Automatic rubber coating equipment

A glue-covering and automatic technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding feed movement, etc., can solve the problems of high labor intensity, prolonging the production cycle, and poor economic benefits, and shorten the production cycle , stable production quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

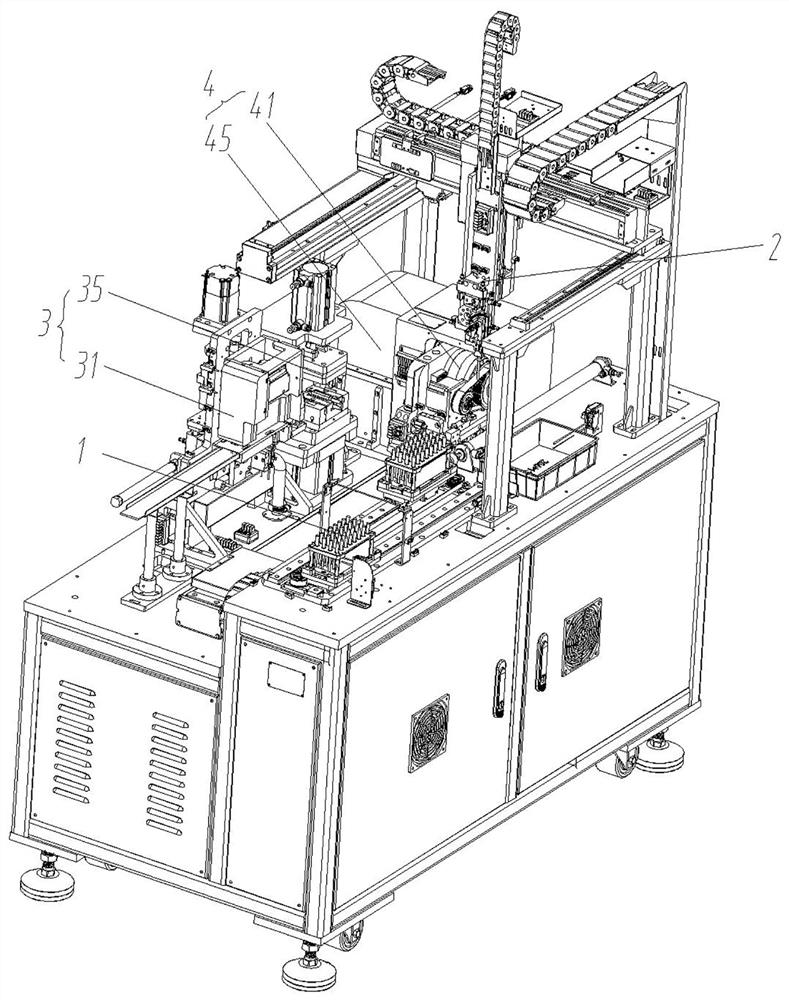

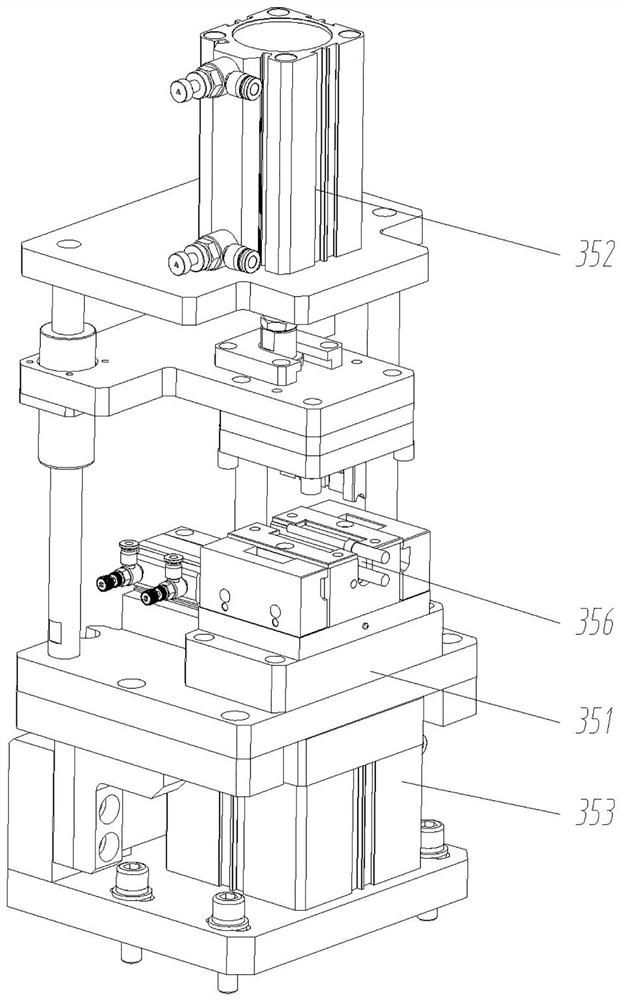

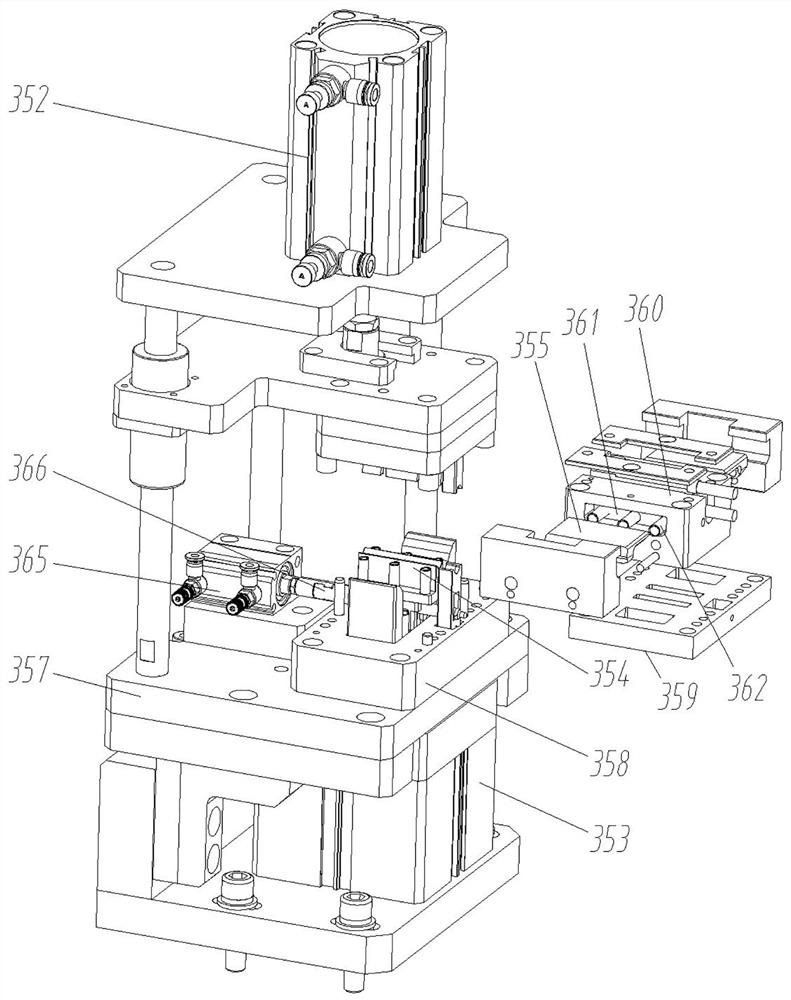

[0029] Such as Figure 1 to Figure 13As shown, in this embodiment, the present invention includes an iron core conveying mechanism 1, a product loading and unloading mechanism 2, an automatic rubber wrapping mechanism 3 and a rubber grinding mechanism 4, the iron core conveying mechanism 1 and the product loading and unloading mechanism 2 Matching, the automatic rubber wrapping mechanism 3 and the rubber grinding mechanism 4 are matched, the automatic rubber wrapping mechanism 3 and the rubber polishing mechanism 4 are all matched with the product loading and unloading mechanism 2, and the iron core The conveying mechanism 1 is used for feeding the iron core, the automatic rubber wrapping mechanism 3 is used for wrapping the iron core, and the rubber grinding mechanism 4 is used for rubber polishing the iron core covered with glue, and the product loading and unloading The mechanism 2 is used to transfer the iron core on the iron core conveying mechanism 1 to the automatic enc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap