Grinding device

A grinding and arc-shaped technology, applied in grain processing, application, grain pod removal, etc., to achieve the effect of improving the rate of embryo retention, improving the degree of embryo retention and reducing food loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

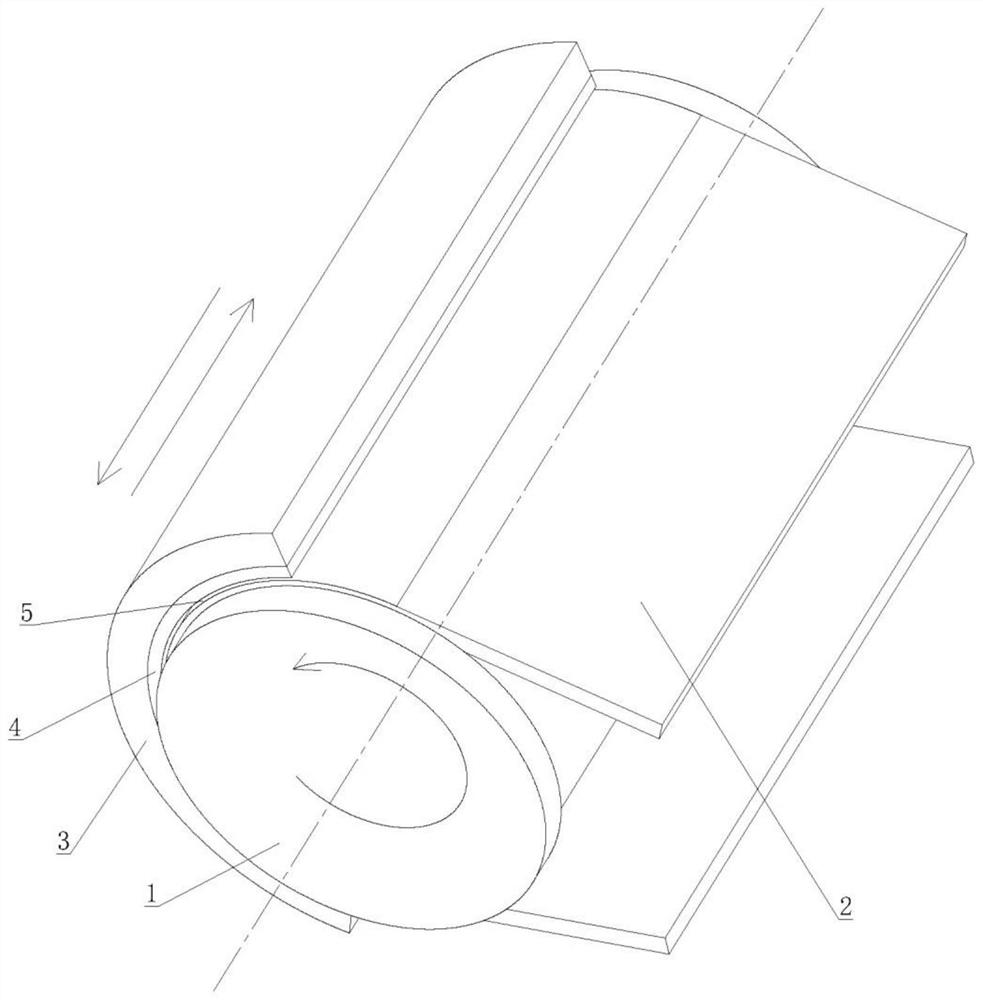

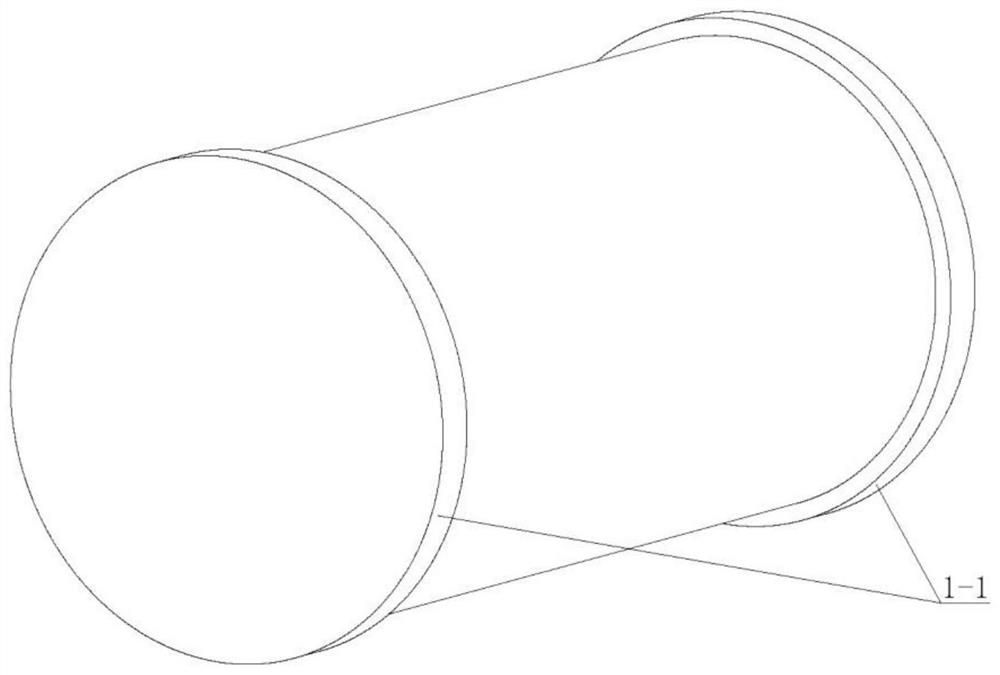

[0020] Such as figure 1 , This embodiment includes a roller 1, a grinding belt 2, a grinding plate support seat 3, an arc-shaped grinding plate 4, and a grinding chamber 5. Such as figure 2 , Both ends of the roller 1 are provided with ribs 1-1, the grinding belt 2 is set on the roller 1, and the ribs 1-1 limit the movement of the grinding belt 2 along the axis of the roller 1. The inner surface of the arc-shaped grinding plate 4 is an arc-shaped cylindrical surface, and its axis coincides with the axis of the roller 1, and the outer surface of the arc-shaped grinding plate 4 is fixed with the grinding plate support seat 3. The gap between the inner surface of the arc-shaped grinding plate 4 and the grinding belt 2 forms a grinding chamber 5 .

