Hosiery knitter convenient for discharging socks of different models

A sock knitting machine and sock technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as troublesome replacement procedures, and achieve the effect of simplifying the adjustment procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 2-7 The application is described in further detail.

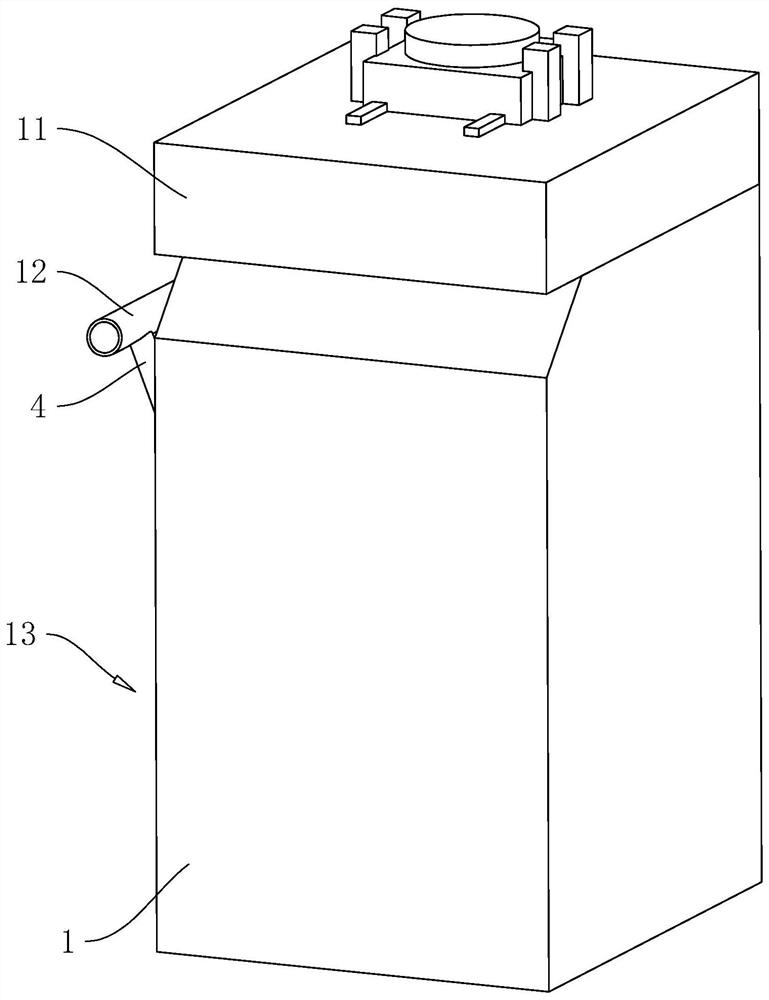

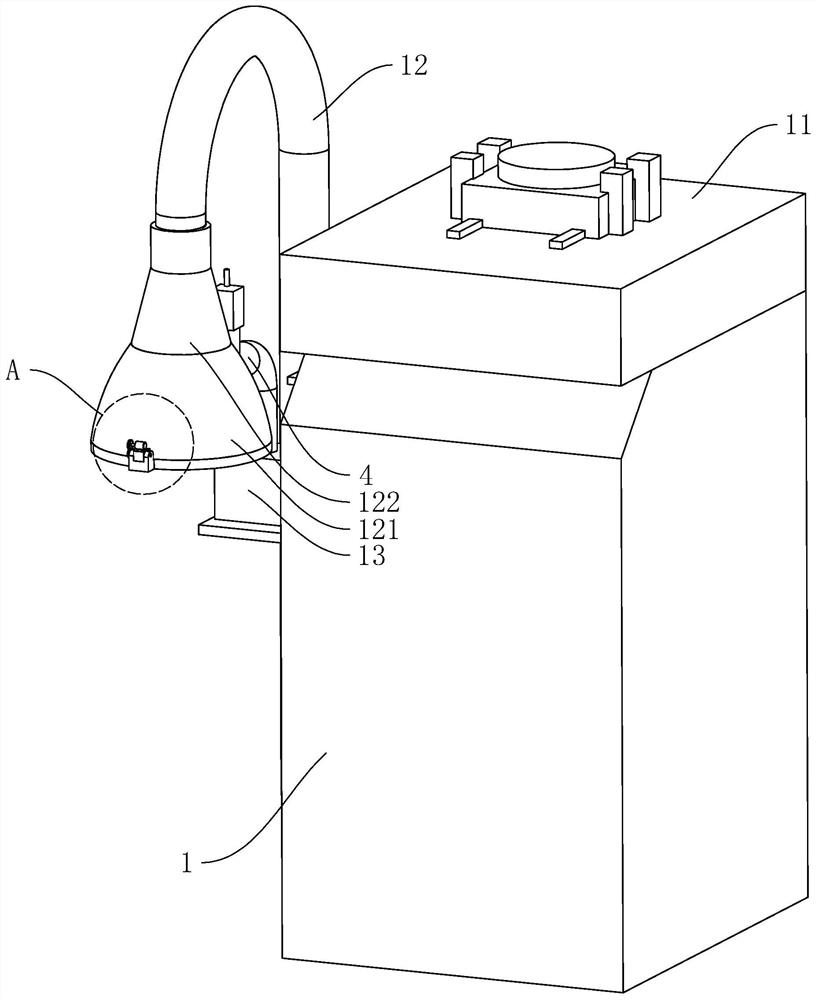

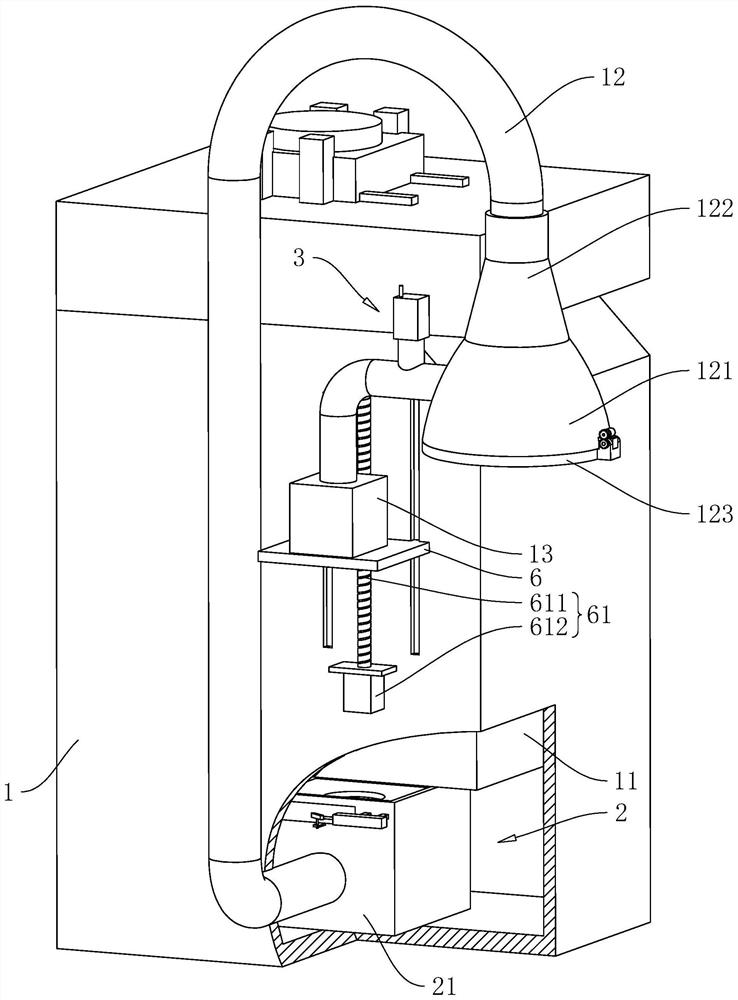

[0040] The embodiment of this application discloses a sock knitting machine that is convenient for discharging different types of socks. figure 2 and image 3 , comprising a frame 1, the frame 1 is fixedly mounted with a cuboid-shaped body 11 for weaving socks, the upper end of the body 11 is used to input yarn, and the bottom end of the body 11 is used to output the woven socks. The frame 1 directly below the body 11 is provided with a cutting mechanism for cutting the knitted socks. A vertical suction pipe 12 is fixedly installed on the frame 1 , the suction pipe 12 is transparent, and a detection mechanism 2 is arranged at the lower end of the suction pipe 12 . The detection mechanism 2 includes a collection box 21 fixedly installed on the frame 1 , the collection box 21 is located directly below the machine body 11 , and the vertical position of the cutting mechanism is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com