A kind of high-efficiency heat exchange tube production method

A production method and technology of heat exchange tubes, which are applied in the field of heat exchange tubes, can solve problems such as the expansion joints of tube expanders are easily damaged by grooves, the production process of high-efficiency heat exchange tubes is cumbersome, and the production efficiency is low, so as to achieve automatic continuous production , prevent expansion joints from being tight, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

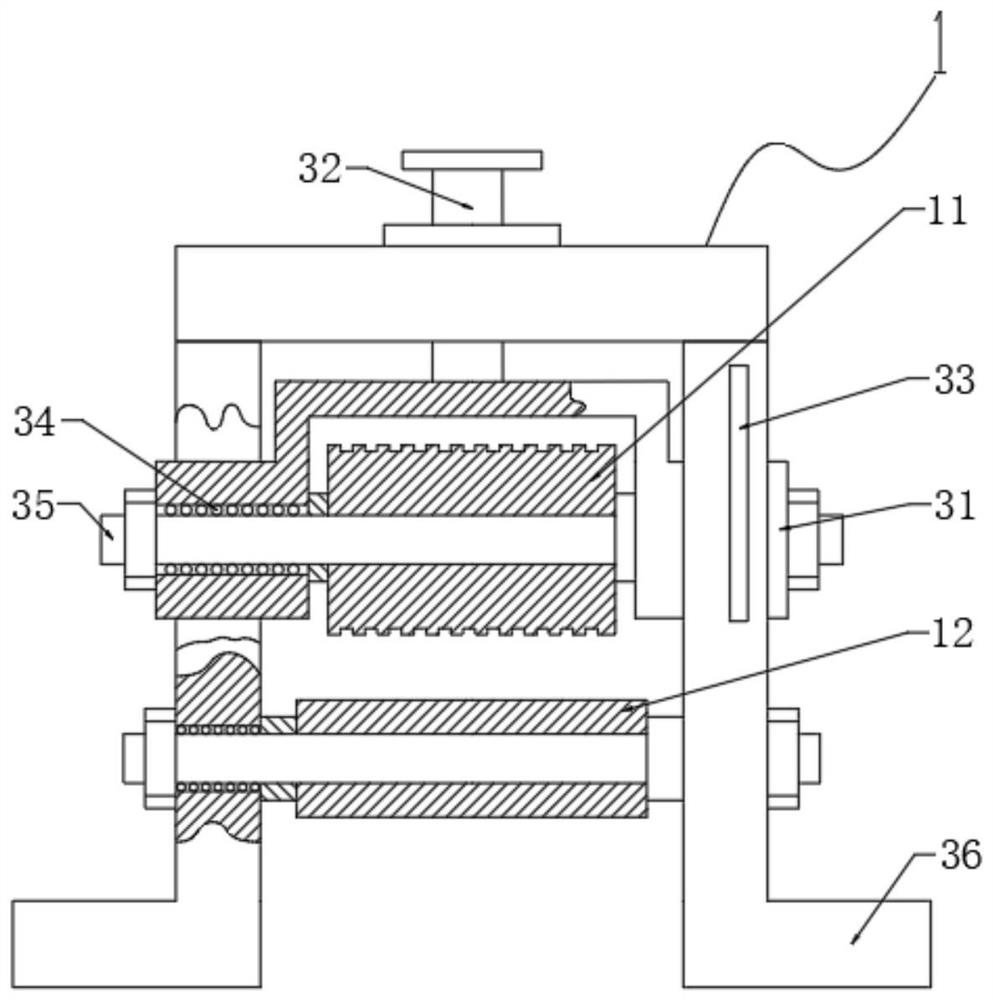

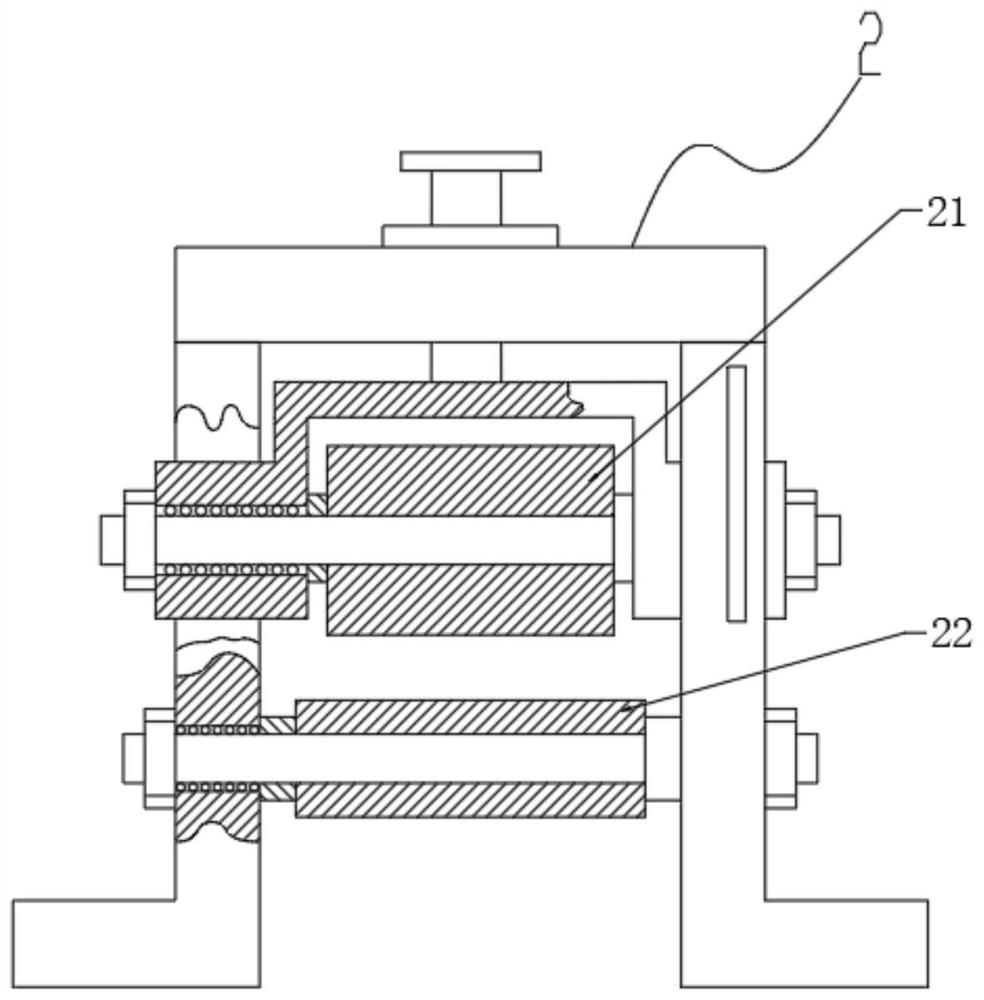

[0034] Refer to appendix Figure 1-3 , the pattern roll and the smooth upsetting roll are installed on the sliding shaft, the glossy roll is mounted on the fixed shaft, under the above production process, rolling 29.7mm width, 0.5mm thickness of the strip, by controlling the ginning and forming drive motor speed, at a production speed of 3m / min to produce a tooth height of 0.15mm, the number of internal patterns of 40 heads / inch of the C-shaped pattern efficient heat exchanger tube. Through the implementation of this process method, the production cost of the internal pattern high-efficiency heat exchanger tube is reduced by 20,000 yuan / ton, and the production efficiency is increased by 20%.

Embodiment 2

