Plastic extruder device capable of effectively improving unstable pressure of machine head

A plastic extruder and head pressure technology, which is applied in the field of plastic extruders, can solve the problems affecting the molding quality of plastic products, pressure instability, plastic molding pressure and molding compactness, etc. Stable and guarantee the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

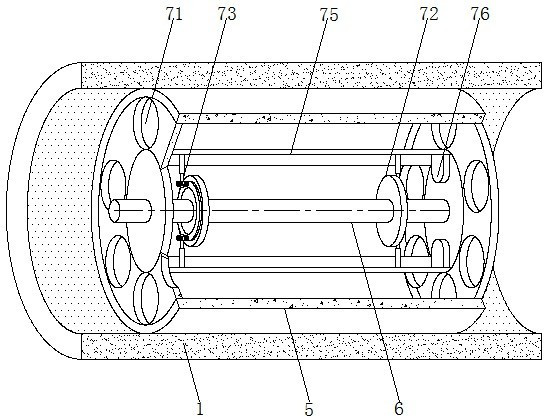

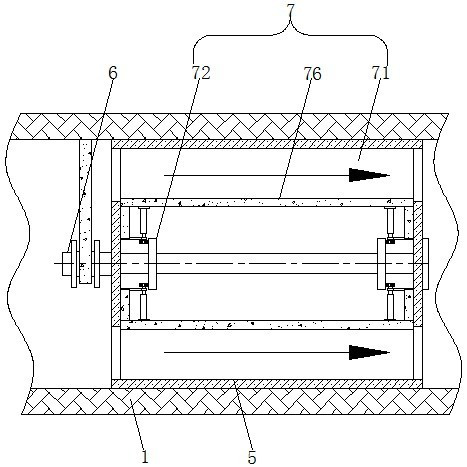

[0027] see Figure 1-5 , a plastic extruder device that can effectively improve the pressure instability of the head, including a body 1, an extrusion screw 2 is arranged inside the body 1, and is used to transport molten materials, and a filter mechanism 3 is arranged inside the body 1 , for filtering the molten material, the filter mechanism 3 includes a fixed screen 31, the fixed screen 31 adopts a semi-spherical screen design, fixedly connected with the inner surface of the body 1, and cooperates with the movable screen 33 to filter the molten material For filtering, a driving gear 32 is arranged inside the filtering mechanism 3 for driving the movable screen 33 and the conveying screw 35 to rotate.

[0028] The inside of filtering mechanism 3 is provided with movable net plate 33, and movable net plate 33 adopts semicircular spherical net plate design, and adopts coaxial design between driving gear 32, and the outer surface of movable net plate 33 is opposite to the inner...

Embodiment 2

[0031] see Figure 1-5 , a plastic extruder device that can effectively improve the pressure instability of the head, including a body 1, an extrusion screw 2 is arranged inside the body 1, and is used to transport molten materials, and a filter mechanism 3 is arranged inside the body 1 , used to filter the molten material, the surface of the body 1 is provided with a discharge tank 4, the side surface of the discharge tank 4 is provided with a discharge port, the inside of the discharge tank 4 communicates with the inside of the body 1, and is used for impurities Particle storage and discharge.

[0032] The inside of the body 1 is provided with a guide ring 5, the outer surface of the guide ring 5 is adapted to the inner surface of the body 1, and cooperates with the guide channel 71 to adjust the movement mode of the molten material. The transmission shaft 6 is connected to the internal rotation, which is used to drive the toothed disc 72 to rotate, and includes a diversion...

Embodiment 3

[0036] see Figure 1-5, a plastic extruder device that can effectively improve the pressure instability of the head, including a body 1, an extrusion screw 2 is arranged inside the body 1, and is used to transport molten materials, and a filter mechanism 3 is arranged inside the body 1 , for filtering the molten material, the filter mechanism 3 includes a fixed screen 31, the fixed screen 31 adopts a semi-spherical screen design, fixedly connected with the inner surface of the body 1, and cooperates with the movable screen 33 to filter the molten material For filtering, a driving gear 32 is arranged inside the filtering mechanism 3 for driving the movable screen 33 and the conveying screw 35 to rotate.

[0037] The inside of filtering mechanism 3 is provided with movable net plate 33, and movable net plate 33 adopts semicircular spherical net plate design, and adopts coaxial design between driving gear 32, and the outer surface of movable net plate 33 is opposite to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com