Metal wire drawing device

A metal wire and wire drawing technology, applied in the direction of wire drawing dies, etc., can solve the problems of affecting the wire drawing effect, easy accumulation of debris and sludge at the bell mouth, and achieve the effect of not easy to wash dead corners, ensuring the effect of wire drawing and ensuring the effect of washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

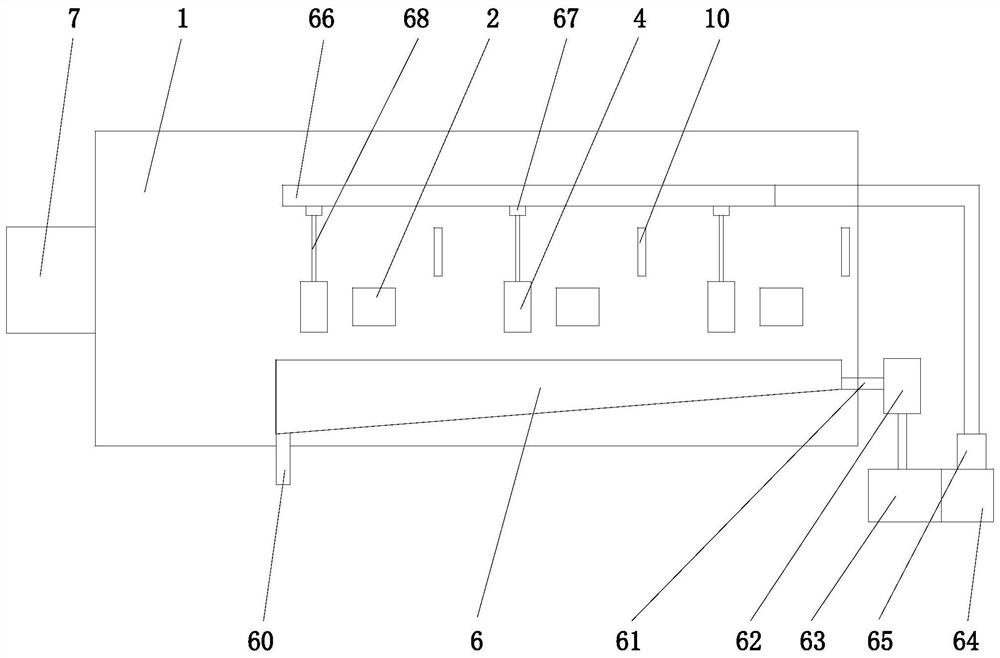

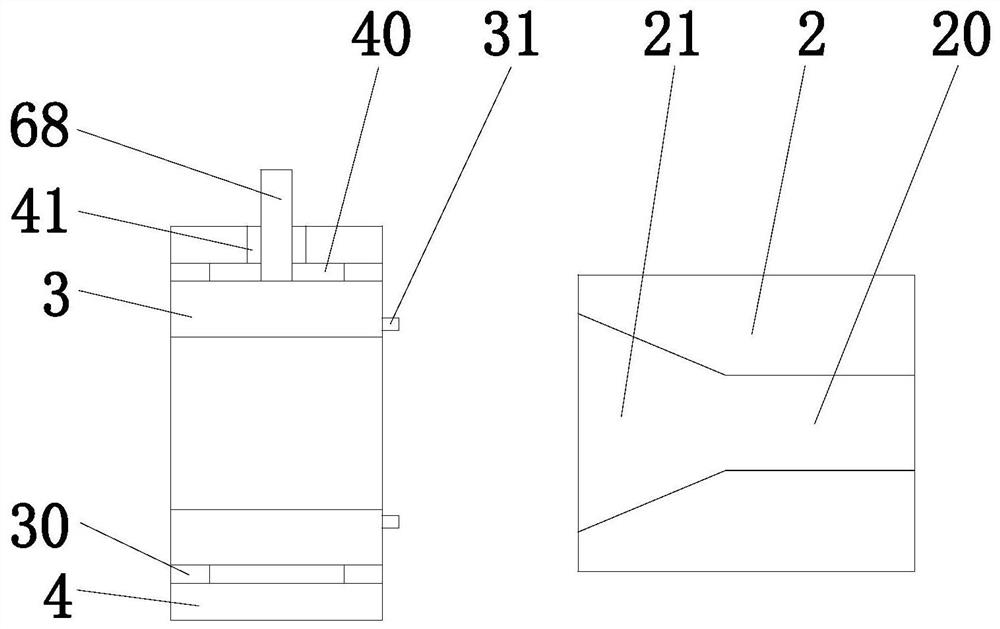

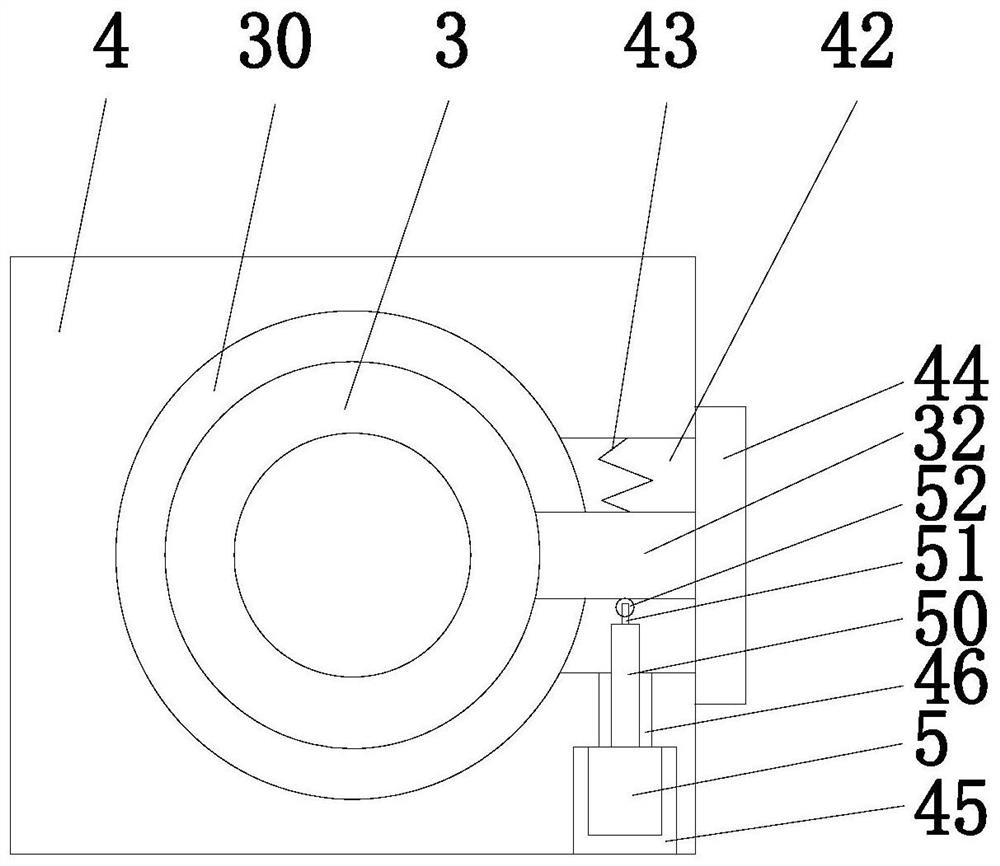

[0017] See figure 1 , figure 2 with image 3 According to a metal wire drawing device including a brigadier body 1, a drawing die 2, a spray spray barrel 3, a mounting block 4, a tank 6, a solid-liquid separation device 63, a first liquid pump 62, a second liquid pump. 65, the supply liquid tube 66, the supply liquid soft branch pipe 68, the control device 7, the brigade body body 1 includes a plurality of drawing die 2, the drawing die 2 is provided with a horizontal arrangement hole 20, the mold hole 20 The line side is provided with a horn port 21, and a plurality of mounting blocks 4 corresponding to the wire drawing die 2 is provided inside, and the mounting block 4 is located on the wiring side of the drawing die 2, and one is provided on the mounting block 4. The mounting hole 40 coaxially with the mold hole 20 is provided with a spray hole 30 with the shaft of the mold hole 20, and each of the outer ends of the outer wall of the spray cylinder 3 have a bearing 30, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com