Scanning equipment capable of achieving automatic marking

A technology of scanning equipment and automatic marking, applied in sorting and other directions, can solve the problems of increasing working hours, reducing efficiency, increasing working costs, etc., and achieving the effect of saving working hours, improving efficiency and saving working costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

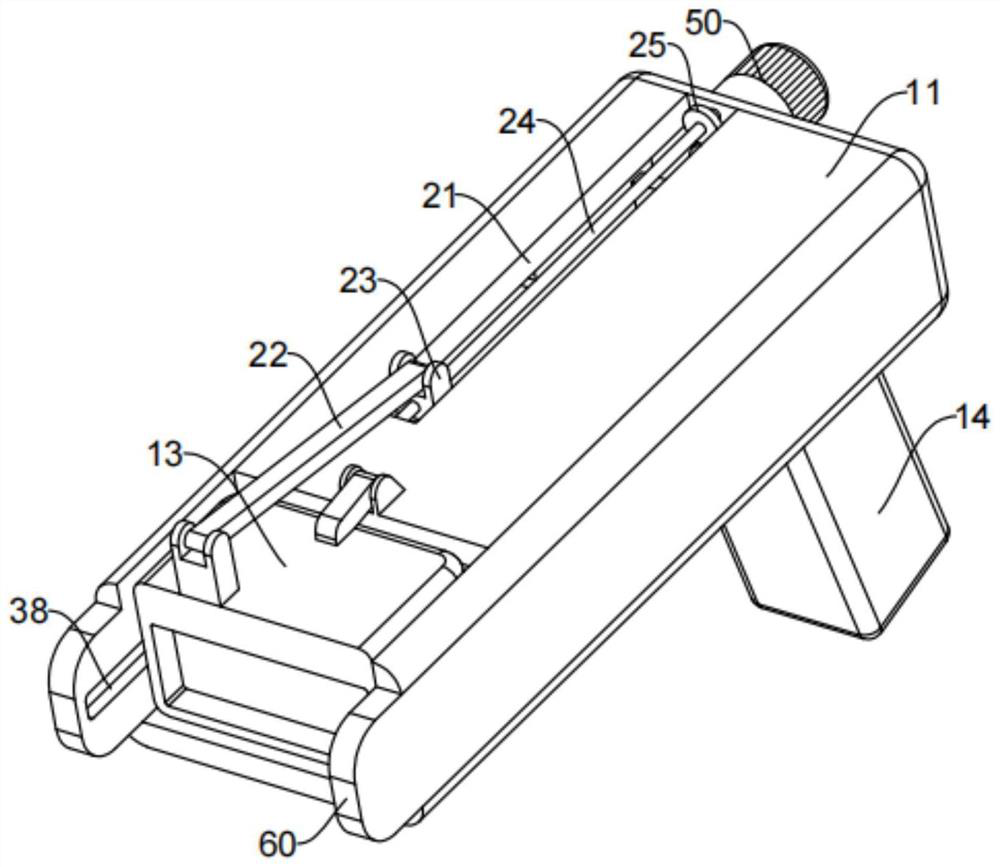

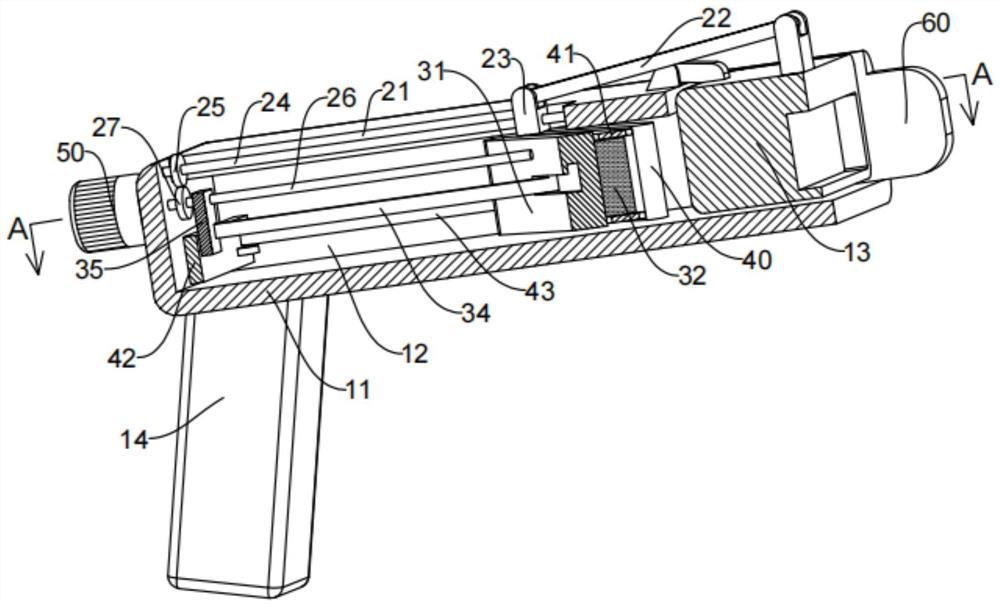

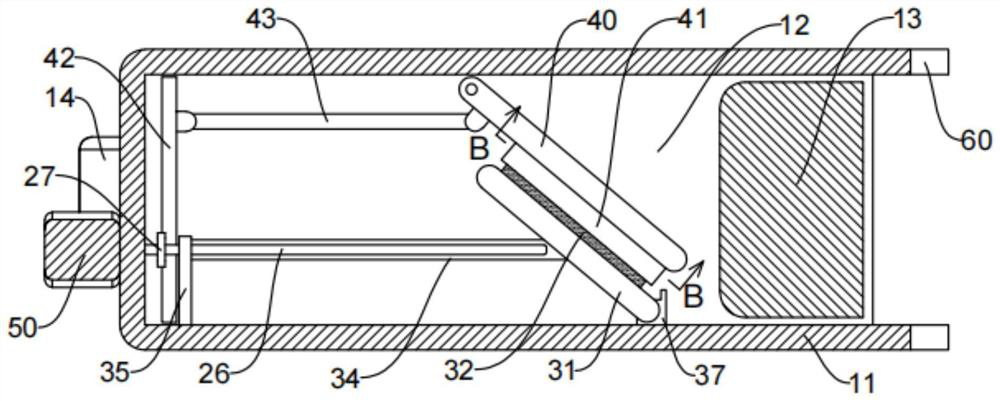

[0024] refer to Figure 1 to Figure 5 As shown, this embodiment provides a scanning device for automatic marking, which is mainly used for scanning barcodes and marking waste barcodes in logistics sorting, receiving and returning goods.

[0025] This embodiment includes a housing 11, on which a code reader 13 is hinged, and a handle 14 for holding is provided on the lower side of the housing 11, and the user holds the handle 14 to read the code The scanner 13 is aligned with the barcode to scan, and the housing 11 is provided with two positioning pieces 60 at the opening of the inner cavity 12, and the user presses the two positioning pieces 60 against both sides of the barcode for alignment. Accurate, convenient code reader 13 scans the barcode accurately and quickly.

[0026] There are generally multiple waste barcodes on a logistics receiving box. This embodiment is used to scan and mark these waste barcodes during the scanning work. At the same time, after scanning the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com