[0036] The pattern roll and the glossy upsetting roll are installed on the sliding shaft, the glossy roll is mounted on the fixed shaft, under the above production process, the strip with a width of 48.8mm and a thickness of 0.9mm is rolled, and by controlling the speed of the ginning and forming drive motor, the tooth height is 0.2mm at a production speed of 2.5m / min, and the number of threads is 45 heads / inch. Through the implementation of this process method, the production cost of cross-tooth pattern high-efficiency heat exchanger tubes is reduced by 23,000 yuan / ton, and the production efficiency is increased by 20%.

Embodiment 3

[0038] The pattern roll and the glossy upsetting roll are installed on the sliding shaft, the glossy roll is installed on the fixed shaft, under the above production process, the strip with a width of 59.0mm and a thickness of 0.7mm is rolled, and by controlling the speed of the ginning and forming drive motor, the tooth height is 0.16mm and the number of external patterns is 40 heads / inch C-shaped external pattern high-efficiency heat exchange tubes are made at a production speed of 3m / min. Through the implementation of this process method, the production cost of the external pattern high-efficiency heat exchanger tube is reduced by 30,000 yuan / ton, and the production efficiency is increased by 20%.

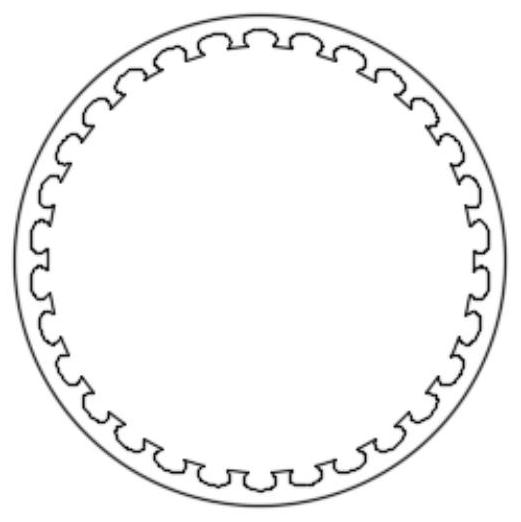

[0039] as Figure 4 As shown, the present invention may also produce a heat exchanger tube with an outer pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com