Straight core hydraulic connector assembling device

A technology of hydraulic joints and assembly devices, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of troublesome assembly of straight core hydraulic joints, poor sealing performance of workpieces, and a lot of time and energy, so as to reduce poor sealing performance, Improve production efficiency and facilitate large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

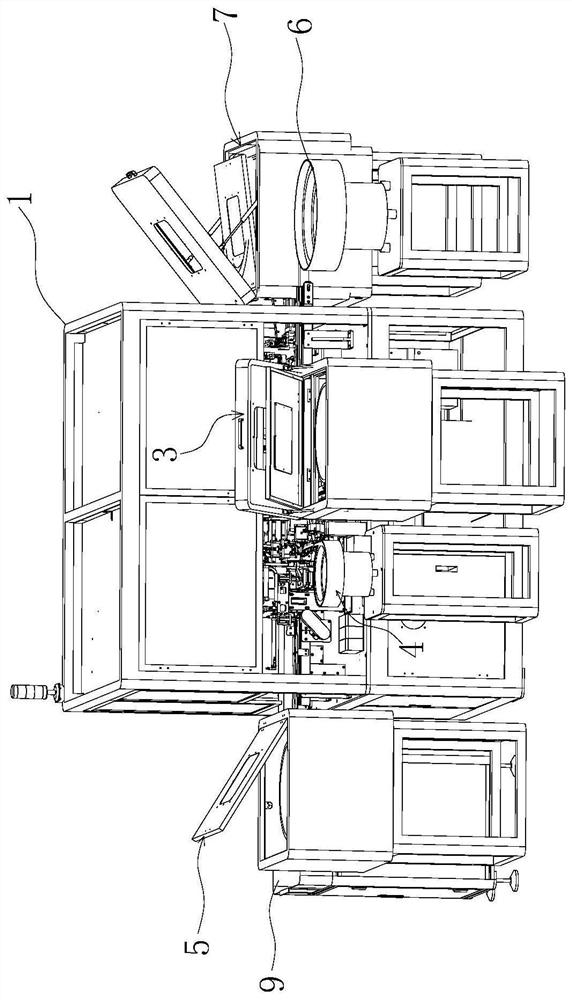

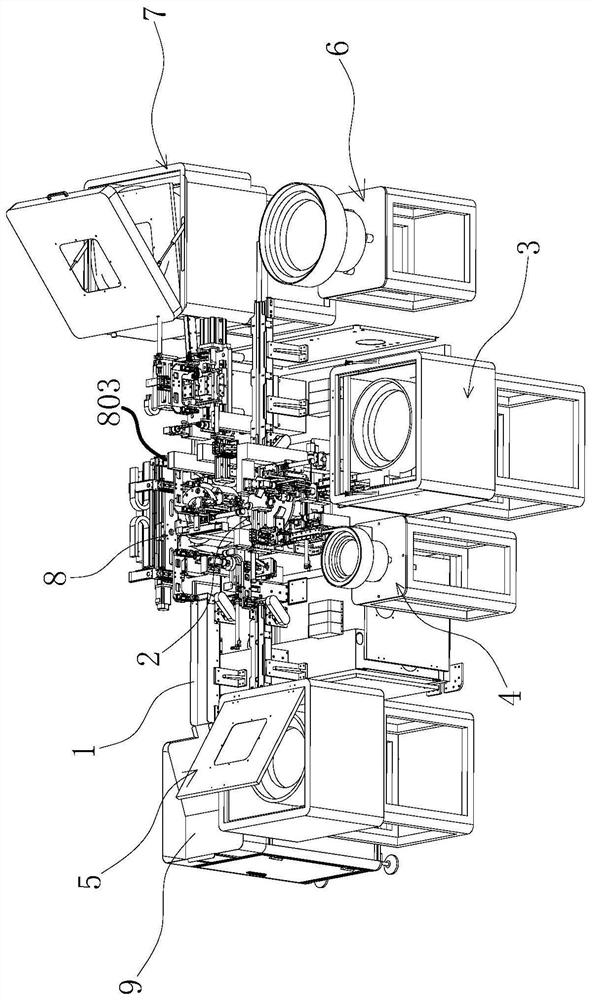

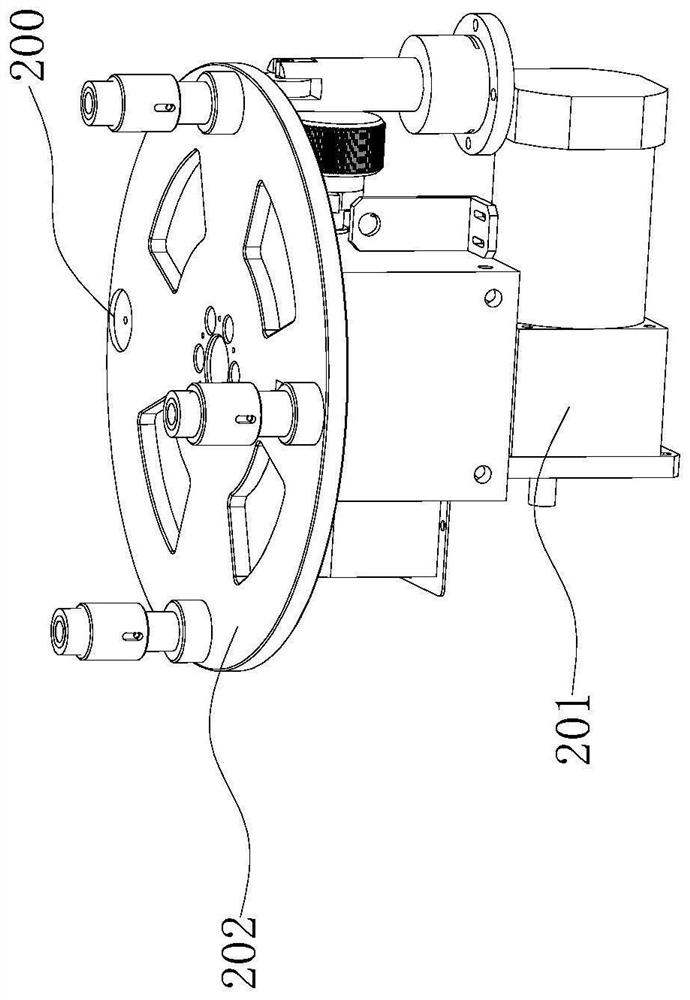

[0065] Such as figure 1 As shown, the straight core hydraulic joint assembly device includes: a workbench 1; a rotating mechanism 2, which is arranged in the middle of the workbench 1, and the rotating mechanism 2 is used to transmit the workpiece to be assembled; a straight core mechanism 3, which is arranged on the On the workbench 1 and located on the side of the rotating mechanism 2, the straight core mechanism 3 is movable with a straight core jaw 300, and the straight core jaw 300 can grab the straight core workpiece to be assembled and move to the preset position; the O-ring mechanism 4. It is set on the workbench 1 and is located next to the straight core mechanism 3. On the O-ring mechanism 4, an O-ring jaw 400 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com