Smoke pipe mounting part and gas heating water heater

A technology for gas heating and installation parts, which is applied in the direction of combustion methods, fluid heaters, exhaust gas devices, etc., and can solve problems such as improper installation of smoke pipe angles, to ensure standardization and consistency, to ensure the degree of difficulty, to improve The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

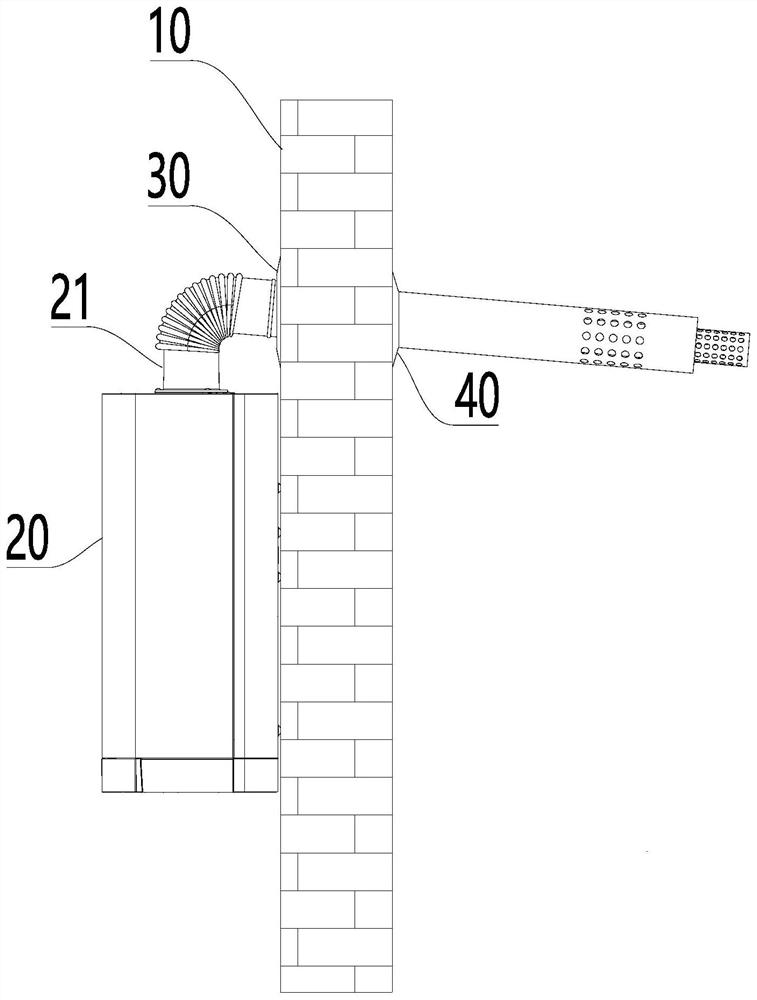

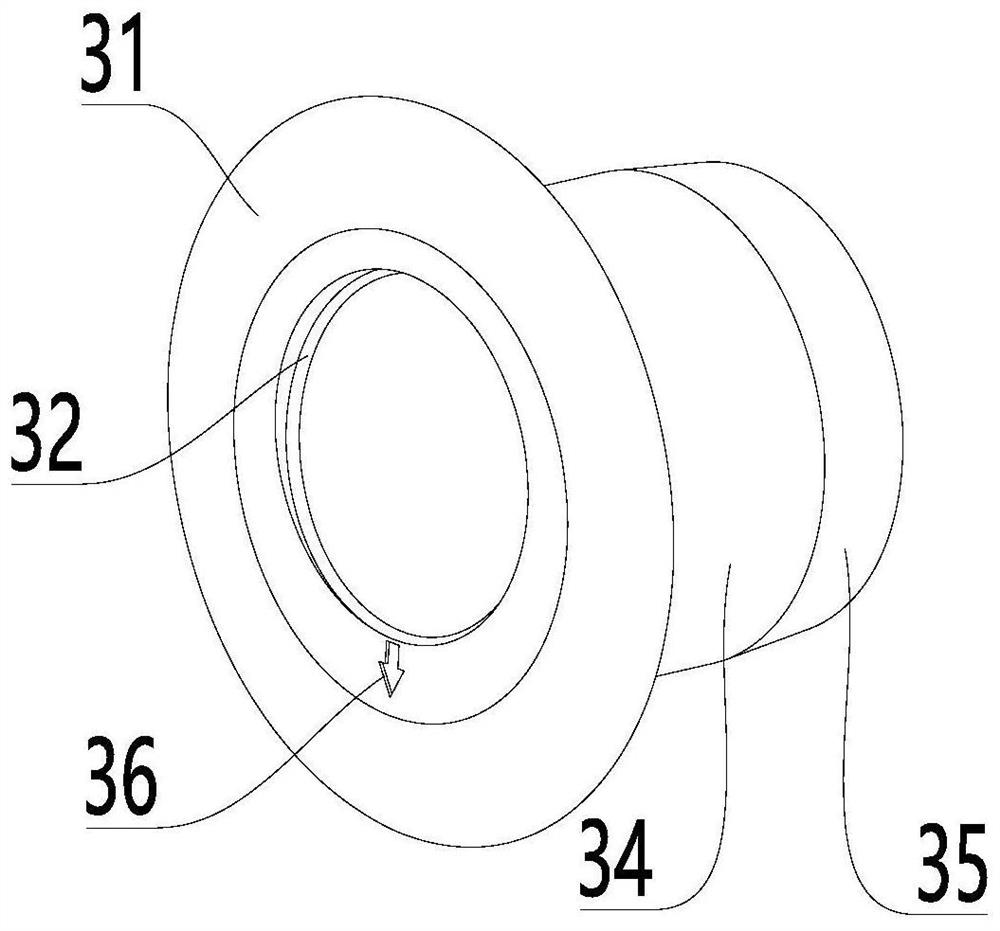

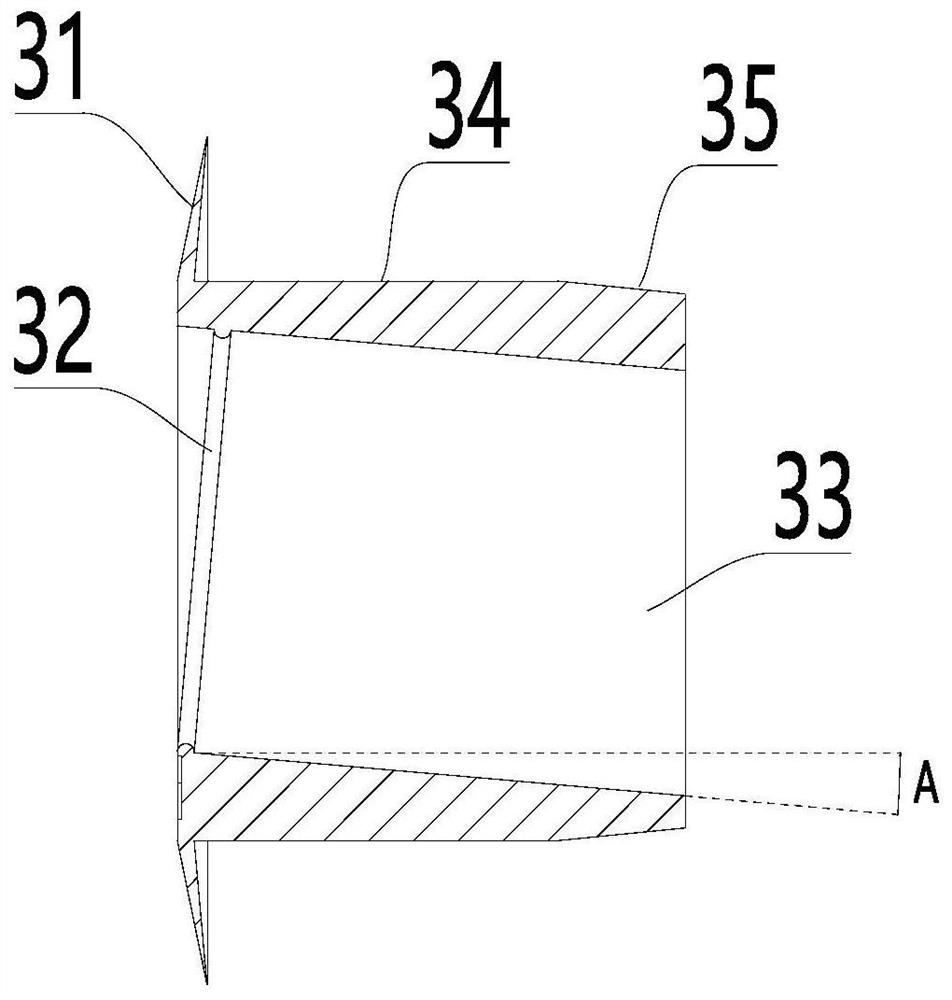

[0039] combine Figure 1-Figure 4 As shown, the smoke pipe installation provided in this embodiment includes:

[0040] The cylinder 34 is adapted to be installed through the wall 10;

[0041] The via hole 33 is formed by penetrating the inside of the cylinder body 34. The via hole 33 is suitable for passing through the smoke pipe 21; the angle between the extension direction of the via hole 33 and the horizontal plane is A, wherein, 3°≤ A≤5°.

[0042] It should be noted that, the extension direction of the via hole 33 refers to the extension direction when the cylinder body 34 and the wall body 10 are in an installed state. Preferably, the through hole 33 is suitable for passing through the smoke pipe 21, and when the smoke pipe 21 is passed through the through hole 33 and installed on the wall 10, the exposed part of the smoke pipe 21 is inclined downward. Set the state to ensure the installation angle of the smoke pipe.

[0043] Preferably, a hole needs to be opened on t...

Embodiment 2

[0067] combine figure 1 As shown, this embodiment provides a gas heating water heater 20, including:

[0068] The unit is adapted to be arranged on the first side of the wall 10;

[0069] A smoke pipe 21, one end of which is installed on the unit, the smoke pipe 21 is adapted to pass through the wall 10 and the other end of the smoke pipe 21 is located on the second side of the wall 10;

[0070] And the smoke pipe mounting part 30 as described above.

[0071] The gas-fired heating water heater provided in this embodiment can guide the smoke pipe 21 and limit the installation angle of the smoke pipe by using the smoke pipe mounting part, so as to prevent rainwater from flowing into the unit through the smoke pipe, and ensure that the smoke pipe 21 can be installed in place , simplify the installation process, greatly improve the installation efficiency of the smoke pipe, reduce the after-sales problems caused by the improper installation of the smoke pipe, and ensure the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com