Equipment for uniformly spraying glaze to surface and interior of ceramic on the basis of artwork processing

A ceramic surface and art technology, applied in the field of ceramic technology, can solve problems such as glaze spraying only applicable to shapes, complex or thin tire products, wrong glaze slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

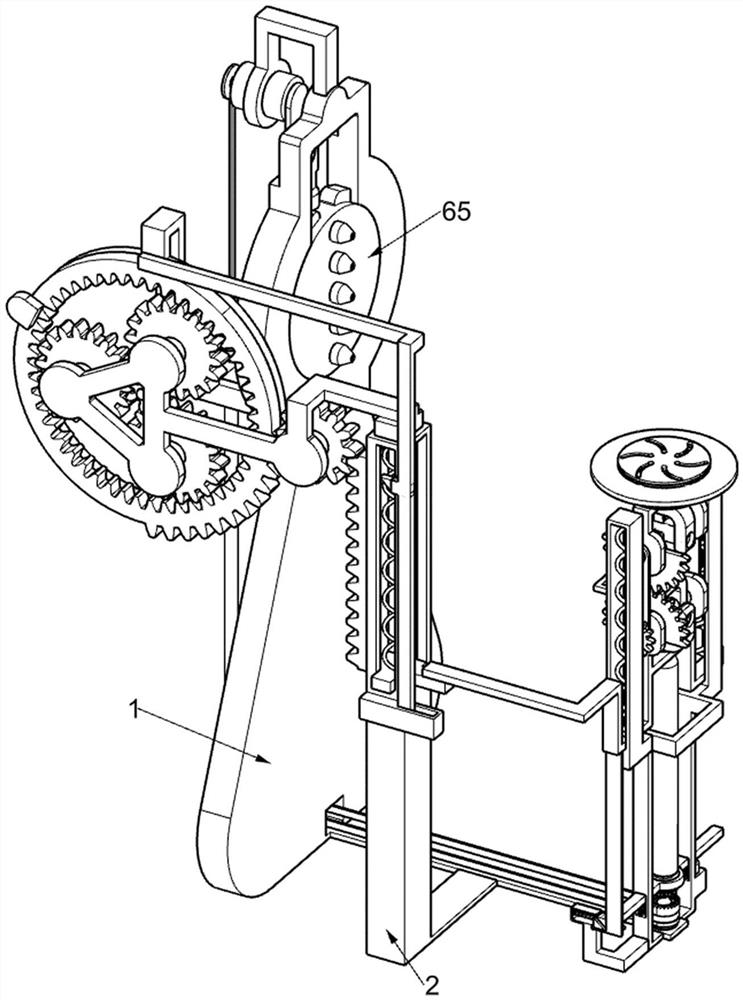

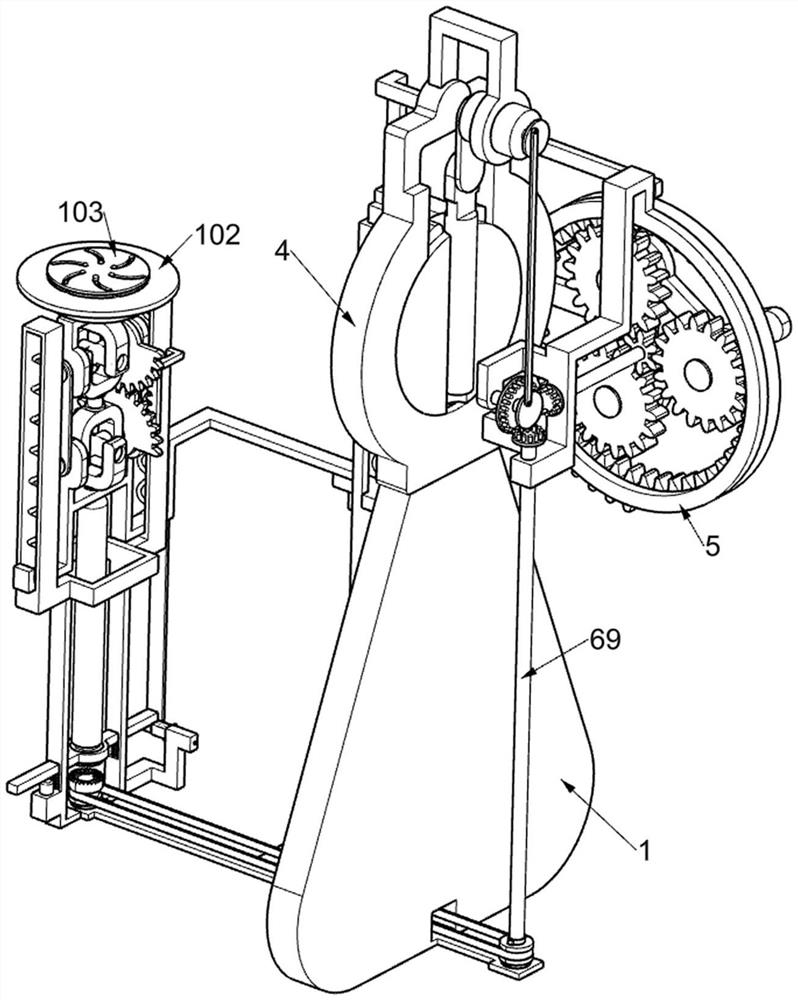

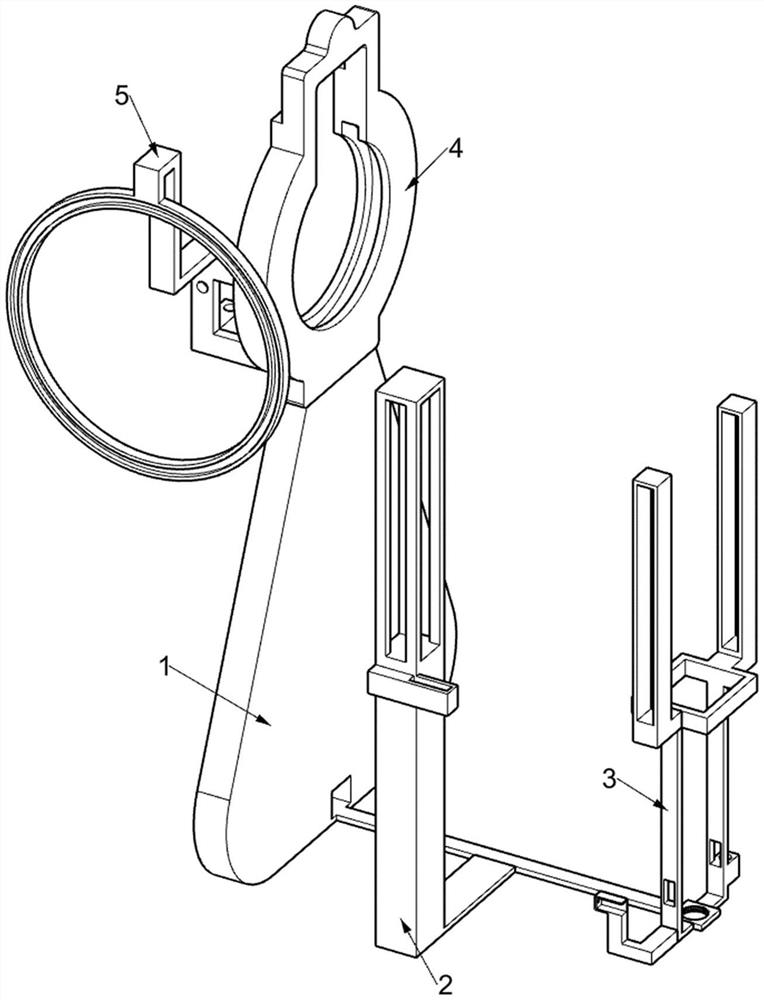

[0028] Embodiment: a kind of equipment based on artwork processing to the ceramic surface and internal uniform spray glaze, such as Figure 1-11 As shown, it includes a special-shaped bottom frame 1, a special-shaped flower slide rail frame 2, a special-shaped slotting frame 3, a roller frame 4, a special-shaped opening support frame 5, a driving swing mechanism 6, a downward rotation mechanism 7, an intermittent drive mechanism 8, Rotate the adjustment mechanism 9 and the clamping mechanism 10, the special-shaped flower slide rail frame 2 is fixedly installed on the special-shaped bottom frame 1, the special-shaped slotted frame 3 is arranged on the special-shaped bottom frame 1, and the roller frame 4 is fixedly installed on the bottom frame far away from the special-shaped slotted frame 3 On the special-shaped bottom frame 1, the special-shaped opening support frame 5 is welded on the roller frame 4, and the driving swing mechanism 6 is arranged on the roller frame 4. The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com