Tea leaf rolling machine capable of automatically adjusting rolling pressure according to rolling time

An automatic adjustment and kneading machine technology, applied in the direction of tea processing before extraction, can solve the problems of excessive kneading of tea leaves, affecting the kneading quality of tea leaves, and controlling kneading pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

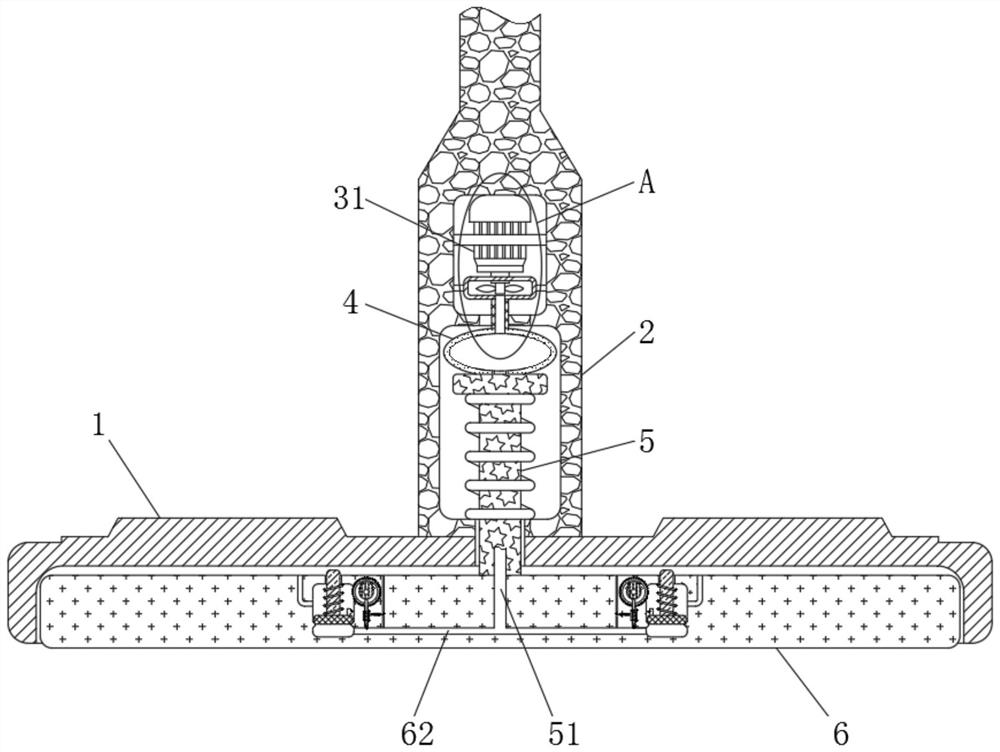

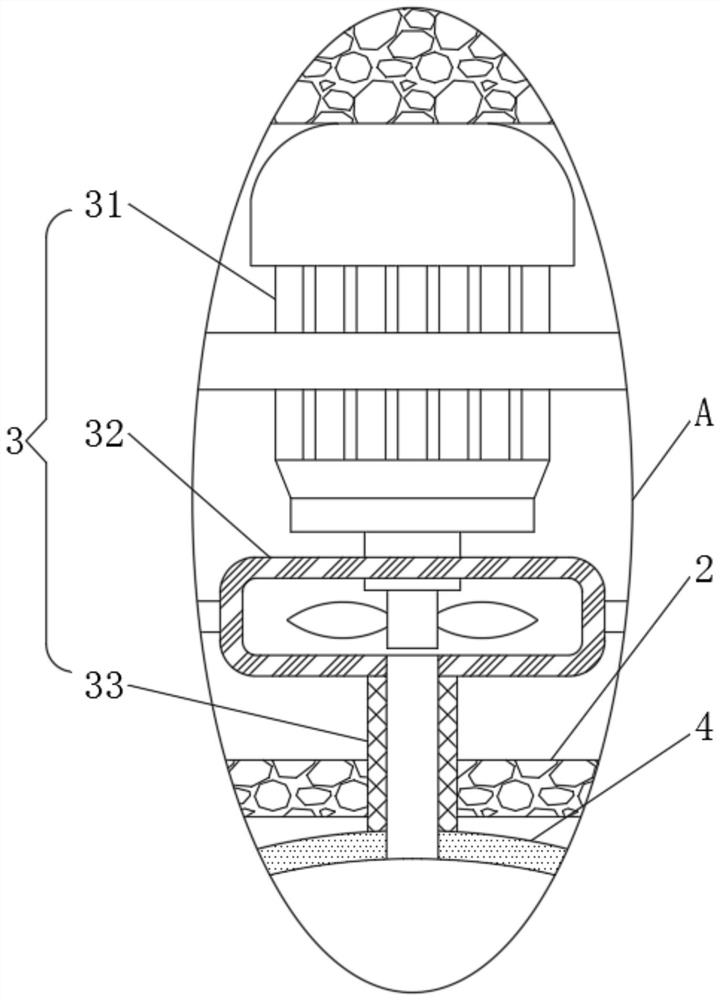

[0025] see Figure 1-4 , a tea rolling machine that automatically adjusts the rolling pressure according to the rolling time, including a cover plate 1, a column 2 is welded on the top of the cover plate 1, an air blowing mechanism 3 is welded on the inner top wall of the column 2, and the bottom of the air blowing mechanism 3 is welded There is an elastic airbag 4, the bottom of the elastic airbag 4 is fixedly connected with a movable rod 5, the top of the movable rod 5 is provided with an inflation pipe 51, the bottom of the movable rod 5 is welded with a pressure plate 6, and the top of the pressure plate 6 is inserted with a ring Arranged pressure relief mechanisms 7, the inside of the pressurizing plate 6 is rotatably connected with an annular arrangement of timing mechanisms 8.

[0026] Blowing mechanism 3 comprises motor 31, and the bottom of motor 31 is rotatably connected with blower 32, and the bottom of blower 32 is plugged with air intake pipe 33, and the bottom of...

Embodiment 2

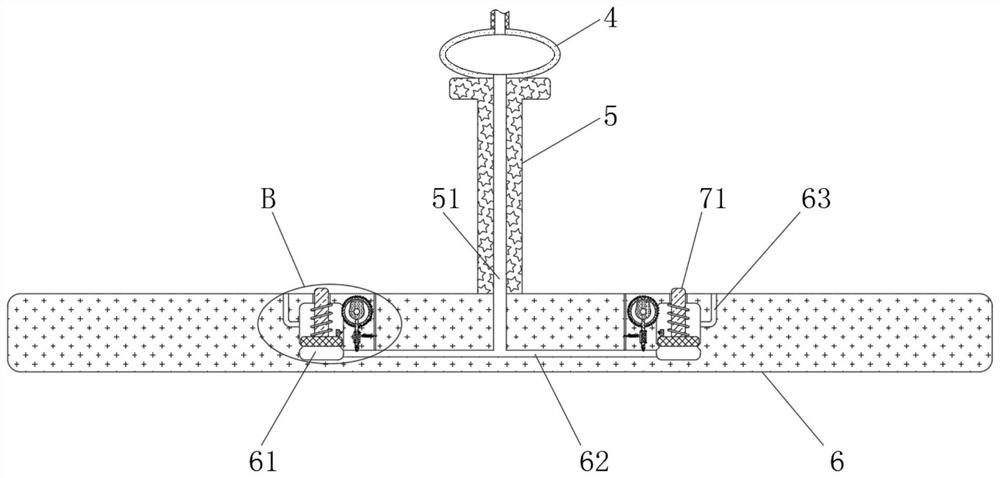

