Metal pipe fitting bending equipment

A technology for metal pipe fittings and equipment, applied in the field of metal pipe bending equipment, can solve the problems of displacement, difficult to adjust the bending angle, affecting the shape and angle of the bending pipe, and achieve the effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

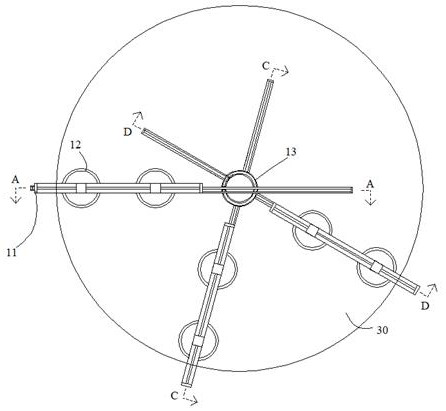

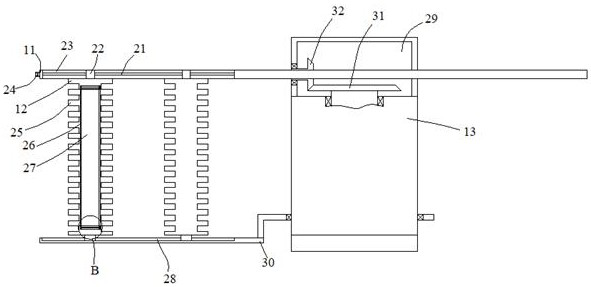

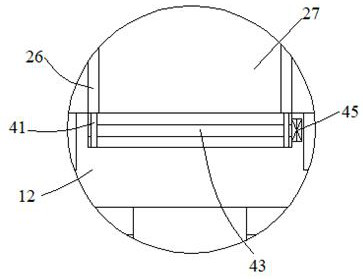

[0019] Such as Figure 1-Figure 5 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. A metal pipe bending equipment of the present invention includes a matching box 13, and the outer surface of the matching box 13 is rotated. An outer bracket 30 is arranged inside the outer bracket 30. There are several bottom chute 28, the opening of the bottom chute 28 is provided, and three boxes 11 are provided for sliding in the matching box 13, and there is a gap between the box 11 and the outer support 30 for pipe material The placing device placed therebetween, the said matching box body 13 is provided with a driving device that simultaneously makes the said box body 11 extend and retract into the said matching box body 13 .

[0020] Beneficially, wherein, the placeme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap