Multi-section high-precision spiral rock debris weighing device and method

A weighing device and high-precision technology, which is applied in the field of oil drilling, can solve problems such as inability to directly weigh, fail to weigh, and shake, and achieve the effects of solving the influence of weighing sensors, improving measurement accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

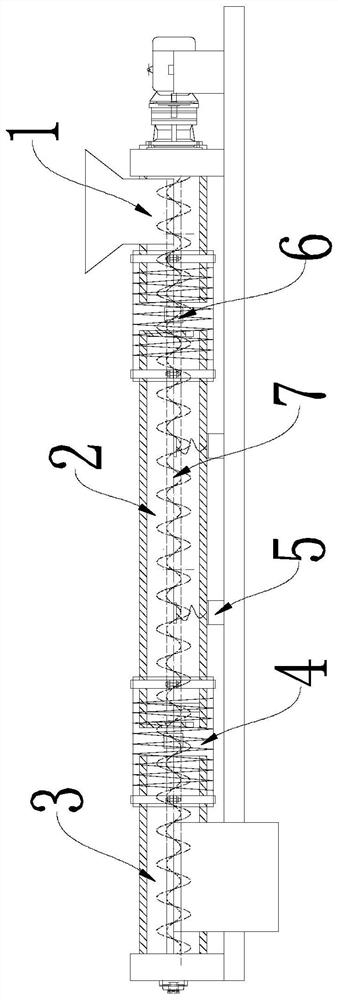

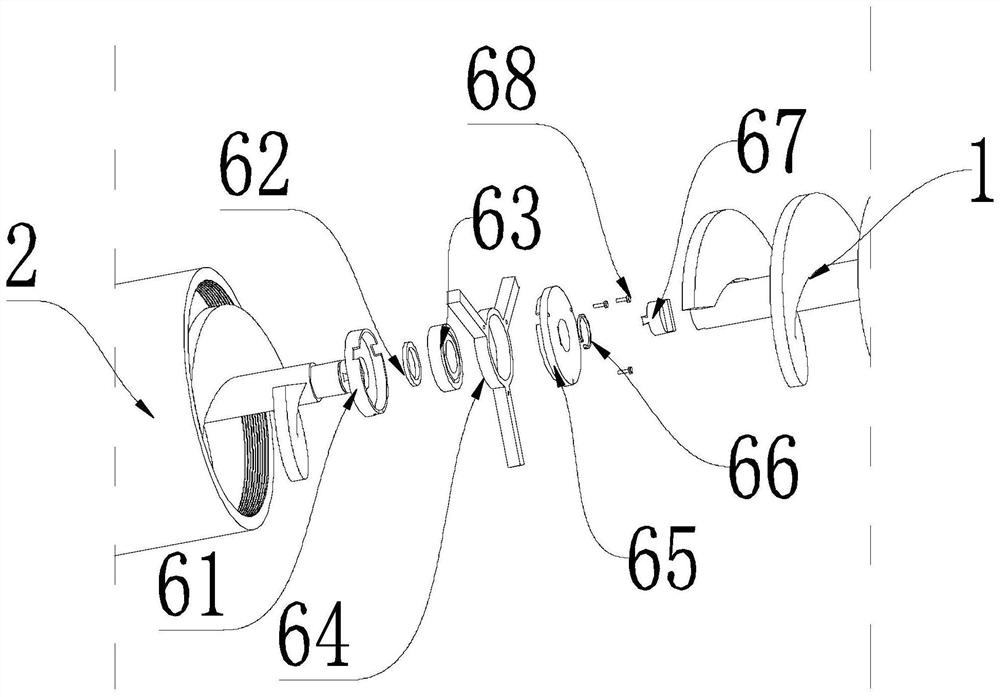

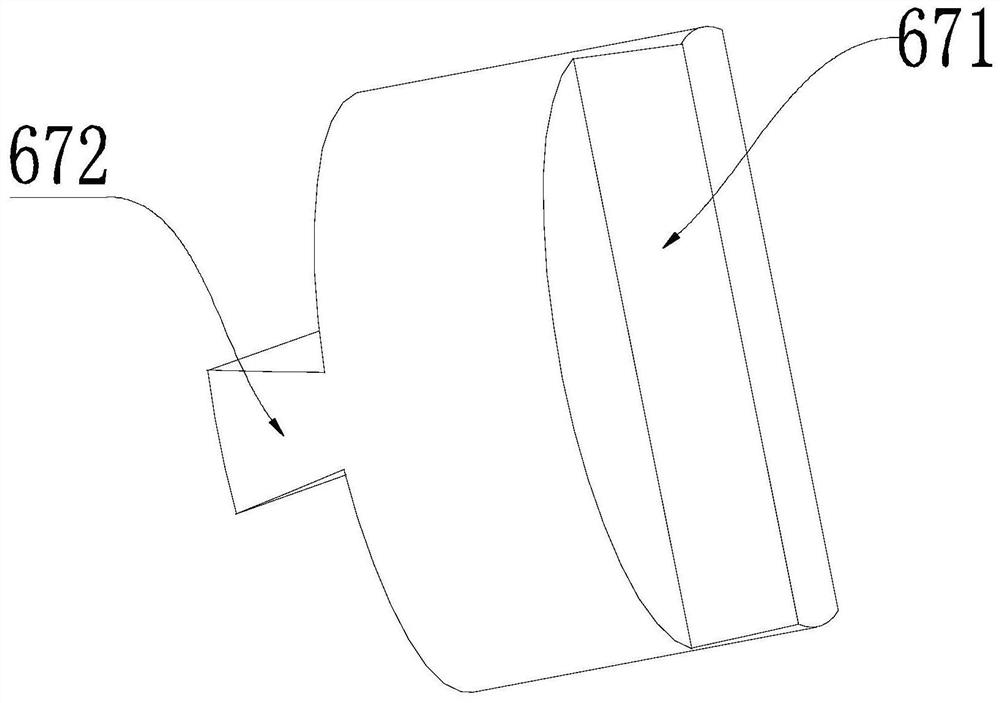

[0026] Example 1: See Figure 1 to Figure 3 , a multi-stage high-precision spiral cuttings weighing device of this embodiment, including a feed section 1, a weighing section 2 and a discharge section 3, the feed section 1 is used to receive the bottom of the well and pass through the vibrating screen The processed cuttings, the weighing section 2 is used to weigh the cuttings, the discharge section 3 is used to discharge the cuttings, and one end of the weighing section 2 is provided with a The first floating connection device 6, the other end is provided with the second floating connection device for connecting the discharge section 3; the floating connection device 6 includes a connecting block 67, and the first linear concave groove, the discharge section 3 is provided with a second linear groove, one side of the connecting block 67 is provided with a first fixing protrusion 672 for connecting with the first linear groove, and the other side is provided with There is a sec...

Embodiment 2

