Conductivity detection device for tungsten-zirconium electrode bar production

A detection device and electrode rod technology, which can be applied to measurement devices, measurement device casings, components of electrical measurement instruments, etc., can solve problems such as poor detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

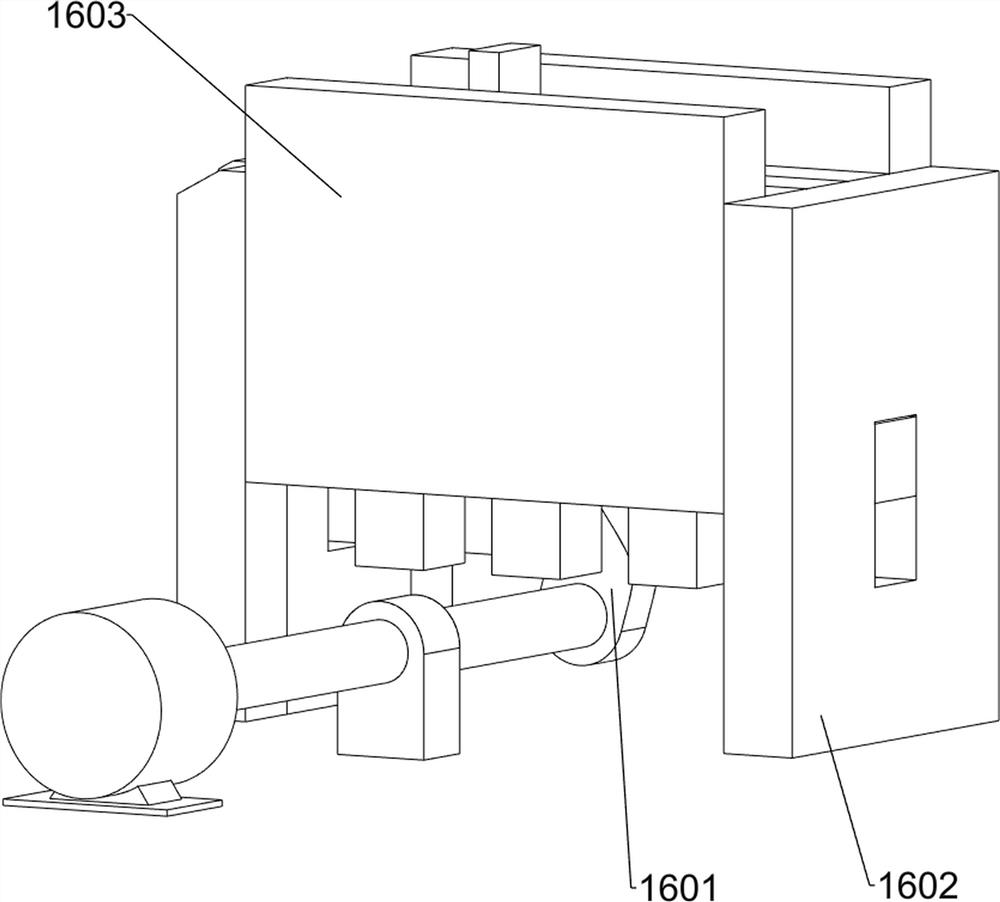

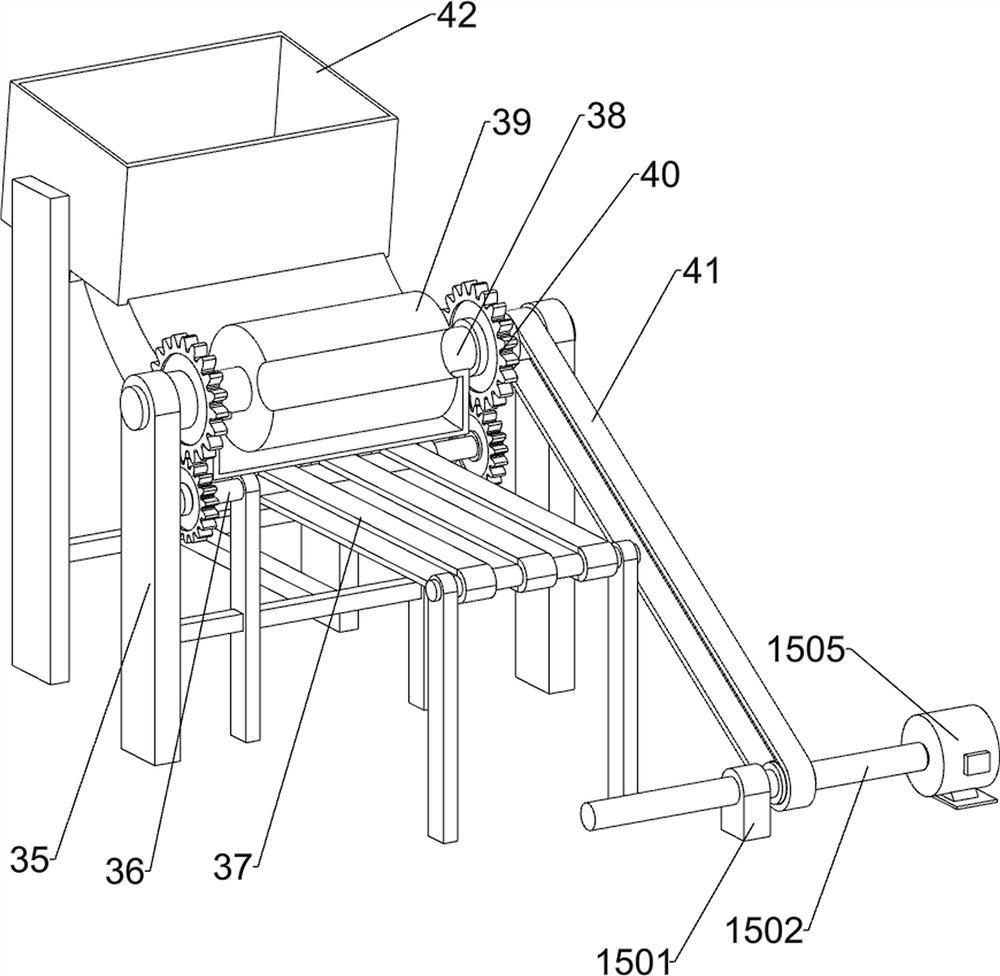

[0080] A conductivity detection device for the production of tungsten-zirconium electrode rods, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a base 1, a first bracket 2, a first crawler belt 3, a placement table 4, an electrified metal block 5, a light bulb 6, a coil 7, an electric wire 8, a first baffle plate 9, a first guide block 10, a second Guide block 11, the first slider 12, the first elastic member 13, the first material box 14, the drive mechanism 15 and the fixing mechanism 16; The rotary type is provided with three rotating shafts, five first crawlers 3 are wound around the three rotating shafts, a placing platform 4 is arranged on the left rear side of the top of the base 1, and an electrified metal block 5 is arranged on the front side of the placing platform 4 top. 4. A light bulb 6 is arranged on the right side of the top, and a coil 7 is arranged on the left side of the top of the placing table 4. An electric wire 8 is connect...

