A method for replacing and removing impurities by zinc sulfate solution and its purification tank

A technology of zinc sulfate solution and purification tank, which is applied in the direction of improving process efficiency, etc., can solve the problems of low activity of zinc powder, separation, and small particle size difference of copper and cadmium slag, so as to ensure replacement capacity, ensure chemical activity, and remove copper Cadmium Cobalt Thorough Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

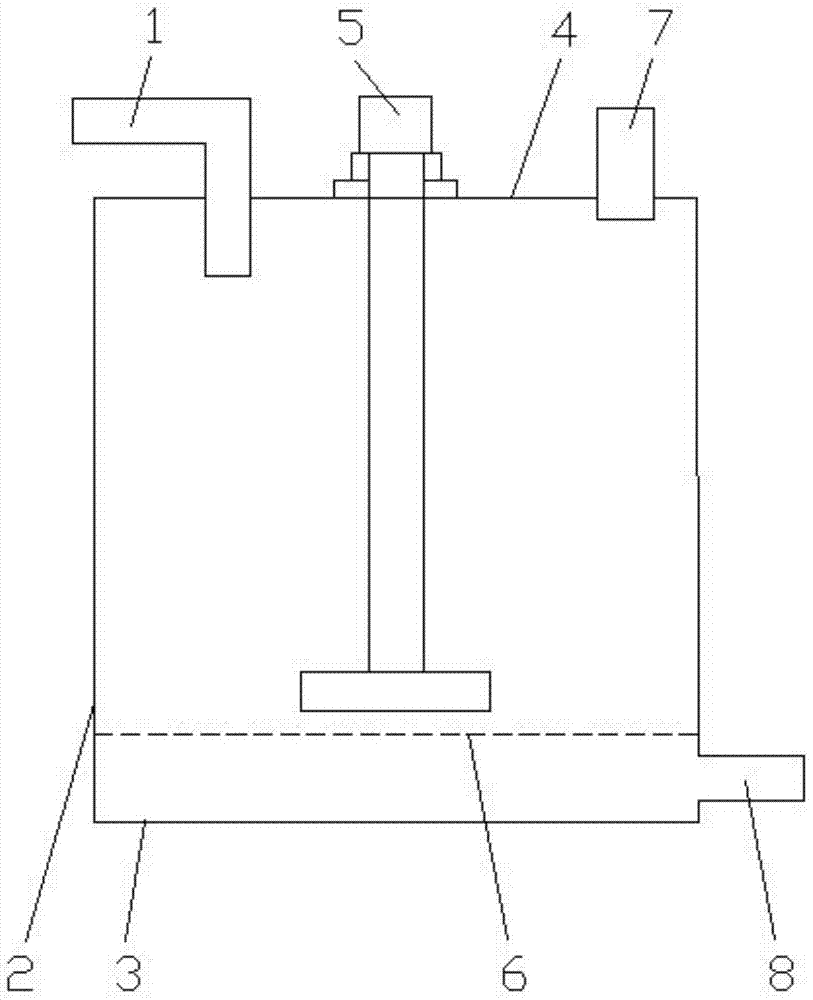

[0034] Such as figure 1 As shown, it includes liquid inlet pipe 1, purification tank tank wall 2, purification tank tank bottom 3, purification tank cover plate 4, mixer 5, exhaust pipe 7 and liquid outlet pipe 8, and the purification tank tank wall 2, purification tank The tank bottom 3 and the septic tank cover 4 form the septic tank body, and the septic tank wall 2, the septic tank bottom 3 and the septic tank cover 4 form the septic tank body, which is a reinforced concrete structure with a thickness of 300mm. The lining thickness is 50mm with anti-corrosion tiles, the internal size of the tank is Φ3.6m×H4.0m, and the total volume is 40.7m 3 , the effective volume is 35m 3 .

[0035] The agitator 5 includes a motor, a support, a stirring shaft and a stirring paddle, the motor and the support are centered on the cover plate 4 of the purification tank, the stirring shaft and the stirring paddle are all located in the center of the purification tank body, and the mixer 5 T...

Embodiment 2

[0043] Such as figure 1 As shown, it includes liquid inlet pipe 1, purification tank tank wall 2, purification tank tank bottom 3, purification tank cover plate 4, mixer 5, exhaust pipe 7 and liquid outlet pipe 8, and the purification tank tank wall 2, purification tank The tank bottom 3 and the septic tank cover 4 form the septic tank body, and the septic tank wall 2, the septic tank bottom 3 and the septic tank cover 4 form the septic tank body, which is a reinforced concrete structure with a thickness of 300mm. The lining thickness is 50mm with anti-corrosion tiles, the internal size of the tank is Φ4.6m×H5.0m, and the total volume is 83.0m 3 , the effective volume is 70m 3 .

[0044] The agitator 5 includes a motor, a support, a stirring shaft and a stirring paddle, the motor and the support are centered on the cover plate 4 of the purification tank, the stirring shaft and the stirring paddle are all located in the center of the purification tank body, and the mixer 5 T...

Embodiment 3

[0054] Such as figure 1 As shown, it includes liquid inlet pipe 1, purification tank tank wall 2, purification tank tank bottom 3, purification tank cover plate 4, mixer 5, exhaust pipe 7 and liquid outlet pipe 8, and the purification tank tank wall 2, purification tank The tank bottom 3 and the septic tank cover 4 form the septic tank body, and the septic tank wall 2, the septic tank bottom 3 and the septic tank cover 4 form the septic tank body, which is a reinforced concrete structure with a thickness of 300 mm. The lining thickness is 50mm with anti-corrosion tiles, the internal size of the tank is Φ4.6m×H5.0m, and the total volume is 83.0m 3 , the effective volume is 70m 3 .

[0055] The agitator 5 includes a motor, a support, a stirring shaft and a stirring paddle, the motor and the support are centered on the cover plate 4 of the purification tank, the stirring shaft and the stirring paddle are all located in the center of the purification tank body, and the mixer 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap