Accurate equipment for detecting tubular automobile part by utilizing light reflection principle

A tube-type automobile and accessory technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of slowing down the detection time, increasing the detection steps, delaying work efficiency, etc., to ensure accuracy and reduce detection steps , The effect of speeding up the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

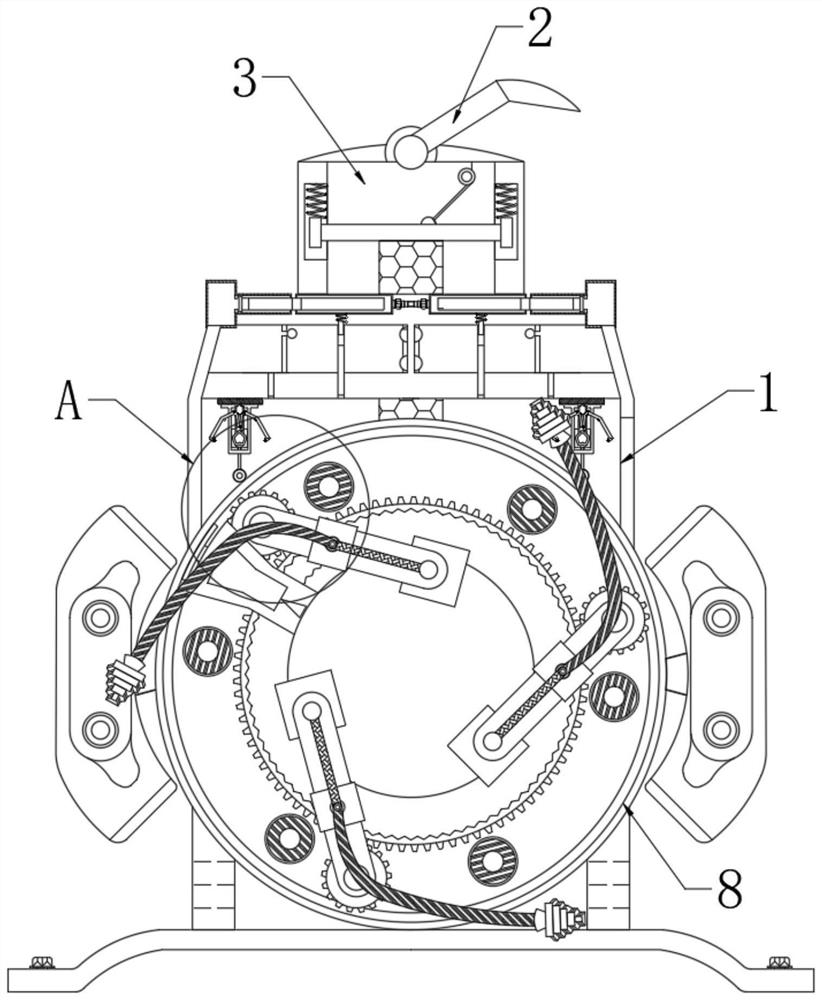

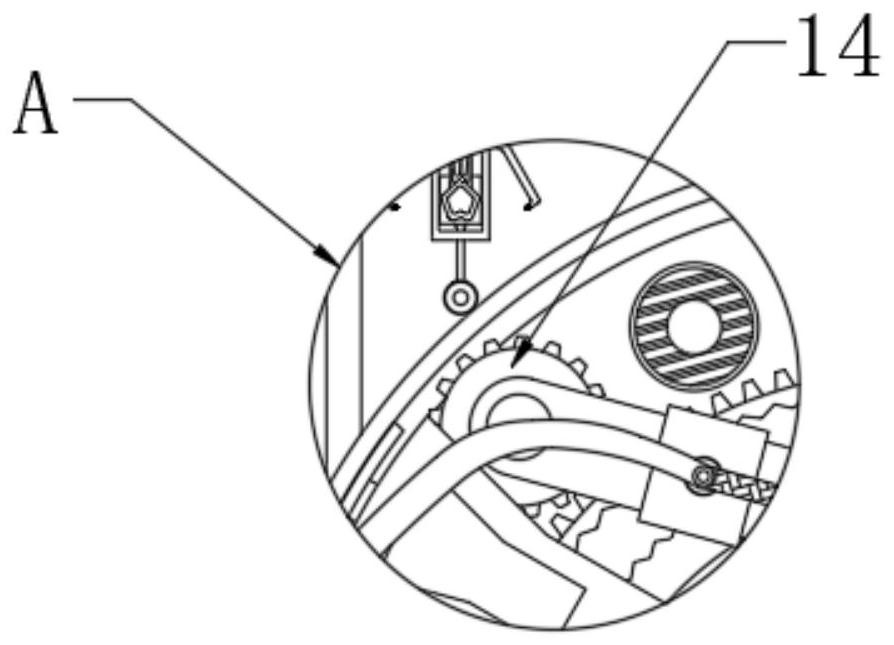

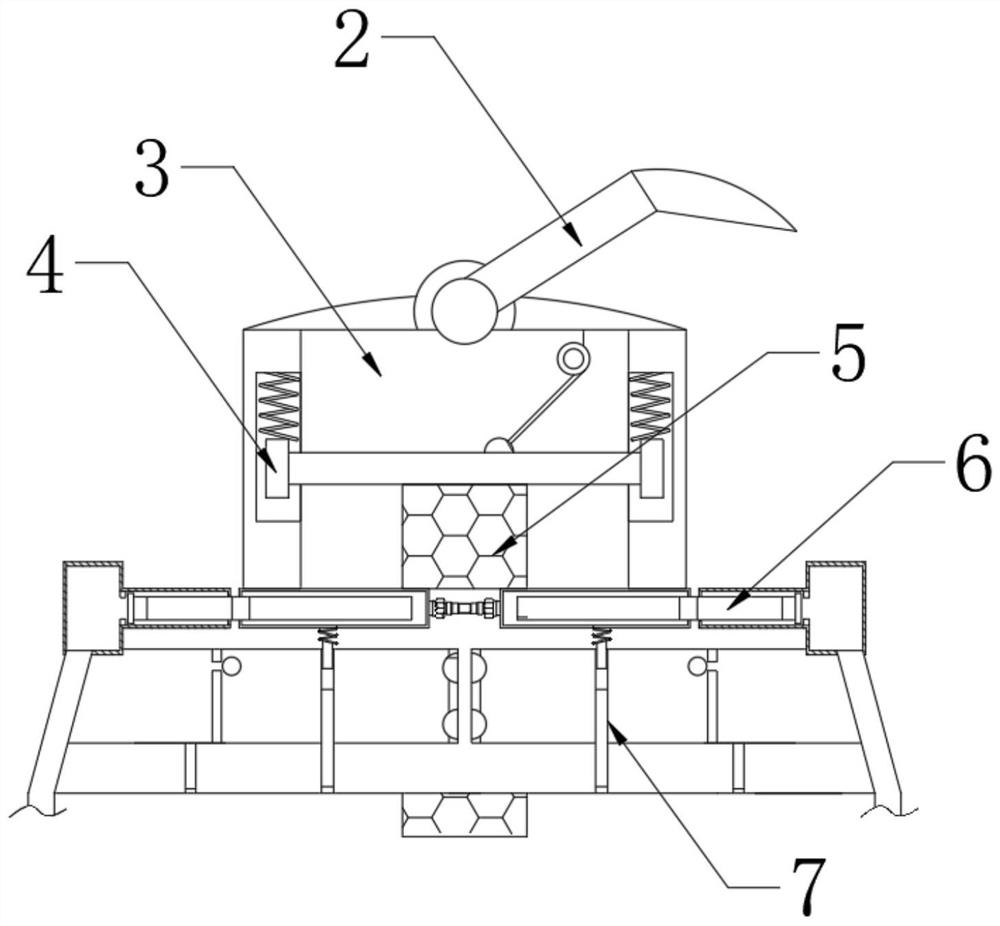

[0027] see image 3 with Figure 4 , a precise device for detecting tubular auto parts by using the principle of light reflection, comprising a main body 1, a driving rod 2, a central block 3 is movably connected to the top of the main body 1, and protective strips 4 are movably connected to the left and right sides of the central block 3, A main shaft 5 is movably installed at the center of the protective strip 4, and a mounting frame 6 is movably installed at the bottom of the main shaft 5, and a strut 7 is movably connected directly below the mounting frame 6, and a rolling roller 8 is movably connected to the bottom end of the strut 7, and the rolling roller 8 shafts The heart place is movably connected with tooth block 9.

[0028] Further, the main shaft 5 includes a rubber block 10, the front end of the rolling roller 8 is movably connected with a slide bar 11, and the front end of the slide bar 11 is movably connected with a center bar 12, and there are three center ba...

Embodiment 2

