Laser cutting equipment convenient to clean

A laser cutting and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as enterprise loss, laser head damage, and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

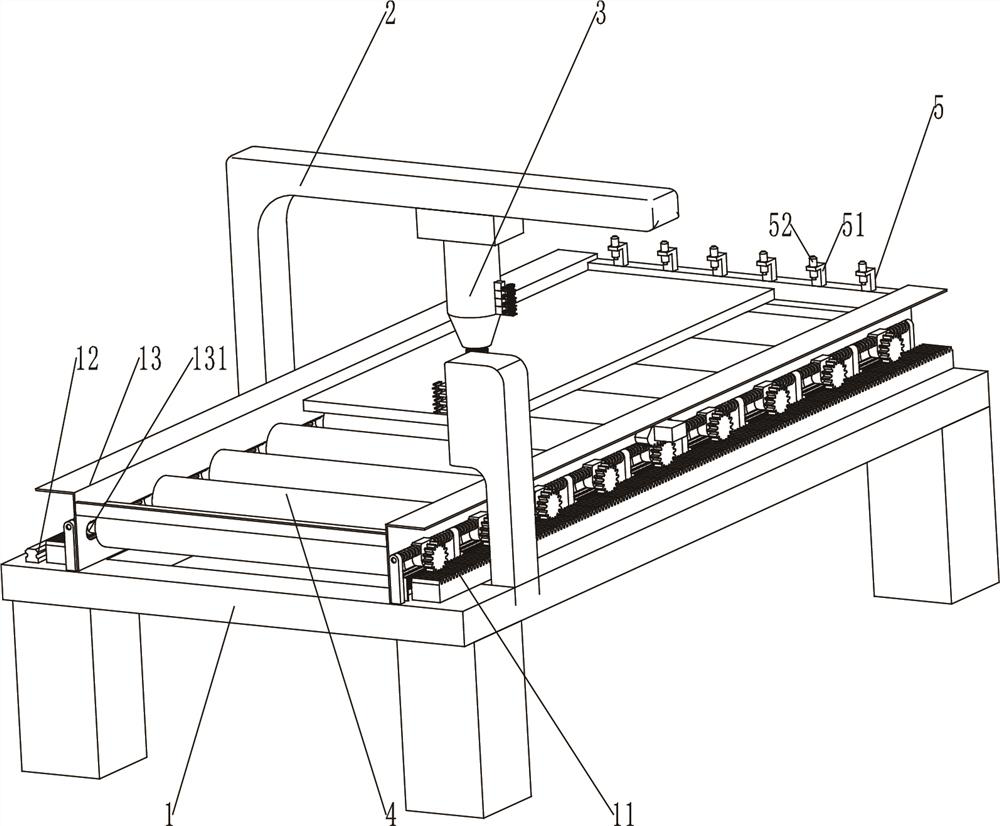

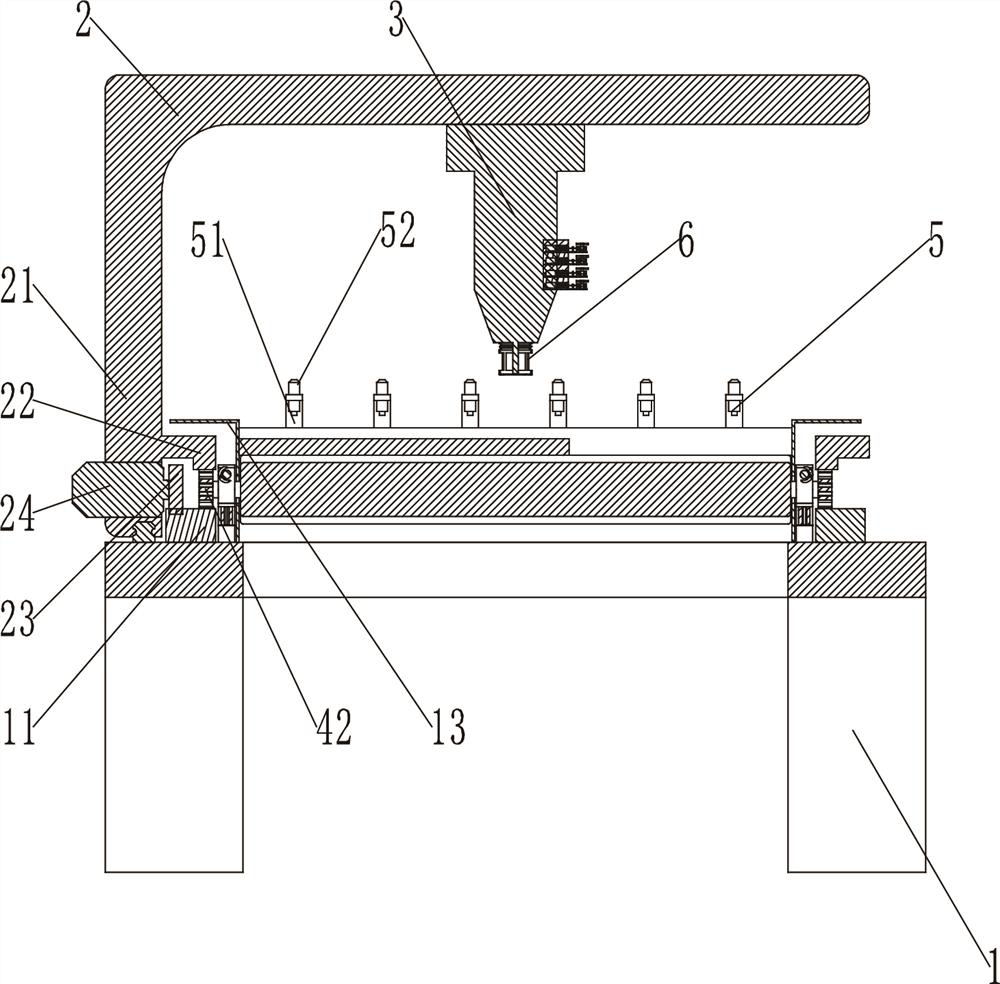

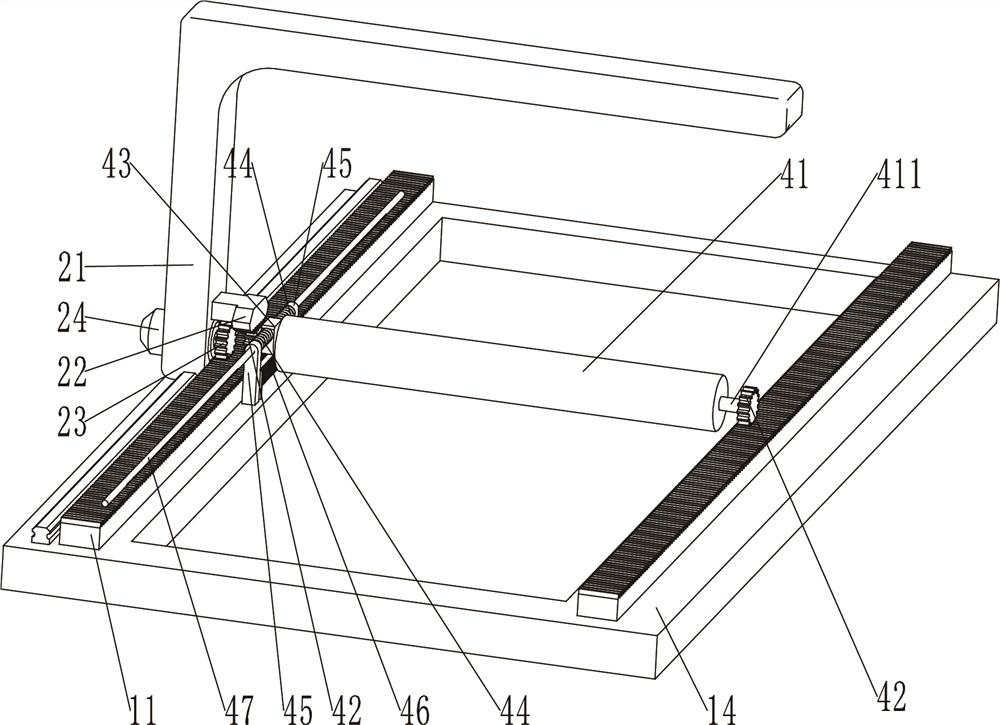

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 4 ,

[0036] A laser cutting device that is easy to clean, including a base 1, a three-coordinate walking part 2, a laser head 3, a bearing part 4 and a pressing device 5, the laser head 3 is arranged on the three-coordinate walking part 2, and the three-coordinate walking part 2 is set On the base 1, it is used to drive the laser head 3 to move in the X-axis, Y-axis and Z-axis. The three-coordinate walking part 2 includes a walking frame 21, a moving rack 22, a traveling gear 23 and a driving motor 24. The moving rack 22 is arranged on the walking frame 21 , the driving motor 24 is arranged on the walking frame 21 , and the traveling gear 23 is arranged on the driving motor 24 .

[0037] The base 1 includes a fixed rack 11, a guide rail 12 and a frame 14. The fixed rack 11 is arranged on the left and right sides of the ...

Embodiment 2

[0053] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 14 ,

[0054] A laser cutting device that is easy to clean, including a base 1, a three-coordinate walking part 2, a laser head 3, a bearing part 4, a pressing device 5, an anti-light pollution device 6, a spraying device 7, a calibration reset device 8, and an outer cover frame 61 , the laser head 3 is set on the three-coordinate walking part 2, and the three-coordinate walking part 2 is set on the base 1, which is used to drive the laser head 3 to move on the X-axis, Y-axis and Z-axis, and the anti-light pollution device 6 is set on the laser head 3, used to block the strong light generated when the laser is working, the spraying device 7 is arranged on the laser head 3, and the correction and reset device 8 is arranged on the base 1, and the spraying device 7 and the correction and reset device 8 are arranged in cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com