Dust removal system for alumina powder production workshop

A production workshop and alumina powder technology, which is applied in air conditioning systems, air humidification systems, heating and ventilation control systems, etc., can solve problems such as inconvenient maintenance, achieve the effects of improving quality, reducing floating time, and increasing air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

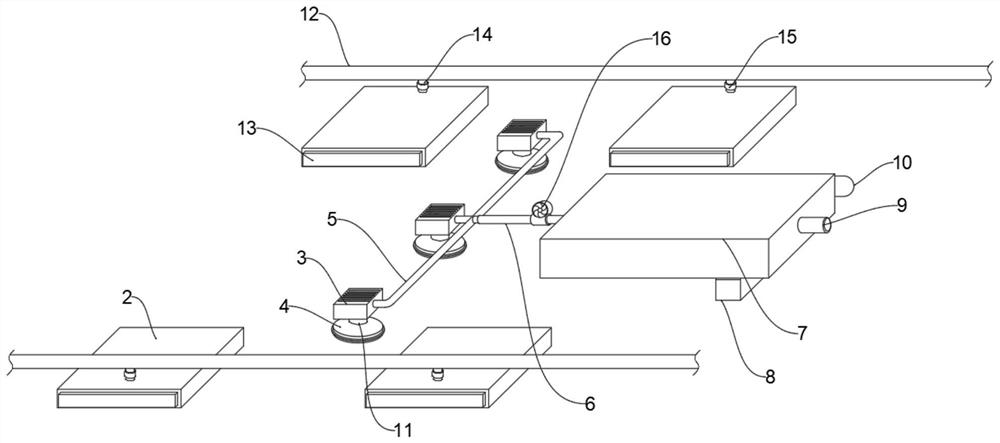

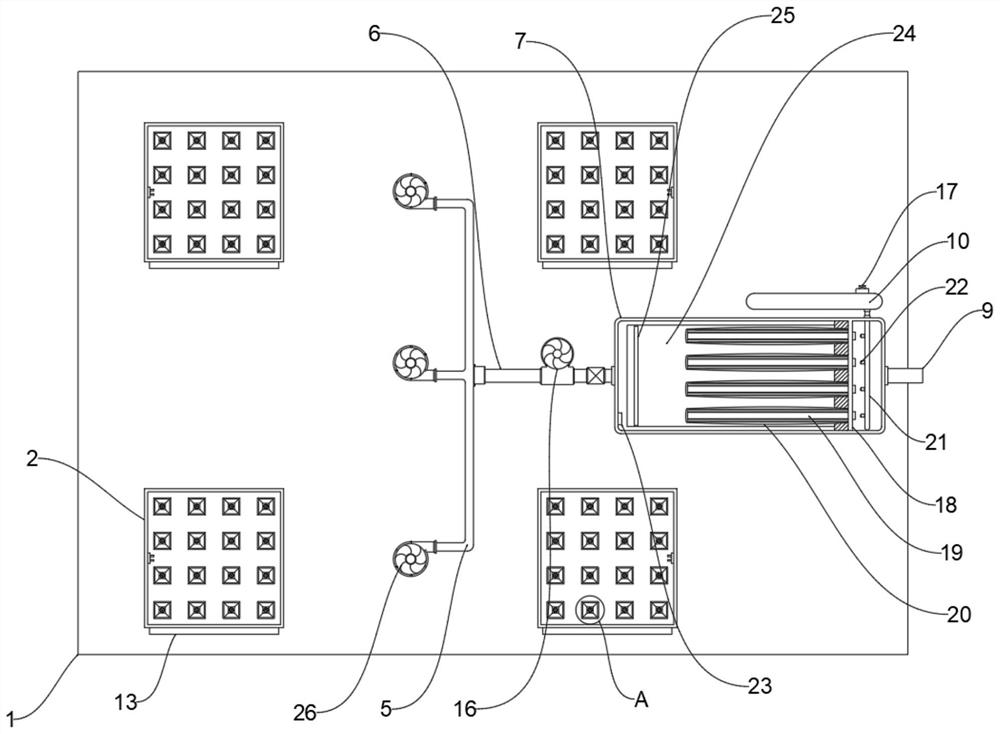

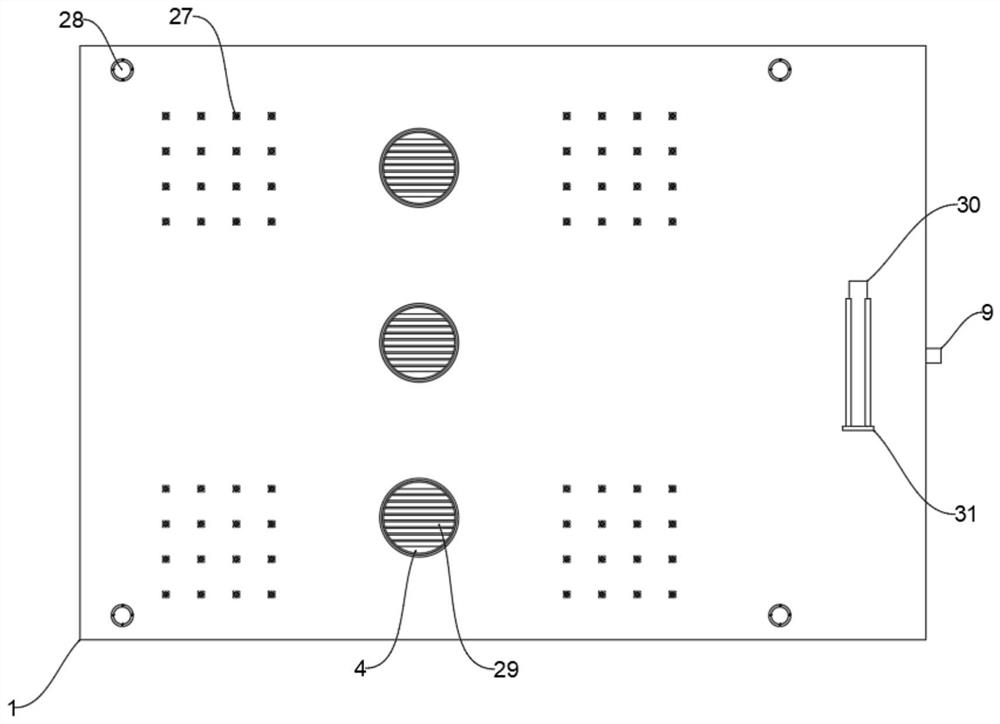

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0031] see Figure 1-8 , an embodiment provided by the present invention: a dust removal system for an alumina powder production workshop, including a workshop roof 1, and atomization and humidification modules 2 are installed at the four corners of the bottom of the workshop roof 1, and the atomization and humidification modules 2 are connected to the workshop roof 1 Fixed by bolts, the interior of the atomization humidification module 2 is provided with a number of rectangularly distributed atomization tanks 32. The interior of the atomization tanks 32 is equipped with piezoelectric ceramic microporous atomizing sheets 33, and the bottoms of the atomization tanks 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com