Cross type ultrasonic temperature measuring pipe section body structure and method

A temperature-measuring tube, cross-type technology, applied in the field of cross-type ultrasonic temperature-measuring pipe segment structure, can solve the problems of high processing precision, high assembly conditions, high manufacturing cost, etc., and achieve the effect of reducing the number and measuring multiple sound paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

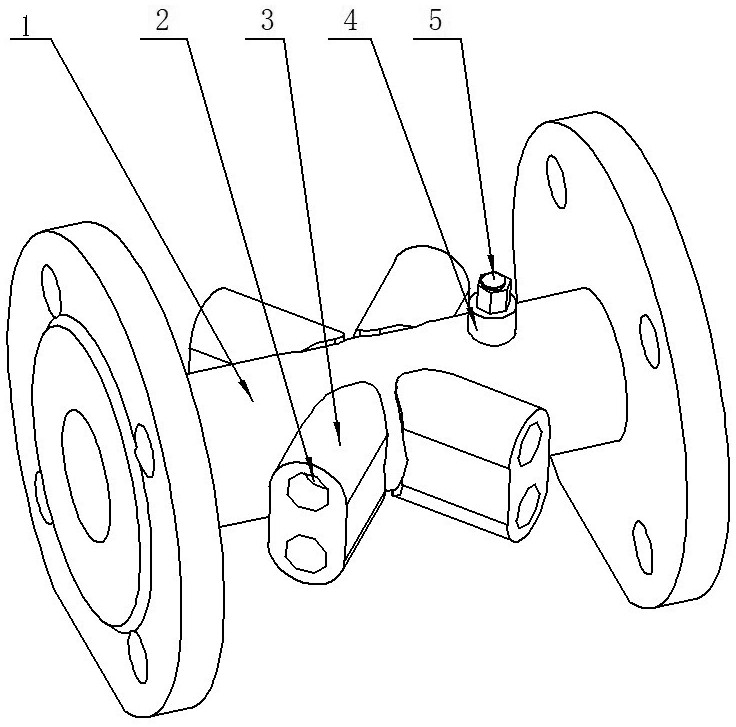

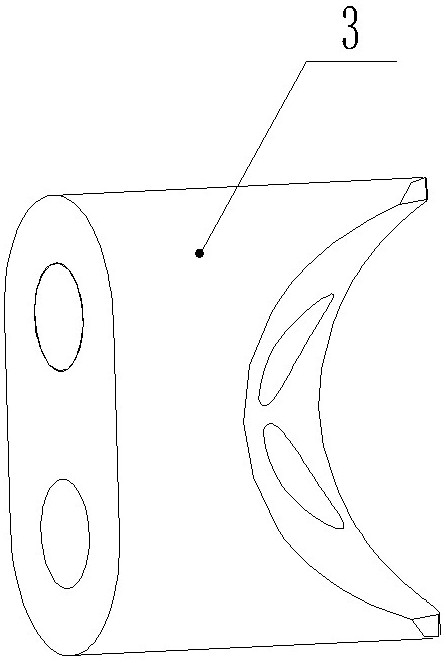

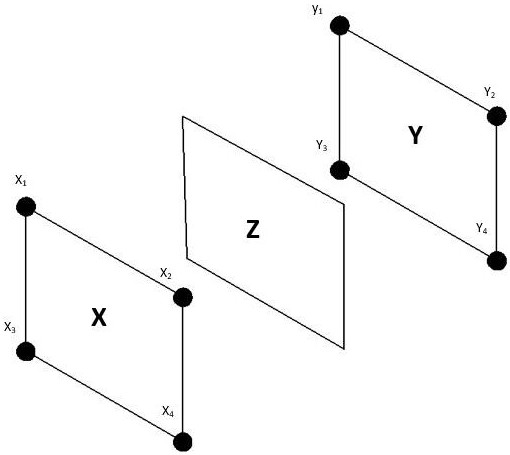

[0030] A cross-type ultrasonic temperature measurement pipe section body structure, comprising a pipe section body 1, a probe mounting seat 3, a probe 2, a temperature sensor 5, and a temperature sensor mounting seat 4; the pipe section body 1 is provided with a probe mounting seat 3 and a temperature sensor mounting seat 4, The probe 2 and the temperature sensor 5 are installed on the probe mounting base 3 and the temperature sensor mounting base 4 respectively; the probe mounting base 3 is provided with a mounting hole, and there is an angle between the center line 6 of the mounting hole and the horizontal line 7, which are not parallel to each other; There are multiple probes, which are divided into upstream probes and downstream probes according to their arrangement positions; the number of upstream probes is equal to the number of downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com