Ash tank capable of detecting amount of residual ash in real time

A technology of real-time detection and ash volume, which is applied in the direction of measuring devices, measuring capacity, and volume measuring instruments/methods, etc., can solve problems such as potential safety hazards, difficulties in normal supply of cement, and labor-intensive problems, achieving rapid detection and judgment, saving manpower, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

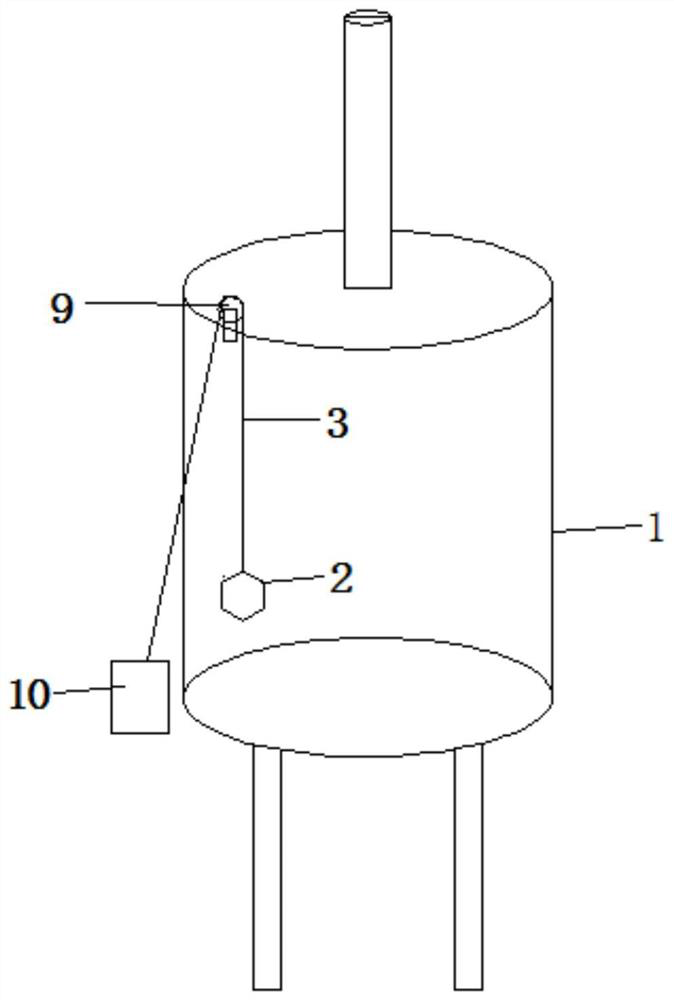

[0036] On the basis of the above structure, in this embodiment, the traction mechanism includes a rope 3 , and one end of the rope 3 passes through the top of the tank body 1 and is fixedly connected with the measuring piece 2 . During detection, the staff manually pulls the rope 3, and drives the measuring piece 2 to move up and down in the tank body 1. When the measuring piece 2 contacts the gray surface in the tank body 1, the rope 3 relaxes, and according to the outer rope 3 of the tank body 1, The length of the tank can be used to determine the position of the ash surface in the tank body 1, thereby judging the amount of ash remaining in the tank body 1, and then judging whether it is necessary to add ash to the tank body 1 to ensure normal production and easy operation.

[0037] Based on the above scheme, in order to judge the length of the rope 3 outside the tank body 1 more accurately, scale marks can be set on the rope 3 along its length direction. During detection, w...

