Valve port conveying and detecting assembly

A technology for detecting components and valve ports, which is applied in transportation and packaging, mechanical valve testing, transportation packaging, etc., can solve problems such as difficulty in heat sealing, damage and fracture, and failure to detect transmission failures, and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

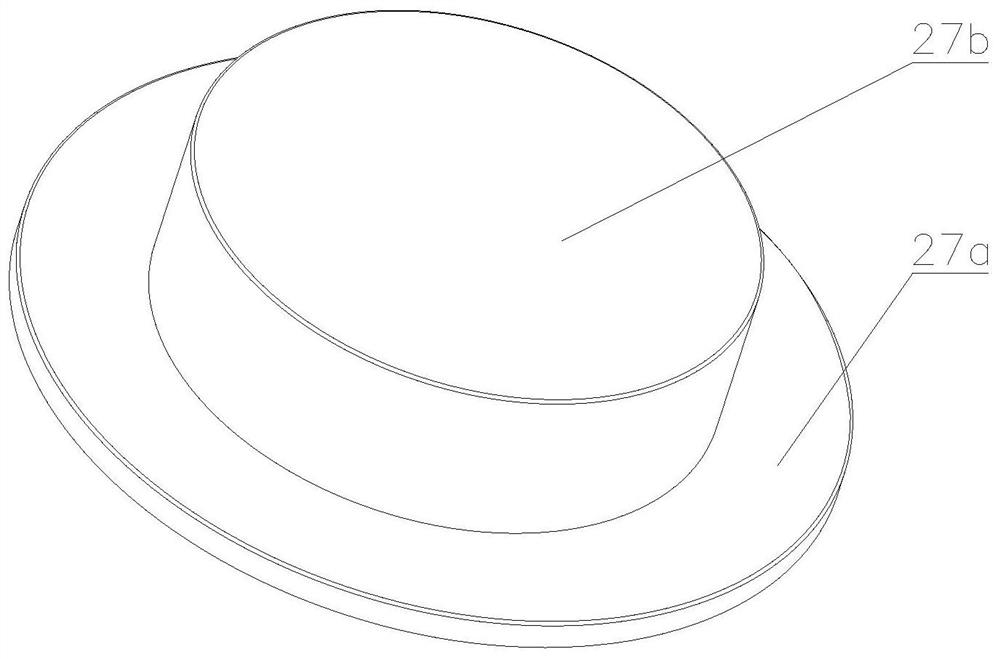

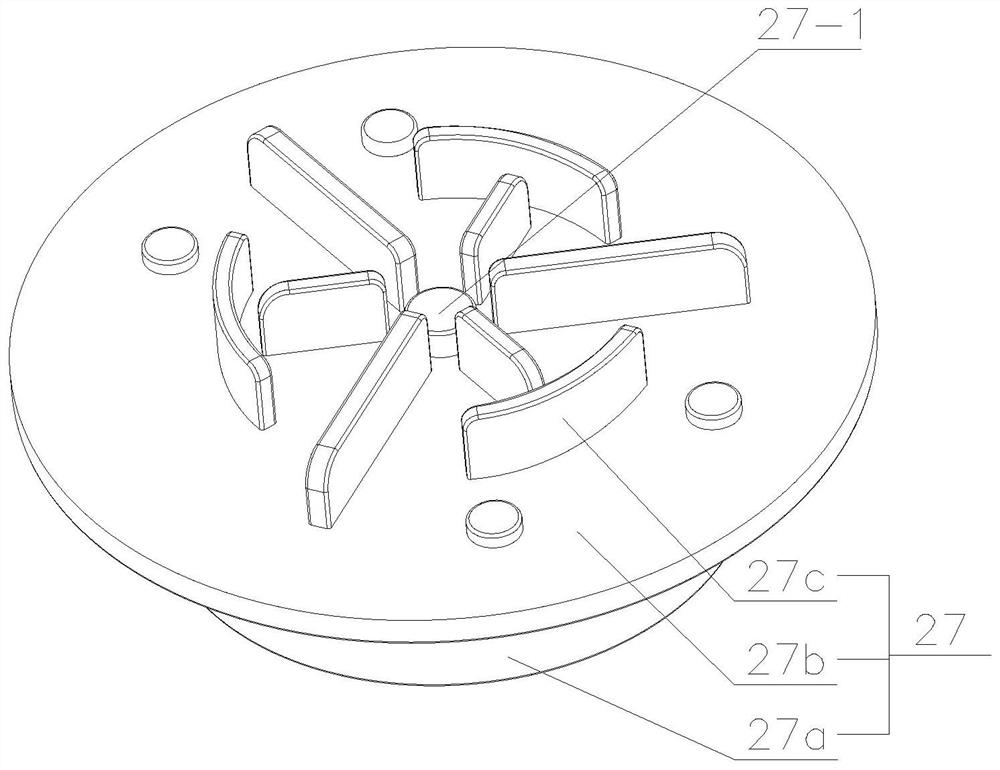

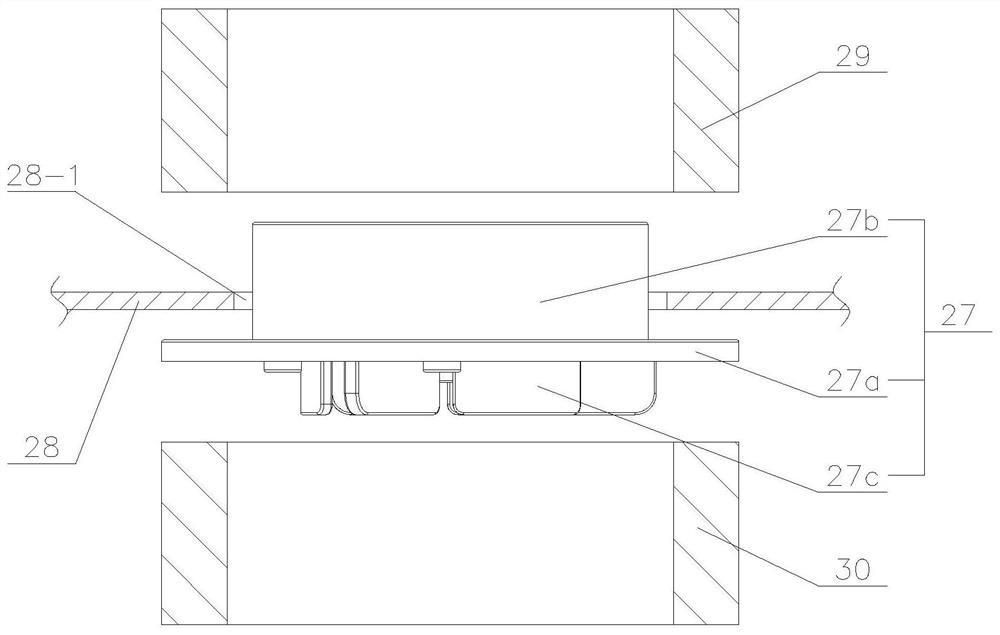

[0072] First of all, briefly describe the structure of the valve port 27 and the hot pressing and heat sealing treatment method, such as figure 1 and figure 2 As shown, the valve port 27 includes a disc-shaped chassis 27a and a boss 27b arranged on the upper surface of the chassis 27a. The axis line of the boss 27b coincides with the axis line of the chassis 27a. Valve (not shown in the figure), the bottom center of the chassis 27a is provided with a suction port 27a-1, and the circumferential direction of the suction port 27a-1 is evenly distributed with convex ribs 27c, and the outer part of the chassis 27a located on the boss 27b belongs to the hot pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com