Rope slow release mechanism

A rope and slow-release technology, which is applied in the direction of motor vehicles, space navigation equipment, space navigation vehicles, etc., can solve the problems of fast release speed, transfer of objects and astronaut injuries, etc., to achieve simple operation and controllable slow-release release speed , the effect of high fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

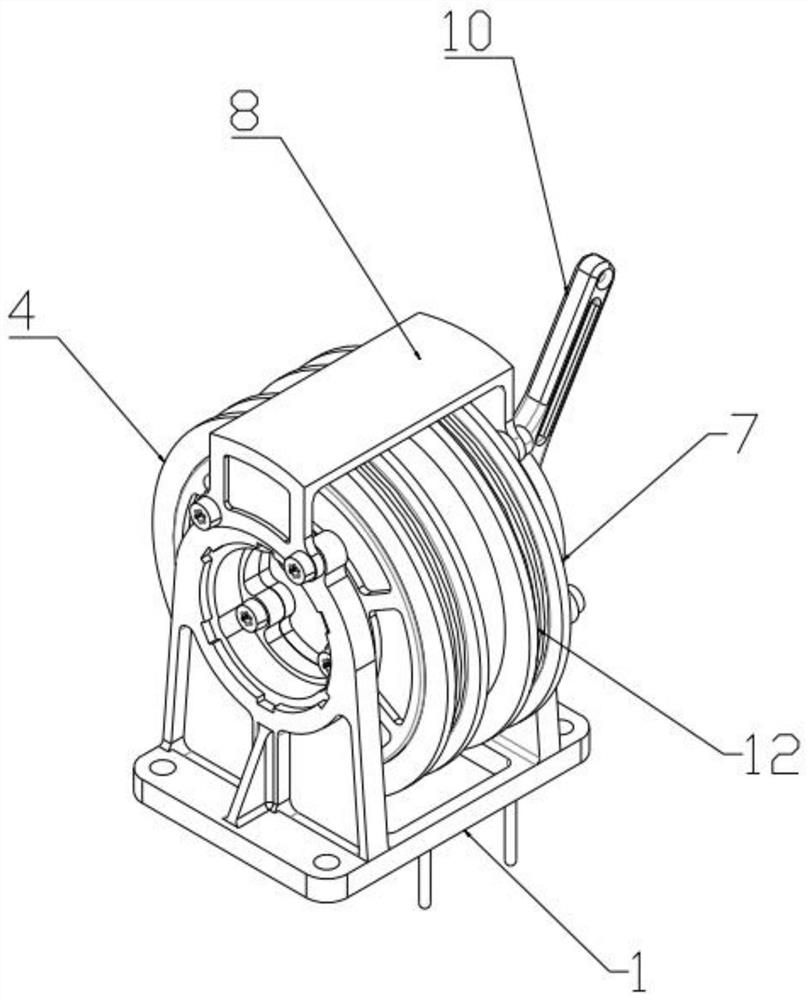

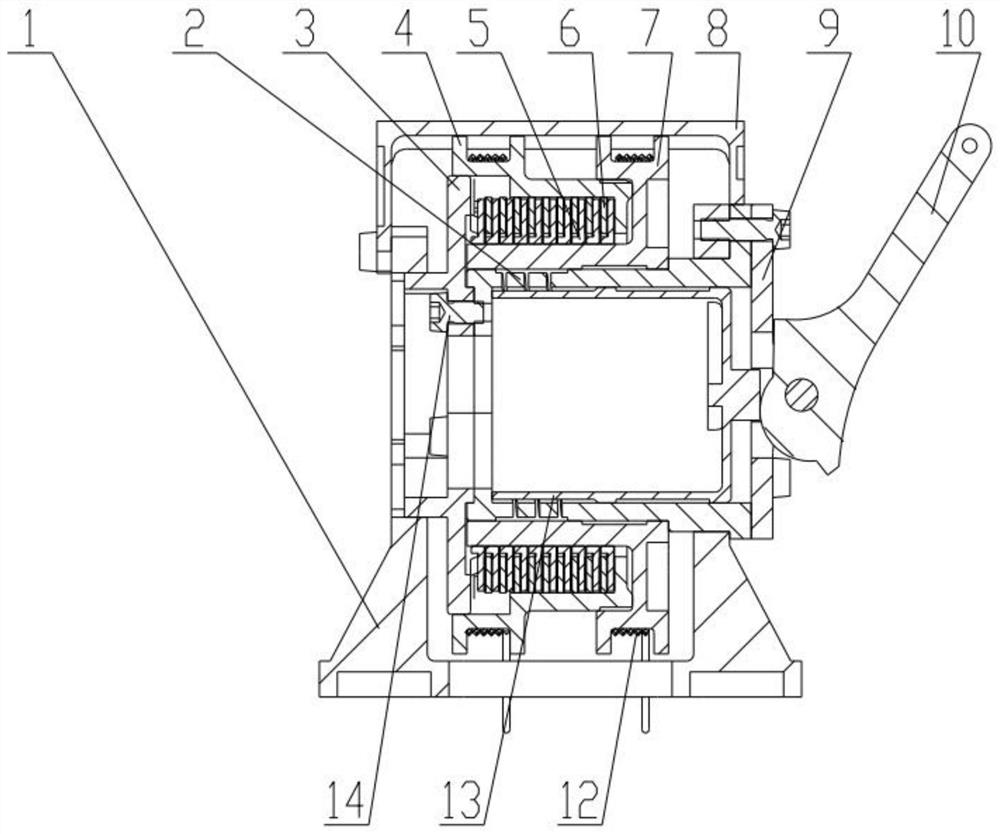

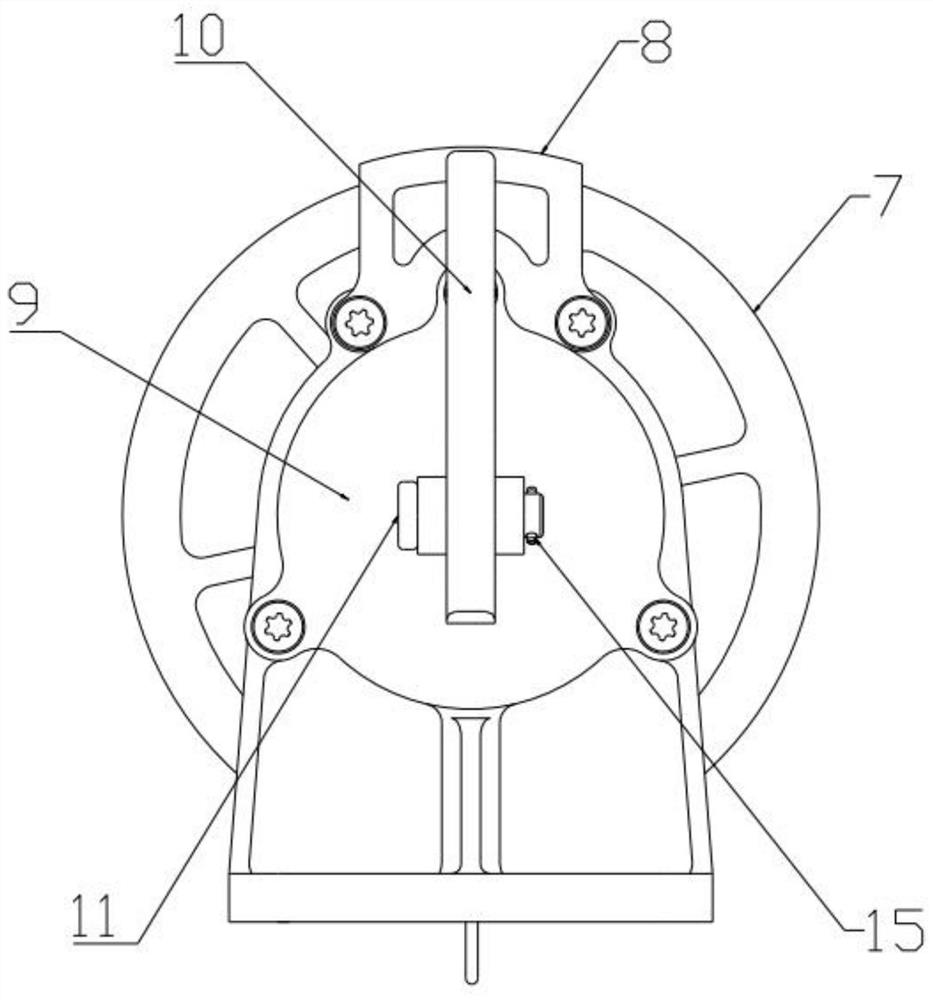

[0040] Specific implementation plan one: combine Figure 1 to Figure 12 As shown, the present invention provides a slow release mechanism for ropes, including a frame 1, a first sheave 4, a second sheave 7, an elastic shaft 2, an elastic shaft end cover 3, a slow release push sleeve 13, a friction Assembly and cam swing arm 10, the frame 1 is provided with an elastic shaft end cover 3 and an elastic shaft 2 connected by screws 14, the slow-release push sleeve 13 is built in the elastic shaft 2, and can be moved along the elastic shaft 2 Axial movement, the second sheave 7 is sleeved on the outside of the elastic shaft 2, the elastic shaft 2 is provided with a shoulder, the second sheave 7 is engaged with the shoulder, the elastic shaft end cover 3 and A friction assembly and a first sheave 4 are sequentially arranged between the second sheave 7, and the cam swing arm 10 is hinged with the frame 1 and is in contact with the slow-release push sleeve 13 for being pushed by the sw...

specific Embodiment approach 2

