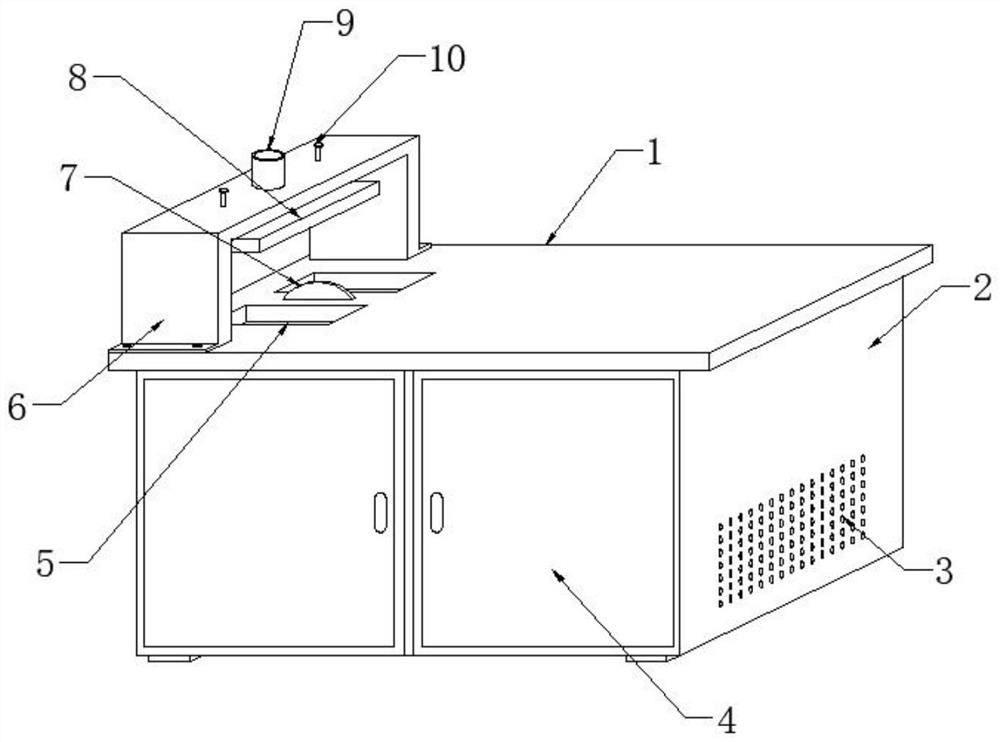

Fiberboard material production equipment with recovery function

A technology for production equipment and fiberboard, which is applied in the field of fiberboard material production equipment, and can solve the problem of no collection of limit board powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

