Totally-closed sound barrier

A sound barrier and closed technology, which is applied in the direction of construction and noise absorption devices, can solve the problems of increasing the safety risk of the sound barrier, increasing the cost of the use of the sound barrier, and not having fire protection performance, so as to avoid casualties and property losses. Excellent energy absorption and anti-collision performance, remarkable effect of sound absorption and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

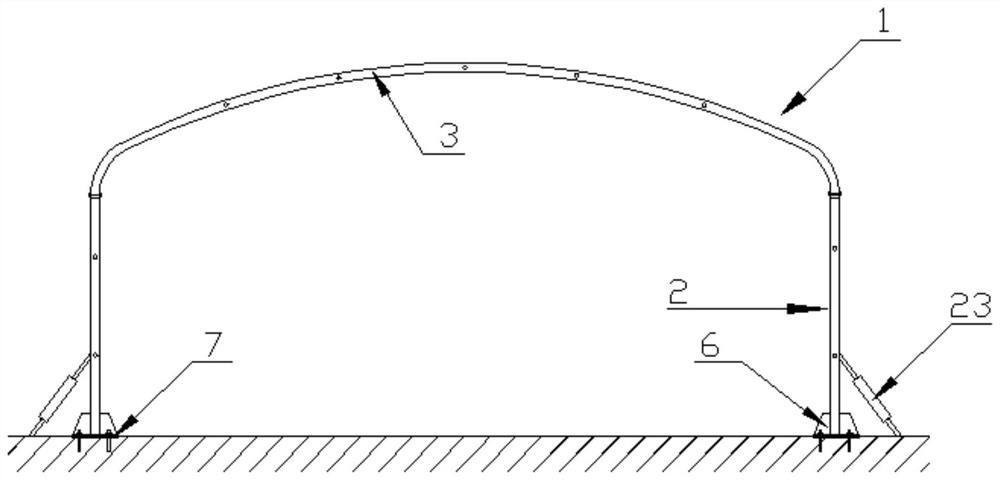

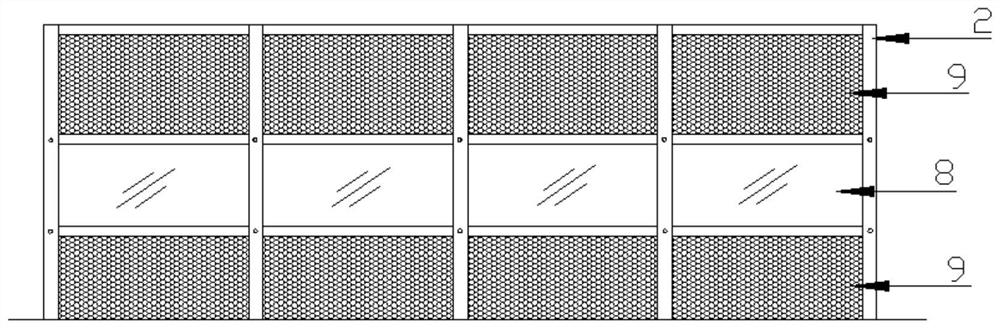

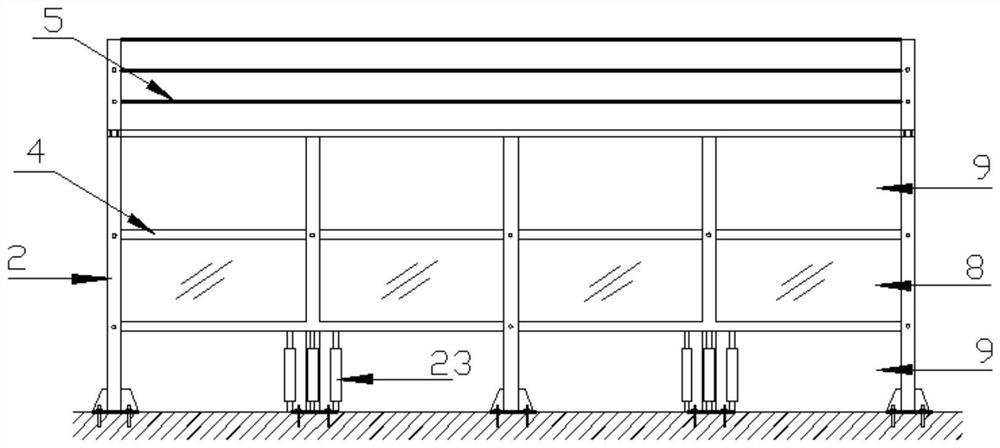

[0045] It can be seen from the accompanying drawings that it is a fully enclosed sound barrier. The sound barrier includes a group of door-shaped frames 1 fixed to the ground foundation in sequence. Column 2, the top of two H-shaped steel columns 2 is connected with an arched H-shaped steel top beam 3, and three sets of beams Ⅰ4 are fixed horizontally between the front and rear adjacent H-shaped steel columns 2, and the front and rear adjacent H-shaped steel top beams 3 There are five sets of crossbeams II5 fixed horizontally; the bottom of the H-shaped steel column 2 is provided with an installation base 6, and a vibration-damping rubber pad 7 is provided between the installation base 6 and the ground foundation, and the installation base 6 and the ground foundation are fixedly connected by bolts;

[0046] There is a set of transparent sound barrier panels 8 between the front and rear adjacent H-shaped steel columns 2, and the multiple sets of transparent sound barrier panels ...

Embodiment 2

[0052] It can be seen from the accompanying drawings that the difference between this embodiment and Embodiment 1 is that there are three support columns 29 vertically arranged inside the sound barrier, and the three support columns 29 are respectively fixed on the first, third and fifth door-shaped frames. 1, the top of the support column 29 is fixedly connected to the H-shaped steel roof beam 3, and the bottom of the support column 29 is fixedly connected to the ground foundation; the near top of the support column 29 is fixed with a beam III30 horizontally, and both ends of the beam III30 are connected to the H-shaped steel top beam. The beam 3 is fixedly connected;

[0053] Below the crossbeam III30, there are two reinforcing beams 31 inclined downwards. The two reinforcing beams 31 are located on both sides of the support column 29 respectively. One end is connected to the shock-absorbing end of the shock-absorbing device II32, the fixed end of the shock-absorbing device ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap