Multifunctional epoxy resin prefabricating and stirring equipment

A technology of epoxy resin and mixing equipment, applied in the field of industrial mixing, which can solve the problems of inconvenient separation of solid particles, improvement of mixing effect, lack of filtering function, etc., to achieve overall weight and cost control, and improve smoothness and stability , Improve the effect of positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

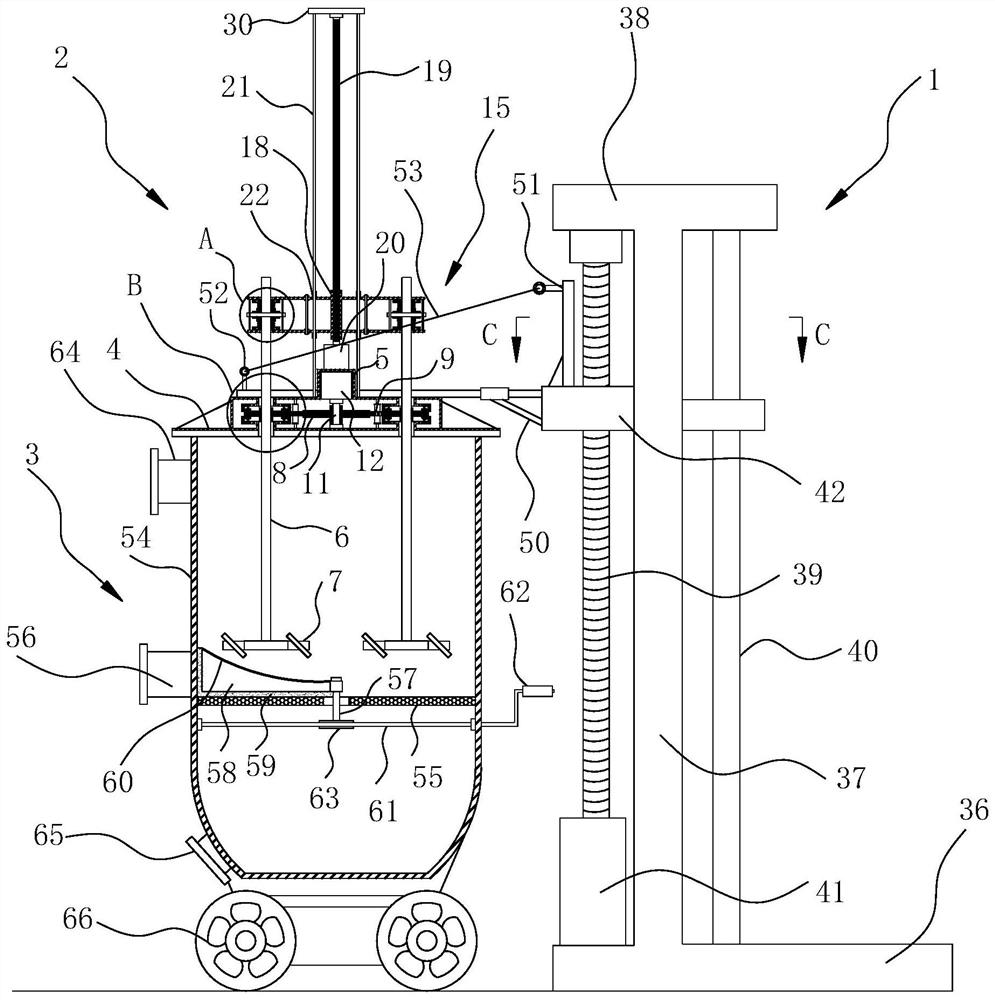

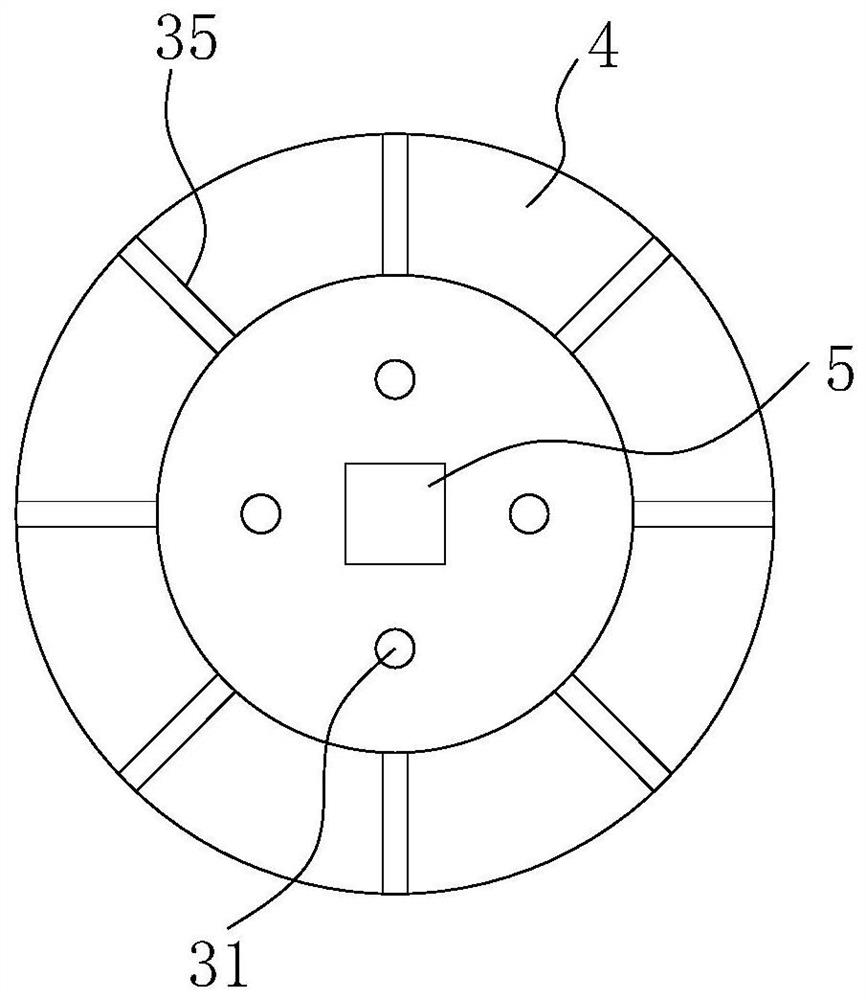

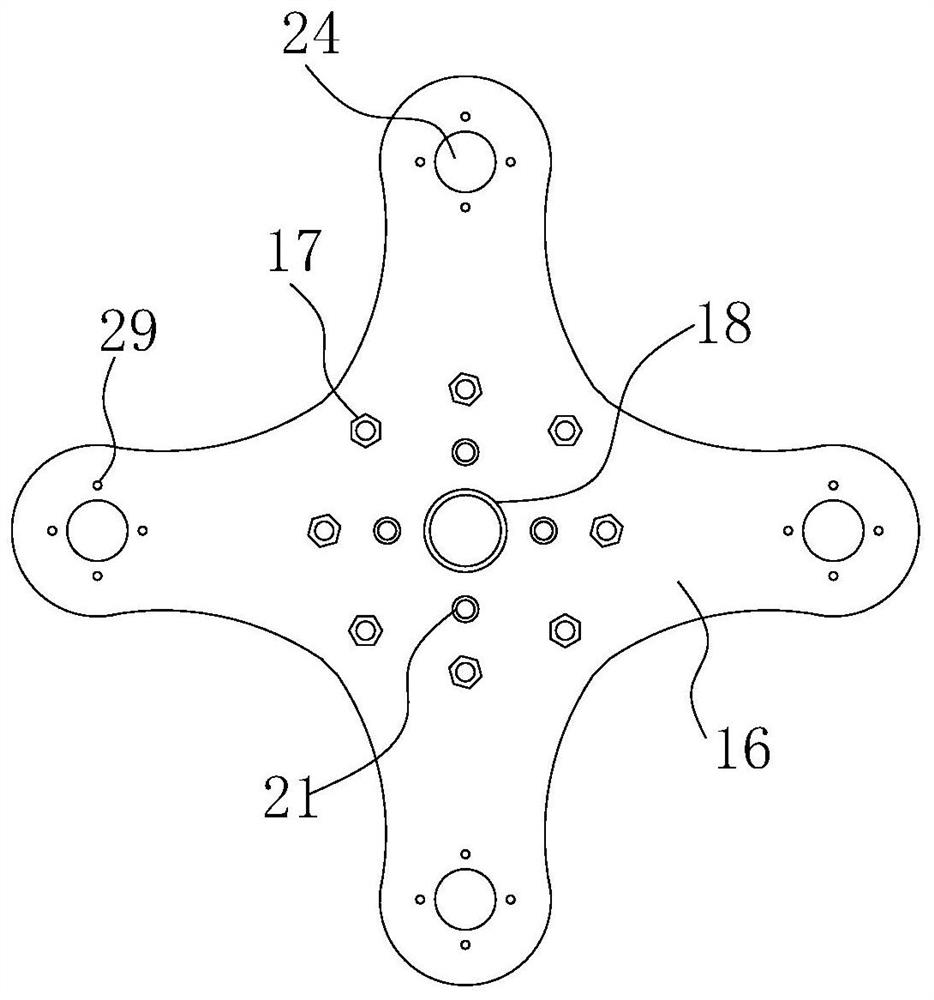

[0029] like Figure 1-9 As shown, a multi-functional epoxy resin prefabricated mixing equipment includes a lifting frame 1, a stirring mechanism 2 installed on the lifting frame 1, and a mixing barrel 3 arranged below the stirring mechanism 2. The stirring mechanism 2 and the stirring barrel 3 of the present invention adopt split-type independent design, the stirring barrel 3 is mainly used for containing materials, and as a place for stirring materials, the stirring mechanism 2 is used to realize stirring the materials in the stirring barrel 3, and the lifting frame 1 It is used to drive the stirring mechanism 2 to lift up or down. When lifted, the mixing barrel 3 can be moved in or out from the bottom of the stirring mechanism 2. When it is lowered, the mixing mechanism 2 and the mixing barrel 3 can be assembled.

[0030] Compared with the traditional stirring device, the present invention has three main differences:

[0031] One, the overall form of the stirring mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com