Embodiment 2

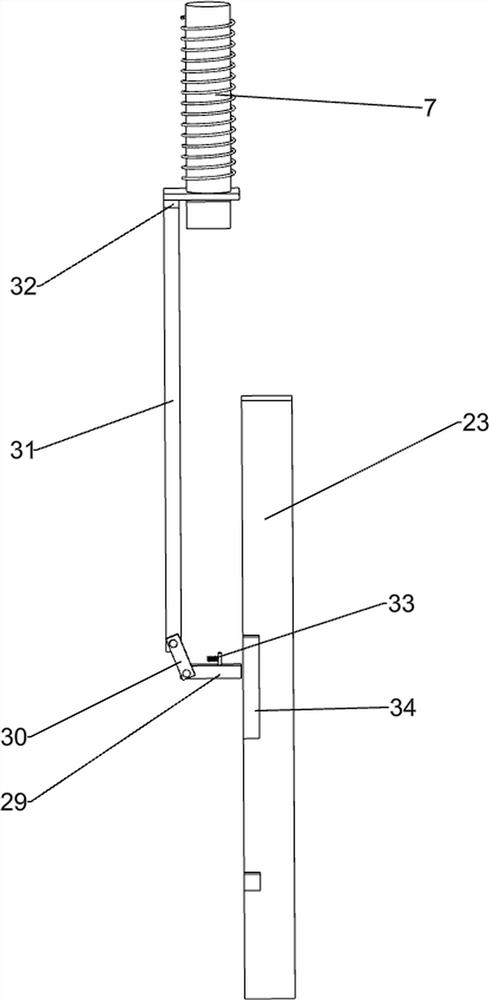

[0087] On the basis of Example 1, such as Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 Shown, also comprise the 3rd bracket 17, the 3rd guide block 18, the first sliding bar 19, the first iron block 20, the second baffle plate 21 and guide bar 22, the first baffle plate 9 upper side and place table 4 front The third support 17 is provided on each side, and the third guide block 18 is arranged between the third support 17. The inner side of the left part of the third guide block 18 is slidably provided with a first sliding rod 19, and the rear side of the first sliding rod 19 is provided with The first iron block 20, the first iron block 20 cooperates with the coil 7, the middle part of the first sliding rod 19 is slidably provided with a guide rod 22, the middle part of the guide rod 22 is provided with a second baffle plate 21, and the second baffle plate 21 is placed on the third Slide in the guide block 18.

[0088] In the initial state, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com