Vacuum heat preservation and moisture preservation sealing tank and using method thereof

A technology of vacuum insulation and sealed tanks, which is applied in the direction of sealing, heat preservation containers, applications, etc. It can solve the problems of water loss, bad experience for guests, loss of towel temperature, etc., and achieve the effect of improving the sense of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

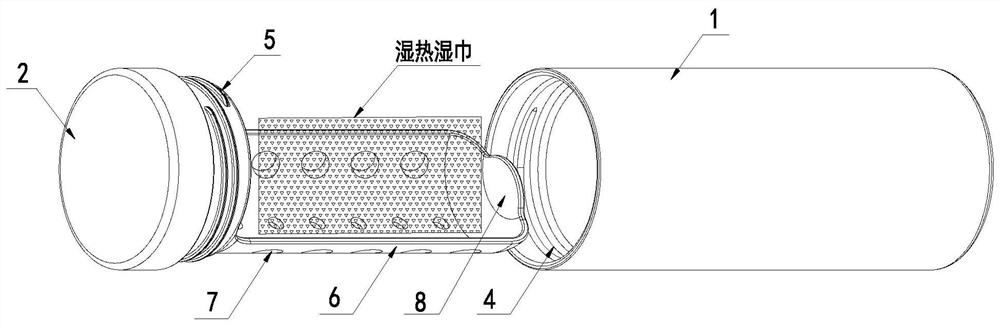

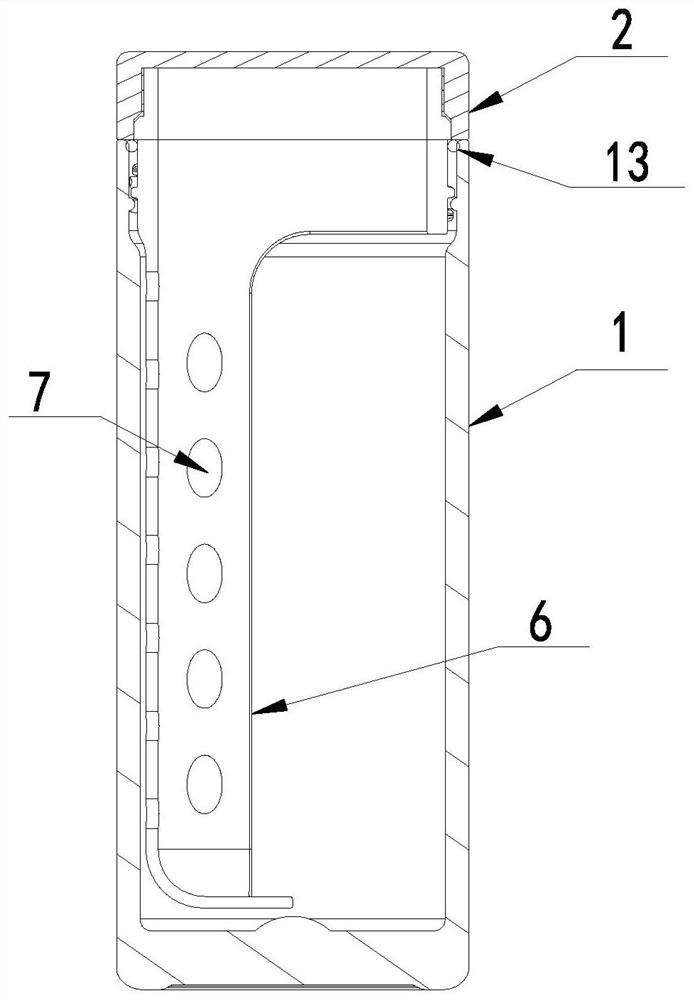

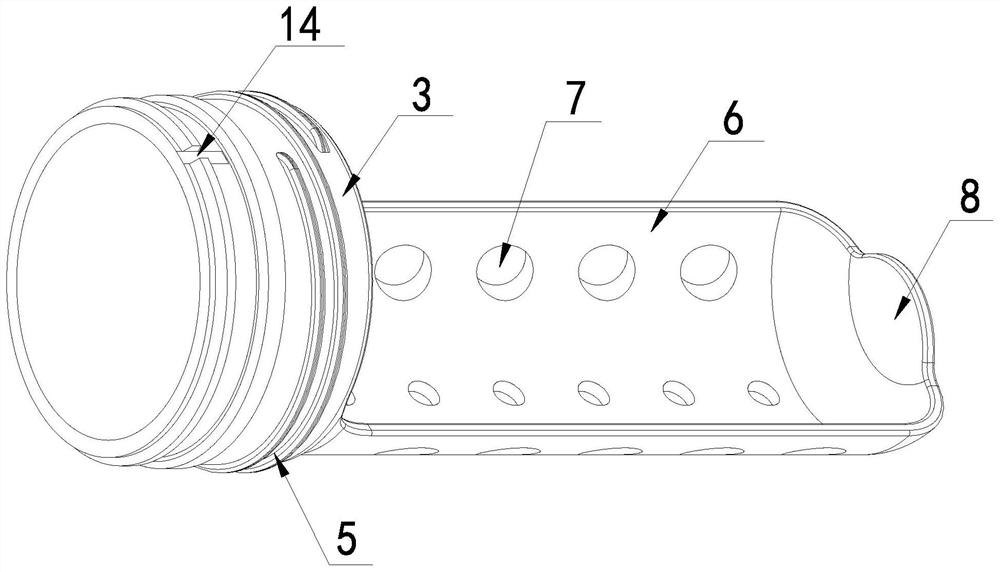

[0047] Embodiment 1: The preferred structure of the towel fixing assembly is a towel drag bucket 6 with a drag bucket structure, the top of the towel drag bucket 6 is fixed on the bottom end of the connector 3, and the outer wall of the towel drag bucket 6 is provided with a plurality of The drain through hole 7 and the end of the towel drag bucket 6 away from the connector 3 are fixedly provided with a support baffle 8 for supporting hot and humid towels.

[0048] In this embodiment, when the preferred structure of the towel fixing assembly is a towel drag bucket 6 in a bucket-like structure, the method for using the vacuum heat preservation and moisturizing sealed tank includes the following specific steps:

[0049] S1: Fold the hot and humid towel after heating and humidification into a strip shape or a cylindrical shape, and put it into the towel drawer 6;

[0050] S2: Grasp the towel drag bucket 6, then insert the wet and hot towels into the tank body 1 together, then tur...

Embodiment 2

[0053] Embodiment 2: The preferred structure of the towel fixing assembly is a towel hook 9 in a hook-shaped structure, and the top end of the towel hook 9 is fixed on the bottom end of the connector 3 .

