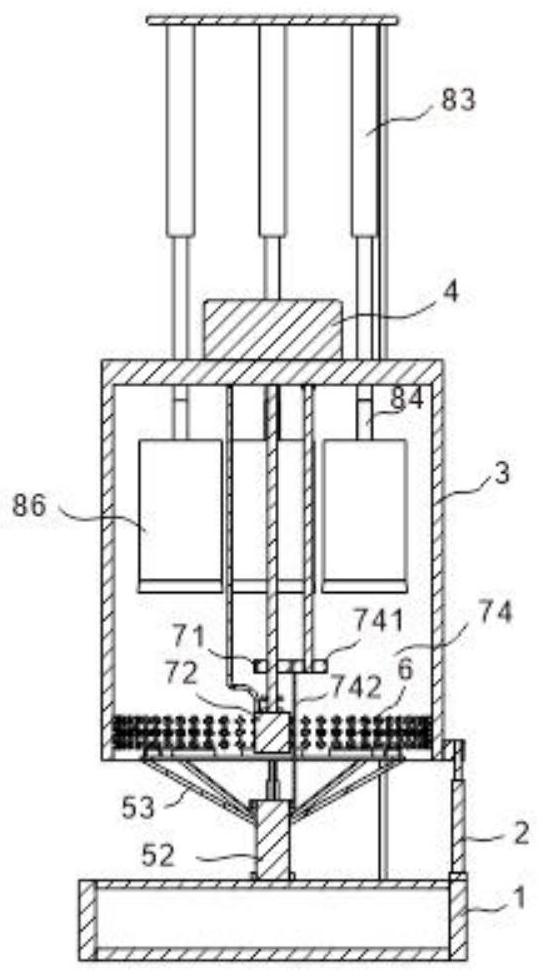

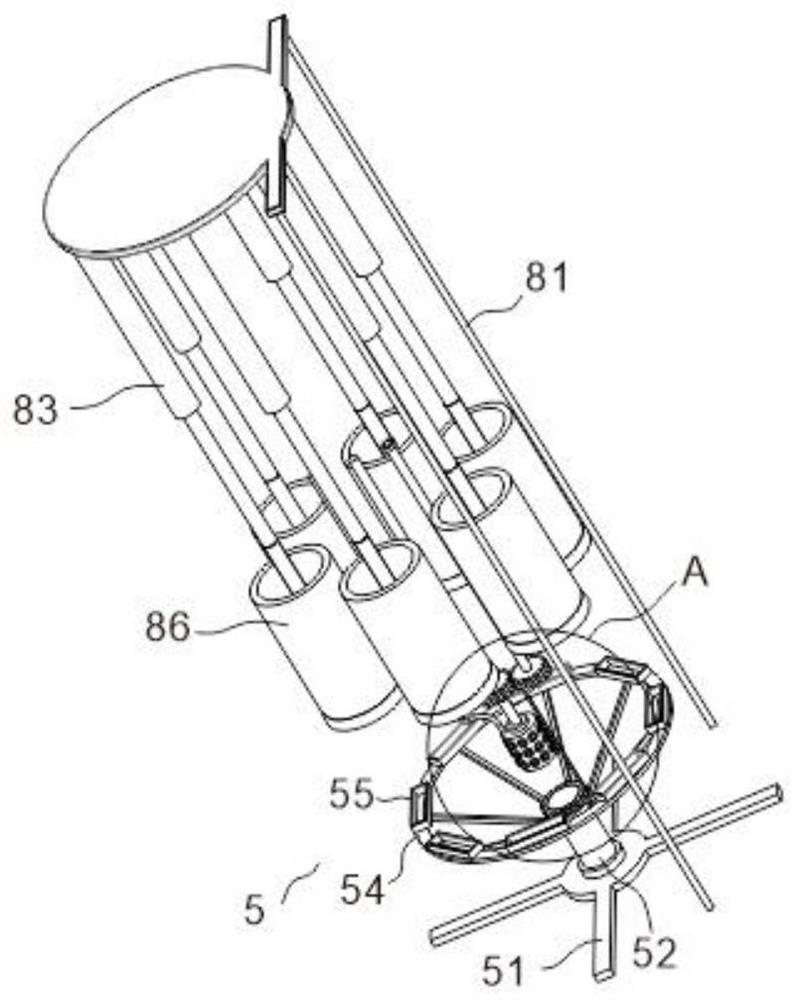

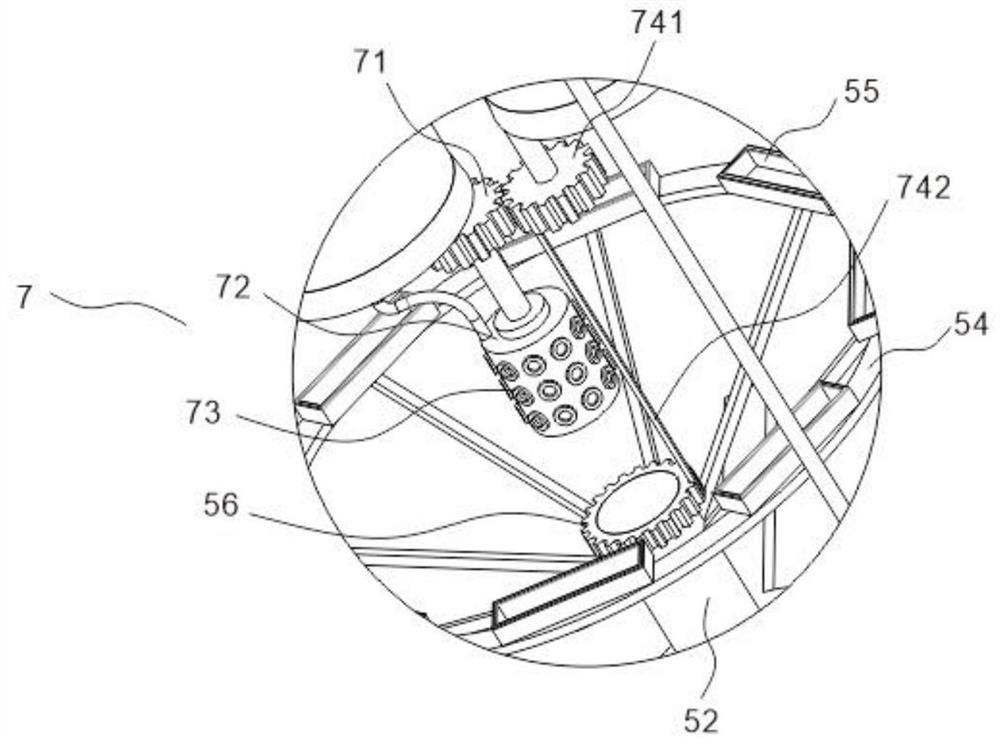

[0018] Energy-saving production equipment for intelligent manufacturing of printed density electronic circuit boards, see Figure 1 to Figure 3 , including a water receiving tank 1, which is used to catch the water drops dropped during drying. The top of the water receiving tank 1 is evenly provided with a lifting device 2, and the power end of the lifting device 2 is fixedly connected with the fixed cover 3. The lifting device 2 is used for When taking and placing the circuit board, it drives the fixed cover 3 to move vertically, without affecting the taking and placing of the circuit board. The bottom of the inner wall is evenly connected with the outer nozzle 6, the top of the fixed cover 3 is connected with the inner air injection mechanism 7, and the fixed cover 3 is connected with the air supply port of the hot air blower 4, and the fixed cover 3 is evenly provided with a storage assembly 8.

[0019] The circuit board placement assembly 5 includes a support frame 51 arra...

Embodiment 2

[0026] see Figure 1 to Figure 4 , the storage assembly 8 includes a mounting rod 81 arranged on the top of the water tank 1, the top of the mounting rod 81 is connected to the top plate 82, the bottom of the top plate 82 is evenly provided with an electric telescopic device 83, and the power end of the bottom of the electric telescopic device 83 runs through the fixed cover 3 Connected with a piston rod 84, the bottom end of the piston rod 84 is connected with a piston 85, and the piston 85 is connected to the inner wall of the storage tube 86, the top of the storage tube 86 is closed, the bottom of the storage tube 86 is open, and the storage tube 86 It is located inside the fixed cover 3, and the storage tube 86 is fixedly connected to the water receiving tank 1. The top of the storage tube 86 is externally connected with a through pipe that runs through the top of the fixed cover 3. The connecting structure between the through pipe and the storage tube 86 and the water rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com