Mono drill/pump pre-profile stator inner cavity spiral curve processing equipment and method

A stator inner cavity and helical curved surface technology, applied in metal processing equipment, milling machine equipment, details of milling machine equipment, etc., to achieve the effect of improving cooling efficiency, improving machining accuracy, and ensuring accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

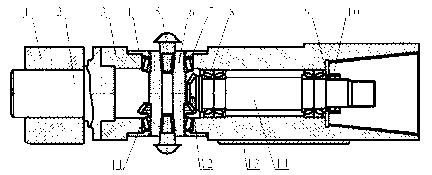

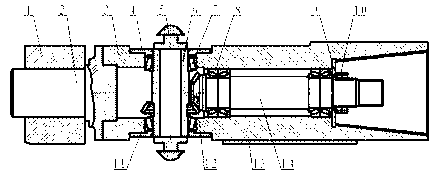

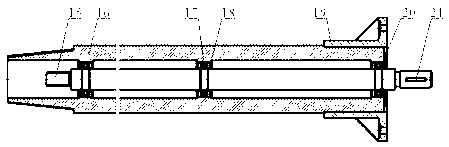

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of Monodrilling tool of the present invention and Monopump pre-contour stator inner cavity helical curved surface processing equipment include a cutter head and a cutter bar, and its structure includes a centering cap 1, a centering plug 2, a cutter head body 3, a One end cover 4, milling cutter 5, cutter holder 6, righting tile 13, bevel gear shaft 14, transmission shaft 15, cutter body rod 16, connector flange 19, second end cover 20, its structural features are: righting block One end of the head 2 is connected with the centering cap 1 and positioned by the tightening bolt, and the other end is connected with the cutter head body 3 and positioned by the bolt. The centering cap 1 can change its outer diameter according to the change of the inner diameter of the stator, so as to be used for different sizes. The machining of the spiral curved surface of the inner cavity of the stator; the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com