Casting method for screw rotor of single-screw compressor

A single-screw compressor and single-screw technology, which is applied in the field of parts manufacturing, can solve the problems that the casting of the screw rotor of the single-screw compressor cannot be realized, and achieve the effect of shortening the processing cycle and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

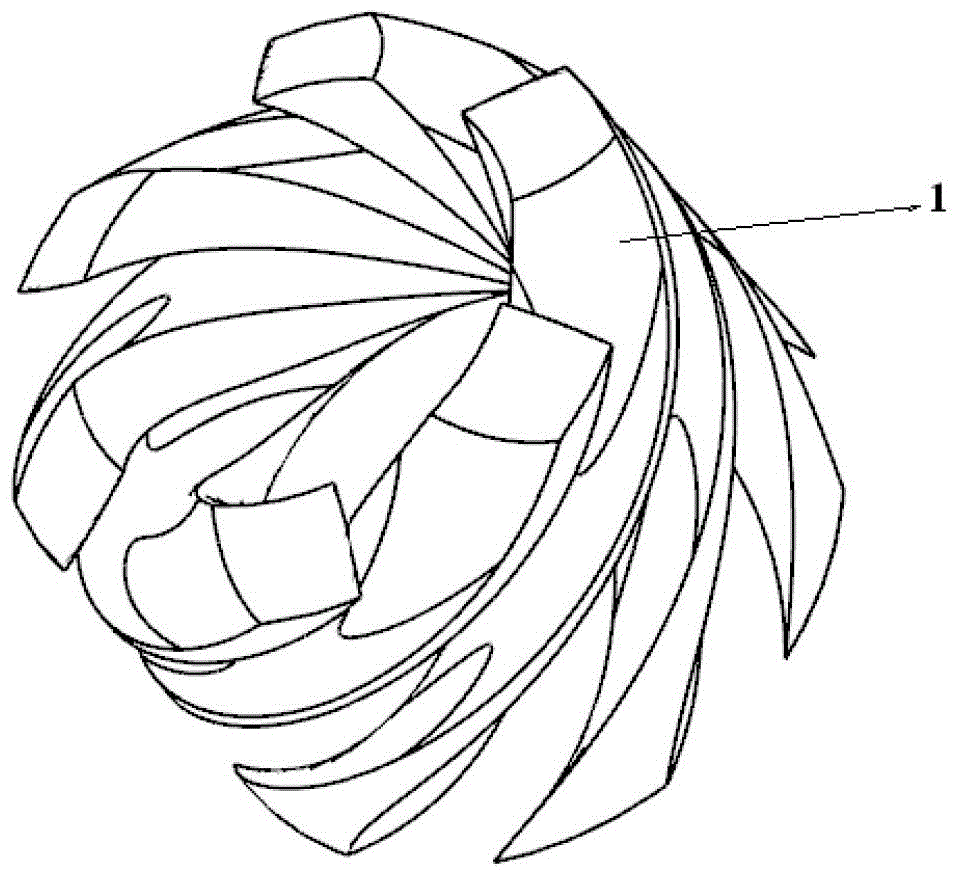

[0033] see Figure 1 to Figure 8 Shown, a kind of single-screw compressor screw rotor casting method of the present invention comprises the following steps:

