Diaphragm compressor gas side leakage guide hole device

A technology of diaphragm compressors and guide holes, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve problems such as production stop loss, leaking pressure instruments, and labor hours loss, and achieve the effect of extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

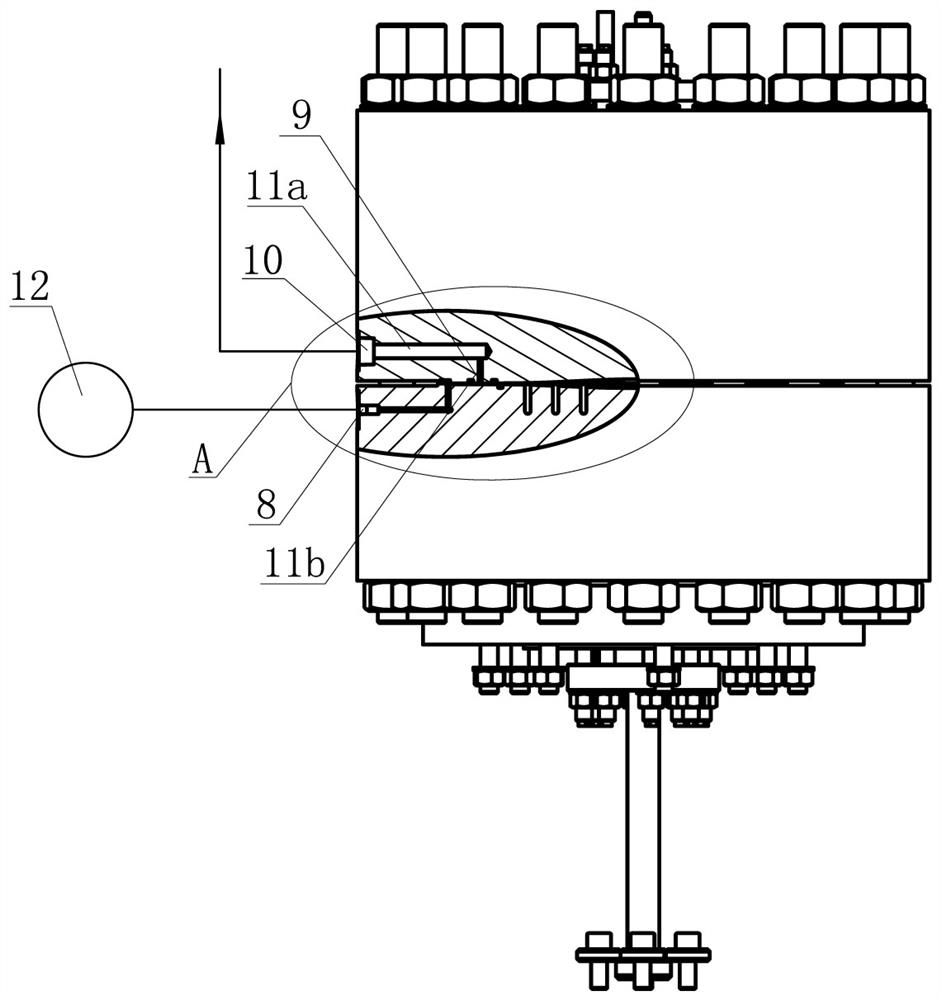

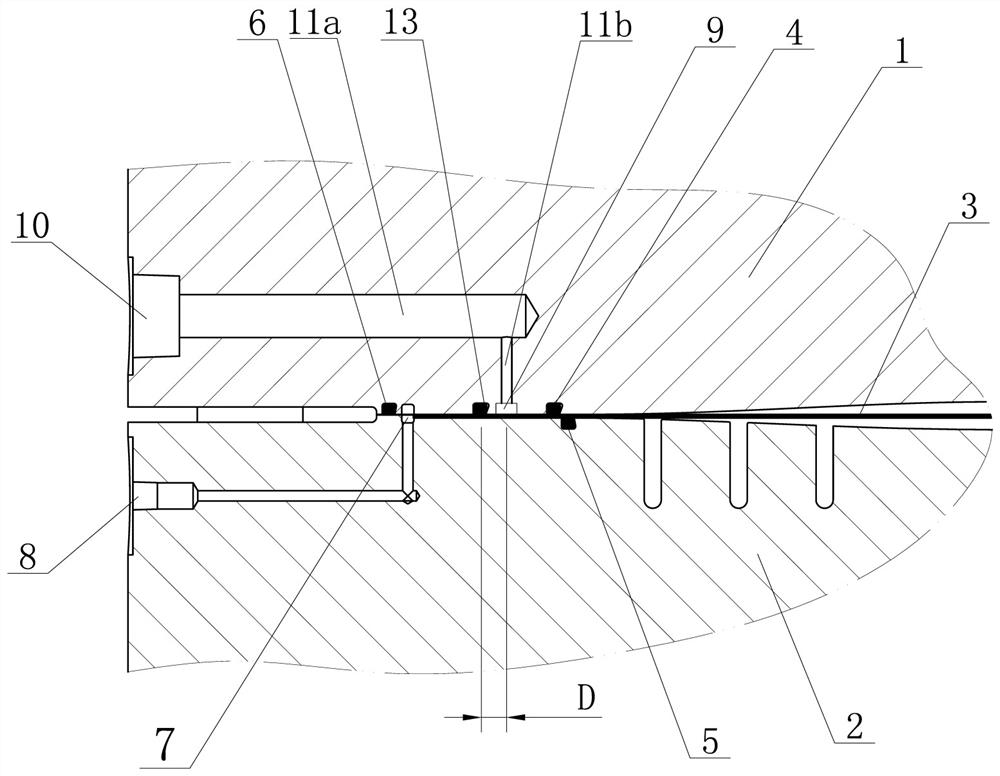

[0018] The diaphragm compressor gas side leakage guide hole device described in this embodiment, such as figure 1 with image 3 As shown, the air pan 1 and the oil pan 2 of the diaphragm compressor are included. A diaphragm 3 is provided between the air pan 1 and the oil pan 2. The air pan 1 and the diaphragm 3 are connected to form a closed air cavity. The oil pan 2 and the membrane The plates 3 are connected to form a closed oil chamber, an air disc sealing ring 4 is provided on the contact surface between the air disc 1 and the diaphragm 3, and an oil pan sealing ring 5 is provided on the contact surface between the oil pan 2 and the diaphragm 3 . On one side of the air pan 1, there is an air pan leakage converging groove 9, and the air pan leakage converging groove 9 communicates with the air pan leakage interface 10 through a guide hole. The guide hole is divided into a radial guide hole 11a and an axial guide hole 11b, and the radial guide hole 11a The two ends of the ...