[0044] Specific implementation plan two: combine Figure 7 As shown, the elastic shaft 2 includes an integrally formed elastic shaft spring part 2-1 and an elastic shaft fixing part 2-2, and the elastic shaft spring part 2-1 is connected with the elastic shaft end cover 3 by screws 14. The elastic shaft fixing part 2 - 2 is connected with the frame 1 through screws 14 . By being provided with the elastic shaft spring part 2-1 and the elastic shaft fixing part 2-2, both can ensure that the elastic shaft 2 has elasticity, push the elastic shaft end cover 3, and then change the first sheave 4, the second sheave 7 and the friction Friction between components, adjust slow release rate. The other combinations and connections of this embodiment are the same as those of Embodiment 1.

specific Embodiment approach 3

[0045] Specific implementation plan three: combination Figure 1 to Figure 12 As shown, the elastic shaft end cover 3 , the friction assembly, the first sheave 4 and the second sheave 7 are pressed together in sequence, and in the initial state, the friction assembly is in a compressed state with friction. It is used to ensure the initial state and when the cam swing arm 10 is accidentally released, the elastic shaft 2 is in the initial state or automatically returns to the initial state, and the slow release mechanism is locked to prevent the tool bag or other items connected by the rope 12 from being released too quickly and damaged. The other combinations and connections of this embodiment are the same as those of the second embodiment.

[0046] Specific implementation plan four: combination Figure 8 to Figure 10 As shown, the friction assembly includes a plurality of inner friction plates 5 and a plurality of outer friction plates 6 , and the inner friction plates 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com