Embodiment 2

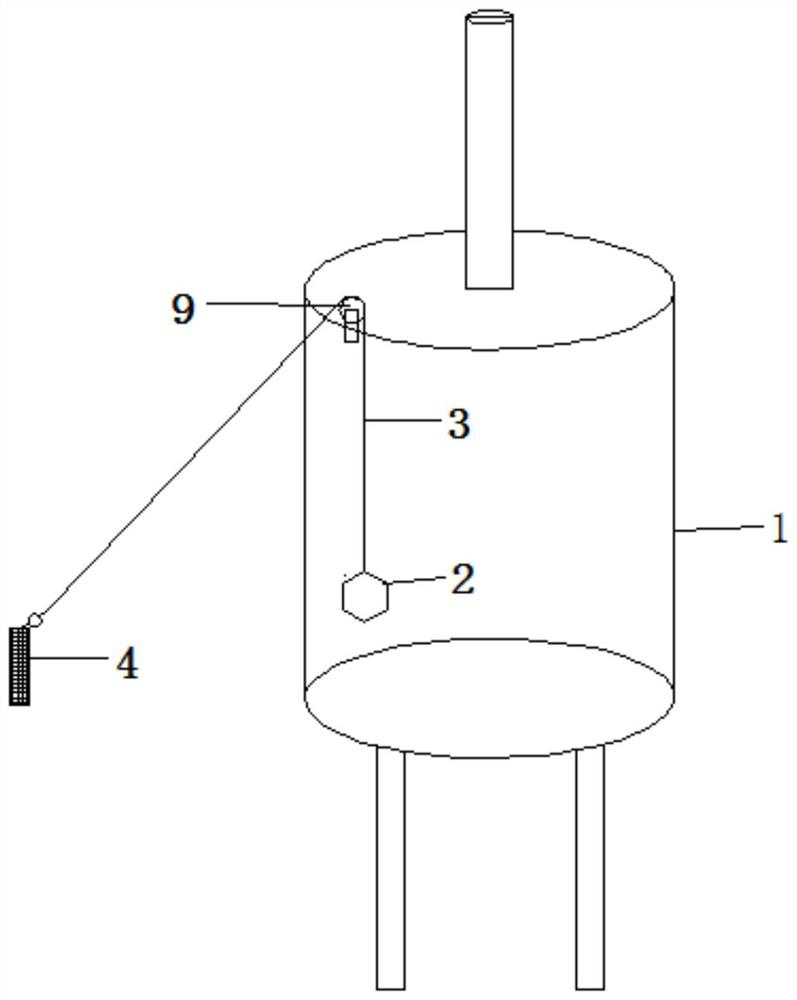

[0039] like figure 1 As shown, on the basis of Embodiment 1, in this embodiment, the other end of the rope 3 is fixedly connected with a tension gauge 4 . During detection, the staff manually pulls the tension meter 4, and drives the measuring piece 2 to move up and down in the tank body 1 through the rope 3; display on the meter 4; when the measuring piece 2 contacts the gray surface in the tank body 1, the tension of the rope 3 is zero, and the number displayed on the tension meter 4 is also zero at this moment, and according to the length of the rope 3 outside the tank body 1 Judging the position of the ash surface in the tank body 1, thereby judging the amount of remaining ash in the tank body 1, and then judging whether it is necessary to add ash to the tank body 1, so as to ensure normal production and easy operation.

[0040] Based on the above scheme, in order to judge the length of the rope 3 outside the tank body 1 more accurately, scale marks can be set on the rope...

Embodiment 3

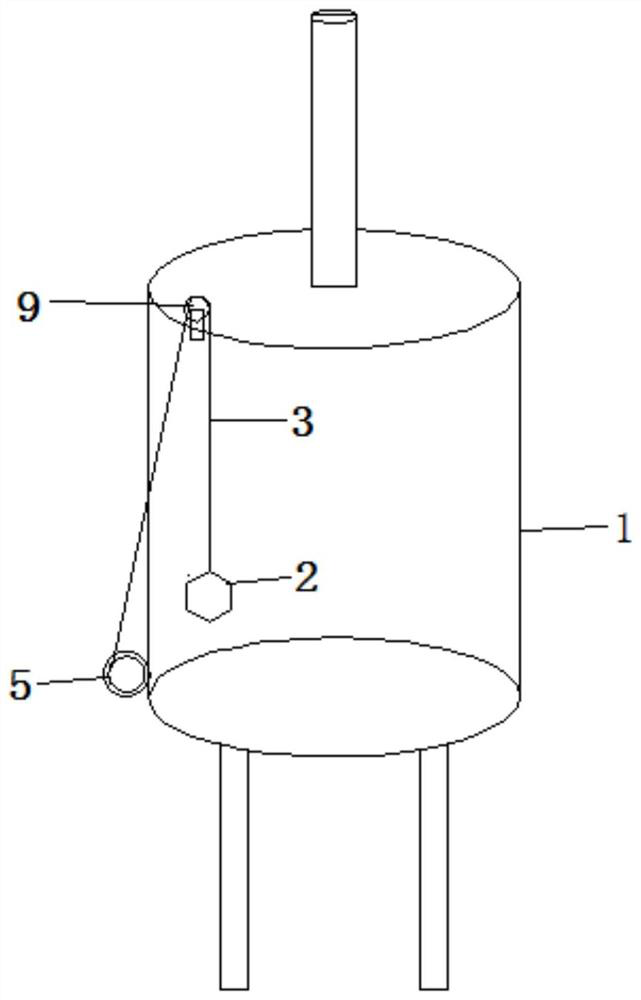

[0042] like figure 2As shown, on the basis of Embodiment 1 or Embodiment 2, this embodiment further includes a fixing member 5 which is fixedly arranged and connected to the other end of the rope 3 in a detachable manner. When testing, manually pinch the other end of the rope 3 or the tension gauge 4; when not testing, fix the other end of the rope 3 through the fixing part 5, so as to prevent the rope 3 from moving up under the action of the gravity of the measuring part 2 and cause the next During the detection, the staff cannot pull the rope 3 due to their height, so the operation is simple and convenient.

[0043] When the above-mentioned scheme is based on the basis of embodiment 1, the fixing part 5 can be fixedly installed on the support frame at the bottom of the tank body 1 at this time, so as to facilitate fixing the rope 3 and prevent the rope 3 from moving up to a relatively high position under the action of the gravity of the measuring part 2. The high position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com