Inductance coil end removal equipment and utilization method thereof

A technology of inductance wire and equipment, which is applied in the field of inductance wire tail removal equipment, can solve the problems of low processing accuracy, longer time consumption, and high labor cost, so as to improve product qualification rate and processing accuracy, avoid product defects, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

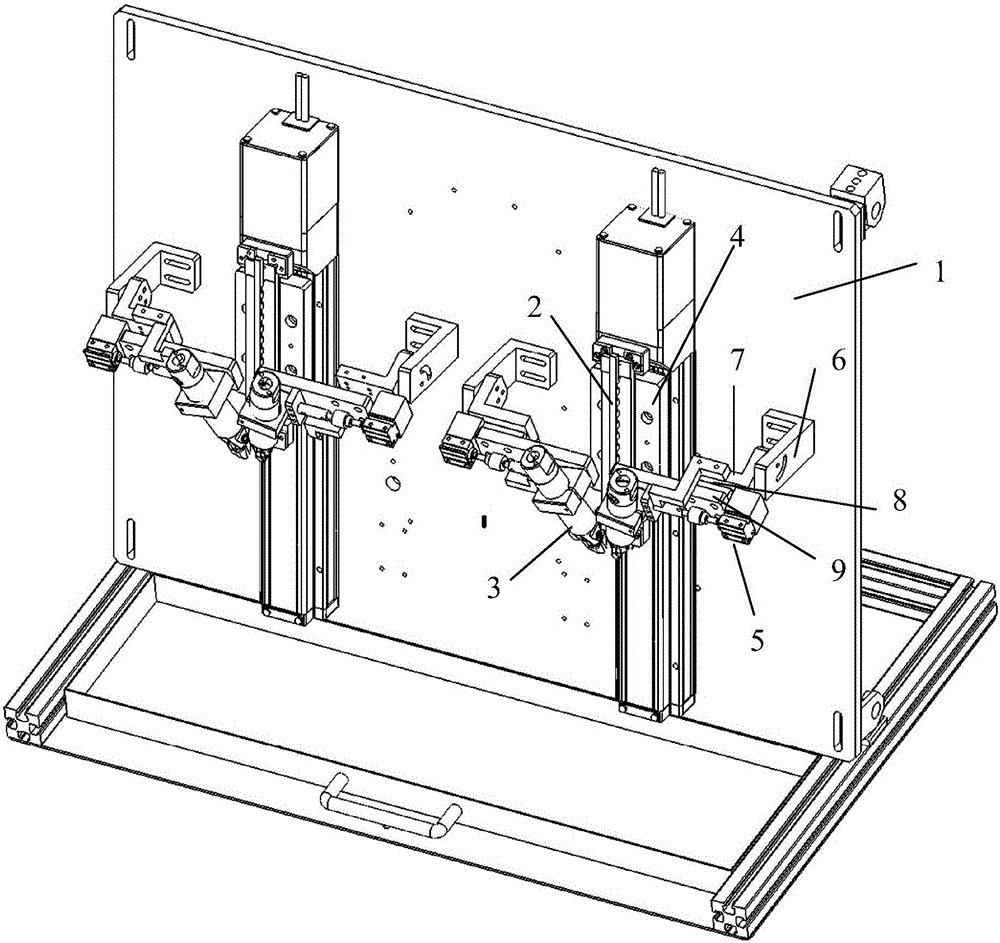

[0039] This embodiment describes a device for removing inductance wire tails, which can be used to automatically remove inductance wire tails of ZJY series inductors and the like. The structure of the inductance line tail removal equipment is as follows: Figure 1 to Figure 5 Shown; Inductance wire tail removal equipment includes a control device, a frame 1, a jig 2, a shearing device 3, a shearing bracket 7, a fixed seat 6, a slide table 8 and a slider 9.