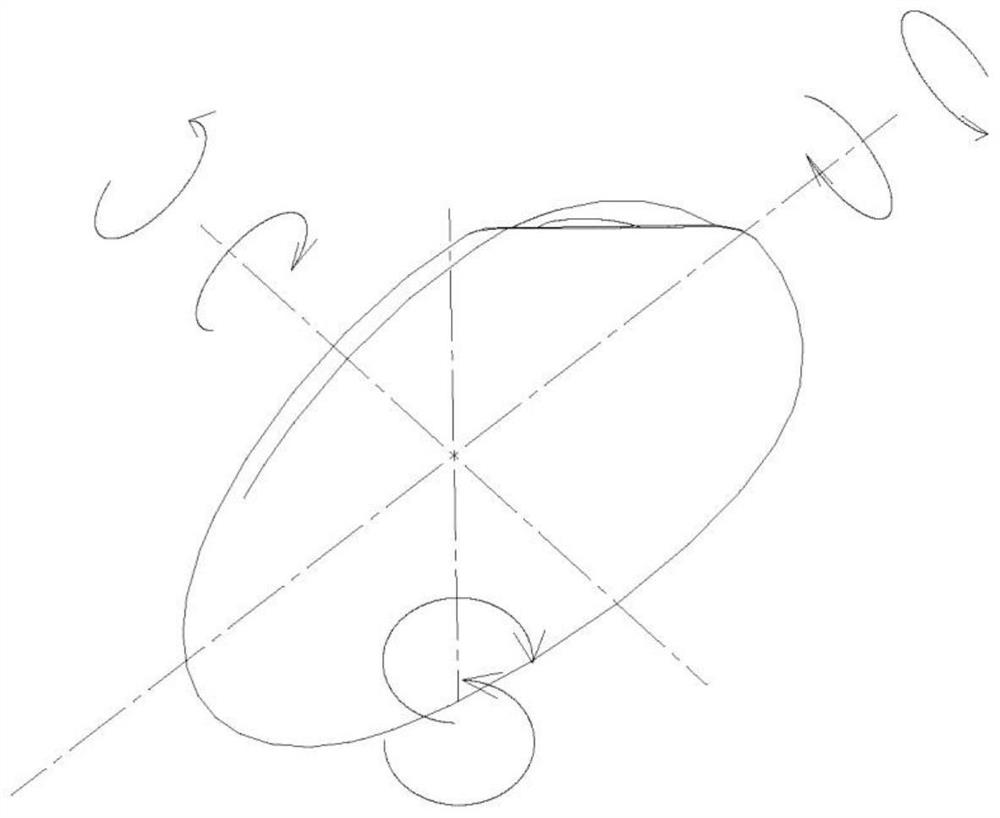

[0021] Such as figure 1 , the roller 1 rotates around the direction of the arrow, the part of the grinding belt 2 in contact with the roller makes a circular motion, and at the same time, the arc-shaped grinding plate 4 moves back ...

Embodiment approach 2

[0024] The arc-shaped grinding plate 4 in Embodiment 1 is set as rubber, which is elastic and has the same properties on the arc-shaped cylindrical surface, which can ensure that each grain of brown rice can be subjected to sufficient grinding pressure. The hardness of the rubber is smaller than that of the brown rice. When the brown rice moves in the grinding chamber 5, it will not be subjected to rigid force and impact, the broken rice rate of the product is significantly reduced, and the germ retention rate and germ retention degree are significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com