Semi-automatic chip testing machine and working method

A chip testing, semi-automatic technology, applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of high labor cost, low efficiency, affecting testing efficiency, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

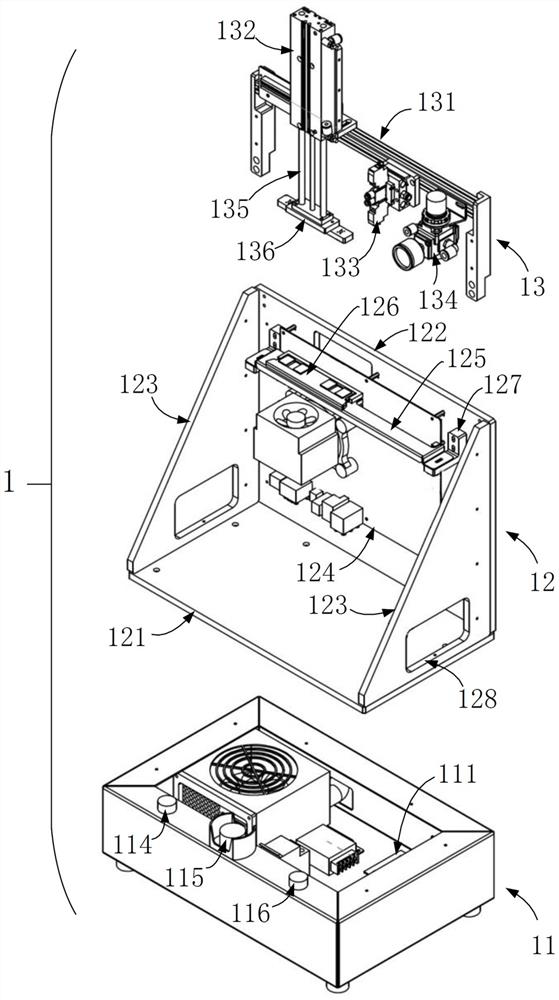

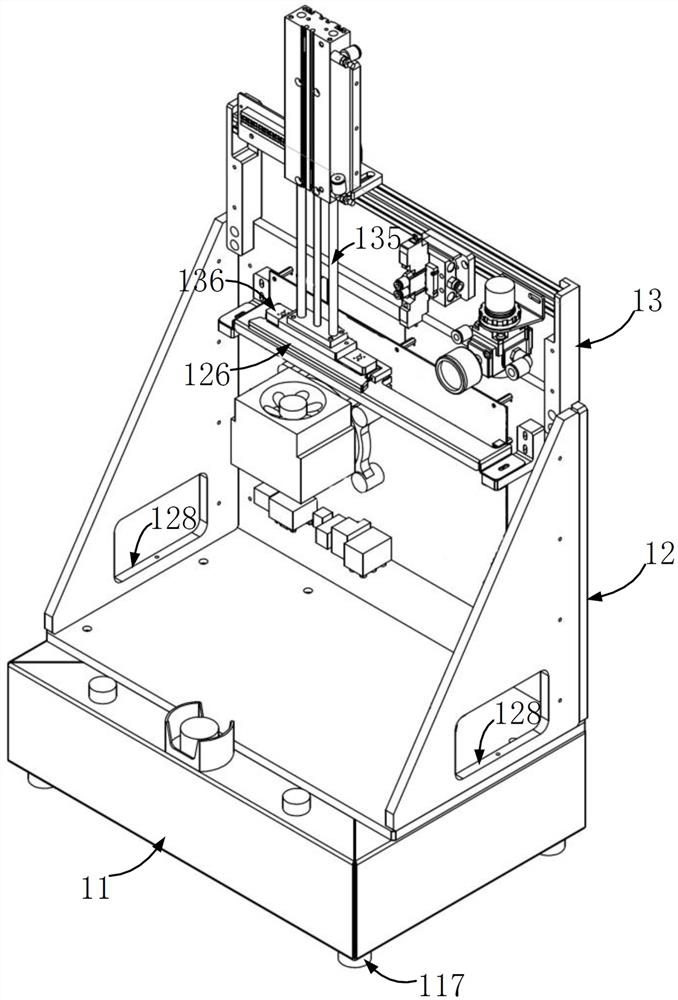

[0049] This example figure 1 As shown, it is a semi-automatic chip testing machine 1 , which includes a testing base 11 , a testing platform 12 and an action mechanism 13 .

[0050] In this embodiment, the test machine base 12 is a rectangular parallelepiped, and a control board 111 is installed inside the test machine base 12. The control board 111 is used to control the test platform 12 to perform a test action and to control the action mechanism 13 to perform a pressing action.

[0051]It should be noted that the test base 12 is preferably in the shape of a cuboid, and may also be in the shape of a cube, or a polygonal shape that can satisfy the technical solution, which is not limited in this embodiment.

[0052] In this embodiment, the four corners at the bottom of the test stand 11 can also be provided with a leg 117 (such as figure 2 As shown), the height of the feet 117 can be adjusted, so the semi-automatic chip testing machine 1 recorded in this technical solution ...

Embodiment 2

[0088] The difference between this embodiment and embodiment 1 is that this embodiment is a working method applied to embodiment 1, and its specific working method is as follows (the work flow chart is as follows Figure 5 shown):

[0089] S101. Power on the test machine (or semi-automatic chip test machine):

[0090] In this embodiment, the step S101 is specifically: the external power supply is connected to the power interface 112 of the test machine, and then the power switch button 113 is turned on, so that the semi-automatic chip test machine 1 is powered on It should be pointed out that the external power supply in this embodiment is common commercial power, and the commercial power needs to be transformed and rectified before it can be used by the test machine after it is connected to the test machine.

[0091] S102. Loading the chip to be tested:

[0092] In this embodiment, the step S102 is specifically: the operator manually loads the chip to be tested (in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com