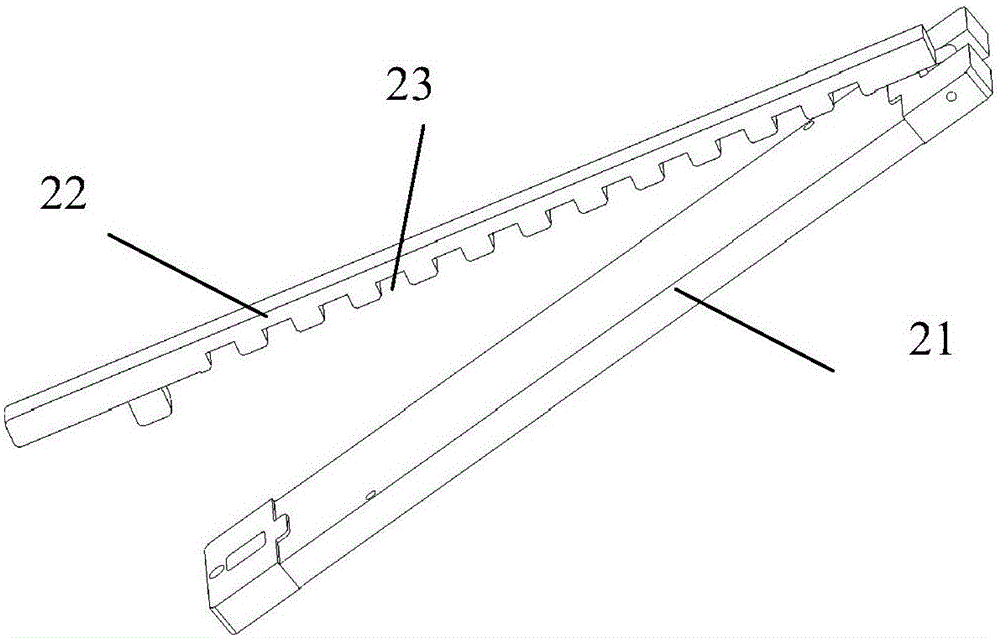

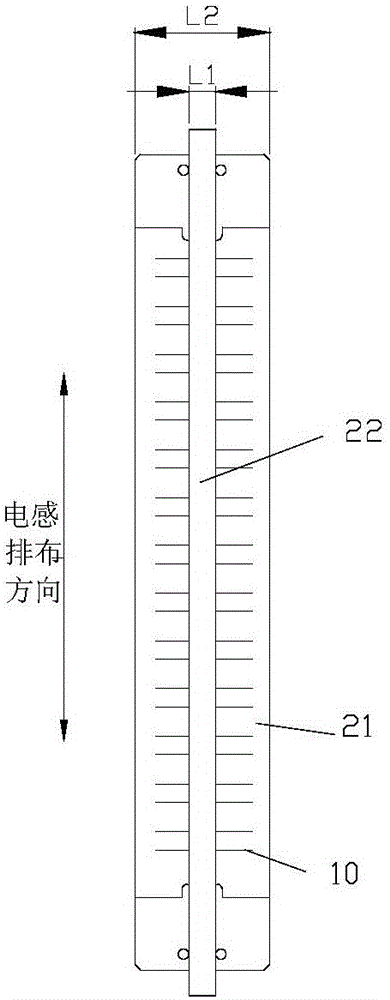

[0040] Wherein, the jig 2 includes a jig base 21 and a cover rod 22 hinged with the jig base 21 and covered on the jig base 21, the jig base 21 and the cover rod 22 form a clamping structure together; the jig base 21 and A positioning piece is provided between the cover rods 22 to realize the fixation between the jig base 21 and the cover rod 22 . The cover rod 22 is provided with a plurality of grooves 23 arranged side by side for clamping the coil; the width L1 of the cover rod

Embodiment 2

[0051] This embodiment describes a device for removing the tail of an inductor, which includes a frame, a control device, a jig for positioning the inductor, and a cutting device for cutting the tail of the inductor; the cutting device is formed to be used with the tail of the inductor Position relative clipping regions. The jig is connected to the frame; the shearing device is connected to the frame through the first driving device and the second driving device, so as to respectively realize the movement of the shearing device along the direction of inductance arrangement and the movement toward or away from the end of the inductance line; the drive The first device, the second driving device and the shearing device are respectively connected with the control device for signals.

[0052] When working, first move the shearing device along the direction of inductance arrangement, so that the tail of the inductance line is opposite to the cutting area of the shearing device; t...

Embodiment 3

[0056] This embodiment describes a device for removing the tail of an inductor, which includes a frame, a control device, a jig for positioning the inductor, and a cutting device for cutting the tail of the inductor; the cutting device is formed to be used with the tail of the inductor Position relative clipping regions. The jig is connected to the frame through the drive device 1 to realize the movement of the jig along the direction of the inductance arrangement; the shearing device is connected to the frame through the drive device 2 and the drive device 3 to respectively realize the movement of the shearing device along the direction of the inductance arrangement. And the shearing device moves toward or away from the tail of the inductor.

[0057] When working, first move the shearing device and the jig towards each other along the direction of inductance arrangement, so that the tail of the inductance line is opposite to the shearing area of the shearing device, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com