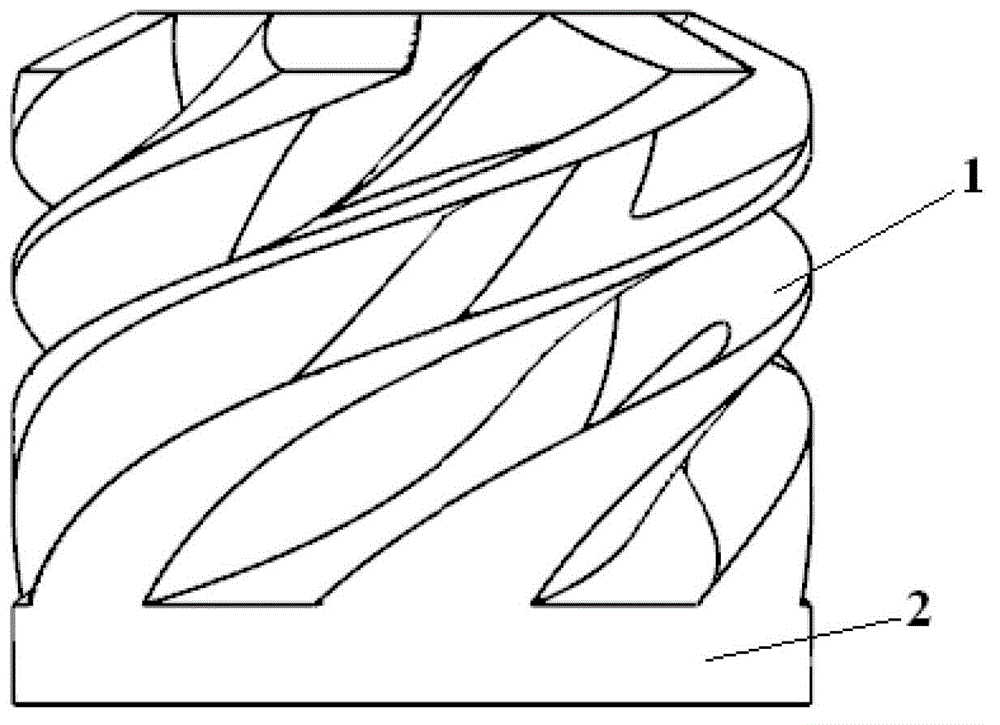

[0034] 1), see figure 1 and figure 2 As shown, a solid cylinder is processed into a toothed single-screw rotor blank with a lathe, and the single-screw rotor blank includes a kidney-shaped solid blank and 6 screw tooth blanks 1 evenly arranged on the outer periphery of the kidney-shaped solid blank; 6 screw teeth Blank 1 is inclined and evenly arranged on the waist-shaped solid blank, and the teeth are twisted;

[0035] The machining allowance of the single-screw rotor blank relative to the finished product is 2-5mm;

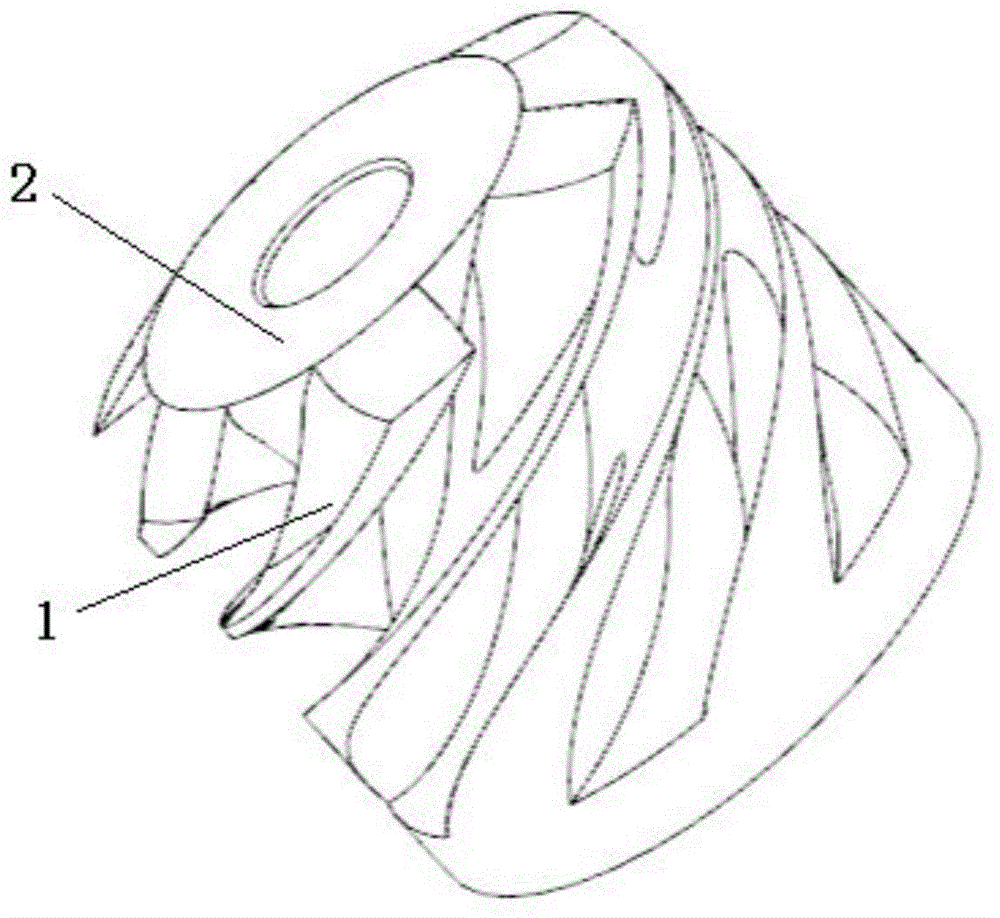

[0036] 2), see image 3 As shown, the waist-shaped solid blank 2 other than the screw tooth blank 1 is turned off by a CNC lathe, leaving a complete six screw tooth blank 1;

[0037] 3) Then, use a lathe to process a solid cylinder into a kidney-shaped solid blank 2 with the same structure and size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com