Pressure detection device for automobile shock absorber processing

A technology for automobile shock absorbers and detection devices, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc. Avoid damage to shock absorbers, facilitate collection and removal of shock absorbers, provide cushioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

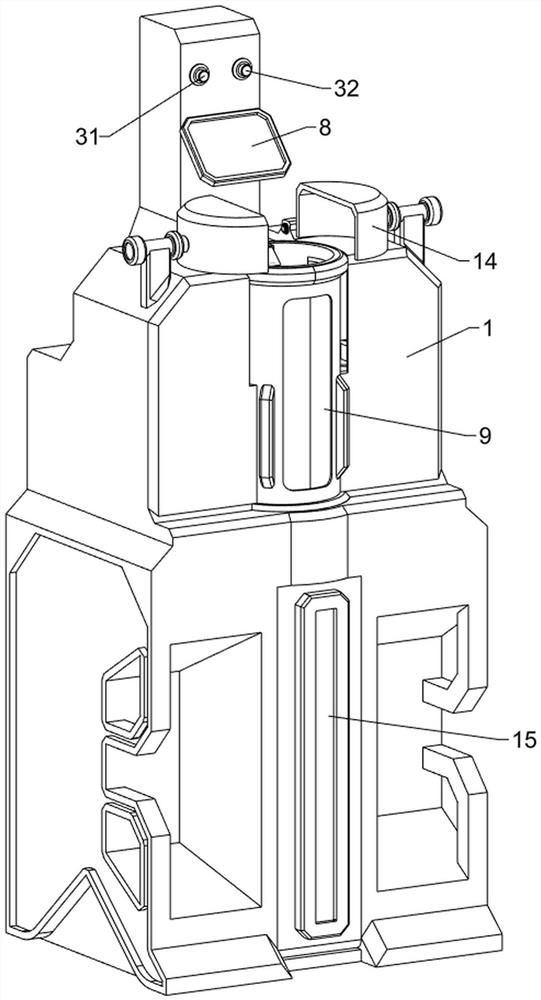

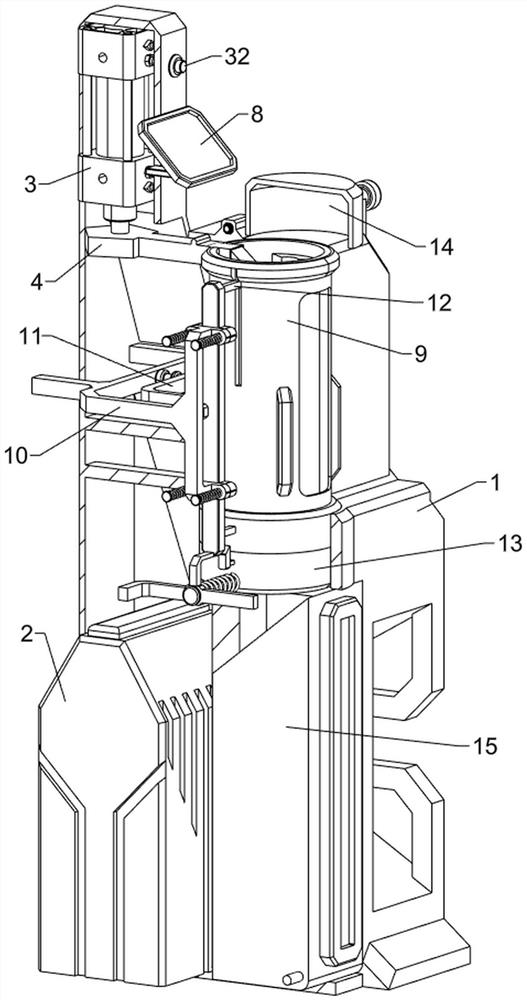

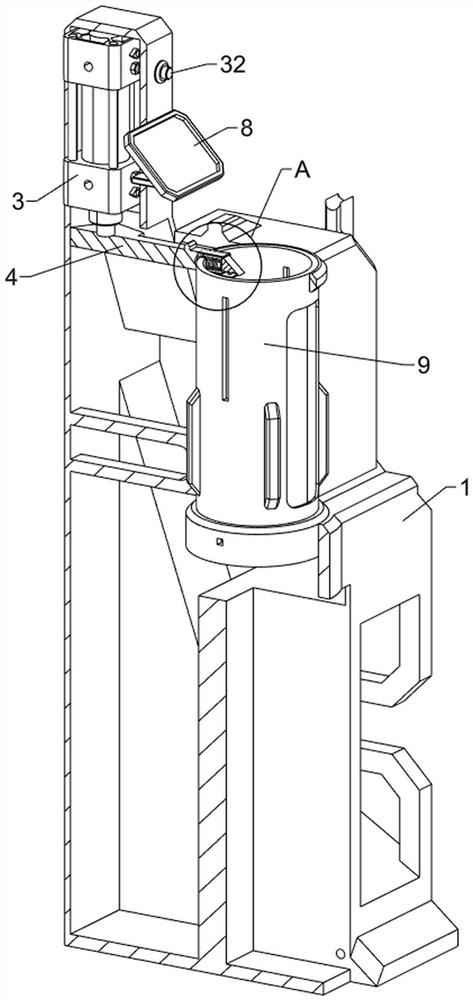

[0039] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a pressure detection device for automobile shock absorber processing, including a housing 1, a first electric push rod 3, an extension button 31, a shortening button 32, a first connecting rod 4, and a first wedge block 5. The first pressure sensor 6, the first spring 7, the LCD display 8, the placement frame 9, the fixing assembly 10 and the pushing assembly 11, the first electric push rod 3 is installed on the upper rear side of the casing 1, and the upper left front side of the casing 1 An extension button 31 is installed, a shortening button 32 is installed on the right front side of the upper part of the casing 1, the first connecting rod 4 is connected to the lower side of the telescopic rod of the first electric push rod 3, and the first wedge-shaped sliding connection is connected to the inner side of the middle part of the first connecting rod 4. Block 5, the first spring 7 is connected between t...

Embodiment 2

[0044] Such as figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 with Figure 17 As shown, in some embodiments, a precision measurement assembly 12 is also included, and the precision measurement assembly 12 includes a second clamp block 121, a third spring 122, a second pressure sensor 123 and a third pressure sensor 124, and the second connecting rod 102 upper inner sides are all slidably connected with a second clamping block 121, and the second clamping block 121 is all slidably connected with the placement frame 9, and the second clamping block 121 is all in contact with the first connecting rod 4, and the second clamping block 121 is in contact with the second connecting rod 4. The third spring 122 is connected between the connecting rods 102, and the second pressure sensor 123 is installed in the middle of the bottom right side of the second clamping block 121 on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com