Embodiment 2

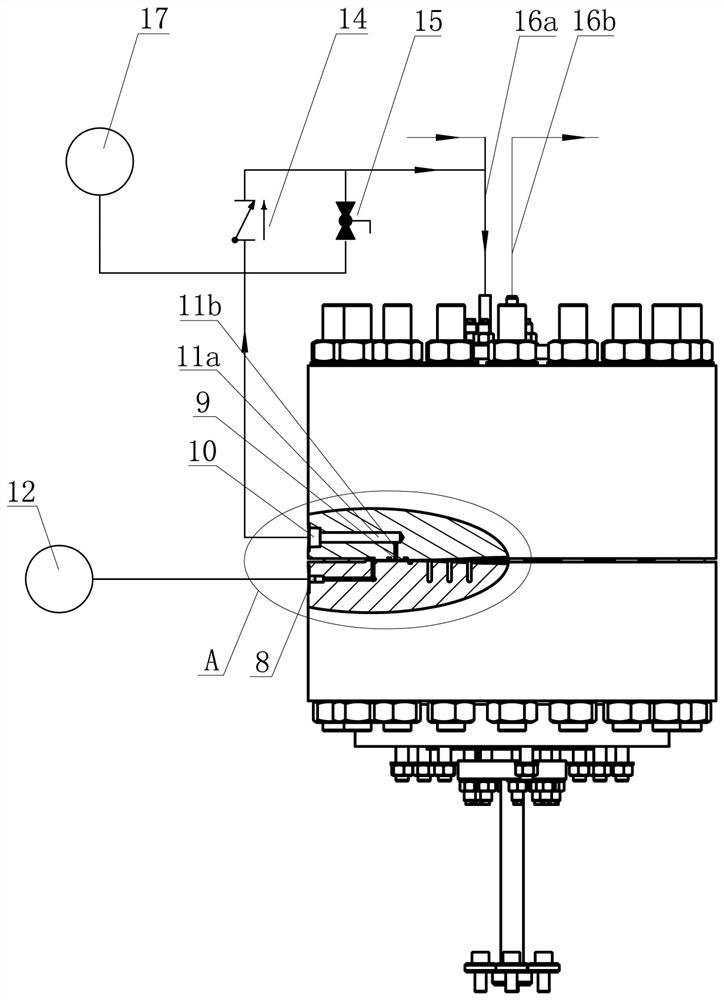

[0024] The gas-side leakage guide hole device of the diaphragm compressor described in this embodiment is an improvement to Embodiment 1 on the basis of Embodiment 1, such as figure 2 with image 3 As shown, the gas pan leakage interface 10 of the device is connected with a pressure gauge 17, and according to the reading of the pressure gauge 17, it can be judged whether there is leakage on the gas pan side. The air disc leakage interface 10 is connected to the input port of the one-way valve 14, and the output port of the one-way valve 14 is connected to the intake line 16a of the diaphragm compressor, and the diaphragm compressor also includes the exhaust line 16b of the diaphragm compressor. When the pressure of the leaked gas at the side of the air disc is higher than the gas pressure of the diaphragm compressor intake line 16a, the leaked gas will return to the diaphragm compressor intake line 16a.

[0025] Specifically, the gas disc leakage port 10 is also connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com