[0027] Example 2: See Figure 1 to Figure 3 , the cross-section of the first linear groove in this embodiment is a trapezoidal structure, the cross-section of the first fixing protrusion 672 is an inverted trapezoidal structure, and the first fixing protrusion 672 has a larger width. The side fits the first linear groove. Similar to the Oldham coupling, this structure is used to compensate for the different axis errors during installation and processing, as well as the deformation and displacement of each section of the screw during the working process of the device, so as to improve the coaxiality between the weighing section 2 screw and the shell. degree, thereby improving the measurement accuracy of the device, so that the screw shaft of the weighing section 2 will not be affected by the other two sections of the screw conveyor during the rotation process. The inverted trapezoid prevents the bumps and grooves from falling out. In this embodiment, the first fixing protrusi...

Embodiment 3

[0028] Example 3: See Figure 1 to Figure 3 , the floating connection device 6 of this embodiment also includes a snap spring 66, a stopper 62, a roller bearing 63, a support seat 64 and a protective shell arranged outside the connection block 67 in sequence, and the support seat 64 is provided with a A support rod connected with the outer cylinder, the protective shell is provided with a fixing hole through which the support rod passes. The number of support rods is three, and the angle between two adjacent support rods is 120°. The protective shell prevents impurities from entering the bearing and causing failure. The protective shell includes a first protective shell 61 and a second protective shell 65 which are detachably connected, and the first protective shell 61 and the second protective shell 65 are connected by screws 68 . The support seat 64 has threads on the outside for supporting on the outer cylinder, and the inside has holes for placing bearings, and its effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com