[0033] see Figure 4 with Figure 5 , a precise device for detecting tubular auto parts by using the principle of light reflection, comprising a main body 1, a driving rod 2, a central block 3 is movably connected to the top of the main body 1, and protective strips 4 are movably connected to the left and right sides of the central block 3, A main shaft 5 is movably installed at the center of the protective strip 4, and a mounting frame 6 is movably installed at the bottom of the main shaft 5, and a strut 7 is movably connected directly below the mounting frame 6, and the bottom end of the strut 7 is movably connected with a rolling roller 8, and the rolling roller 8 is a shaft The heart place is movably connected with tooth block 9.

[0034]Further, it also includes a central block 21, the outer side of the central block 21 and the inner side of the auxiliary strip 19 are movably connected with a frame 22, a circumferential rod 23 is fixedly installed between the frame 22 an...

Embodiment 3

[0037] see Figure 1-5 :

[0038] A precision device for detecting tubular auto parts by using the principle of light reflection, including a main body 1, a driving rod 2, a central block 3 is movably connected to the top of the main body 1, and protective strips 4 are movably connected to the left and right sides of the central block 3. A main shaft 5 is movably installed at the center of the strip 4, and a mounting frame 6 is movably mounted on the bottom end of the main shaft 5, and a strut 7 is movably connected directly below the mounting frame 6, and a rolling roller 8 is movably connected to the bottom end of the strut 7, and the axis center of the rolling roller 8 The place is flexibly connected with tooth block 9.

[0039] Further, the main shaft 5 includes a rubber block 10, the front end of the rolling roller 8 is movably connected with a slide bar 11, and the front end of the slide bar 11 is movably connected with a center bar 12, and there are three center bars 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com