Energy storage striking device and mechanical remote brake system

A release mechanism and locking mechanism technology, applied in the direction of valve device, mechanical equipment, valve operation/release device, etc., can solve the problems such as the large force required for the brake handle, the risk of overrunning, and the untimely action, etc., to achieve Improve the response speed of equipment failure, reduce the number of directly involved personnel, and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0053] The mechanical remote brake system of the present invention is used to remotely brake the steam-driven pump, avoiding problems and various safety risks caused by manual brakes performed by staff at close range.

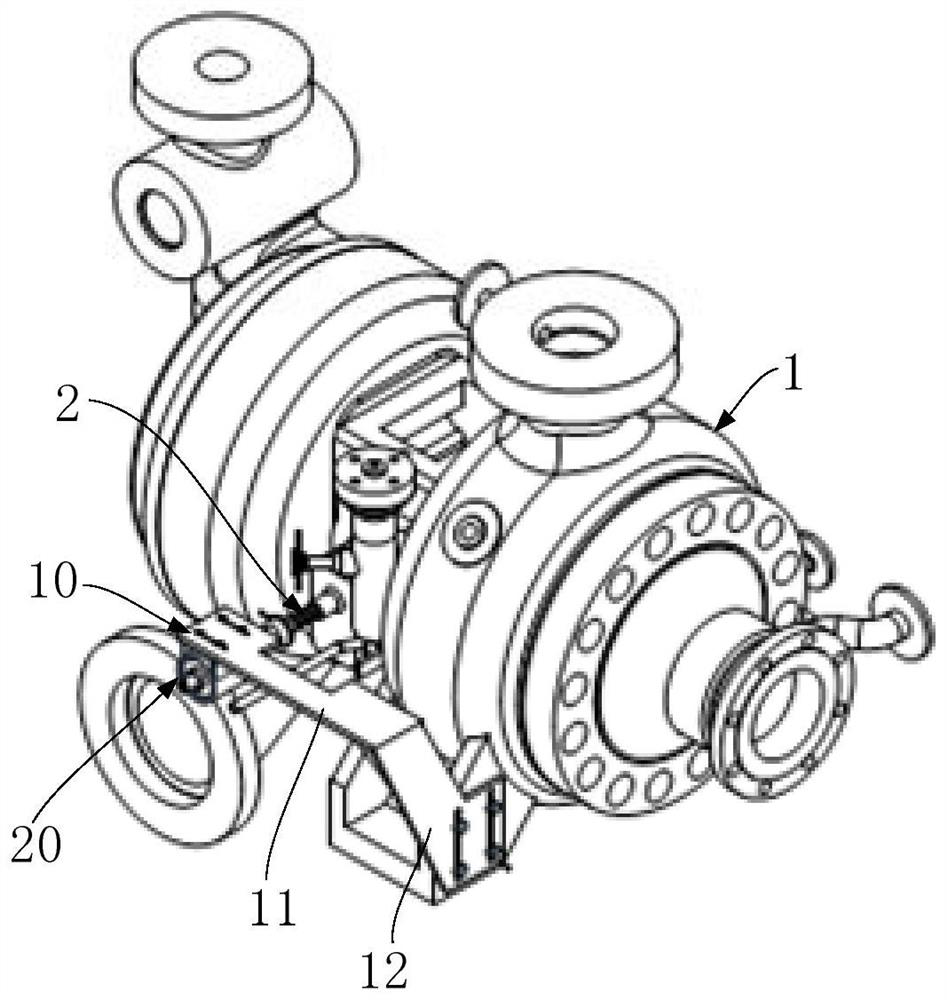

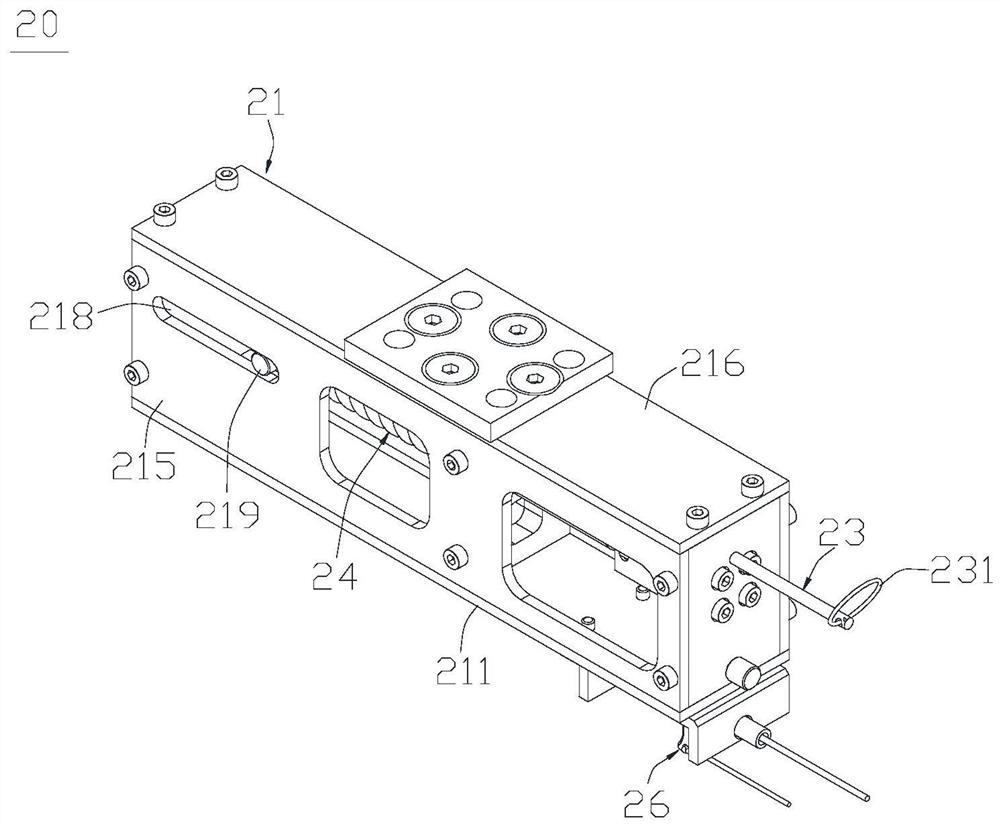

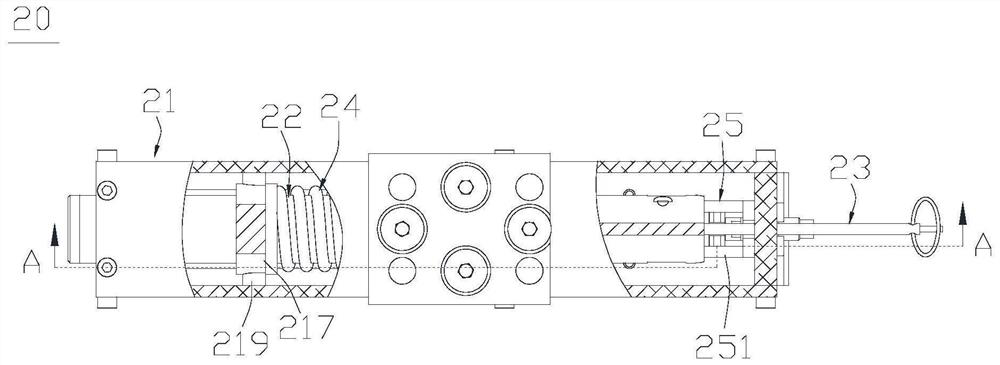

[0054] like figure 1As shown, the mechanical remote braking system of the present invention may include a mounting bracket 10 installed on the pump body 1 of the turbopump, an energy storage striking device 20 fixed on the mounting bracket 10, and an energy storage striking device 20 Connected gravitational transmission lines (not shown). On the mounting bracket 10 , the energy storage striking device 20 is directly opposite to the brake handle 2 on the pump body 1 , and the distance between the two is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com