Mechanical part wear test device with locking structure

A mechanical component and wear test technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficult cleaning of metal debris, to avoid unstable placement, safe working environment, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

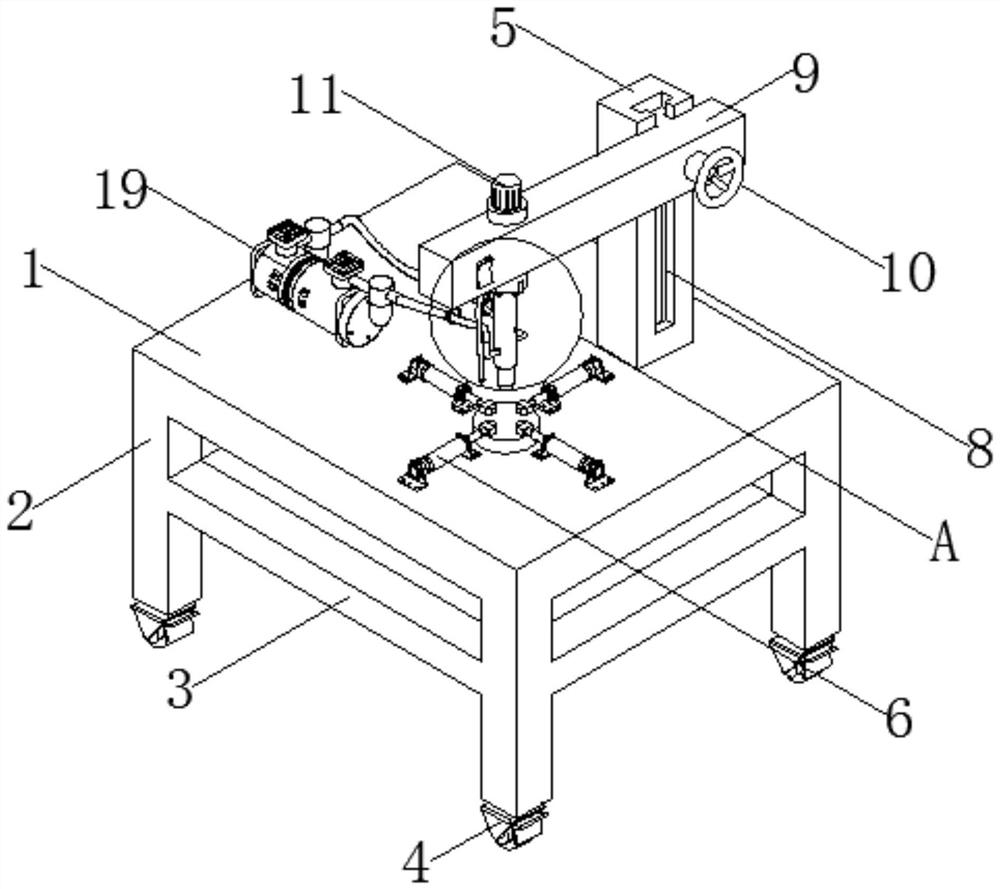

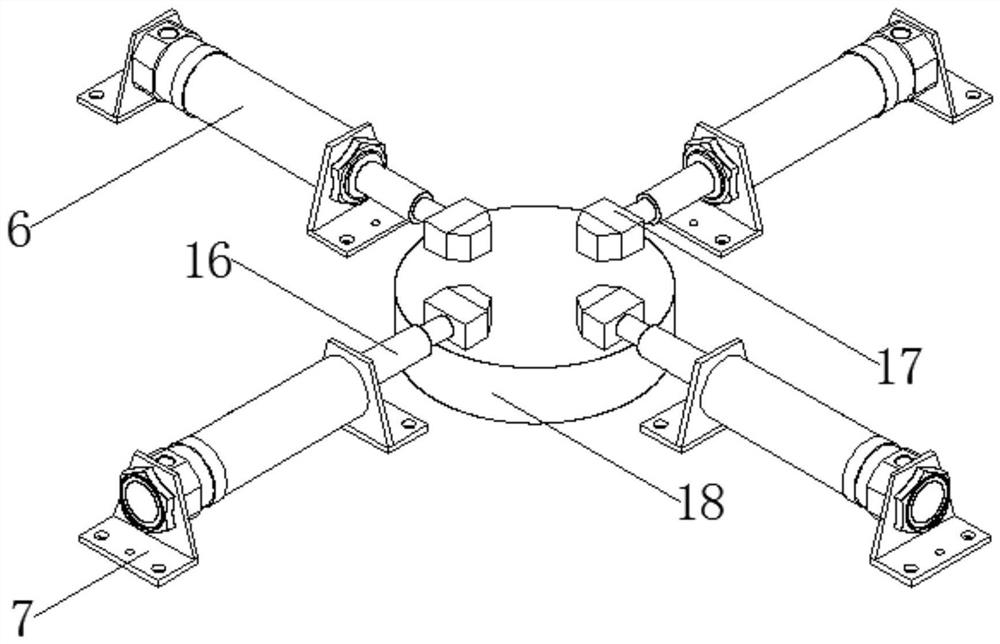

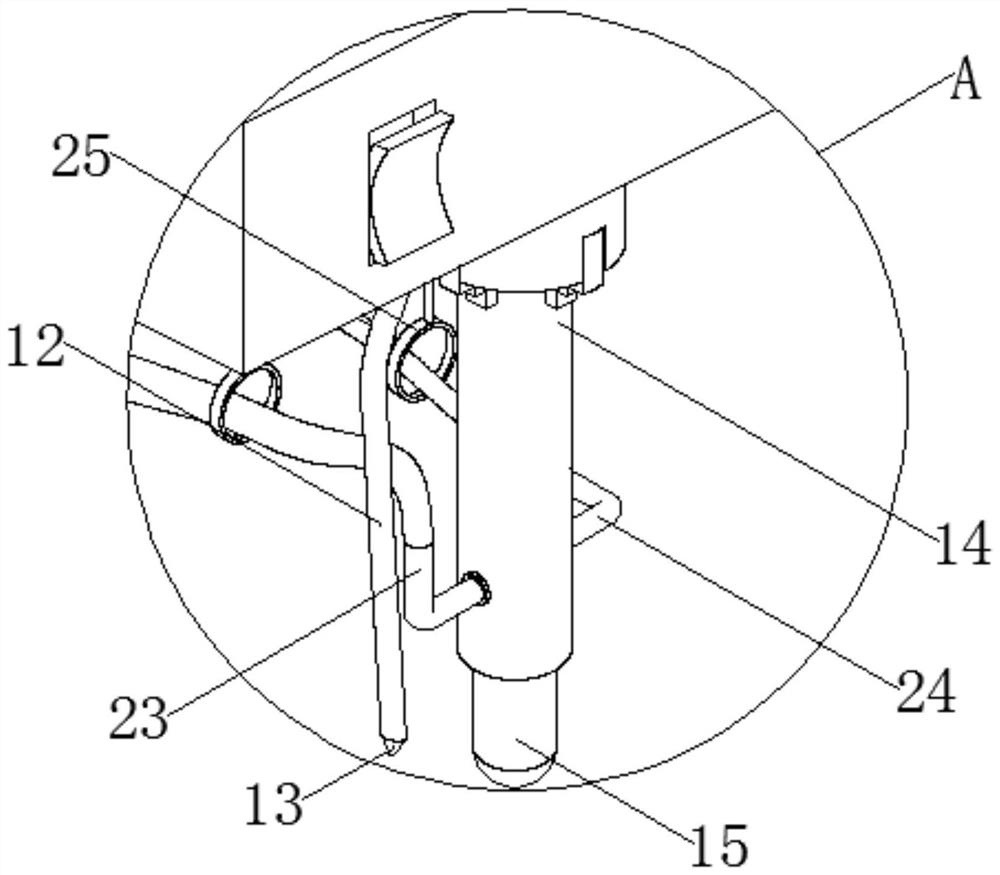

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Please refer to Figure 1~3 , the embodiment of the present invention is as follows:

[0029] A wear test device for mechanical parts with a locking structure, comprising a console 1, support legs 2 are fixedly installed at the four corners of the bottom of the console 1, support frames 3 are fixedly connected between the support legs 2, and self-supporting legs 2 are fixedly installed at the bottom Lock the universal wheel 4, the top side of the console 1 is fixedly installed with the lifting table 5; Holes and connections connect bolts to move the joints.

[0030] exist figure 1 and image 3 Middle: There is a groove 8 on one side of the lifting table 5, a lifting arm 9 is arranged inside the groove 8, a lifting limit wheel 10 is fixedly installed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com