Cyclic Variable Center of Gravity Rotating Wheel Mechanism for Excavator Water Surface Operation

A technology of rotating wheels and excavators, which is applied in the direction of earth movers/shovels, construction, etc., can solve problems such as changes in the center of gravity of excavators, inability of excavators to work freely, and inability of excavators to work normally and smoothly. Corrosion, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

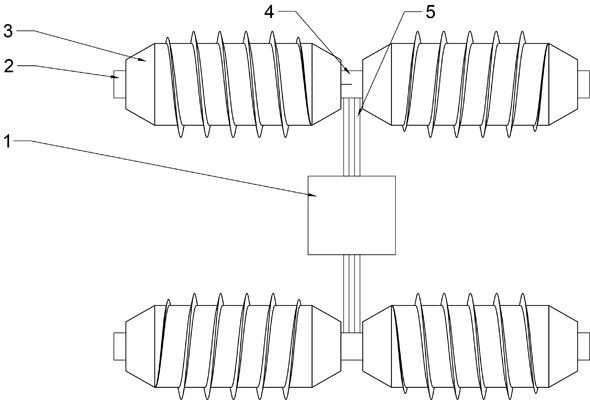

Embodiment 1

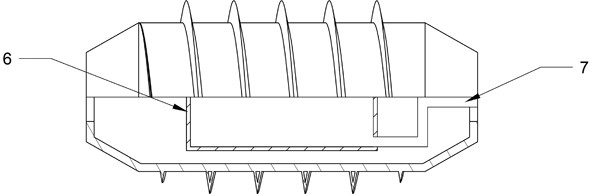

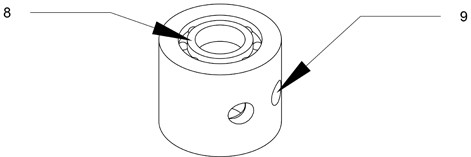

[0046] In the embodiment of the present invention, the water pump unit includes four water pumps 11 and a total water tank 10, one end of each water pump 11 communicates with the water tank 6 in a rotating wheel 3, and the other end is connected with the total water tank 10 The number of the water pipes 5 is 4, and one end of each water pipe 5 is connected with the water pump 11, and the other end is respectively connected with the water tank 6 in the corresponding rotating wheel 3. Such as Figure 4 As shown, the cycle center-of-gravity mechanism 1 includes a housing wrapped around the balance control module and the water pump unit, the housing is provided with a pipe hole 9 for accommodating the water pipe 5, and the pipe hole 9 and the water pipe 5 are connected to each other. It is filled with seals, and in the actual implementation process, the seals can be made of a waterproof adhesive layer, which can ensure that the internal equipment of the circulation variable center...

Embodiment 2

[0053] The difference between the embodiment of the present invention and embodiment 1 is: as Figure 5 and 6 As shown, the water pump unit includes 4 telescopic pipes 12, 4 air pumps 13 and 4 water pumps 11, wherein two telescopic pipes 12 are arranged on the outside of the first transmission mechanism 4, and the other two are telescopic The pipeline 12 is arranged on the outside of the second transmission mechanism; each air pump 13 is respectively connected to a telescopic pipeline 12, and the telescopic pipeline 12 is inflated and deflated according to the demand so that the telescopic pipeline goes deep into or lifts off the water surface;

[0054] One end of each water pump 11 communicates with the water tank 6 in a rotating wheel 3 through a water pipe respectively, and the other end is in the external water environment, and is used to extract the water in the corresponding water tank or the water in the external water environment to the corresponding water tank 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com