[0029] see figure 1 and 3-5, a tea rolling machine that automatically adjusts the rolling pressure according to the rolling time, including a cover plate 1, the top of the cover plate 1 is welded with a column 2, the inner top wall of the column 2 is welded with an air blowing mechanism 3, and the air blowing mechanism 3 The bottom is welded with an elastic airbag 4, the bottom of the elastic airbag 4 is fixedly connected with a movable rod 5, the top of the movable rod 5 is provided with an inflation pipe 51, the bottom of the movable rod 5 is welded with a pressure plate 6, and the top of the pressure plate 6 is plugged in There are pressure relief mechanisms 7 arranged in a ring, and a timing mechanism 8 arranged in a ring is rotatably connected to the inside of the pressure plate 6 .

[0030] The inside of the pressurizing plate 6 is provided with a ring-shaped inner chamber 61, and the opposite side of the inner chamber 61 is provided with a vent pipe 62, and the opposit...

Embodiment 3

[0034] see Figure 1-5 , a tea rolling machine that automatically adjusts the rolling pressure according to the rolling time, including a cover plate 1, a column 2 is welded on the top of the cover plate 1, an air blowing mechanism 3 is welded on the inner top wall of the column 2, and the bottom of the air blowing mechanism 3 is welded There is an elastic airbag 4, the bottom of the elastic airbag 4 is fixedly connected with a movable rod 5, the top of the movable rod 5 is provided with an inflation pipe 51, the bottom of the movable rod 5 is welded with a pressure plate 6, and the top of the pressure plate 6 is inserted with a ring Arranged pressure relief mechanisms 7, the inside of the pressurizing plate 6 is rotatably connected with an annular arrangement of timing mechanisms 8.

[0035] Blowing mechanism 3 comprises motor 31, and the bottom of motor 31 is rotatably connected with blower 32, and the bottom of blower 32 is plugged with air intake pipe 33, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com