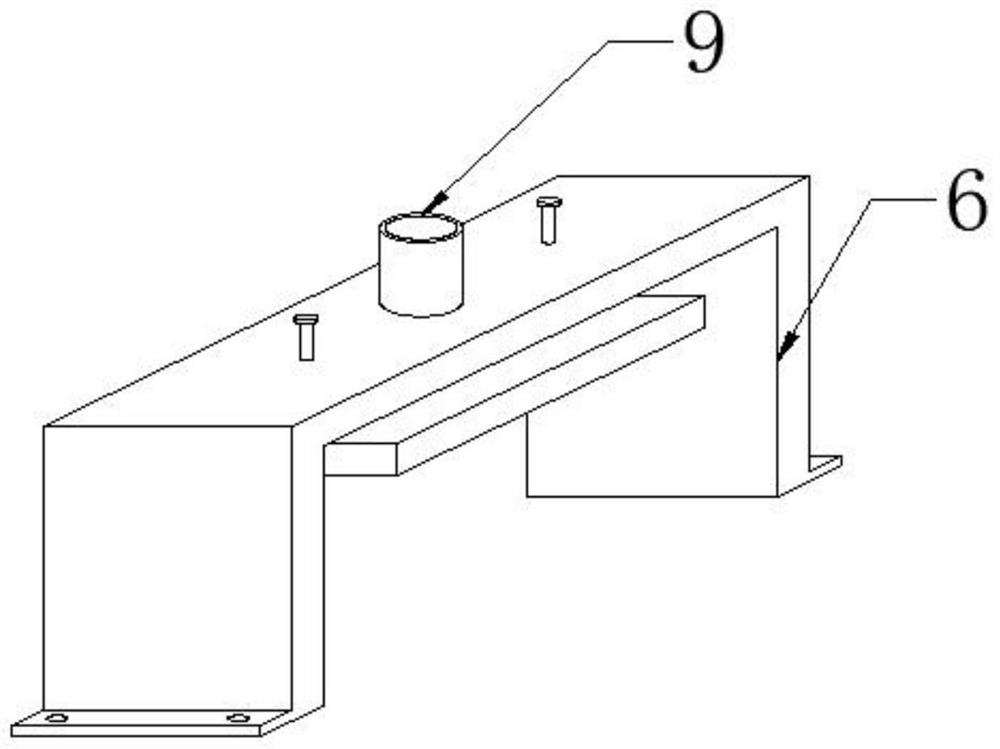

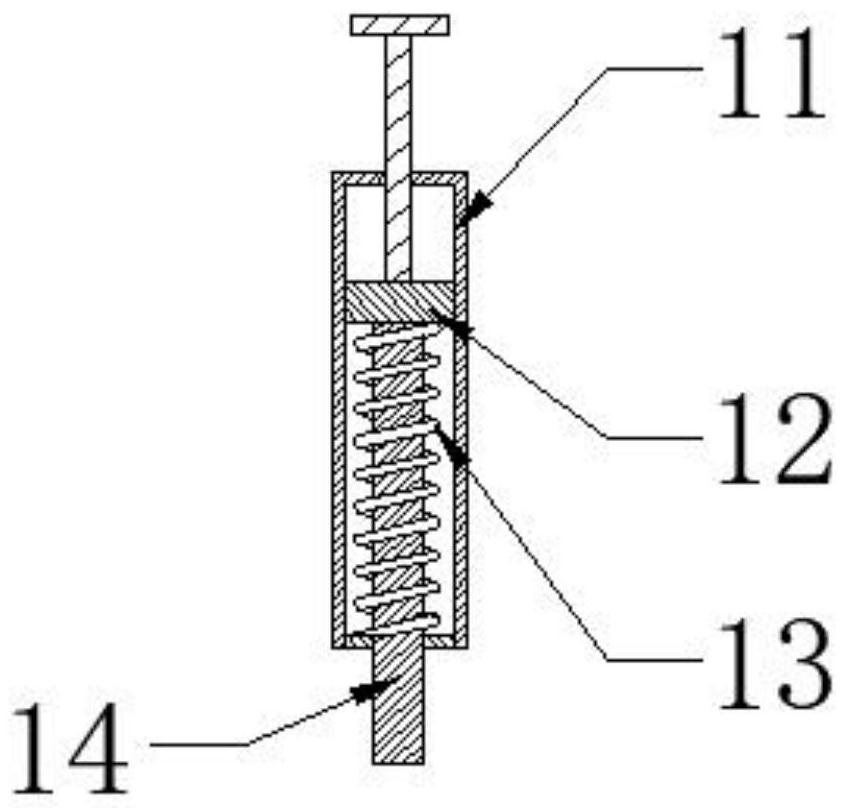

[0023] Specific implementation method: when in use, first install the fixed frame 6 on the left side of the upper end surface of the processing table 1, connect the discharge pipe 9 with the external suction device, and then turn the adjusting screw 10, and the adjusting screw 10 passes through The rotation drives the adjustment block 12 to move downward, thereby realizing the adjustment rod 14 located on the lower side of the adjustment block 12 to move downward, and then driving the suction frame 8 fixed with the adjustment rod 14 to move to a position close to the processing table 1, Then the purpose of adjusting the distance between the suction frame 8 and the plate is achieved, and under the action of the spring 13, the adjustment screw 10 moves upward, and then the adjustment block 12 moves upward under the action of the spring 13, so as to achieve the purpose of adjusting the suction frame 8 The purpose of moving to the upper side is to start the drive motor, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com