Sulfuric acid tail gas and waste gas combined acid making method and device

A sulfuric acid tail gas and waste gas technology, applied in the direction of sulfur compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as fluctuations in the ratio of hydrogen sulfide to air, affect conversion, increase processing risks, etc., to facilitate subsequent conversion reactions and system production stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

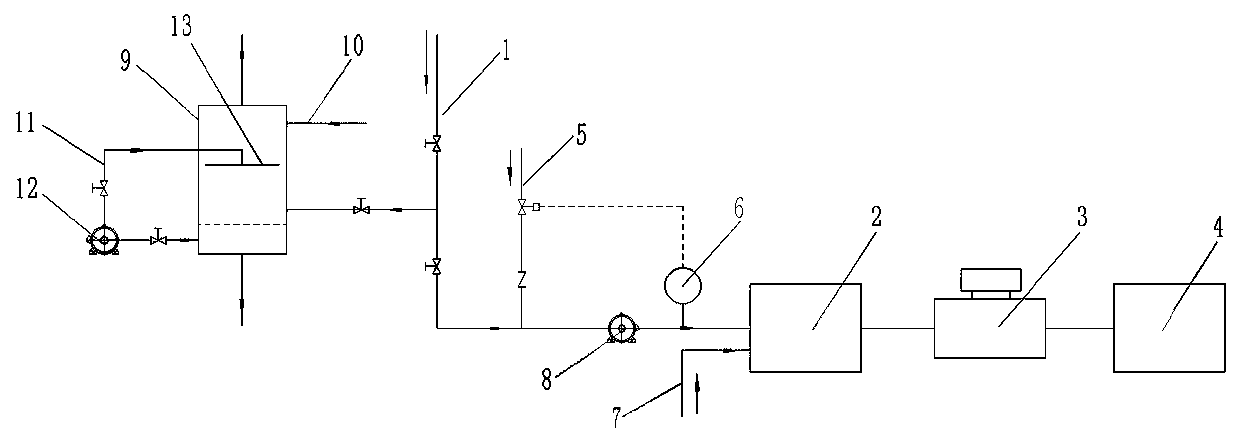

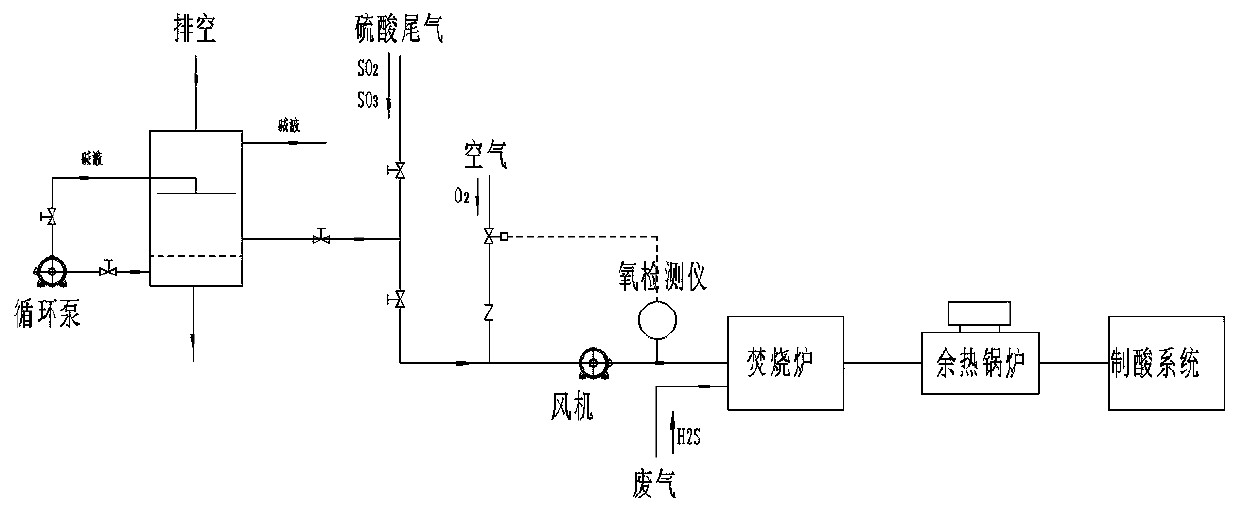

[0037] A method for joint acid production of sulfuric acid tail gas and waste gas, comprising the following steps:

[0038] (a) Air is injected into the sulfuric acid tail gas to obtain a mixed gas;

[0039] (b) Mixing and incinerating the mixed gas in step (a) with hydrogen sulfide;

[0040] (c) Use the incinerated gas to make acid.

Embodiment 2

[0042] A method for joint acid production of sulfuric acid tail gas and waste gas, comprising the following steps:

[0043] (a) Air is injected into the sulfuric acid tail gas to obtain a mixed gas;

[0044] (b) Mixing and incinerating the mixed gas in step (a) with hydrogen sulfide;

[0045] (c) Use the incinerated gas to make acid.

[0046] Further, the ratio of the volume fraction of sulfuric acid tail gas to the volume fraction of oxygen is 20:2-3.

Embodiment 3

[0048] A method for joint acid production of sulfuric acid tail gas and waste gas, comprising the following steps:

[0049] (a) Air is injected into the sulfuric acid tail gas to obtain a mixed gas;

[0050] (b) Mixing and incinerating the mixed gas in step (a) with hydrogen sulfide;

[0051] (c) Use the incinerated gas to make acid.

[0052] Further, the incineration temperature is 1000°C±50°C, and the incineration time is 3-5 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com