Multi-stage automatic production line for agricultural product processing

A technology for agricultural product processing and automatic production line, which is applied to heating devices, lighting and heating equipment, dry goods handling, etc. It can solve problems such as inability to separate, poor quality of agricultural product powder, affecting manual operation, etc., and achieve the effect of improving the utilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

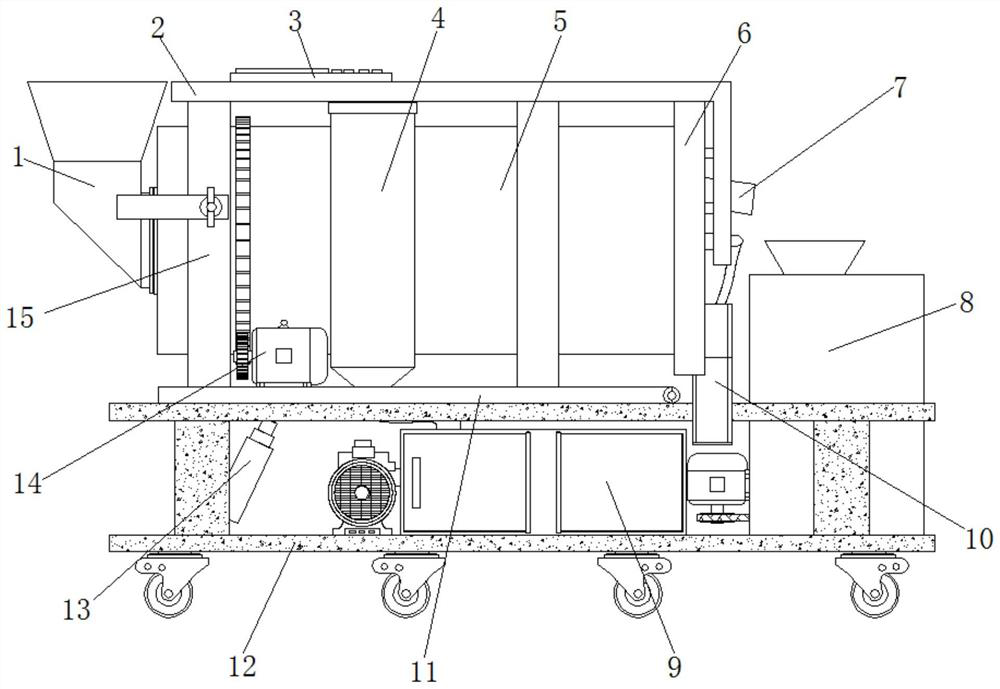

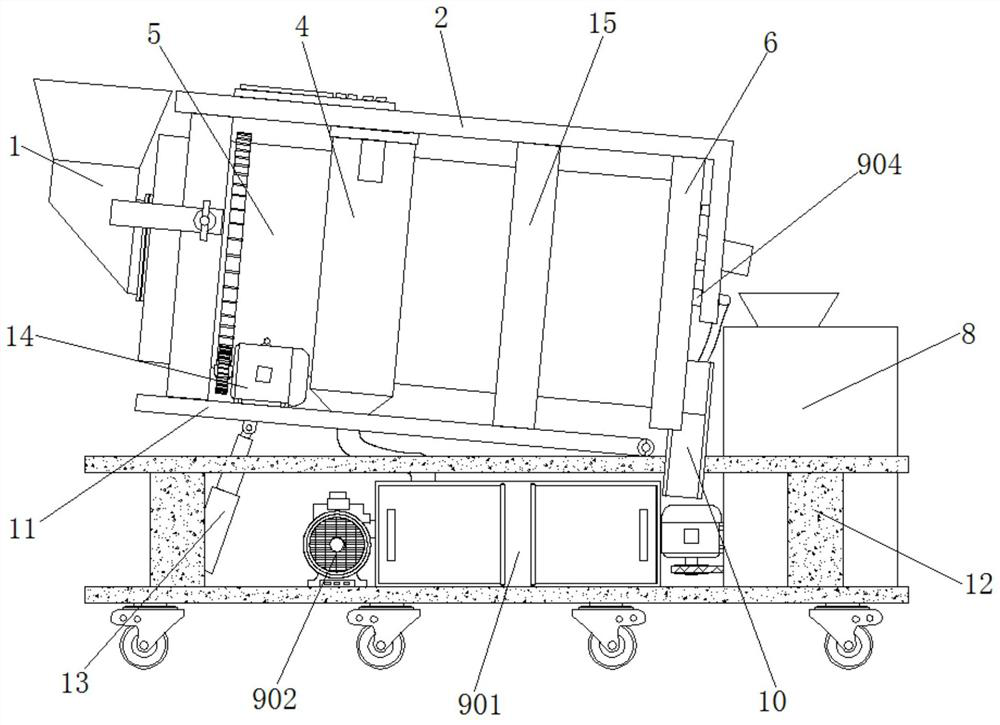

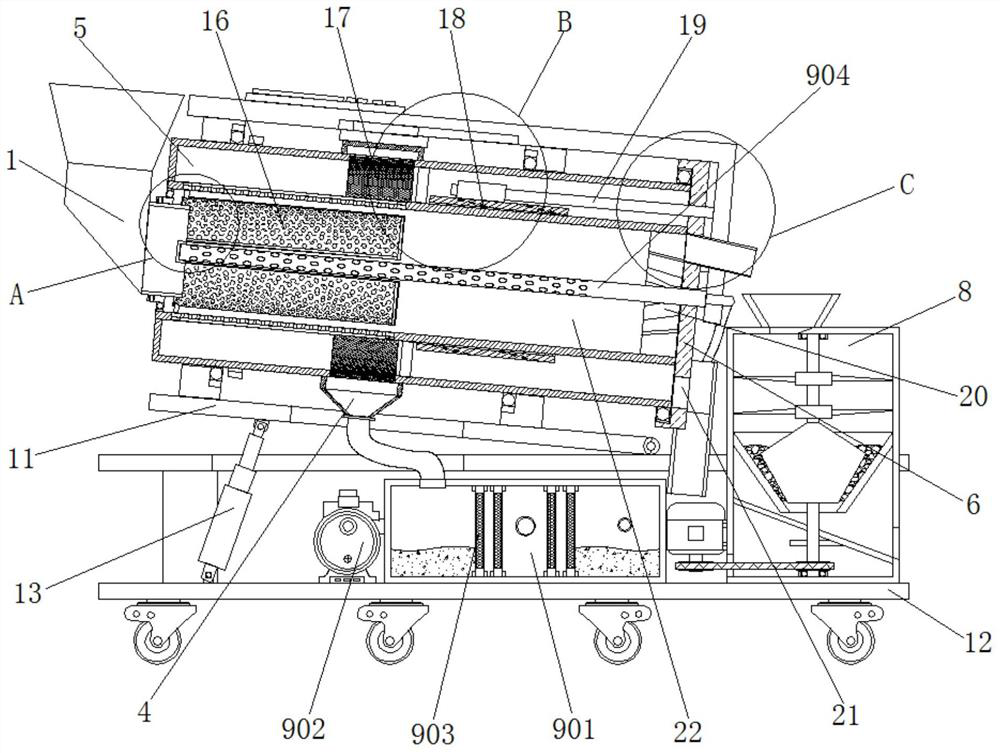

[0044] Example 1, as Figure 1-9 As shown, when the agricultural products need to be dedusted, the filter chamber 901 is controlled to inhale the inside of the outer drum 5 and the inner drum 22. During the tumbling process of the agricultural products in the inner drum 22, the dust flying around the inner drum 22 passes through the air intake in turn. The hole 905, the installation pipe 904 and the connecting pipe enter the interior of the filter bin 901, and the curved screen 16 sieves the tumbling agricultural products. The inferior particles in the agricultural products are smaller than those on the curved screen 16 The holes gradually enter the interior of the outer drum 5, and the dust that is not flying will also enter the interior of the outer drum 5 through the screen holes of the arc-shaped screen 16, and then the defective agricultural products are mixed with the dust inside the outer drum 5. Rolling and moving, when the inferior particles of agricultural products p...

Embodiment 2

[0045] Example 2, as Figure 1-9 As shown, when the filtered intact agricultural product particles need to be input into the powder beater 8, it is only necessary to wait until the red-dried intact agricultural product particles inside the inner drum 22 are completely moved to the inner drum 22. The intact agricultural product particles will gradually enter the inside of the discharge bin 20 at the bottom, and when the inner drum 22 rotates, it will also drive multiple groups of discharge bins 20 to rotate together. At the top of the discharge bin 20, the intact agricultural product particles inside the discharge bin 20 will be discharged through the discharge chute 7 and directly fall into the feeding port of the powder beater 8, and then when the set of discharge bins 20 is rotated to the bottom again, the inner drum 22. The intact agricultural product particles inside will then refill the set of discharge bins 20 , so that the intact agricultural product particles in the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap