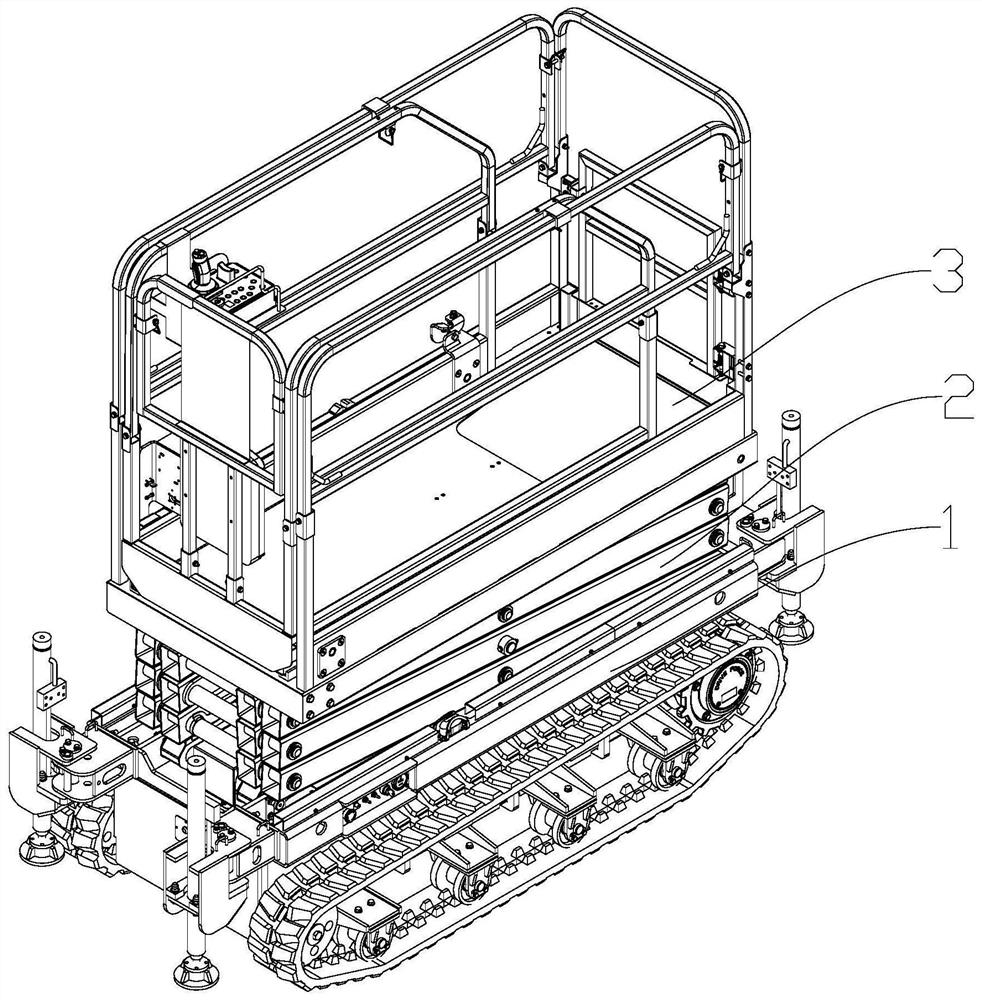

Crawler shear forklift with detachable supporting legs

A technology for scissoring forklifts and crawler tracks, which is applied in the direction of lifting devices, etc., can solve the problems of poor transportation convenience and economy, limited wheelbase and wheelbase, and poor adaptability, so as to meet the requirements of large-load operations and increase the support area. , the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

