Supporting equipment for tunnel construction

A technology for supporting equipment and tunnel construction, applied in tunnels, mining equipment, tunnel lining, etc., can solve problems such as floating points, achieve the effects of preventing floating points, improving structural stress, and shortening construction reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

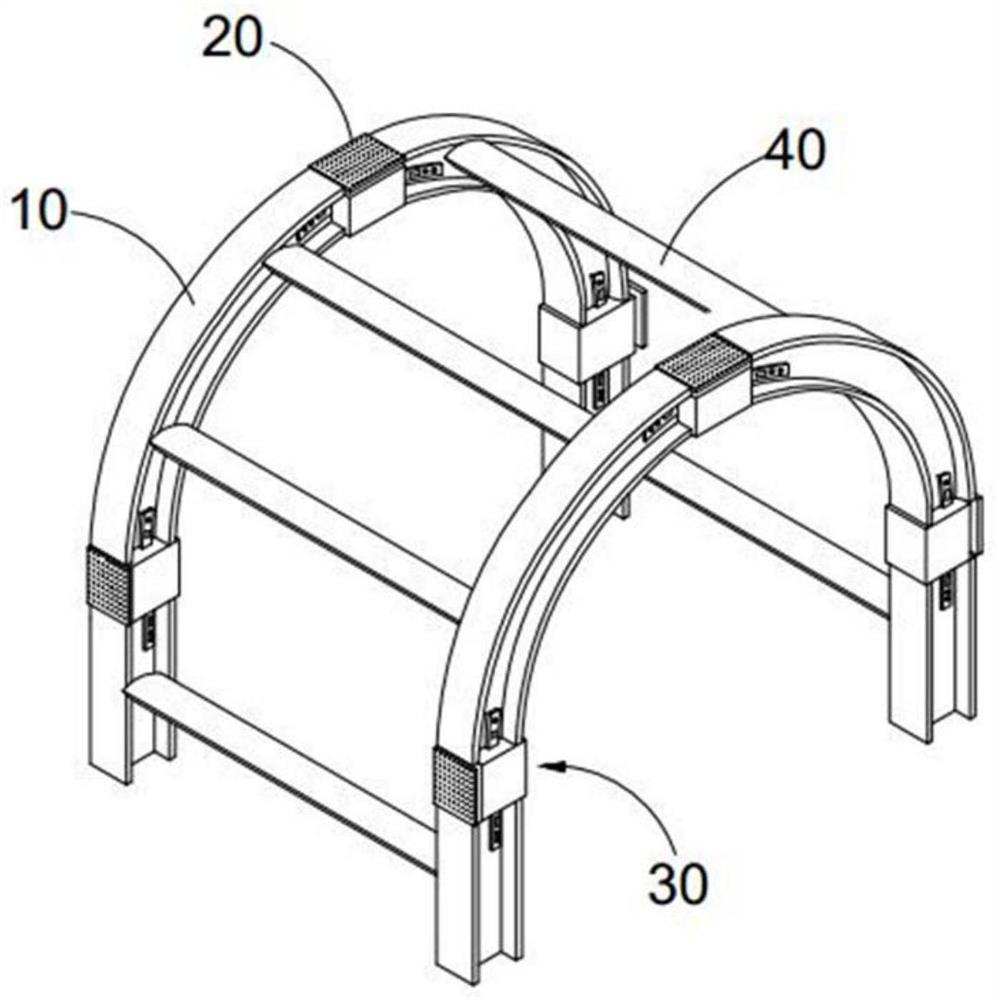

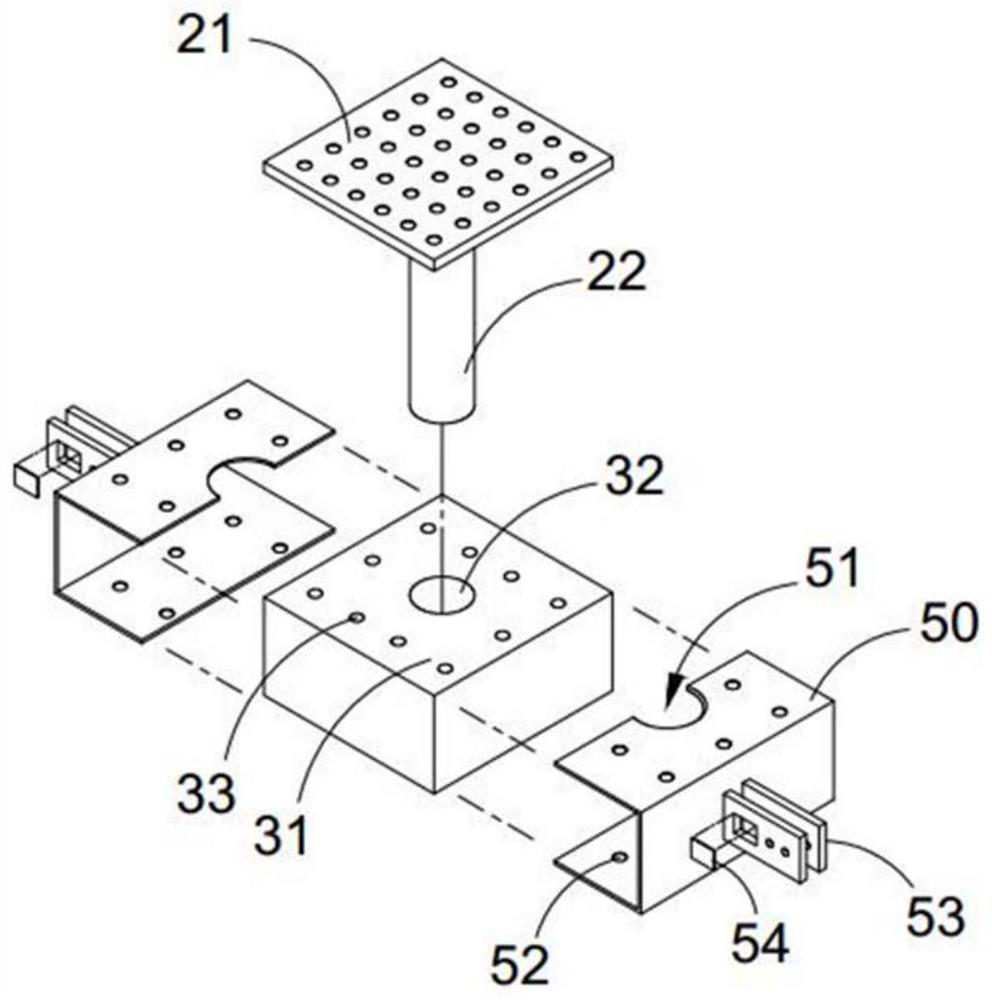

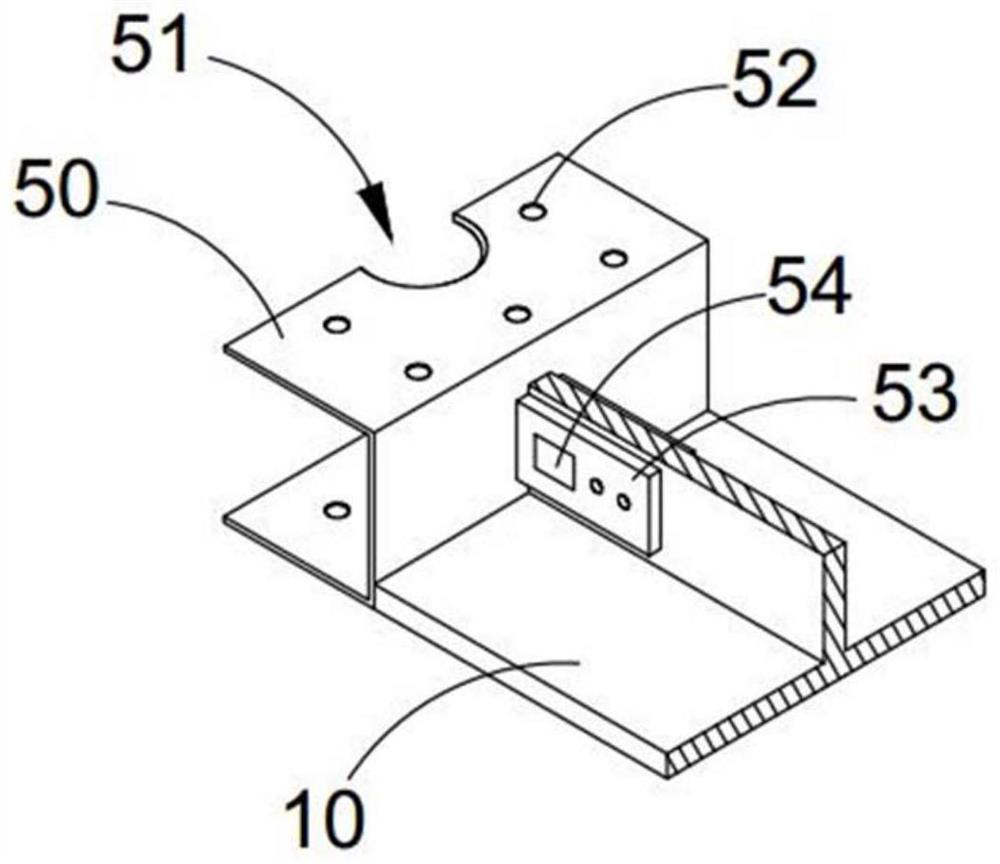

[0032] see Figure 1-7 as shown,

[0033] The support equipment used for tunnel construction includes: support members 10, processing components 30, used to connect the support members 10 to form an arch support structure, and the adjacent surfaces of the formed arch support structure are connected through a bonding substrate 40, and the bonding support The plate assembly 20 is plugged on the processing assembly 30 and is in contact with the construction surface, wherein the processing assembly 30 includes a base 31 of a cubic box structure, and a first hole is provided in the center of the base 31 to be plugged and fitted with the lamination spreader assembly 20 . Assembling the through hole 32, the two corresponding sides of the base body 31 are clamped with a half sleeve body 50. The half sleeve body 50 has a fitting side corresponding to the side of the base body 31, and the upper and lower ends of the fitting side are connected with the upper and lower end surfaces of the...

Embodiment 2

[0044] In the actual use of the supporting equipment for tunnel construction of the present invention:

[0045] Bending the I-shaped profile as a half-arched beam supported by the tunnel and connecting the two half-arched beams through the processing component 30 to form an arched beam structure, and then connecting the linear I-shaped beam through the processing component 30 The profiles are connected to form the side beam structure, and finally an arched support structure is formed, and then the connection between two adjacent arched support structures is realized by laminating the base plate 40, which can be quickly installed in the tunnel during the excavation process of the tunnel. Tunnel support equipment, and when the deformation of the tunnel rock formation leads to expansion and displacement increases, it will give the tunnel rock formation counterforce in real time during the support process to improve the stability of the rock formation.

Embodiment 3

[0047] In this embodiment, the tunnel excavation simulation is carried out by artificially piling up the mountain, and the support equipment for tunnel construction of the present invention with different support angles is respectively erected at both ends of the tunnel. 7 times of excavation, and measured the settlement of the vault after each excavation, the results are as follows Figure 8 As shown, it can be seen that when the erection support angle of the present invention is selected to be 120°, the vault settlement is lower than 90° of erection equipment, and the two erection support angle equipment can effectively ensure the manual simulation of the tunnel after 7 times of simulated excavation in the tunnel. Stability of the rock formation with no occurrence of collapse or dislodgement of rock fragments.

[0048] At the same time, in this embodiment, the stress analysis of the laminated spreader assembly 20 and the base body 30 under compression, the results are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com