Electronic weighing scale of loader

A technology for loaders and electronic scales, applied to special scales, measuring devices, mechanically driven excavators/dredgers, etc., can solve the problems of increasing the cost of electronic scales, and the acceleration sensor is easily damaged, so as to achieve simple structure and increase weight The effect of measurement accuracy and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

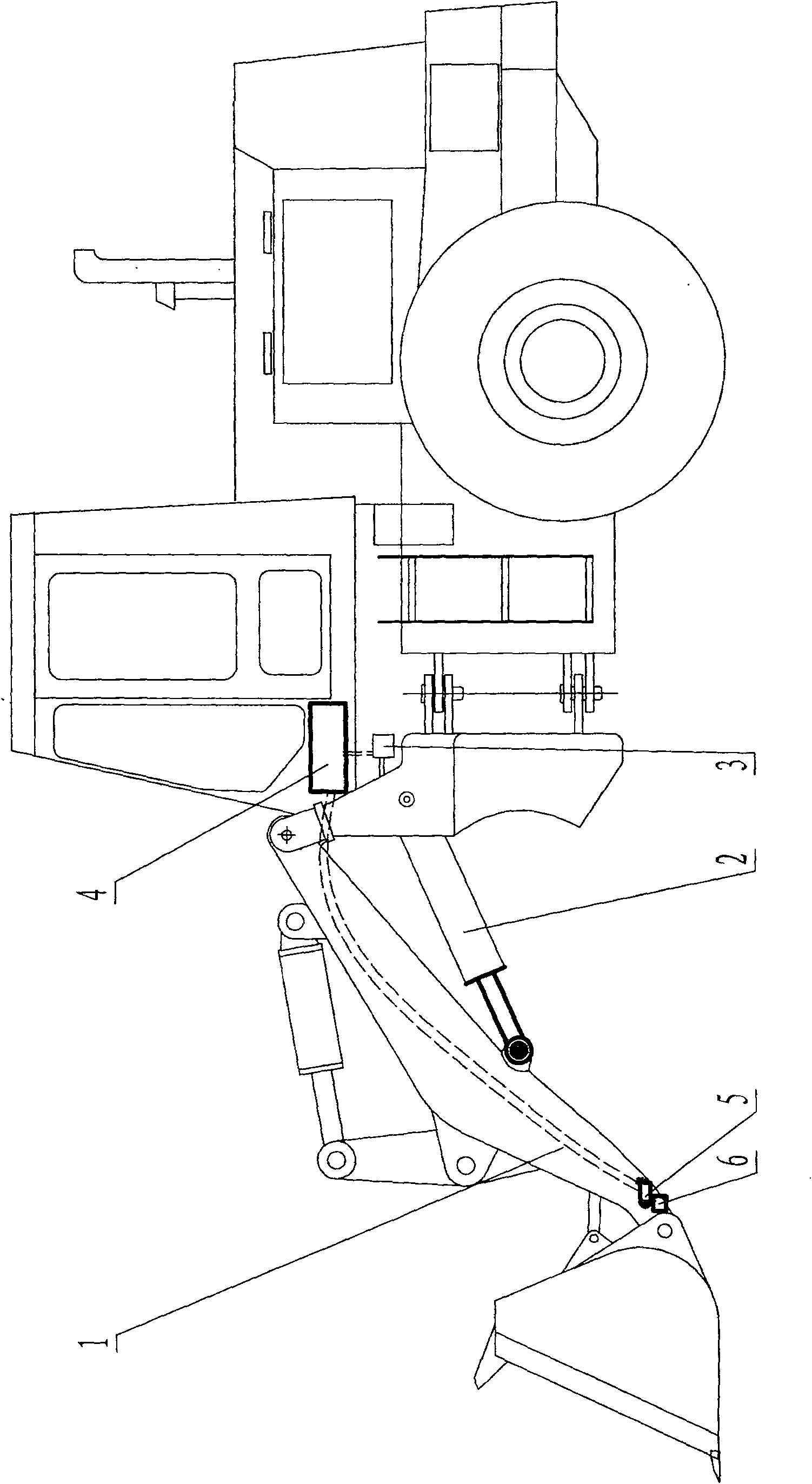

[0010] The loader electronic scale includes a loader arm 1, a hydraulic push rod 2, a pressure sensor 3, and a secondary instrument 4 installed in the loader cab, and a load cell 5 is arranged on the loader arm 1, The load cell 5 is electrically connected to the secondary instrument 4 , the fixed end of the load cell 5 is fixedly connected to the arm body of the loader boom 1 , and the load end of the load cell 5 is provided with a weight 6 . When the loader is working, if the vehicle body is tilted, the boom 1 of the loader is also tilted at the same angle, and the load cell 5 and the bucket installed on the boom 1 of the loader are also tilted at the same angle at the same time. The vertical downward component force of the weight of the counterweight 6 and the vertical downward component force of the material weight in the bucket change in the same ratio. According to this ratio, the secondary instrument 4 is composed of the load cell 5 and the pressure sensor. 3. Compensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com