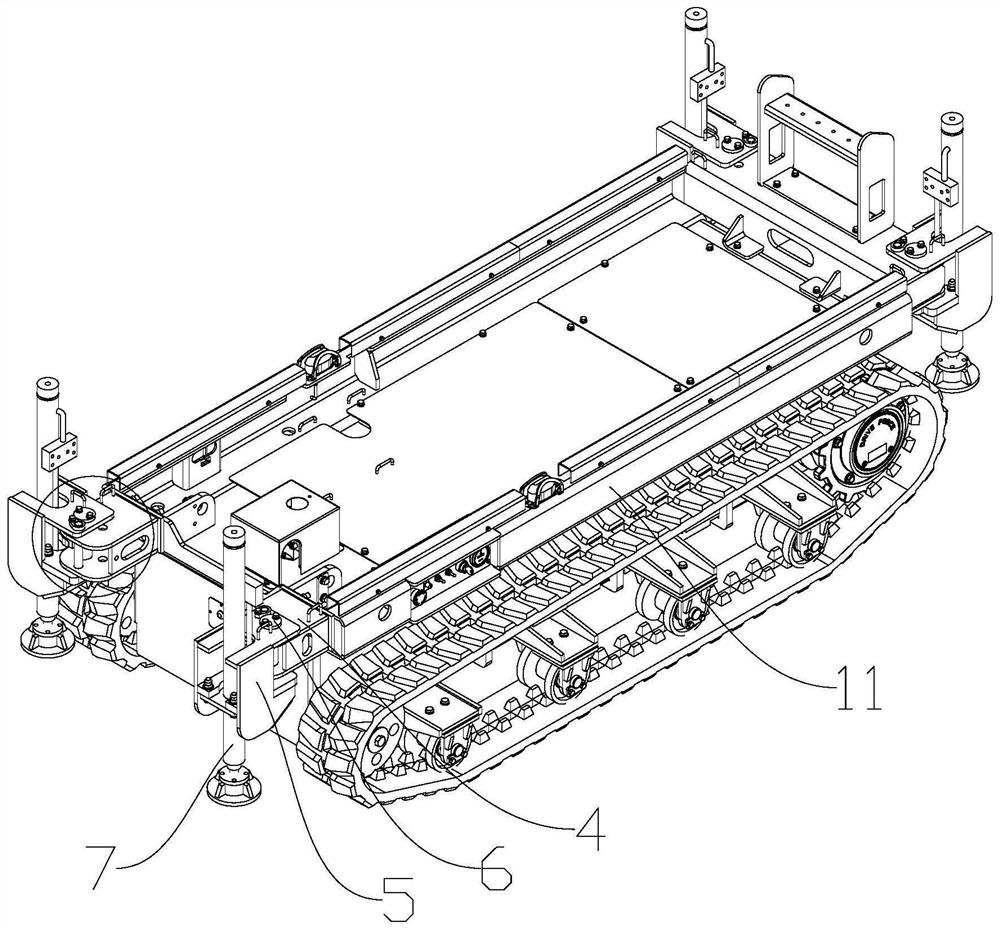

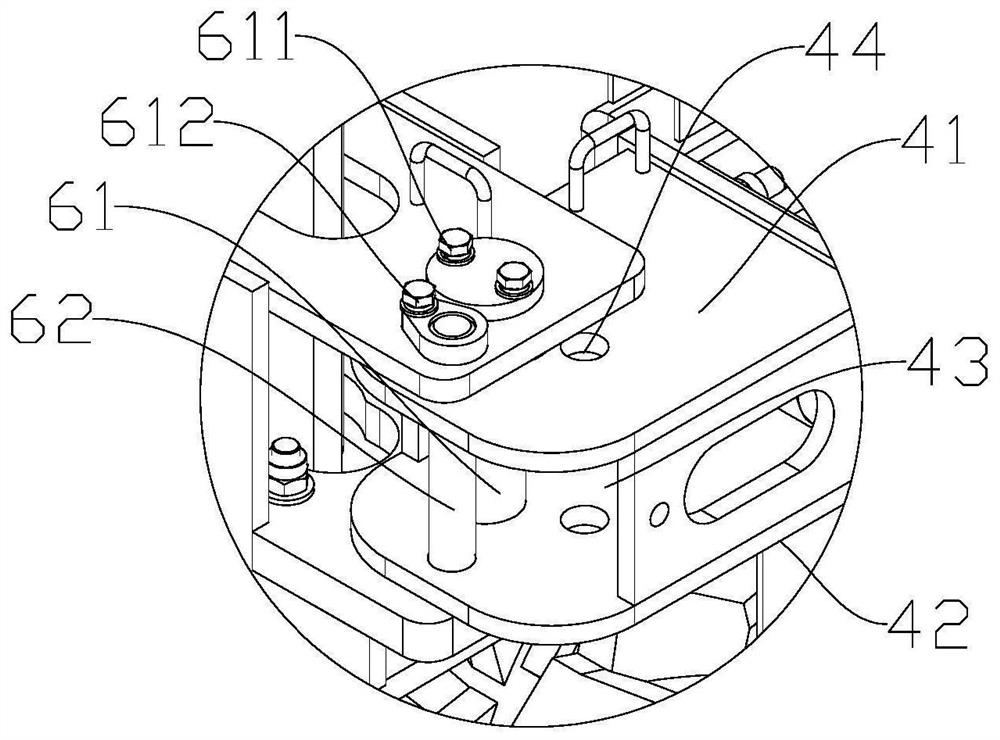

[0024] refer to Figure 1 to Figure 4 As shown, a crawler scissors forklift with detachable legs of the present invention includes a chassis mechanism 1, a fork frame mechanism 2, and a main working platform mechanism 3 arranged sequentially from bottom to top, and the chassis mechanism 1 is provided with walking crawlers. , the fork frame mechanism 2 is an existing scissor mechanism. In addition, the present invention also includes: a mounting seat 4, a leg seat 5, a pin assembly 6, and a leg body 7. The mounting seat 4 includes an upper end surface 41, Install the lower end face 42; the leg seat 5 is installed on the chassis mechanism 1 through the mounting seat 4, the leg seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com