[0054] In this embodiment, when the preferred structure of the towel fixing assembly is a towel hook 9 in a hook-shaped structure, the method for using the vacuum heat preservation and moisturizing sealed tank includes the following specific steps:

[0055] S1: Fold the hot and humid towel after heating and humidification into a strip shape or cylindrical shape, and then hang the carrying ring on the hot and humid towel on the towel hook 9;

[0056] S2: Hold the tank body 1 with one hand, hold the sealing cover 2 with the other hand, put the damp and hot towel into the tank body 1, turn the tank body 1 or the sealing cover 2, and use the principle of screw teeth to make the sealing cover 2 and the tank body 1 Close to each other and produce a pressing force on the sealing ri...

Embodiment 3

[0059] Embodiment 3: The preferred structure of the towel fixing assembly is a towel fixing fork 10 in a fork-like structure. The towel fixing fork 10 includes three support columns 11 arranged parallel to each other and spaced apart from each other. The top ends of the three support columns 11 are fixed on the connector 3, the bottoms of the three support columns 11 are all fixed on the same horizontal support column 12, and the overall length of the horizontal support column 12 is greater than the arrangement width of the three support columns 11.

[0060] In this embodiment, when the preferred structure of the towel fixing assembly is a towel fixing fork 10 in a fork-like structure, the method for using the vacuum heat preservation and moisture sealing tank includes the following specific steps:

[0061] S1: Roll the hot and humid towel on the outer surface of the towel fixing fork 10 evenly after heating and humidifying;

[0062] S2: Hold the tank body 1 with one hand, hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com